Professional Documents

Culture Documents

Ms Sidus Buildcon PVT .LTD Mix Design m10 Opc+Pfa

Uploaded by

abhijit.paikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ms Sidus Buildcon PVT .LTD Mix Design m10 Opc+Pfa

Uploaded by

abhijit.paikCopyright:

Available Formats

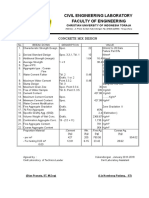

SWASTIK INFRA LOGICS PVT.LTD.

Project

Client M/S SIDUS BUILDCON PVT. LTD

SITE PANVEL

Mix Design for M 10 Grade

Mix Calculation 0

Data for Mix

1 Characteristic Compressive Strength (fck) 10.0 Mpa

2 Degree of Quality Control V/Good

3 Target Mean Strength As Per 456-2000 15.78 Mpa

4 Specific Gravity of Cement 3.15

5 Specific Gravity of FLYASH 2.26

6 Specific Gravity of Mic Silica 2.20

7 Specific Gravity of 20 mm 2.82

8 Specific Gravity of 10 mm 2.80

9 Specific Gravity of R.Sand 0.00

10 Specific Gravity of C.Sand 2.70

11 Specific Gravity of Water 1.00

12 Water /Cement Ratio (max= 0.60 by CementAs per is 456) 0.59

(Minimum Cement As per is 456-2000) 220 Kg/m3

13 Cementitius Content kg/m3 of concrete 280 Kg/m3

14 Cement Content Kg/m3 202 Kg/m3

15 GGBS Content Kg/m3 78 Kg/m3

16 Mic. Silica Content Kg/m3 0 Kg/m3

17 Free Water content per cum. of concrete 165 Kg/m3

18 Type of Exposure Severe

19 Workability in mm 120+/-25

DESIGN FORMULA

V = {W+C/Sc+1/P x fa/Sfa} x 1/1000

V = {W+C/Sc+1/P x ca/Sca} x 1/1000

Where,

V = Absolute volume of fresh concrete

W = Mass of water Kg/m3

C = Mass of Cement Kg/m3

Sc = Specific Gravity of Cement.

Sfas = Specific Gravity of FLYASH

Smsc = Specific Gravity of Micro silica

P = % of fine or coarse aggregate to total aggregate

fa & ca = Mass of fine and coarse aggregate Kg/m3

Sfa & Sca = Specific Gravity of fine and coarse aggregate.

Target Mean Strength as per IS 456 : 2000

Standard Deviation of Very good Quality control (s) 3.5

Tolrance faactor 1.65

Characteristics Strength of concrete (fck) 10 Mpa

therfor tms=fck+(t*s) 15.78 Mpa

TMS = 15.78 Mpa

% FINE & COARSE AGGREGATE TO TOTAL

AGGREGATE as Per Blending of Combined Graph

20 mm = 31.0 %

10 mm = 20.0 %

R.Sand = 0.0 %

C.Sand = 49.0 %

DESIGN CALCUTION

20 mm V = {W+C/Sc+ Fas/Sfas+Msc/Smsc+1/P x Ca1/Sca1} x 1/1000

202 78 0 1 Ca1 )x 1

1=( 165 + + + + x

3.15 2.26 2.20 0.31 2.820 1000

Ca2 = 644 Kg

10 mm V = {W+C/Sc+ Fas/Sfas+Msc/Smsc+1/P x Ca2/Sca2} x 1/1000

202 78 0 1 Ca2 )x 1

1=( 165 + + + + x

3.15 2.26 2.20 0.20 2.800 1000

Ca1 = 412 Kg

R/Sand V = {W+C/Sc+ Fas/Sfas+Msc/Smsc+1/P x Fa1/Sfa1} x 1/1000

202 78 0 1 Fa2 )x 1

1=( 165 + + + + x

3.15 2.26 2.20 0.000 0.000 1000

Fa1 = 0 Kg

C/Sand V = {W+C/Sc+ Fas/Sfas+Msc/Smsc+1/P x Fa2/Sfa2} x 1/1000

202 78 0 1 Fa1 )x 1

1=( 165 + + + + x

3.15 2.26 2.20 0.490 2.700 1000

Fa2 = 974 Kg

Final Ingredients given as below (in SSD)

3

Cement 202 Kg/M Ambuja OPC 53

FLYASH 78 Kg/M3 ASHTECH

3

Kg/M 0

20 mm 644 Kg/M3 Swastik Crusher Uran

10 mm 412 Kg/M3 Swastik Crusher Uran

R.Sand 0 Kg/M3 0

C.Sand 974 Kg/M3 Swastik Crusher Uran

Water 165 Kg/M3 0

Admixture 4.20 Kg/M3 CAC SUPER FLOW 65

3

Density of Mix = 2479 Kg/M

Mix Details

Grade of Concrete M 10

W/C Ratio 0.59

Water Content Kg 165 1.00 152

Cementatitus Kg 280

Cement Content Kg 202 3.15 Ambuja OPC 53 64

FLYASH Kg 78 2.26 ASHTECH 49

MICRO SILICA Kg 0 2.20 5

Proportion of Aggregate

20 mm Kg 644 2.820 31 % Swastik Crusher Uran 218

10 mm Kg 412 2.800 20 % Swastik Crusher Uran 134

Avg.spg. 2.810

R.Sand Kg 0 0.000 0 %

C,Sand Kg 974 2.700 49.0 % Swastik Crusher Uran 300

Coarse Aggregate Kg 1056 51.0 %

Fine Aggregate Kg 974 49.0 %

Admix Dose % 1.50 1.245 CAC SUPER FLOW 65

All in Aggregate Gradation ( IS: 383-2016Table - 10 )

Aggregates R/Sand C.Sand 20 mm 10 mm R/Sand C.Sand 20 mm 10 mm

Proportion Midlimits

0 49.0 31 20 Combined Specific Limits MSA

Individual Passing % Passing

of Sp.

20 mm

Ratio 0 0.49 0.31 0.2 Limits

Sieve (mm) % Passing

40.0 100 100 100 100 0.0 49.0 31.0 20.0 100.0 100.0 100

20.0 0 100 93.5 100 0.0 49.0 29.0 20.0 98.0 97.5 95-100

4.75 0.0 93.02 0.31 4.36 0.0 45.58 0.10 0.87 46.5 40.0 30-50

0.600 0.0 38.60 0.00 0.00 0.0 18.91 0.00 0.00 18.9 22.5 10-35

0.150 0.0 12.08 0.00 0.00 0.0 5.92 0.00 0.00 5.9 3.0 0-6

Blending Graph for Concrete

100

80

60

% Passing

40

20

0

0.0 0.1 1.0 10.0 100.0

IS Sieve size in 'mm'

Note:- Aggregate may vary as per gradation and material properties.

Swastik InfraLogics Pvt. Ltd.

QA/ QC Manager

You might also like

- Concrete Mix Design: Target Mean StrengthDocument12 pagesConcrete Mix Design: Target Mean StrengthAkash Kumar VermaNo ratings yet

- Mix Design M20 Grade ConcreteDocument13 pagesMix Design M20 Grade ConcreteJaime Manalili LandinginNo ratings yet

- C40 Concrete Mix DesignDocument2 pagesC40 Concrete Mix DesignIsaiahogeda50% (2)

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 pagesTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Analysis and Evaluation of Heat Pump Efficiency in Real-Life ConditionsDocument44 pagesAnalysis and Evaluation of Heat Pump Efficiency in Real-Life ConditionsNADYANo ratings yet

- Checkpoint Revision Science Checklist 2018Document12 pagesCheckpoint Revision Science Checklist 2018Hoàng Anh Bùi100% (1)

- Ms Sidus Buildcon PVT .LTD Mix Design m25 Opc+PfaDocument3 pagesMs Sidus Buildcon PVT .LTD Mix Design m25 Opc+Pfaabhijit.paikNo ratings yet

- Ms Sidus Buildcon PVT .LTD Mix Design M 40 Opc+PfaDocument3 pagesMs Sidus Buildcon PVT .LTD Mix Design M 40 Opc+Pfaabhijit.paikNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignUma MaheshwaraNo ratings yet

- Is Mix Design Final PlainDocument6 pagesIs Mix Design Final Plainksasi27No ratings yet

- Grade of Concrete:M 25/20Document9 pagesGrade of Concrete:M 25/20Niroj MaharjanNo ratings yet

- Parameters For Mix Design M40Document3 pagesParameters For Mix Design M40Abhijit ErandeNo ratings yet

- Concrete Mix DesignDocument22 pagesConcrete Mix DesignkevalNo ratings yet

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyNo ratings yet

- M30 Normal - Mix Design With Trial SheetDocument4 pagesM30 Normal - Mix Design With Trial Sheetabir senguptaNo ratings yet

- Mix Design FormatDocument18 pagesMix Design FormatChandan MondalNo ratings yet

- Mix Design Bet OnDocument12 pagesMix Design Bet Onmalik mushthofaNo ratings yet

- Form - Trial Mix Report: Technical Marketing Department CustomerDocument6 pagesForm - Trial Mix Report: Technical Marketing Department CustomerRedi PascaNo ratings yet

- Mix Design CorrectionsDocument11 pagesMix Design CorrectionsVijay JamadarNo ratings yet

- Mix Design Calculation Sheet: Mix: Csdwii/Mcc/Sbc/01Document7 pagesMix Design Calculation Sheet: Mix: Csdwii/Mcc/Sbc/01Aulia NrkNo ratings yet

- Chapter Four: 4.0 Results and DiscussionsDocument10 pagesChapter Four: 4.0 Results and DiscussionsAyo OshoNo ratings yet

- M30 Design MixDocument10 pagesM30 Design Mixpendotavinay6No ratings yet

- M40 Concrete Mix Design AppendixDocument3 pagesM40 Concrete Mix Design AppendixKunjbihari ParmarNo ratings yet

- K 250 Purnabakti Karya BintanDocument1 pageK 250 Purnabakti Karya BintanArda S ArsNo ratings yet

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- CM36 Pattissery M20 Trial 1Document10 pagesCM36 Pattissery M20 Trial 1sudhakarthekingNo ratings yet

- Trail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningDocument4 pagesTrail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningMohammad Arif RasheedNo ratings yet

- PRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M30 GRADEDocument3 pagesPRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M30 GRADEabir senguptaNo ratings yet

- Plain Concrete FootingDocument6 pagesPlain Concrete FootingAnonymous mcHqIfbnV1No ratings yet

- Concrete Mix Design M20 GradeDocument4 pagesConcrete Mix Design M20 GradeSyerifaizal Hj. MustaphaNo ratings yet

- Cv. Zhafirah Mulia MandiriDocument15 pagesCv. Zhafirah Mulia MandiriBengkulu BetonNo ratings yet

- Mix Designs: Appendix 2Document33 pagesMix Designs: Appendix 2BartoFreitasNo ratings yet

- Concrete Mix DesignDocument35 pagesConcrete Mix DesignAbraham Henry BernardNo ratings yet

- Rencana Anggaran Biaya (RAB) : KegiatanDocument26 pagesRencana Anggaran Biaya (RAB) : Kegiatanyemima RanaNo ratings yet

- Mix Design M-40 GradeDocument2 pagesMix Design M-40 GradePruthvi TejaNo ratings yet

- PILE FDN DESIGN For NMD TOWERDocument12 pagesPILE FDN DESIGN For NMD TOWERraj mNo ratings yet

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- 21m TG Values OnlyDocument21 pages21m TG Values OnlyEngineeri TadiyosNo ratings yet

- Design Singly Reinforced BeamDocument9 pagesDesign Singly Reinforced BeamMian M KhurramNo ratings yet

- نکات کلیدی برای انجنیران ساحویDocument22 pagesنکات کلیدی برای انجنیران ساحویMarsila SultaniNo ratings yet

- Cube TestDocument7 pagesCube TestMani PathakNo ratings yet

- Concrete Mix Design M-40 (RCC) GradeDocument6 pagesConcrete Mix Design M-40 (RCC) GradeAshok amlapureNo ratings yet

- Concrete Mix Design M-40 (RCC) GradeDocument6 pagesConcrete Mix Design M-40 (RCC) GradeAshok amlapureNo ratings yet

- Concrete Field Mix Proportion Calculation: I. Design DataDocument2 pagesConcrete Field Mix Proportion Calculation: I. Design DataJefry AjaNo ratings yet

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Pipe Thickness Design For 1900mm DiameterDocument8 pagesPipe Thickness Design For 1900mm DiameterAjayvidyanand SharmaNo ratings yet

- Mix Design MDocument3 pagesMix Design MPrabhakar Kumar BarnwalNo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignfaheemqcNo ratings yet

- Civil engineering guide for important pointsDocument21 pagesCivil engineering guide for important pointsVijay M100% (2)

- M 35 With FlyashDocument54 pagesM 35 With FlyashCIVIL ENGINEERINGNo ratings yet

- DMF K-300Document1 pageDMF K-300deasyaja1212No ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 pagesTest Report: M/S Abhi Engg Corporation PVT LTDimran khanNo ratings yet

- Estimate of Materialand Labor-10Document1 pageEstimate of Materialand Labor-10MohMohkNo ratings yet

- Concrete Mix Design ResultsDocument13 pagesConcrete Mix Design Resultsshamsuddin ShaikhNo ratings yet

- PRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M40 GRADEDocument3 pagesPRISM JOHNSON LIMITED CONCRETE MIX DESIGN FOR M40 GRADEabir senguptaNo ratings yet

- DMF K-250Document1 pageDMF K-250deasyaja1212No ratings yet

- Mix DesignDocument6 pagesMix DesignDhl KshtjNo ratings yet

- 1) Summary of RequirementsDocument4 pages1) Summary of RequirementsSolomon MehariNo ratings yet

- Civil Engineering Laboratory Faculty of Engineering: Concrete Mix DesignDocument3 pagesCivil Engineering Laboratory Faculty of Engineering: Concrete Mix DesignDian PranataNo ratings yet

- Calculation of Concrete Mix Design: Cirebon - Jawa BaratDocument11 pagesCalculation of Concrete Mix Design: Cirebon - Jawa Baratelang ghifariNo ratings yet

- Earth and Life Quiz 2 ReviewerDocument2 pagesEarth and Life Quiz 2 Revieweririshpajarillaga13No ratings yet

- Ice Plant Visit Report 2019 PDF ThermalDocument10 pagesIce Plant Visit Report 2019 PDF ThermalMonuj BorahNo ratings yet

- CH 6 - Periodic PropertiesDocument5 pagesCH 6 - Periodic PropertiesKakashi HowardNo ratings yet

- Esag 20190206 Energy Storage in Ieso Markets Powin EnergyDocument34 pagesEsag 20190206 Energy Storage in Ieso Markets Powin EnergyGooge ReviewerNo ratings yet

- Hydrologic Cycle and Water Budget EquationDocument14 pagesHydrologic Cycle and Water Budget EquationShafizatulNo ratings yet

- Innovative approaches to moving lunar regolithDocument63 pagesInnovative approaches to moving lunar regolithWaseem TahirNo ratings yet

- About Kawah IjenDocument3 pagesAbout Kawah IjenDwiti NurayaNo ratings yet

- Aggregate: Lecture 4. AggregatesDocument27 pagesAggregate: Lecture 4. AggregatesMustafa MustafaNo ratings yet

- CHE 507 1st Lectures PresentationDocument34 pagesCHE 507 1st Lectures PresentationTahiru SakaNo ratings yet

- Astm F819Document3 pagesAstm F819edmarrobNo ratings yet

- Heat Rate of TG PDFDocument9 pagesHeat Rate of TG PDFTapash Nag0% (1)

- 17 References PDFDocument6 pages17 References PDFVedhas WalimbeNo ratings yet

- 1.incoming Register July 2014Document24 pages1.incoming Register July 2014BeLlCoNtInEnT MNo ratings yet

- KIE 4004 Modern Power System AnalysisDocument13 pagesKIE 4004 Modern Power System AnalysisOmarRagabNo ratings yet

- Midterm Solar ThermalDocument1 pageMidterm Solar ThermalAshavi ShahNo ratings yet

- GENED Science1Document78 pagesGENED Science1Mary-Rose CasuyonNo ratings yet

- NEET Chapter-wise weightage 2023 guide for Physics, Chemistry & BiologyDocument15 pagesNEET Chapter-wise weightage 2023 guide for Physics, Chemistry & BiologyKaranNo ratings yet

- Soil & Tillage Research: Alicja Kici Nska, Justyna WikarDocument11 pagesSoil & Tillage Research: Alicja Kici Nska, Justyna WikarYoselin GomezNo ratings yet

- Eep-Internal Arc Testing of MV Switchgear IEC 62271200 Part OneDocument2 pagesEep-Internal Arc Testing of MV Switchgear IEC 62271200 Part Oneabdulyunus_amirNo ratings yet

- Steam System Basics PDFDocument67 pagesSteam System Basics PDFEduardo Miranda100% (1)

- Course OutlineDocument3 pagesCourse OutlinehekiNo ratings yet

- 1 Kinetic Molecular TheoryDocument23 pages1 Kinetic Molecular TheoryAeron Kurt AcuñaNo ratings yet

- Chemistry 1 - 2013 PDFDocument6 pagesChemistry 1 - 2013 PDFAlexNo ratings yet

- Tectonostratigraphic Terranes in Colombia: An Update First Part: Continental TerranesDocument27 pagesTectonostratigraphic Terranes in Colombia: An Update First Part: Continental TerranesEsteban Giraldo ZuluagaNo ratings yet

- Modified Penman Method TablesDocument9 pagesModified Penman Method TablesSannyBombeoJomocNo ratings yet

- Analyzers: By, Barath Srinath A 1241110025Document13 pagesAnalyzers: By, Barath Srinath A 1241110025vishnuvarmarajaNo ratings yet

- Class 3 Science Exam QuestionsDocument3 pagesClass 3 Science Exam QuestionsPrasenjit NandiNo ratings yet

- Lecture 1 - Intro To Envi SciDocument28 pagesLecture 1 - Intro To Envi ScijambeatrizNo ratings yet