Professional Documents

Culture Documents

USMW Fuel System Diagnostic Tree

USMW Fuel System Diagnostic Tree

Uploaded by

nicolas cabreraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

USMW Fuel System Diagnostic Tree

USMW Fuel System Diagnostic Tree

Uploaded by

nicolas cabreraCopyright:

Available Formats

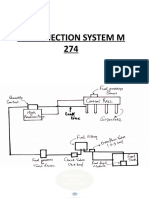

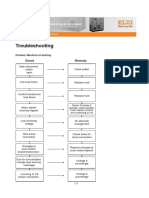

FUEL SYSTEM DIAGNOSTIC TREE

Turn key to

No gas on position

Gas at engine

at engine

Pump No sound Pump

makes sound from engine makes sound

Check all fuel system Check for proper voltage at fuel Install a pressure gauge

components for leaks or pump connector, if OK, to fuel line test port and

disconnected lines replace fuel pump install a new fuel filter

Repair leaks or Turn key on

damaged lines

Pressure too high or System OK, pressure OK,

No pressure Has correct pressure,

too low (based on check for other symptoms but cannot hold

vehicle specifications)

Check fuel lines & With the ignition on,

fuel pump inlet for any pinch the supply line

blockage or restriction

Too high Too low

If OK,

Disconnect the return replace fuel pump

Block or pinch the

fuel line from the fuel Holds pressure No pressure

return line closed

pressure regulator

Attach a hose to the return port

on the regulator & place the other Pressure low Un-pinch the supply Replace

end in a fuel safe container line & turn key on fuel pump

A. Check pump connection & in-tank filter Apply 10” vacuum to

Turn key on B. Check correct pump for application fuel pressure regulator

C. Pump may be faulty

Does not

Pressure too high Pressure OK Holds pressure

hold pressure

Remove restriction Replace fuel Check for leaking

Replace fuel

pressure regulator from return line pressure regulator cold start and standard

fuel injectors

Keep your work area clean!

The number 1 cause of fuel pump failures is from fuel pump contaminants such as dirt, rust, & moisture. If the fuel

system is not cleaned, then these contaminants will cause the replacement fuel pump to fail prematurely. Make sure

to clean your fuel tank & keep your work area clean to prevent this type of contamination.

You might also like

- Air Brake System TroubleshootingDocument5 pagesAir Brake System Troubleshootingbhanuka2009No ratings yet

- Cummins PT Pump Adjust PDFDocument3 pagesCummins PT Pump Adjust PDFHugh O'Brien Gwaze100% (1)

- 2 Ats 07Document12 pages2 Ats 07carlos maradiagaNo ratings yet

- Chevrolet 327 V8 Engine Rebuild ManualDocument120 pagesChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Map Sensor Drivability SymptomsDocument15 pagesMap Sensor Drivability SymptomsmichaelsilvaNo ratings yet

- Fuel Injection System M274Document53 pagesFuel Injection System M274Abu SAUD100% (2)

- 03 Engine Fuel SystemDocument24 pages03 Engine Fuel SystemAbel OviedoNo ratings yet

- 1106D Fuel System Diagnosis ProcedureDocument2 pages1106D Fuel System Diagnosis ProceduredubimouNo ratings yet

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3No ratings yet

- Hyundai D6GA Fuel System PDFDocument53 pagesHyundai D6GA Fuel System PDFTonny Nguyen100% (3)

- Diesel Engine Troubleshooting and MaintenanceDocument8 pagesDiesel Engine Troubleshooting and MaintenanceIhsan Ahmed100% (2)

- DK013,00Document47 pagesDK013,00marceloNo ratings yet

- Subaru EngineRepairDocument6 pagesSubaru EngineRepairstartaxis33% (3)

- Engine Management Common Rail Diesel Fuel SystemDocument53 pagesEngine Management Common Rail Diesel Fuel SystemBiruk TilahunNo ratings yet

- M47 DIESEL DIAGNOSIS GB-13-004-03 KW PDFDocument20 pagesM47 DIESEL DIAGNOSIS GB-13-004-03 KW PDFSteven KoinakNo ratings yet

- TOM Training Centrifugal Compressors: TroubleshootingDocument5 pagesTOM Training Centrifugal Compressors: TroubleshootingAhmedNo ratings yet

- D399 Industrial EngineDocument49 pagesD399 Industrial EngineMohamed SaiedNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- Suzuki Vitara Fuel Pressure CheckDocument2 pagesSuzuki Vitara Fuel Pressure CheckmGraci520100% (1)

- Hyundai HD 78Document19 pagesHyundai HD 78manuelmanriqueNo ratings yet

- Fault Code 779Document6 pagesFault Code 779Enrrique Lara100% (1)

- Fuel Pump Pressure & Volume Testing: Y ARL EyfertDocument1 pageFuel Pump Pressure & Volume Testing: Y ARL Eyfertford62bNo ratings yet

- Fuel System Diagnosis Secc 1fDocument6 pagesFuel System Diagnosis Secc 1fMiguel Antonio Sanchez ValeraNo ratings yet

- Cazafallas 2Document4 pagesCazafallas 2oscarNo ratings yet

- TroubleshootingDocument1 pageTroubleshootingSurendran RadhakrishnanNo ratings yet

- 7-1. Troubleshooting GuideDocument3 pages7-1. Troubleshooting GuideGetachew GechNo ratings yet

- Carter Fuel Pump DiagnosisDocument2 pagesCarter Fuel Pump Diagnosishassan ahmad100% (1)

- Petrol Eng Trouble DiagDocument30 pagesPetrol Eng Trouble Diagdessie tarekegnNo ratings yet

- Emiss) On Control SYSTEM 21-125: BepairDocument11 pagesEmiss) On Control SYSTEM 21-125: Bepairthunderstorm60No ratings yet

- Diagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardDocument11 pagesDiagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardAlejandro HernandezNo ratings yet

- 7-1 Troubleshooting MotorDocument1 page7-1 Troubleshooting Motorhernan giraldoNo ratings yet

- SUN Compression TesterDocument8 pagesSUN Compression TesterWongstorn DamrongmaneeNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument8 pagesGroup 2 Operational Checks and TroubleshootingMarco OlivettoNo ratings yet

- Liste Des Defauts 38Document5 pagesListe Des Defauts 38MMF PLUSNo ratings yet

- phú-đã chuyển đổiDocument20 pagesphú-đã chuyển đổiNguyễn CaoThắngNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument7 pagesGroup 2 Operational Checks and TroubleshootingREMZONANo ratings yet

- Compressor Trouble ShoutingDocument7 pagesCompressor Trouble ShoutingDhiraj ShrivastavNo ratings yet

- Rail Pressure ControlDocument7 pagesRail Pressure ControlMaxy ServiçosNo ratings yet

- 99-02 Chevrolet Camaro - Fuel System DiagnosisDocument5 pages99-02 Chevrolet Camaro - Fuel System DiagnosisGreg MartinNo ratings yet

- Principle and Application of WEICHAI Electrical High Common Rail SystemDocument44 pagesPrinciple and Application of WEICHAI Electrical High Common Rail Systemheri setyonoNo ratings yet

- Suntec Fuel Unit Test ManualDocument17 pagesSuntec Fuel Unit Test ManualsunnygyadavNo ratings yet

- Fuel Pressure: Main MenuDocument2 pagesFuel Pressure: Main MenusoftallNo ratings yet

- 75 Ts GuideDocument3 pages75 Ts GuideasursNo ratings yet

- R-ME-HC-S-020 Governor System Test RecordDocument9 pagesR-ME-HC-S-020 Governor System Test Recordrotimi olalekan fataiNo ratings yet

- ToolsCat 74Document58 pagesToolsCat 742791957No ratings yet

- Ann Marie Kelly Cessna 421 ChecklistDocument3 pagesAnn Marie Kelly Cessna 421 ChecklistOlga Lucia Duque QuijanoNo ratings yet

- 24-20 Fuel System Pressure and Residual Pressure Checking PDFDocument7 pages24-20 Fuel System Pressure and Residual Pressure Checking PDFmefisto06cNo ratings yet

- Troubleshooting, RE80: Machine RE80 Serial Number Build Year Customer Customer Number Invoice Number Shipment DateDocument4 pagesTroubleshooting, RE80: Machine RE80 Serial Number Build Year Customer Customer Number Invoice Number Shipment DateFelipe Ambrocio GranadinoNo ratings yet

- Genpowerusa Generator TroubleshootingDocument2 pagesGenpowerusa Generator TroubleshootingKarthyc PillaiNo ratings yet

- Auto Transmission Air Pressure TestDocument1 pageAuto Transmission Air Pressure TestChinthaka Nayana Kumara RajapakshaNo ratings yet

- Linear Programming: Gas Lift RateDocument7 pagesLinear Programming: Gas Lift RateQuy Tran XuanNo ratings yet

- Cielo Euro IIIDocument603 pagesCielo Euro IIIb btb100% (1)

- Engine ServiceDocument18 pagesEngine ServiceDhanu MalarNo ratings yet

- Fuel Systems: EnrichmentDocument4 pagesFuel Systems: EnrichmentRich UrbanNo ratings yet

- Engine Electrical EeDocument17 pagesEngine Electrical EePedro LopezNo ratings yet

- A042g474 Rev2Document2 pagesA042g474 Rev2Rahul AR XNo ratings yet

- Gear Pump Troubleshooting GuideDocument3 pagesGear Pump Troubleshooting GuideRALPH JULES SARAUSNo ratings yet

- 64L - Coffee - Table - Book (1) (1) (1) - 032Document1 page64L - Coffee - Table - Book (1) (1) (1) - 032Nilda Ester RomeroNo ratings yet

- 951-130-172-MKU - MKF - 122-1 - 122 - 2 Pump UnitsDocument5 pages951-130-172-MKU - MKF - 122-1 - 122 - 2 Pump Unitsli geneNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Learning-From-Disagreement A Model Comparison andDocument16 pagesLearning-From-Disagreement A Model Comparison andDanish VasdevNo ratings yet

- Lab5Report PDFDocument5 pagesLab5Report PDFVasilica BoaghiNo ratings yet

- Construction Management System Final Year ReportDocument53 pagesConstruction Management System Final Year ReportMebiratu BeyeneNo ratings yet

- Arrays - One+ Multi Dimensional: Introduction To Programming CSE141 (3+1) Lab Dated: 23 Dec 2010Document3 pagesArrays - One+ Multi Dimensional: Introduction To Programming CSE141 (3+1) Lab Dated: 23 Dec 2010Hammad ShamsNo ratings yet

- Graham Construction Digitizes Travel Expense Business ProcessDocument2 pagesGraham Construction Digitizes Travel Expense Business ProcessNOURDINE EZZALMADINo ratings yet

- Cybercrime and Cyber-Terrorism: Module 4: Practical Aspects of Cybercrime InvestigationsDocument33 pagesCybercrime and Cyber-Terrorism: Module 4: Practical Aspects of Cybercrime InvestigationsMohammad Mizanur RahmanNo ratings yet

- Mew Fuel Tutorial PDFDocument7 pagesMew Fuel Tutorial PDFbalakrishnan manoharanNo ratings yet

- ZTE Proposed IP Metro Solution For Aftel V 2.0Document24 pagesZTE Proposed IP Metro Solution For Aftel V 2.0mujibrahmanNo ratings yet

- Makita Ga7020Document12 pagesMakita Ga7020Jennylyn DañoNo ratings yet

- Manual T Mobile 4G ZTE Z915Document13 pagesManual T Mobile 4G ZTE Z915Henrry Jose Utrera MichelenaNo ratings yet

- Internet and Distributed Systems PDFDocument258 pagesInternet and Distributed Systems PDFMichael OrtizNo ratings yet

- UntitledDocument24 pagesUntitledpersonnel sidolaNo ratings yet

- How To Modify A Fridge Compressor Into A Silent AiDocument5 pagesHow To Modify A Fridge Compressor Into A Silent AiDazz DazzNo ratings yet

- Electrical PointsDocument4 pagesElectrical PointstumuuNo ratings yet

- AAU - ABB - SACO 16D1 - 2012 (10kV)Document44 pagesAAU - ABB - SACO 16D1 - 2012 (10kV)Ana Milena Alfaro VásquezNo ratings yet

- 1990 - Copy II PC V6Document25 pages1990 - Copy II PC V6radutariNo ratings yet

- Remaining DurationDocument12 pagesRemaining DurationKhan the GreatNo ratings yet

- Creative Digital Marketing Communications Manager in San Francisco Bay CA Resume Mikiko MurdochDocument2 pagesCreative Digital Marketing Communications Manager in San Francisco Bay CA Resume Mikiko MurdochMikikoMurdochNo ratings yet

- STC3100IQTDocument21 pagesSTC3100IQTNguyen HuanNo ratings yet

- Moment of Safety Pressure TestDocument6 pagesMoment of Safety Pressure TestKavitha SandiahNo ratings yet

- Yellow Dynamic Business Plan Flowchart Diagram Mind MapDocument2 pagesYellow Dynamic Business Plan Flowchart Diagram Mind MapMUHAMMAD AKMAL BIN ZAHARI A21HP0076No ratings yet

- I5000 Utility Locating System: 10W TransmitterDocument29 pagesI5000 Utility Locating System: 10W TransmitterjairNo ratings yet

- Microcontroller Managed Module For Automatic Ventilation of Vehicle InteriorDocument4 pagesMicrocontroller Managed Module For Automatic Ventilation of Vehicle Interiorhamed razaNo ratings yet

- Bash CheatsheetDocument1 pageBash CheatsheetjeffNo ratings yet

- Electrical Safety in Mines: Work Regulations 1989. Approved Code of PracticeDocument21 pagesElectrical Safety in Mines: Work Regulations 1989. Approved Code of PracticeAyu Wanda SaraswatiNo ratings yet

- JTC Tones FaqDocument9 pagesJTC Tones FaqPencitraan APNo ratings yet

- Tsung - ManualDocument108 pagesTsung - ManualstrokenfilledNo ratings yet

- Ir 1153Document20 pagesIr 1153ytnateNo ratings yet

- Digital Logic Design: Shift RegistersDocument32 pagesDigital Logic Design: Shift RegistersZelalem MeskiNo ratings yet

- Marual Mercury PanesDocument28 pagesMarual Mercury Panescarlos torresNo ratings yet