Professional Documents

Culture Documents

AUX 1 NOx Tech File

AUX 1 NOx Tech File

Uploaded by

issam elmoharir0 ratings0% found this document useful (0 votes)

8 views19 pagesAUX 1 NOx Tech File

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAUX 1 NOx Tech File

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views19 pagesAUX 1 NOx Tech File

AUX 1 NOx Tech File

Uploaded by

issam elmoharirAUX 1 NOx Tech File

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 19

Valid with unbroken seal only

Technical File

for C18 Marine

Auxiliary Engine

@ 1200&1500&1800 RPM

(Engine Family C18A 1200&1500& 1800)

| Performance Spec. i a

GL Family Approval No. | _37755-03HH

Do Not Discard

This Document is to be kept on board.

EMISSION CERTIFICATION

‘Approval No, Date

46022 -07 tH 2007 -93 - 20

K. Diekmann,

‘Technical File C18A 1200& 1500& 1800-06

Table of Contents

18 Engine Part Number Table* ..

Installation Requiremen

Engine Parameter Check Method.

1. Check Engine Parameters:

2, Identify Emission-Related Engine Component:

3. Record Changes to Emissions Related Components:...

4, Identify Adjustable Feature

Appendix A: IMO Certification Test Report ~ D2...

Engine Information’...

Engine Family Information’.

Test Cell Information® .

Ambient and Gaseous

Engine Test Data* .

Technical File C18A1200&1500& 1800-06

‘

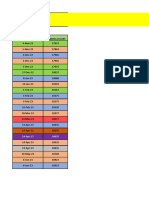

C18 Engine Part Number Table*

iE Performance Specification ‘OK5663 | OK56E4 | OKE6ES | 0KS6E6 | 0KE6GT | 0KE66S | 0K6669 | 0K6670

rpm 1800 | 1800 | 1800 | 1200 | 1800 | 1800 | 1800 | 1800

kW s47_|_547_|_601|_ 601 | sa7_| 547 | 601 | 601

enone anos (ndvertied) (bhp) 733)_|_(733)_|_@06)_|_¢@06)_|_(733)_| (733) | (606) | (806)

Testcycle | 02 _| 02 | oz | _o2 | oz | oz | oz | vz

Engine Ratings (Overioad) rpm. 800] 1800 |_1800_| 1800 | 1800 | 1800 | 1800 | 1800

NOTE: Applies to Marine Auxilliary Engines Only KW cor [601 |_661_| 661 | 601 | 601 | 661 | 661

(bhp) (206) | (806) |_(@87)_ | (#e7) | (@06) | (606) | e87) | (287)

Engine Model PartNumber | cis |_cte | cre | cis | cis | cts | crs | cre

5 17720

Engine Arangoment Partnumber | aosea| 2a20se4|2420387| 2420367] 2617718 2617719] 2617721 2617721

‘Compression Ratio 1454 | 1451 | 1454 | 145: | 1452 | 1452 | 1454 | 1454

Static Timing Deg. NA [NA | NA | NA | NA | NA | NA | NA

Piston Part Number [2358098 |2358008| 27358096 | 2356098] 2356098] 2358098 | 2358008 | 2358098

E 1982

Syne runny | i rz id ez zz

Camshaft Part Number __|2012677|2012677|2012677|2012677| 2012677 |2012677 |2012677|2012677|

'2167455|2167455|2167455|2167455| 2167456 |2167455| 2167455] 2167455

rarecore Part Number |2463387|2463367| 2463387; 2463367] 2463387 |2463387| 2463387 |2463387,

‘24nazta|2423219| 2423219 |2425219] 2423219|2423219|2423219| 2425219

2 2660053 | 2660053| 2660053] 2660053] 2650053 2660053] 2660053 2660053)

'2014824|2014824| 2014824] 2014824| 2014824 2014826] 2014824|2014824|

aLemiceh toe eee. Cree? PartNumber _ |-917275|2017275|2017275|2017275| 2017275 |2017275|2017275|2017275|

injector Part Number |2113028|2113028)2113028|2113026|2113028|2113028|2113028| 2113026]

2443495 | 2443495] 2443497 [2443497 | 2628544] 2628544 | 2626546 | 2626546

Personality Module Software Part Number |2720678|2720678|2720679|2720673| 2720686 2720686 2720687 2720687|

2785674|2785574| 2785575 | 2785575 2785582 |2785582| 2785583 | 2785583|

\Updated: March 2, 2007

Page 3 of 19

‘Technical File C18A1200&15008&1800-06

4

C18 Engine Part Number Table”

Performance Specification ‘OK5659 | 0K5660 | 0K5661 | 0K5662 | 0K5726 | OKE663 | OKE664 | OKE665

rpm 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1600

Bkw 372 372 465 465, 410 372 372 465

Eanne nenings (advertised) (bhp) (499) | (499) | (624) | (624) | (650) | (499) | (49 | (624)

Test Cycle 2 D2 D2 02 D2 D2 D2 b2

Engine Ratings (Overload) rpm. 1800 1800 1800 1800 1800 1800 1800 1800

NOTE: Applies to Marine Auxilliary Engines Only BkW. 4o9_| 409 | 512 | 512 | 451 | 409 | 409 | 512

(bhp) (S49) | (649) | (686) | (686) _| (605) _| (549) | (549) | (686)

Engine Model Part Number C18 C18 C18 C18 C18 C18 C18 C18

Engine Arrangement Part Number __ |2420375|2420360|2420361| 2420382 | 2458375|2617714|2617715|2617716|

Compression Ratio 16.51 16.5:1 | 16.5:1 | 16.5:1 | 16.5:1 | 16.5:1 16.5:4 16.5:4

Static Timing Deg. NIA NIA N/A NA N/A N/A N/A N/A

Piston es Part Numi 2397844 | 2397844 | 2397844 | 2397844 | 2397844 | 2397844 | 2397844 | 2397844

'2221982|2221982|2221982|2221982|2221982|2221982|2221982| 2221982

Gulectisee PartNumber |>237263|2237263|2237263 | 2237263 | 2237263 | 2237263 |2237263| 2237263

Camshaft Part Number 2396139 | 2396139 | 2396139 | 2396139 | 2396139 |2396139|2396139| 2396139)

2167455 | 2167455 | 2167455 | 2167455 | 2167455 | 2167455 | 2167455 | 2167455)

SS Part Number | 2463387|2463387 |2463367 |2463387 |2463387 |2463387|2463387 | 2463307|

2423219 |2423219|2423219|2423219|2423219| 2423219 | 2423219 | 2423219)

'2660053| 2680053 | 2660053 |2660053| 2660053 | 2660053 | 2660053 | 2660053

Turbocharger Basic Group Part Number 2420267 | 2420267 | 2420267 | 2420267 | 2420267 | 2420267 | 2420267 | 2420267

2321135 |2321135|2321135| 2321135 }2321135| 2321135 | 2321135

Injector Part Number 2447718|2447718| 2447718 | 2447718| 2321135 | 2447718 | 2447718 | 2447718,

| 2530618 | 2530618 | 2530618 | 2530618 | 2530618 | 2530618 | 2530618 |

2443491 | 2443491 | 2443493 | 2443493 | 2458425 | 2628540 | 2628540 | 2628542

2720676 | 2720676 | 2474656 | 2474656 | | 2720684 | 2720684 | 2720685}

Recsonsiky. Module Sorters. PartNumber |>795572| 2785572 |2720677 |2720677| 2785580 |2785580|2785581

2785573 | 2785573 |

(Updated: March 2, 2007

Page 4 of 19 Technical File C18A1200&1500& 1800-06,

C18 Part Number Table*

a eS ora | es ces oe | rt ont] ca

aa 5 va

— ‘en ot =

ie aes rah ser ie

re Aoi tsi hay Engle ony | Baws mt

(oe. i

eri Peano |e ce

eel Pamir

neon | at al ar roe ere

zn sve xo ari aro azine

eee ammo rt arg mars 03237 20789

one at ess a

thi a ear ear

nid 3387

ran rein rn one

200081805

, 4

cla ngie Pat Namba Tale

Cesc

ert ne Eels ees

perme nm ee a eee ee

sore cane] — ga gt ae oP ree

= achat e

eee mee

ae siete ar

= ee

Steen hwo

a eel a

ae 0 Sn

we reonme_fg ee

oes es

Te t : f

Pe “st e184 20M s008 10.05

» 3

C18 Engine Part Number Tablet

rae Tectia le CA 20 SURII00.6

Installation Requirements

‘The flowing inslation reuremens mast met rie nda ped tebe te engine 12

amply withthe nitogn ones (NOs) cso ina regi 3 of Anex V1 of MARBOL,

a8

Max. Joke Water let Temperire 52° (198F)

Max. Aerooer Wat nt Temperature

or seater aerosol ergs 52°C (126°F Combined Cut Kel Cooks

32°C (00°F) Heat Eachage Cooled

Maximum Aire Retin 6SkPa ae" Wate)

Missin cst Bakr APA 40" Wate)

Engine Perform:

‘The rtd sped and rat power fhe npn nds onthe engine information raepe For

righ hand sone engines th smelt ested on op ofthe eng ci one Fo Ft ad

Service ones he nepa is vse le nd sich ae mechani a

Engine Emissions

ata mensrmen scons wih he recedes desribed in Reston 2 of he 1997

(Conference “Tectia Codon Corr of Esens of Nieogen Oxides tom Marie

Pr This engine's exon emissions aren orphan withthe Inertia! Nang

5 3 of Annex Vl the MARPOL 73/78 Conseton The NO iit fore

“esha ile C18 1200815041800-96

46022-07HH

2007 -03 ~20

‘On-board Nox Verfeton procedure

Tagine Parameter Check Method

Introduction

‘The engine parame chck mth at allows sal be wed by he saya wri hat he engine

«isle on tard esp, amples wih be nogen ies (NOx emo to Regula

13 of Ampex ot MARPOL TST. Th metho itn Be el fr tein efiation sive.

pero annem eves

Procedure

‘The procedures tte bel ae dee onthe lowing pages. The cn be wed 1 demote

compan wit the NOx ensions ims

Steps of tingine Parameter Check Methods

1 Check Engine Param

2 Lei Emision ele Engine Componens

2 Resor Changs o Eso Reed Components

4 enityAdjsnble Fens

“Techical ie C2001 on 180.06

1. Chek gine Parameter

Teen aati ie part eo NO min hat apy alo

‘sing bused wit ing he pie eat of manures en

[Brac proganma nie ECM Fecenc Con Me a ppm es ae 63

‘etry. Trea ein reid muse pruners bce wee

2 Meaty Emin Relat Haga Componen:

“Tete soins the cone tha inne eg NO sn fr his cgi

‘Tels wd ton Fie Pr Nts Tae of Oem ese rman o ese

‘eponet ashiped or Cail fats,

“Tow pet tantra be dene en he ery mp bend th ego

{ing ih Tate nome of i et

“Teper mae pt umber and he pe aig cab nd nh main Pe

‘a vende

Nate temrrepe

Seen etn Recor Change Ein Rene Compre

Piast i =

Sees Erb hm bebo Same

Geerantoneenart ieceni ie

Congr bv par nb wit pr ube rn he utes on ae ae

‘tte par rambes const teen etl cen

Emission Related Component List:

Component Location on engine

Item Description: of component part No. Also see diagrams

below:

1 Piston On the top of the piston crown assembly.

See note 1)

2 {Camshaft Stamped on the end of the camshaft.

(See note 1)

3__[Injector Etched on top of the injector.

4 Aftercooler _|Stamped on the aftercooler core body or

(See note 1)_|mounting flange.

5 Turbocharger |On nameplate of turbocharger on center

section.

“ss Personality |On Information Plate of engine located on

module top of oil cooler for right hand service

6 software engines or on the left hand side of the valve

mechanism base for left hand service

engines or use the Electronic Technician

(ET) Service Tools.

Cylinder Cast into the left hand side face of the

Head cylinder head. Visible from above. Also,

7 |(See note 1) lowest level assembly part number of

cylinder is affixed by label to front face of

cylinder head.

Note 1:

Part number not accessible without significant engine disassembly. Therefore it is not

necessary to be checked by the surveyor.

_ Part Number Locations:

2 ~

2. Camshaft 3. Injector

Technical File C18A12008&1500& 1800-06

242-3219 216-7455 & 246-3387

5, Turbocharger

6. Personality Module Software

Right Hand Service

-@ Left Hand Service

6, Personality Module Software

7. Cylinder Head

Technical File C18A 1200& 1500 1800-06

Verification procedure for the Electronic Engine Software:

1. Hook up the laptop computer (with ET) to the engine Electronic Control Module (ECM) as

shown in the diagram below.

enone comm

JUNICATION ADAPTER II

conrRou mou ec W013) uwvensaL twas

OATAUNCCABLE G77) semaennue arn

onsneaee

Jo “Comecror ATNEOLONLY —coummycarion

‘ADAPTER I

171-4400 (0)

2. Start the Electronic Technician (ET) program on the computer.

3. Select the desired ECM from the displayed list. If the engine has only one ECM, only one

ECM option will be displayed.

4. The display screen will show the engine model, engine location, and engine serial number.

Displayed below this information will be a list of two columns, the first column lists the

“Parameter”. The second column lists the value for that parameter. The fourth parameter listed

is the “Personality Module Part Number”. This is the engine software. The corresponding

value is the software part number.

Technical File C18A1200&1500& 1800-06

3. Record Changes to Emissions Related Components:

A record must be kept of the changes to the emissions related components listed on the previous table.

Use the table below to record these changes in chronological order as they occur.

Note:

Emission related components may only be replaced as listed in this Technical File or otherwise

approved by the Adminstration or Recognised Organisation, which has approved the technical File.

Caterpillar recommends emission related components and all other components be replaced with parts

approved by your Caterpillar Dealer.

Record Of Changes to Emissions Related Components:

Manufacturer

Date of Change Old Part No. New PartNo. Component of Component __Approved By:

tify Adjustable Features:

adjustable features on the engine that will significantly affect NOx emissions. Other than

programmed in the ECM (Electronic Control Module), all programmable features are

| Therefore a section to record adjustable features becomes unnecessary.

Technical File C18A1200& 1500& 1800-06

Appendix A: IMO Certification Test Report — D2

Parent Engine

Engine Information*

Emissions Test Report N

Engine

Manufacturer Caterpilar inc, Peoria, llinois, USA

Engine Type. C18.

Family or Group identification (C18A12008150087600

Serial number 1012479

Rated sj 1800

Rated power

Intermediate speed.

‘Maximum torque at intermediate 6;

Static injection timi

Electronic injection timi

Variable injection timi

Variable turbochar

Bore

Stroke

“410 KW,

NA tpm:

NWANm:

‘CABTOG,

es

es

nO.

445 mm.

4163.mm.

ed

NA

jeomett

‘Nominal compression ratio 1454

Mean effective pressure at rated power 1507 KPa

‘Maximum cylinder pressure at rated 714,300 kPa.

Cylinder number and configuration Number: 6.cyl,_16

Auxiliaries

‘pum,

Specified ambient conditions:

‘Maximum sea water temperature:

‘Maximum charge air temperature

‘Cooing system spec. intermediate cooler

Cooling system spec. charge air stages

Lowihigh temperature cooling system set

Maximum inlet depression

32°C.

NAC.

‘Yes

T stage.

N/A°C.

“65 kPa

ints

‘Maximum exhaust back pressure 10.0 kPa,

Fuel oil specification IMO DMX Fuel

Fuel oil temperature 30°C

‘Lubricating Oil specification. (CHa 10W30 CAT PTASP2586

‘Applicationiintended for:

‘Customer.

Final appication/installation, Shi

Final applicationvinstallation, Ei

Shi

Auxiliar

ine

Emissions test result:

©) D2

NOx 6.85 gikW-hr

Test identification C18 Certification Test

[Datertime 16 September 2003/10:29 AM.

[Test site/bench TC-L, Cell 614

[Test number. C183.

[ Surveyor

Date and Place of re

Technical File C18A 1200&1500& 1800-06

Engine Family Information*

Emission Test Report No.: C18-3 ‘Sheet 2/5

| Engine Family Information (Common specifications)

‘Combustion cycle 4 stroke cycle

Cooling medium Water

Cylinder configuration 6

Method of aspiration Pressure charged

Fueltype to be used on board Distillate

‘Combustion chamber Open chamber

Valve port configuration Cylinder head

4 valves per cylinder Intake dia: 47,00 mm

Valve port size and number Exhaust dia.: 41.81 mm

eo Fuel system type Electronic Unit Injector

Miscellaneous features:

Exhaust gas recirculation No

Water injectiton/emuision No

Ar injection No,

Charge cooling system Yes

Exhaust after-treatment No

Exhaust after-reatment type NA

Dual fuel No.

Engine Family Information (Selection of parent engine for test bed test

Family Identification €18A12008 150081800

Method of pressure charging Turbocharged

Charge air cooling system ‘Seawater aftercooled

Griteria of the Selection (specify) Maximum D2 weighted NOx

‘Number of cylinder (parent) 6

Max, rated power per cylinder (parent) 68 kW.

1800 rpm

6to 22 °BTDC

1408 g/min

C18, Performance Specification 0K-5726

Auxiliary

‘Technical File C18A1200&1500&1800-06

Test Cell Information”

Emissions Tost Roport No. C183 Shoot 0/5

Exhauet Pipe

Diameter

Length

Insulation Wo

Probe Location ES nm om Doe

Remark

"27, 203 | Mm

0.46, 5.34 | M

‘Measurement equipment

Manufacturer

Caitbration

‘Span gos cone.

‘Measurement

Ranges

Analyser

2306 ppm.

2845 ppm

157%

20.90%

‘9609 ppm

10-2500 ppm

(0.9000 ppm.

016%

025%

10-1000 pom.

(010000 rpm

10-5084 Nm

NWAKW.

Rosemont

Rosemont

Rosemont

Rosemont

Rosemont

‘CAT

Revere

CAT,

880

880

‘40

3008

USPI-D3.2.5K 05

3009)

‘Micro-Mation OMFO2S 0.3000 g/m

Brandt NZP1443-10°-1-MG (0-4117 kofhe

NA NA WA

760°C

°C.

1000 °C.

760°C

760°C

760 °C

HP-E14218

HPLETA218

HP-ETA218

HPEMDIB

HP-E14218

HP-E14218

0340 KPa

0340 KPa

BO-1T0 KPO

207

207

370

Sera

Setra

Seta

‘Sera 207 O25 psi

1151020 °C

Dew Point Mentor

Ful Charactoristics

Edge Tech

Fuel olemental analysis

‘Carbon

Hydrogen,

Nitrogen,

Oxygen

‘Sulphur

0.8595 ko

2.675 mm2is

Technical File C18A 1200& 1500& 1800-06

Amlet ans Garou Emissions Oo”

rie can anes 6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EM. DG NOx Tech. FileDocument23 pagesEM. DG NOx Tech. Fileissam elmoharirNo ratings yet

- ETB AnneSiDocument17 pagesETB AnneSiissam elmoharirNo ratings yet

- AUX 2 NOx Tech. FileDocument19 pagesAUX 2 NOx Tech. Fileissam elmoharirNo ratings yet

- AUX 3 NOx Tech FileDocument19 pagesAUX 3 NOx Tech Fileissam elmoharirNo ratings yet

- 7.16NYK Engine Cadet Course Handouts (Incinerator)Document11 pages7.16NYK Engine Cadet Course Handouts (Incinerator)issam elmoharirNo ratings yet

- Emergency GeneratorDocument3 pagesEmergency Generatorissam elmoharirNo ratings yet

- Blackout ActionDocument1 pageBlackout Actionissam elmoharirNo ratings yet

- X Onboard Energy Saving and The EnvironmentDocument31 pagesX Onboard Energy Saving and The Environmentissam elmoharirNo ratings yet

- Auxiliary BoilerDocument3 pagesAuxiliary Boilerissam elmoharirNo ratings yet

- Monitoring Pleiger Sys Fault - 28.05.23Document1 pageMonitoring Pleiger Sys Fault - 28.05.23issam elmoharirNo ratings yet

- Air Compressor Plant PDFDocument162 pagesAir Compressor Plant PDFissam elmoharirNo ratings yet

- PumpsDocument141 pagesPumpsissam elmoharirNo ratings yet

- Fire Fighting CesDocument7 pagesFire Fighting Cesissam elmoharir100% (1)