Professional Documents

Culture Documents

(15-25) Application of Biopolymers in The Pharmaceutical Formulation - DS Edits-Format

Uploaded by

Ioana StanciuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(15-25) Application of Biopolymers in The Pharmaceutical Formulation - DS Edits-Format

Uploaded by

Ioana StanciuCopyright:

Available Formats

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

A Review: Application of Biopolymers in the Pharmaceutical

Formulation

Maghchiche Abdelhak

Associate Professor, Department of Pharmacy, Medicine faculty, Batna 2 University, Algeria

Email: amaghchiche@yahoo.fr

DOI: http://doi.org/ 10.5281/zenodo.2577643

Abstract

This review discusses some of the most commonly used biopolymers in pharmaceutical and

medical application. Biopolymers are the choice of our review because of its low toxicity,

stability, renewable nature, and biodegradability. Biopolymers are among the most

widespread compounds in the world and are often naturally occurring materials.

Biopolymers have been found to have very promising industrial application in various forms.

We give a brief layout of their pharmaceutical and medical use. Medical and pharmaceutical

industries are turning to natural materials, due to their biodegradability and resorbability.

Several types of biopolymers are known and used for medical and pharmaceutical

applications; the role played by the biopolymer varies depending on the mechanism drug

release and its form. The biopolymers were used for many years as excipients in

conventional, immediate-release forms by the oral route, playing a role in the manufacturing

process and protect the drug from degradation during storage. Excipients such as

biopolymers were used to formulate drugs and improve its effectiveness. Reducing drugs

toxicity and exhibiting prolonged release kinetics of the active ingredient. Decrease the

frequency of daily intake to regulate and support a circulating level of active principle in the

blood throughout the day and offer a better efficiency. Today, they play an increasingly

important role in the manufacture of various prolonged release systems and drug

optimization. Biopolymers are well explored and used in pharmaceutical formulation

development in recent years and also used for delivery of drugs from formulations. These

biopolymers are therefore non-toxic, inexpensive, biodegradable and freely available.

Keywords: Polymers, Biopolymers, Excipients, Pharmaceutical formulation

INTRODUCTION biopolymers such as Polyhydroxyal

The first applications of biopolymers were in kanoates (PHAs), cellulose or polyamino

medical field especially its high starting acids are also suitable for medical and

costs justified in these applications with high pharmaceutical applications [2, 3].

value. Their biocompatibility and

bio-resorbability properties associated with The usual drugs distributed in the body

their mechanical strength are very important without making enough distinctions between

to ensure the expected functions in this field the biological targets they must reach the

[1]. Several types of biopolymers are now tissue sites they meet in passing; they

used in the medical fields which are shown throughout the body. To remedy this

in Table 1. Synthetic polymers such as problem, the galenic has encouraged the

poly-lactides (PLA) and poly-glycolides biodegradable nanoparticles development.

(PGA) as well as their polylactide-co- These nanoparticles can transport drugs to

glycolide co-polymers (PLGA) was known specific sites by the concept of vectorization

and used for sutures and medical implants. of active ingredients. Instead of being free,

These biopolymers are well tolerated and the drug is encapsulated in a polymer to

have no toxicity to the body. Other form a nanoparticle.

15 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

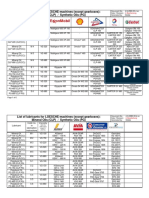

Table 1: The main applications of polymers in the medical field [2]

Biopolymers Medical applications

Polyhydroxyal Kanoates (PHA) Suture, galenic, vascular implant, medical clothing

accessories, osteosynthesis

Polyglycolides (PGA) Suture, clip, staple and adhesive

Polylactides (PLA) Orthopedic fixation, fixation, screw and pin, artificial

ligament and tendon, tissue regeneration matrix, galenic

Polyglactine (PLA-PGA). Sutures, orthopedic fixation, screws and pins, ligaments,

tendons and artificial vessels

Cellulose Drug encapsulation, cell implantation

Polyspartates Medication encapsulation, suture, artificial skin

Poly-lysine Encapsulation of drugs, biosensor, bactericides

For example, materials such as poly- classified into three categories:

cyanoacrylates which are stable with 1. Polymers derived directly from plant

respect to containing the active entity of the resources such as polysaccharides

medication, but which are biodegradable in (cellulose, starch, chitin and chitosan)

living tissues have been used, allowing the and proteins.

medication to be released at the site of 2. Polymers of bacterial origin such as

pharmacological action. This improves the poly hydroxy-butyrate (PHB).

effectiveness of the drug while reducing its 3. Polymers obtained indirectly by

toxicity [4]. By gradually releasing the drug polymerization of monomers

by degradation of the polymer at its themselves. Typically derived from

therapeutic site, these nanoparticles protect plant resources such as lactic acid,

the active ingredient before reaching the these polymers result from the

target and then make it more effective. sugars fermentation or from reactive

monomeric compounds derived from

Polymers are also involved in other vegetable oils.

pharmaceutical areas. Glucose is used as a

physiological saline solution while agar, Several types of biopolymers are used in the

glucose and fructose are used as diluents in medical field. Synthetic polymers such

the manufacturing process of tablets and as polylactides (PLA) and poly-

syrups. In addition, sometimes gelled starch glycolides (PGA) as well as polylactide-co-

is used to coat the tablets. This operation glycolide co-polymers (PLGA) are known

protects the tablet against atmospheric and and used for sutures and medical implants.

mechanical agents, protects the active These biopolymers are well tolerated and

ingredient against gastric attack and masks have no toxicity to the body [2].

unpleasant odors and flavors.

Other biopolymers such as polyhydroxyal

Natural polymers are also used as kanoates (PHA), cellulose or polyamino

excipients in pharmaceuticals. Starch, acids are also suitable for pharmaceutical

polyvinyl acetate (PVAc), vegetable gums, applications [3].

cellulose, silicone is used in emulsions as

anti-foaming agents. Their main role is to This review gives a summary of information

suppress unfavorable organoleptic about biopolymers that may be of

characteristics [5]. Biodegradable importance during their use in specific

biopolymers from renewable resources can biomedical and pharmaceutical applications.

16 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

PHARMACEUTICAL solvent leaves a continuous film of

APPLICATIONS OF BIOPOLYMERS cellulose acetophthalate [8]. Examples of

Celluloses application of cellulose in drugs: Amarel

Used as an excipient, cellulose powders, 4mg tablets, Metopimazine (Vogalene15

often referred to commercially as mg) capsules.

microcrystalline cellulose, are mainly used

in the manufacturing of tablets such as a Bacterial Cellulose

binders, lubricant adjuncts and Bacterial cellulose is used as an external

disintegrators. The mechanism of action of and internal medical treatment.

disintegration involves microcrystalline Conforming well to the surface of the skin,

cellulose causing the bursting of the tablets its ability to keep water and its

by swelling in contact with water through permeability to water vapor makes it an

their fibrous structure which facilitates interesting tool for healing wounds. Hence,

water permeability. Cellulose powder is it is used for dressing wounds including

also used as a dispersal and stabilizer in burns. It also has applications in cartilage

emulsions and suspensions as well as an tissue and bone marrow transplantation. In

absorbent. Cellulose derivatives generally addition, it can help treat ulcer burns and

can modify the solubility/gelling behavior replace internal membranes such as the

of drugs, resulting in different mechanisms outer membrane of the brain [9]. Bacterial

for controlling the release of the drug. For cellulose and gelatin were used to

example, Micro-cellulose (MC) and Nano- synthesize a hydrogel by copolymerization

cellulose (NC) in the applications of between these two agents. This hydrogel

sustained drug delivery were created [6]. composite was developed for drug-

The applications of cellulose and cellulose delivery systems [10]. Bacterial cellulose

derivatives in pharmaceutical industries showed applications in biomedical

include bio adhesive and muco-adhesive materials such as the production of contact

drugs, delivery systems, coating processes, lenses, electro-conductive composite

extended release (ER) solid dosage forms, hydrogels biosensors, wound dressings,

extended release polymeric matrices, artificial skins and biomembranes [11].

osmotic drug delivery systems, thickening Bacterial cellulose has shown to be a

and stabilizing agents, fillers in solid promising entity for preparing artificial

dosage forms, binders in granulation blood vessels as well [12].

process, disintegrating agents, and taste

masking agents [7]. Cellulose Ethers

Cellulose ethers are produced by replacing

Among the derivatives of cellulose, the hydrogen atoms of OH groups in the

cellulose acetate phthalate is a white anhydroglucose units of cellulose with

powder, granular, odorless and weakly alkyl or substituted alkyl groups [7].

acetic. Its main interest is being insoluble Examples of the most commonly used

in acid medium which means it is celluloseethers are: Methylcellulose

insoluble in the stomach, and soluble in (MeC), carboxymethyl cellulose(CMC),

the alkaline medium causing it to be Ethyl cellulose (EC), Hydroxyethyl

soluble in the intestine. It is the product cellulose(HEC), Hydroxypropyl cellulose

most commonly used to make gastro- (HPC), hydroxypropyl methyl cellulose

resistant and enteric-soluble coatings (HPMC), sodium carboxymethyl cellulose

because the tablet disintegration is only at (CMCNa). These polymers are used in the

the level of the intestine due. For coating formulation of dosage forms and

tablets, cellulose acetate phthalate is healthcare products. These compounds are

applied in thin layers as solutions in a playing important roles in further

volatile solvent. By evaporation, the developing different types of

17 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

pharmaceuticals cellulose either. The most [17]. The cyclodextrins in starch increase

studied excipient being hydroxy-propyl- the solubility and absorption of drugs

methyl-cellulose (HPMC).which is a while decreasing undesirable effects such

nonionic hydrophilic polymer prepared by as the irritations of the stomach and the

treating cellulose [13]. The release of a financial costs [18]. Wheat starch, corn

soluble active ingredient from such starch, and potato starch are very fine

systems is generally controlled by erosion white powders, tasteless and odorless.

of the gelled outer layer as well as by Insoluble in cold water, these three

diffusion of the active ingredient into the starches well in water above 80° C without

hydrated matrix. The gelled outer layer dissolving completely to create a kind of

formed in contact with the aqueous jelly. This jelly, or starch paste, is used in

medium is an essential aspect for slowing powder form as excipients to dilute the

the rate of release of the active ingredient active ingredients; in the manufacturing of

which is incorporated into HPMC tablets, as a diluent, lubricant and

matrices. Sodium carboxymethyl cellulose disintegrators; and in the composition of

is the sodium salt of a cellulose tablets. Examples of application of starch

carboxymethyl polyether. Its preparation in drugs include Vogalene15 mg capsules

comprises the cellulose conversion to and Doliprane 500mg tablets.

alkali cellulose by treatment with sodium

hydroxide followed by reaction with Amylose

sodium monochloroacetate. Mixtures of Amylose and its derivatives have several

Sodium carboxymethyl cellulose useful properties of medical materials

(CMCNa) with nonionic cellulose ethers production and in the pharmaceutical

have been prepared as systems for the industry such as non-toxic filaments and

controlled release of drugs. Incorporation fibers for medical sutures. Moreover,

of active ingredient into HPMC: CMCNa amylose sponges can be used during

matrix tablets modulated release kinetics surgical operations for its absorption

as a function of the HPMC: NaCMC ratio capacity. Amylose-iodine complexes

[14]. reported having strong antibacterial

activity against gram-positive and gram-

Starch negative microorganisms. Amylose sulfate

Starch is widely used in food, are used for treating stomach ulcers [19].

pharmaceutical and biomedical Carboxymethyl amylose increases certain

antibiotics (basic in nature) ability to enter

applications due to its biocompatibility,

the lymphatic system, making them

biodegradability, non-toxicity and

suitable for parenteral applications [20].

abundant sources. In pharmaceutical

products, starches are used as carriers for Amylose-resistant starch is used to

the controlled release of drugs and other decrease the fluid loss and diminution

bioactive agents. The chemically modified diarrhea duration of adolescents and adults

starches are used to carry biologically with cholera [21]. In addition, amylose is

active compounds. Certainstarch sources useful as a binding agent in the direct

can be utilized for distinctive applications compression of powders of monolithic

such as bone fixation and replacement due tablets preparation [22]. For example,

to being readily metabolized in the human cross linked amylose has already been

body [15, 16]. used as a binding agent [23, 24]. More

recently, amylose has been used for the

Starch can serve as an excipient in the delivery of bioactive agents to treat several

drug composition due to its low energy diseases affecting the colon as well as for

content and its non-toxicity. It is also used the delivery of proteins and peptides for

in capsule capping and in obtaining tablets systemic absorption at the same site [25].

18 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

Amylopectin suspension while alginates propylene

Amylopectin used as a co-excipient has an glycol is used to stabilize acid suspensions.

extremely low premature permeability in Its emulsifying properties also make it

pellets even to a highly water-soluble participate in the manufacturing of

agent in the acid medium of simulated cosmetic products such as cream, soap,

gastric juice. Amylopectin is used as an and shampoo. It helps to thicken skin

undercoat material in enteric coated pellets creams and plays a key role in heart burn

and enhances the acid resistance properties prevention and in dental additives.

of simulated gastric juice [26, 27]. Alginates also enter the formula of kinds

of toothpaste [28, 29]. Examples of

Alginate application of alginate in drugs:

Alginates are sold as excipients for Arthrodont 1%, Gingival paste,

pharmaceutical specialties that are tested Homeodent Toothpaste.

and certified. Alginate beads can be used

in medicine to encapsulate drugs or fragile Alginate as Excipients

biological substances (enzymes, Alginic Acid

microorganisms, animal or human cells). Alginic acid is insoluble in water, but it

The materials encapsulated within hydrates up to a hundred times his initial

alginate, activated carbon as adsorbent volume. This property makes it a vital

capable of absorbing heavy metals and disintegrating agent in tablets. Table 2

toxic organic compounds in aqueous shows a variety of medications that alginic

solutions. Sodium alginate is used in drugs acid is utilized in.

to thicken or keep up particles in

Table 2: Alginic acid application forms

Forms Examples

Tablets HALDOL 1 mg tablets

ACTICARBINE tablets

ADREXAN 40 mg tablets

FASIGYNE 500 mg tablets

AVLOCARDYL 40 mg tablets

LOGRYX 100 mg tablets

APAROXAL 100 mg tablets

PROPANOLOL RATIO 40 mg tablets

DIPIPERON 40 mg tablets

SPASMAVERINE 40 mg tablets

Cream HALIVITE 5% cream

Sodium Alginate as pasty forms, as extended-release tablets

Sodium alginate is the sodium salt of and as a base for cosmetic and medicated

alginic acid. Sodium alginate is a purified gels [28, 29]. Table three displays a few of

carbohydrate extracted from brown the applications forms that sodium alginate

seaweed algae by careful treatment with plays a role in.

sodium hydroxide. Sodium alginate issued

Table 3: Sodium alginate application forms

Forms Examples

Creams CALMIPHASE cream

HALIVITE 5% cream

Tablets ISOPTINE 240 mg tablets

VERAPAMIL GNR 240 mg tablets

VERAPAMIL MERCK LP 240 and 120 tablets

Gel SODIUM ALGINATE 5.0 g

GLYCERINE 5.0 g

SODIUM BENZOATE 1.0 g

PURIFIED WATER 89.0 g

19 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

Other Alginates The hydrocolloid particles of the outer part

In this section, other types of alginates of the tablet hydrate and form a barrier

used in pharmacy are cited. Their use is which increases the size of the tablet while

less widespread than alginic acid and maintaining its shape and avoiding its

sodium alginate. disintegration. Subsequently, this hydrated

- Calcium and layer dissolves slowly, releasing

sodium alginate: Melleril 100 mg the pharmacologically active substances.

tablets. Tablets buoyancy results from a two

- Sodium triethanolamine alginate: Biafi phenomena combination: the increase in

ne emulsion for a cutaneous volume during the contact with the middle

application. of the stomach and the pores volume

- Calcium maintained within the non-hydrated tablet,

ammonium alginate: Lariam 250 mg partly dependent on the compressive force

tablets Qadri breakable. [30, 31].

- Magnesium alginate: Topaal oral

suspension. Floating Capsules with Low Density

- Propylene The release of the capsule contents

glycol alginate: Questran 4g oral controlled by carbon dioxide bubbles form

powder. in a hydrogel. The hydrocolloid used is

sodium alginate which gels in the stomach

Use of Alginates in Dry Forms acid medium with calcium presence. After

The alginate salts can be used alone or in the gelatin shell dissolution, there is

combination with other polymers to hydration and gelation of the alginate, as

control the release of active ingredients well as crosslinking with calcium. Sodium

into the body from hydrophilic matrix bicarbonate, in contact with the gastric

tablets. The pH influences on juice, creates an effervescent release of

the alginate salts make it possible to delay CO2, the bubbles of which remain trapped

the release of the active substances. In in the gelled network, which results in a

this application of alginates with the other floating capsule [32, 33].

polymers, the alginates are used at

concentrations less than 20% and between Disintegrating Agent

20% - 50% when used alone [28]. Alginic acid is effective in direct

compression as in wet

Extended-release Tablets granulation. Alginic acid is effective at

The physicochemical properties concentrations of 2% and above; 10%

of alginates make them the excipients of concentrations used in the formulation of

choice in tablets to keep a sustained effervescent tablets. Alginates allow the

release of active ingredients. The most suspension dissolution of the active

obvious for this use is their ability to ingredient thus improving bio-availability

form hydrocolloids in an aqueous medium for the body. Alginic acid is the

at acidic pH. In the stomach, this swollen disintegrating agent added during the

membrane then serves as a diffusion granulation phase [34].

barrier reducing the active substance

escaping migration from the tablet [29]. Binding Agent

The alginic acid is used as a binding agent

Alginic Acid Use in Floating Systems in tablets because it is capable of inducing

Floating Tablets with Low Density the powder particles aggregation during

Alginates are hydrocolloids that can be the granulation phase. This facilitates the

used in floating systems preparation: The cohesion of particles together. These

tablet consists of the homogeneous additives diminish the compressive force

mixture of one or more active ingredients applied to a powder. In addition, reducing

with hydrophilic polymers in contact with the compressive force reduces the

the gastric juice. disintegration time. The alginic acid mixed

20 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

with water to get the greatest swelling and used as a binder in tablets formulation as

is then incorporated into the other well as suspending agents, emulsifiers, and

components to bind them; in the case of stabilizers in toothpaste and ointments,

unstable active substances in an aqueous sustained release agent [35-36].

medium, the dry alginic acid is

incorporated [34]. Guar Gum

Guar Gum is a seed gum produced from

Use of Alginates as Thickening and the powdered endosperm of the seeds

Stabilizing Excipients of Cyamopsistetragonolobus Linn (Fam.

Alginates can be used to increase the Leguminoseae). Guar gum is used in

viscosity of suspensions to limit the pharmacy as a binding and disintegrating

sedimentation phenomena, used in agent in tablets, a viscosifying agent, and

ophthalmic solutions to increase contact as an adjuvant for the release of controlled

time or used in topical creams to thicken drugs. Other hydrophilic polymers, such

them. Soluble alginates can be used for as hydroxypropyl methylcellulose HPMC,

preparations intended for the external use. are often added to the Guar gum to

They have the advantage of offering a lot improve the release control properties [37].

of consistency and being fully absorbed by

the epidermis. Chitosan and Chitin

Alginates propylene glycols are suitable Chitosan (Soluble Chitin) is a

stabilizers and emulsifiers for systems with polysaccharide extracted from the shells of

low pH concentrations of 0.25%to 2% crustaceans, such as shrimp, crab and other

which make it possible to get stable sea crustaceans, including Pandalus

emulsions and borealis and cell walls of fungi. Chitin and

suspensions. Alginate solutions have especially chitosan are found to have

excellent lubricity, which explains their important applications in different fields.

use in the formulation of pharmaceutical Table 4 displays these roles that these two

gels. Alginates also enter the formula of substances partake in. All applications of

different toothpaste [34]. chitosan are intimately linked to its poly-

cationic character, which is unique among

Xanthan Gum natural polymers. Actually, there are high-

Xanthangum is produced by a pure culture purity, reproducible, hypoallergenic, non-

fermentation of carbohydrate with animal chitosan bio-polymers from

the Xanthomonas Campestris. Xanthan gu mushrooms, These are used in the medical

m is very thixotropic. The release of field in such areas as cellular engineering,

hydrophilic xanthan matrices is also wound healing, culture support, gene

influenced by the strength of the medium. therapy, oncology, and ophthalmology

At low ionic strengths xanthan gums are [38].

Table 4: Application of Chitin and Chitosan in Medical and Pharmaceutical Fields.

Fields Applications

Pharmaceutical Absorbable material with release control of active ingredients

Formation of microcapsule gels with anionic polymers

Excipients

Drug delivery systems

Vaccination adjuvant.

Encapsulation of drug

Release of drugs

Medical Treatment of epidermal lesions

Artificial blood vessels

Bandage

Angiogenic therapies

Anti-tumor agent

Anti-infectious, anti-bacterial, anti-fungal agent

Anticoagulant

Bioresorbable surgical sutures

21 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

Biomedical and Pharmaceutical such as vaccines, antigens or genes. These

Domains of Chitosan and Chitin hydrogels are used in oncology, gene

The therapeutic use of chitosan has been therapy, tissue engineering or cell biology.

discovered rather recently. Chitosan is During the recent years, chitosan and its

used as a "vehicle" for drugs and other derivatives were well appreciated for its

therapeutic substances and as regenerative excellent performance in pharmaceutical

medicine in reconstructive surgery. The applications an antiparasitic agent,

biological properties like biocompatibility antimicrobial agent, biomaterial, wound

and bioactivity of chitin and chitosan healing, biomedical adhesive, tissue

enable many pharmaceutical, biomedical engineering agent, antitumoral agent, and

and clinical applications. Its antioxidant agent [38-40].

biocompatibility results in

hemcompatibility and low antigenicity. Summary of the Applications of

The hemocompatibility of chitosan is Derivatives of Chitosan and Chitin

manifested by its anti-thrombogenic crater. Material for healing wounds; skin

As a result, it finds applications as a regenerator; absorbable fibrous

coating of objects in contact with the blood sutures.

such as vascular prostheses or heart valves.

Cholesterol reducer in the blood

Chitosan accelerates wound healing, or Water absorbent

Bio-Stimulating Activity, because Fiber preparations and membranes

chitosan, like chitin, promotes a reduction An ingredient in hair products

in unwanted collagen synthesis. These Additives for paper and the coating

healing properties are also used to make layer

sutures and surgical devices used as Support in organic syntheses under

dressings. During the operations, artificial alkaline conditions

skins are made from chitosan for the Flocculent for wastewater treatment

treatment of severe burns. It seems that

Coagulant for residual waters

this skin with analgesic properties allow

healing of burns and a much faster and less treatment.

painful reconstruction of the epidermis. Chemical synthesis reagent

Chitosan is also used to improve certain Complexing of toxic metals

drugs administered by ocular or nasal Agents for gelation and immobilization

route absorption, in periodontics like of enzymes and microbes

mouthwash, plastic surgery and for the Chromatography gel; membranes for

renal insufficiency treatment as adjunct dialysis and ultrafiltration; artificial

treatment. Glucosamine is known for its organs

pain-killing, anti-inflammatory and to Organic synthesis reagents

prevent joints deterioration, however; the Inhibitor of the growth of bacteria,

chitosan derivatives, which are precursors

fungi, and pathogens

of glucosamine, offer a gradual release that

reduces the dose and thereby increase the Emulsifying agent and ingredients of

comfort of the patient. beauty products; liquid crystal

Materials for sequestering toxins and

These polysaccharides present interesting nucleic acids

potentialities in the vectorization of drugs Emulsifier

and the ability to encapsulate the active Anticoagulant.

ingredients in bio-polymers to promote

agradual and controlled release. In many Poly-lactic Acid (PLA)

applications, chitosan is used in the form Polylactic acid (PLA) is a biodegradable

of filled hydrogels to immobilize drugs polymer created from renewable resources

like enzymes or therapeutic substances such as corn starch, tapioca or sugar cane.

22 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

PLA has both ecological advantages and a CONFLICTS OF INTEREST

large number of applications in the The author has no conflict of interest to

medical and pharmaceutical industries. declare and this review article was not

funded.

PLA is used as an artificial skin in tissue

engineering, has applications in bio- ACKNOWLODGEMENT

absorbable sutures, orthopedic implants Journal of Advances in Bio- pharmaceutics

and controlled release systems of drugs. and Pharmacovigilance

Additional applications of polylactic acid

and its composites in the medical and List of Abbreviations Used

pharmaceutical field areas drug carriers, Poly-lactides (PLA), poly-glycolides

antimicrobial agents, orthopedic agents, (PGA), Polylactide-co-glycolide co-

tissue engineering agents, antitumor polymers (PLGA), Polyhydroxyalkanoates

agents, urethral stents, biomaterials, and (PHAs), Polyglactine (PLA-PGA),

other miscellaneous applications [41]. Polyvinyl acetate (PVAc), Poly hydroxy-

butyrate (PHB), Micro-cellulose (MC),

CONCLUSION Nano-cellulose (NC), Extended release

Biopolymers have attractive properties (ER),Methylcellulose (MeC),

particularly biodegradability, Carboxymethyl cellulose (CMC), Ethyl

biocompatibility, selective permeability cellulose (EC), Hydroxyethyl cellulose

and modifiable physical-mechanical (HEC), Hydroxypropyl cellulose (HPC),

properties. These properties find targeted Hydroxypropyl methyl cellulose (HPMC),

applications in a variety of fields, Sodium carboxymethyl cellulose

particularly in the field of pharmacy and (CMCNa).

medicine. The use of natural biopolymers

makes it possible to manufacture SUMMARY

sustained-release forms that should avoid Medical and pharmaceutical industries are

post-consumer peaks (diminish side and turning to natural sources for the

undesirable effects) and spread the enhancement of new medical and

effectiveness of this molecule over time pharmaceutical specimens because they

are inexpensive, biodegradable and

(decrease the number of daily doses).

bioabsorbable, biocompatible, abundant

Different drug carrier systems were and freely available materials. The medical

developed from biopolymers to improve and pharmaceutical field’s development

the efficacy of drug delivery system, and it involve various active pharmaceutical

can be concluded that the incorporation of ingredients and biopolymers from different

the biopolymer excipients into a sustained- sources. These biopolymers influence the

release formulation provides more formulation development and drug

interesting results and provides better delivery process in various ways. The

efficacy. The advantages of polymers like diverse compositions, low toxicity,

the biopolymers over synthetically biodegradability, resorbability, stability,

renewable nature and a wide variety of

produced polymers are that they are non-

additional benefits have fueled the interest

toxic, inexpensive, biodegradable and in biopolymers. These agents are

freely available. They can occupy an particularly attractive to high-value sectors

important place in pharmaceutical such as the pharmaceutical and medical

technology, especially in extended-release fields. The current review is an endeavor

medication applications which offer to describe the utility of a variety

excellent prospects in drug design. of biopolymers in medical and

pharmaceutical applications.

23 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

REFERENCES applications: A Review. American

1. Martin D.P. & Williams S.F. Medical Journal of Polymer Science and

applications of poly-4- Technology. 2017; 3(5): pp. 89-96.

hydroxybutyrate: a strong flexible 12. Lee S.E. & Park Y.S. The role of

Absorbable biomaterial. Biochemical bacterial cellulose in artificial blood

engineering journal. 2003; 16 (2): pp. vessels. Molecular and Cellular

97-105. Toxicology. 2017; 13(3): pp. 257-261.

2. Rabetafika H.N., Paquot M. & Dubois 13. Wade A. & Weller P.J. Handbook of

P. Les polymères issus du Végétal: pharmaceutical excipients.

matériaux à propriétés Spécifiques Washington: American

pour des applications ciblées en Pharmaceutical Association. 1994.

industrie Plastique. Biotechnologie, 14. Park H., Park K. & Shalaby W.S.

Agronomie, société et environnement. Biodegradable hydrogels for drug

2006; 10(3) : pp. 185-196. delivery. CRC Press. 2011.

3. Pillai O. & Ramesh P. Polymers in 15. Kaur L., Singh J. & Liu Q. Starch- a

drug delivery. Current opinion in potential biomaterial for biomedical

chemical Biology. 2001; 5: pp. 447- applications. Nanomaterials and Nano

451. systems for biomedical applications.

4. Sailhan V., Giral L., Montginoul C. & Springer, Dordrecht. 2007; pp. 83-98.

Schue F. Les α-cyanoacrylates: 16. Ochubiojo E.M. & Rodrigues A.

propriétés et Utilisations. L'Actualité Starch: from food to medicine.

chimique.1995; 6: pp. 17-30. INTECH Open access Publishe. 2012.

5. Jacques N. Les polymères dans 17. Hartesi B., SriwidodoA.M. &

l’industrie. Université de Douala. Chaerunisaa A.Y. Starch as

2005. Pharmaceutical Excipient. Int J Pharm.

6. Sun B., Zhang M., Shen J., He Z., SciRev Res. 2016; 41(2): pp. 59-64.

Fatehi P. & Ni Y. Applications of 18. Tiwari G. Tiwari R. & Awani K.R.

cellulose-based Materials in sustained Cyclodextrins in delivery systems:

drug delivery systems. Current Applications. Journal of Pharmacy

medicinal chemistry. 2017. and Bioallied Sciences. 2010; 2(2): pp.

7. Shokri J. & Adibkia K. Application of 72.

cellulose and cellulose derivatives in 19. Ravin L.J., Baldinus J.G. & Mazur

pharmaceutical industries. Cellulose- M.L. Effect of sulfate content of

medical. Pharmaceutical and several anionic polymers on in Vitro

Electronic Applications, Intech. 2013. activity of pepsin. Journal of

8. Chaumeil J.C., & Piton Y. Enteric- Pharmaceutical Sciences. 1962; 51(9):

resistent coatings with cellulose pp. 857-860.

acetophtalate. 2. Relationship between 20. Franz, G. Polysaccharides in pharmacy

film thickness and coating resistance in . In Pharmacy/Thermomechanics/Elast

vivo. In An nales pharmaceutiques omers/TelechelicsSpringer, Berlin,

française. 1973; 31(11): pp. 691. Heidelberg. 1986: pp. 1-30.

9. BéatriceV. & Dylan P. Production de 21. Ramakrishna B.S., Venkataraman S.,

cellulose bactérienne pure. 2013. Srinivasan P., Dash P., Young G.P. &

10. Reesuppharat W., Rojanapanthu P., Binder H.J. Amylase-resistant starch

Siangsanoh C., Manuspiya H., plus oral rehydration solution for

Ummartyotin S. Synthesis and cholera. New England Journal of

characterization of bacterial cellulose Medicine. 2000; 342(5): pp. 308-313.

and gelatin-based hydrogel composites 22. Rutenberg M.W. & Wadym J.

for drug-delivery systems. Washington, DC: U.S. Patent and

Biotechnology Reports. 2017; 15: pp. Trademark Office. 1963; U.S. Patent

84-91. No. 3,081,181.

11. Zohra M. Structure, Properties and 23. Dumoulin Y., Alex S., Szabo P.,

Medical Advances for Biocellulose Cartilier L. & Mateescu M.A. Cross-

24 Page 15-25 © MAT Journals 2019. All Rights Reserved

Journal of Advances in Bio- pharmaceutics and Pharmacovigilance

Volume 1 Issue 1

linked amylose as matrix for Pharmaceutics. 2002; 239(1-2): pp.

drugcontrolled release. X-ray and FT- 81-91.

IR structural analysis. Carbohydrate 33. Murata Y., Sasaki N., Miyamoto E. &

Polymers. 1998; 37(4): pp. 361-370. Kawashima S. Use of floating alginate

24. Cartilier L., Mateescu M.A., DuMoulin gel beads for stomach specific drug

Y. & Lenaerts V. U.S. Patent No. delivery. European Journal of

5,616,343, 1997; Washington, DC: Pharmaceutics and

U.S. Patent and Trademark Office. Biopharmaceutics. 2000; 50(2): pp.

25. Chourasia M.K. & Jain S.K. 221-226.

Polysaccharides for colon targeted 34. Allen L. & Ansel H.C. Ansel's

drug delivery. Drug Delivery. 2004; pharmaceutical dosage forms and drug

11(2): pp. 129-148. delivery systems. Lippincott Williams

26. Jivraj M., Martini L.G. & Thomson and Wilkins. 2013.

C.M. An overview of the different 35. Dumitriu S. Polysaccharides: structural

excipients useful for the direct diversity and functional versatility.

Compression of CRC Press, Ed. 2004.

tablets. Pharmaceutical science and 36. Goswami S. & Naik S. Natural gums

technology today. 2000; 3(2): pp. 58- and its pharmaceutical

63. application. Journal of Scientific and

27. Patell MK. U.S. Patent No. Innovative Research. 2014; 3(1): pp.

4,775,536,1988; Washington, DC: 112-121.

U.S. Patent and Trademark Office. 37. Shah K.P., Rashmi S. & Ulhas G.K.

28. Goujon I. Les Alginates: excipients International Journal of Universal

d'origine marine utilisés dans Pharmacy and Bio Sciences. 43(3): pp.

l'industrie pharmaceutique Application 2014.

à la synthèse d'un gel chimique, 2004. 38. Crini G. Chitine et chitosane: du

29. Tønnesen H.H. Karlsen Alginate in biopolymère à l'application. Presses

drug delivery systems. Drug Univ. Franche-Comté. 2009.

development and industrial Pharmacy. 39. Cheung R., Ng T., Wong J. & Chan W.

2002; 28(6): pp. 621-630. Chitosan: an update on potential

30. Buri J.P., Puisieux F., Doelker E. & biomedical and pharmaceutical

Benoit J.P. Formes pharmaceutiques applications. Marine drugs. 2015;

nouvelles: aspects 13(8): pp. 5156-5186.

Technologiques. Biopharmaceutiques, 40. Delattre C. Opinion about Advances of

et Médicaux, Lavoisier Tec and Doc, Chitosan in Pharmaceutical Field:

Paris, 1985. From Past to Now. Mod Appl Pharm

31. Murata Y., Sasaki N., Miyamoto E. & Pharmacol, 2017; 1(1).

Kawashima S. Use of floating alginate 41. Alsaheb RA A, Aladdin A., Othman

gel be for stomach-specific drug N.Z., Malek R.A., Leng O.M., Aziz R.

delivery. European Journal of & El Enshasy H.A. Recent applications

Pharmaceutics and Biopharmaceutics. of polylactic acid in pharmaceutical

2000; 50(2): pp. 221-226. and medical industries. Journal of

32. Choi B.Y., Park H.J., Hwang S.J. & Chemical and Pharmaceutical

Park J.B. Preparation of alginate beads Research, 2015; 7(12): pp. 51-63.

for floating drug delivery system:

effects of CO2 gas-forming

agents. International Journal of

25 Page 15-25 © MAT Journals 2019. All Rights Reserved

You might also like

- Handbook of Polymers for Pharmaceutical Technologies, Structure and ChemistryFrom EverandHandbook of Polymers for Pharmaceutical Technologies, Structure and ChemistryNo ratings yet

- Polymers in Pharmaceuticals: Advantages of Novel Drug DeliveryDocument15 pagesPolymers in Pharmaceuticals: Advantages of Novel Drug Deliveryosama saeedNo ratings yet

- JPNR - S07 - 638Document12 pagesJPNR - S07 - 638Sriram NagarajanNo ratings yet

- Natural Polymers: A Recent Review: World Journal of Pharmacy and Pharmaceutical SciencesDocument23 pagesNatural Polymers: A Recent Review: World Journal of Pharmacy and Pharmaceutical Sciencespragna novaNo ratings yet

- Pharma Tec Term Paper BilalDocument13 pagesPharma Tec Term Paper BilalRizwan KhanNo ratings yet

- Polimero BiodegradableDocument16 pagesPolimero BiodegradableErika AriasNo ratings yet

- Polymers in Drug Delivery Technology, Types of Polymers and ApplicationsDocument4 pagesPolymers in Drug Delivery Technology, Types of Polymers and ApplicationsSharanya ParamshettiNo ratings yet

- Temp 01Document77 pagesTemp 01Zeyad A AbdullahNo ratings yet

- Polymers_in_Drug_Delivery_Technology_Types_of_PolyDocument5 pagesPolymers_in_Drug_Delivery_Technology_Types_of_Polyvijayambhore1906No ratings yet

- Overcoming The Challenges in Administering Biopharmaceuticals - Formulation and Delivery Strategies PDFDocument18 pagesOvercoming The Challenges in Administering Biopharmaceuticals - Formulation and Delivery Strategies PDFvivitri.dewiNo ratings yet

- Role of Polymers in Sustained Released Microbeads Formulation: A ReviewDocument9 pagesRole of Polymers in Sustained Released Microbeads Formulation: A ReviewVinayNo ratings yet

- 7NaturalpolymersReviewDocument24 pages7NaturalpolymersReviewIonela PintilieNo ratings yet

- Hrutik Credit 3 FinalDocument2 pagesHrutik Credit 3 FinalHrutikNo ratings yet

- Progress in Biopharmaceutical DevelopmentDocument18 pagesProgress in Biopharmaceutical DevelopmentAlexandra BulboacăNo ratings yet

- Prodrugs: A Challenge For The Drug Development: Jolanta B. Zawilska, Jakub Wojcieszak, Agnieszka B. OlejniczakDocument14 pagesProdrugs: A Challenge For The Drug Development: Jolanta B. Zawilska, Jakub Wojcieszak, Agnieszka B. OlejniczakAnand MurugananthamNo ratings yet

- InTech-Pharmaceutically Used PlasticizersDocument25 pagesInTech-Pharmaceutically Used PlasticizersRohan JindalNo ratings yet

- Available Through Online: ISSN: 0975-766XDocument13 pagesAvailable Through Online: ISSN: 0975-766XDrDeepak PrasharNo ratings yet

- Phytosomes: Potential Carriers For Herbal Drugs: January 2013Document14 pagesPhytosomes: Potential Carriers For Herbal Drugs: January 2013Siva PrasadNo ratings yet

- Phytosomes An Approach To Increase The Bioavailability of Plant ExtractsDocument4 pagesPhytosomes An Approach To Increase The Bioavailability of Plant ExtractsFábio Teixeira da SilvaNo ratings yet

- InTech-Pharmaceutically Used PlasticizersDocument24 pagesInTech-Pharmaceutically Used PlasticizersMahmut OdabaşıNo ratings yet

- Capsules Types Manufacturing Formulation Quality CDocument13 pagesCapsules Types Manufacturing Formulation Quality CPriyanshu SharmaNo ratings yet

- Biomedical Applications of Polymers - An: Mini ReviewDocument2 pagesBiomedical Applications of Polymers - An: Mini Reviewاسلام غازي ذياب احمدNo ratings yet

- Molecules: Plant-Based Gums and Mucilages Applications in Pharmacology and Nanomedicine: A ReviewDocument23 pagesMolecules: Plant-Based Gums and Mucilages Applications in Pharmacology and Nanomedicine: A Review10PAMP2Dionisio, Ira Joy D.No ratings yet

- Pharmaceutics 12 00393 PDFDocument17 pagesPharmaceutics 12 00393 PDFsalemNo ratings yet

- Tablet BindersDocument9 pagesTablet BindersIJRASETPublicationsNo ratings yet

- Bio Degradation ModesDocument8 pagesBio Degradation ModesAnudeep Krishna B100% (1)

- Prodrug Delivery: A Concise OverviewDocument6 pagesProdrug Delivery: A Concise OverviewanantachoudhuryNo ratings yet

- Prodrugs SagarDocument30 pagesProdrugs SagarMuskan SharmaNo ratings yet

- Revised Chapiter - The Use of Plants As Phytobiotics A New Challenge - Serge Ndomou and Herve MubeDocument15 pagesRevised Chapiter - The Use of Plants As Phytobiotics A New Challenge - Serge Ndomou and Herve Mubeserge ndomouNo ratings yet

- Applications of Polymers For CDDSDocument53 pagesApplications of Polymers For CDDSRamkanth S100% (1)

- dff expoDocument37 pagesdff expoJoelSandovalNo ratings yet

- Overview of prodrugsDocument11 pagesOverview of prodrugsNIKITANo ratings yet

- MCB 419 Updated NoteDocument37 pagesMCB 419 Updated NotetripsNo ratings yet

- Bakuchiol: A Retinol Like Structure in The Field of CosmeticsDocument6 pagesBakuchiol: A Retinol Like Structure in The Field of CosmeticsEdersson NaitzNo ratings yet

- Institution in Use Physiocochemical and Microbiological StabilityDocument12 pagesInstitution in Use Physiocochemical and Microbiological Stabilitydeepanmb007No ratings yet

- Quality and Functionality of Excipients-Art (Alumnos-S) PDFDocument14 pagesQuality and Functionality of Excipients-Art (Alumnos-S) PDFLaura PerezNo ratings yet

- 2039 PDF PDFDocument11 pages2039 PDF PDFnicko.arya.dharmaNo ratings yet

- Pharmaco G NosyDocument8 pagesPharmaco G NosySaadNo ratings yet

- Beta-Sitosterol PresentationDocument20 pagesBeta-Sitosterol PresentationAishleen SinghNo ratings yet

- Biomedicine & Pharmacotherapy: Majid Saeedi, Masoumeh Eslamifar, Khadijeh Khezri TDocument12 pagesBiomedicine & Pharmacotherapy: Majid Saeedi, Masoumeh Eslamifar, Khadijeh Khezri TDavi MouraNo ratings yet

- Parenteral Preparations, Challenges in Formulations Pharmaceutical Outsourcing - The Journal of Pharmaceutical & BiopharmaceutDocument1 pageParenteral Preparations, Challenges in Formulations Pharmaceutical Outsourcing - The Journal of Pharmaceutical & BiopharmaceutCRYSTAL A. ARIETANo ratings yet

- Polymers in Pharmaceutical ProductsDocument14 pagesPolymers in Pharmaceutical Productsstudent910112No ratings yet

- Synthesis and Evaluation of Some Amino Acid Conjugates of NSAIDSDocument9 pagesSynthesis and Evaluation of Some Amino Acid Conjugates of NSAIDSSACHIN BHASKAR NARKHEDENo ratings yet

- Environmental Friendly Pharmaceutical Excipients Towards Green ManufacturingDocument12 pagesEnvironmental Friendly Pharmaceutical Excipients Towards Green Manufacturingnikhilsachan100% (1)

- Natural ProductDocument22 pagesNatural ProductrrrrrrrrrrrrrrrrrrrrrrNo ratings yet

- 7 Vol. 6 Issue 11 November 2015 IJPSR RE 1694Document11 pages7 Vol. 6 Issue 11 November 2015 IJPSR RE 1694Jayshree PatilNo ratings yet

- Prodrugs 1140-3157-1-PB PDFDocument5 pagesProdrugs 1140-3157-1-PB PDFRishi Ram ParajuliNo ratings yet

- Chitosan ReviewDocument20 pagesChitosan ReviewkarthikNo ratings yet

- Emulsions in Health Care Applications-An Overview: Journal of Dispersion Science and Technology May 2002Document24 pagesEmulsions in Health Care Applications-An Overview: Journal of Dispersion Science and Technology May 2002Quốc ThắngNo ratings yet

- Admin,+Journal+Manager,+12 AJPCR 40 31720Document3 pagesAdmin,+Journal+Manager,+12 AJPCR 40 31720Komal RaneNo ratings yet

- Prodrugs - Design and Clinical ApplicationsDocument16 pagesProdrugs - Design and Clinical ApplicationsBlackbeatle63No ratings yet

- Phytosomes An Approach To Increase The Bioavailability of Plant ExtractsDocument4 pagesPhytosomes An Approach To Increase The Bioavailability of Plant ExtractsHoàng Sơn Nguyễn LêNo ratings yet

- Polymer Applications in Drug Delivery SystemsDocument32 pagesPolymer Applications in Drug Delivery SystemsMaoth AhmedNo ratings yet

- SinghDavinderetal Plant BasedPolysaccharidesandtheirHealthFunctionsApril2021Document23 pagesSinghDavinderetal Plant BasedPolysaccharidesandtheirHealthFunctionsApril2021Olabintan OlabodeNo ratings yet

- Regulatory Aspects and Quality Controls of Polymer-Based Parenteral Long-Acting Drug Products How Challenging Is Approving CopiesDocument24 pagesRegulatory Aspects and Quality Controls of Polymer-Based Parenteral Long-Acting Drug Products How Challenging Is Approving CopiesChaojun JiangNo ratings yet

- Introduction To Bioprocessing NewDocument58 pagesIntroduction To Bioprocessing NewAmit SinghNo ratings yet

- Biopolymers Market Trends and ApplicationsDocument17 pagesBiopolymers Market Trends and ApplicationsManish SoniNo ratings yet

- Aulton - PharmaceuticsThe Science of Dosage Form Design 2 EdDocument682 pagesAulton - PharmaceuticsThe Science of Dosage Form Design 2 Edjumarni anny80% (5)

- ABSTRACTDocument1 pageABSTRACTsamiya akterNo ratings yet

- The Potential of Microextraction Techniques For The Analysis of Bioactive Compounds in FoodDocument20 pagesThe Potential of Microextraction Techniques For The Analysis of Bioactive Compounds in FoodKHAERUL FADLYNo ratings yet

- Thermic Behaviour of Two Copolymers Used As Viscosity Improvers For SAE 10W Mineral OilDocument4 pagesThermic Behaviour of Two Copolymers Used As Viscosity Improvers For SAE 10W Mineral OilIoana StanciuNo ratings yet

- Scientific Bulletin. Series B. Chemistry and Materials ScienceDocument6 pagesScientific Bulletin. Series B. Chemistry and Materials ScienceIoana StanciuNo ratings yet

- Paper PDFDocument4 pagesPaper PDFIoana StanciuNo ratings yet

- Rheological Properties of Rapeseed Oil and Hydraulic Oil: - Research NoteDocument6 pagesRheological Properties of Rapeseed Oil and Hydraulic Oil: - Research NoteIoana StanciuNo ratings yet

- Schematic Pre Lab 2Document8 pagesSchematic Pre Lab 2patricia capolaNo ratings yet

- Learn Mole ConceptsDocument4 pagesLearn Mole Conceptsshaikha_77No ratings yet

- Loesche List of Lubricants 03 2015 - enDocument6 pagesLoesche List of Lubricants 03 2015 - enphucdc095041No ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Paper 2CDocument11 pagesPaper 2Cakamaru KibaNo ratings yet

- Liquid Nickel Sulfate SpecificationsDocument1 pageLiquid Nickel Sulfate SpecificationsAntonio SponholtzNo ratings yet

- Aerosol 120730040104 Phpapp01Document77 pagesAerosol 120730040104 Phpapp01Rassel KabirNo ratings yet

- Kalingastone Quartz Care and MaintenanceDocument4 pagesKalingastone Quartz Care and MaintenanceSabyasachi Bangal100% (1)

- Biochem ExperiementsDocument2 pagesBiochem ExperiementsAlyssa PachecoNo ratings yet

- General Chemistry Guide: Measurements and AtomsDocument94 pagesGeneral Chemistry Guide: Measurements and AtomsCody PalmerNo ratings yet

- UOP 326 Diene Value by Maleic Anhydre Addition ReactionDocument4 pagesUOP 326 Diene Value by Maleic Anhydre Addition ReactionMauricio Huerta JaraNo ratings yet

- Ashu ThesisDocument57 pagesAshu Thesisbabu_com123No ratings yet

- Li Co MN O2Document4 pagesLi Co MN O2Rodolfo Jesus Andrade BenítezNo ratings yet

- Polymerisation Practice TEPEDocument30 pagesPolymerisation Practice TEPESUNILNo ratings yet

- Ken GT-1 High Performance MO (Ti) TDSW 778549Document2 pagesKen GT-1 High Performance MO (Ti) TDSW 778549Elwin arifinNo ratings yet

- Synthesis and Characterization of Kraft Lignin-Graft-Polylactide CopolymersDocument12 pagesSynthesis and Characterization of Kraft Lignin-Graft-Polylactide CopolymersRitaSantosNo ratings yet

- Cfy-21-25 - PT-6 - X Lot-Science (Cbse Type)Document5 pagesCfy-21-25 - PT-6 - X Lot-Science (Cbse Type)Himansu MookherjeeNo ratings yet

- AssayDocument8 pagesAssayzubair1951No ratings yet

- LTI Boiler Application 3pagesDocument3 pagesLTI Boiler Application 3pagesVijay - Spantech EngineersNo ratings yet

- Jurnal Pendukung 2Document11 pagesJurnal Pendukung 2Rehan AshariNo ratings yet

- SP3 SOFT NO R Commercial UnitsDocument9 pagesSP3 SOFT NO R Commercial UnitsCristian ManzoNo ratings yet

- Investigations On Tribological Behavior of Natural Fiber Resin Composite For Brake PadDocument26 pagesInvestigations On Tribological Behavior of Natural Fiber Resin Composite For Brake PadKathireswaran PNo ratings yet

- Preparing and Standardizing Molar SolutionsDocument5 pagesPreparing and Standardizing Molar SolutionsFatima tahirNo ratings yet

- Chemicals Used For Cleaning & Manual Cleaning Processes - FINAL 2Document45 pagesChemicals Used For Cleaning & Manual Cleaning Processes - FINAL 2jerimiah_manzonNo ratings yet

- Pharmaceutical Suspension Definition and UsesDocument38 pagesPharmaceutical Suspension Definition and UsesAhmed KafajiNo ratings yet

- 1) Provide The Structure of Anisole. Answer:: Chapter 19 Reactions of Benzene and Substituted BenzenesDocument69 pages1) Provide The Structure of Anisole. Answer:: Chapter 19 Reactions of Benzene and Substituted BenzenesAbbie BennettNo ratings yet

- Organic Chemistry Lab Final Exam ReviewDocument7 pagesOrganic Chemistry Lab Final Exam ReviewmvmbappleNo ratings yet

- Self Healing ConcreteDocument30 pagesSelf Healing Concreteanon_528202537No ratings yet

- CHEM 103 Exp 05 Qualitative Analysis Anions Part II NEWDocument4 pagesCHEM 103 Exp 05 Qualitative Analysis Anions Part II NEWGail AidNo ratings yet

- (Ye-Tt) Threading Tools PDFDocument176 pages(Ye-Tt) Threading Tools PDFRasatja YongskulroteNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastFrom EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastNo ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- Taste: Surprising Stories and Science About Why Food Tastes GoodFrom EverandTaste: Surprising Stories and Science About Why Food Tastes GoodRating: 3 out of 5 stars3/5 (20)