Professional Documents

Culture Documents

Live Roller Conveyor

Uploaded by

GSPM SBOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Live Roller Conveyor

Uploaded by

GSPM SBCopyright:

Available Formats

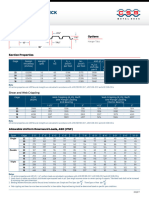

MODEL 192CDLR

MEDIUM DUTY ROLL-TO-ROLL CHAIN DRIVEN LIVE ROLLER

SPECIFICATION TABLE

24 hour shipment

UNIT WEIGHTS (FOR 4” AND 8” ROLLER CENTERS ONLY)

CONVEYOR LENGTH 5’ 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’

CONV. SUR- BF 4” RC 8” RC 4” RC 8” RC 4” RC 8” RC 4” RC 8” RC 4” RC 8” RC 4” RC 8” RC 8” RC 8” RC 8” RC

FACE

12” 15” 334 291 509 431 859 703 1209 948 1659 1247 1909 1519 1790 2065 2340

18” 21” 372 319 572 474 969 773 1367 1073 1764 1372 2161 1671 1971 2276 2581

Conveyor shown with 24” 27” 409 351 634 516 1079 843 1524 1170 1969 1497 2414 1824 2251 2476 2801

optional supports 30” 33” 452 379 697 559 1190 914 1683 1269 2175 1623 2668 1978 2333 2688 3043

36” 39” 469 406 739 600 1278 950 1817 1340 2356 1720 2895 2100 2480 2865 3250

42” 45” 524 430 819 640 1407 1049 1994 1457 2581 1865 3169 2274 2684 3099 3514

48” 51” 562 463 882 683 1517 1119 2152 1555 2788 1992 3423 2428 2864 3299 3734

UNIT WEIGHTS (FOR 6” AND 12” ROLLER CENTERS ONLY)

Roach model 192CDLR is a medium duty chain CONVEYOR LENGTH 5’ 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’

driven live roller conveyor. This conveyor is designed to

CONV. SUR- BF 6” RC 12” 6” RC 12” 6” RC 12” 6” RC 12” 6” RC 12” 6” RC 12” 6” RC 12” 6” RC 12” 6” RC 12”

transport loads such as tote pans, castings, drums or pallet loads. FACE RC RC RC RC RC RC RC RC RC

12” 15” 307 285 457 405 755 651 1053 897 1351 1143 1647 1389 1946 1634 2246 1884 2546 2134

18” 21” 341 301 506 441 837 707 1169 974 1500 1240 1831 1506 2163 1773 2493 2043 2823 2313

HP @ 24” 27” 370 331 555 476 921 763 1287 1050 1653 1337 2019 1624 2385 1911 2755 2201 3125 2491

“A” “B” MAX

45FPM 30” 33” 405 358 605 513 1006 822 1407 1131 1807 1439 2208 1748 2609 2057 3009 2367 3409 2677

1/3 13-1/8” 49-1/2” 36” 39” 418 363 633 528 1066 856 1499 1184 1932 1512 2365 1840 2798 2168 3228 2498 3658 2828

1/2 13-1/8” 49-1/2” 42” 45” 465 406 700 581 1169 931 1637 1280 2105 1629 2574 1979 3044 2330 3514 2680 3984 3030

3/4 13-1/2” 49-1/2” 48” 51” 499 432 749 617 1251 987 1753 1357 2256 1728 2753 2090 3260 2468 3760 2838 4260 3208

1 13-3/4” 50-1/16”

1-1/2 14-5/8” 50-3/8”

OPTIONAL EQUIPMENT

2 15-1/2” 52-1/16” SPEED: Constant speed 1.5-100 FPM; UNDERTRUSSED BED: Available to CEILING HANGERS: 5/8” dia. threaded

DC variable speed; AC inverter variable provide clearance underneath unit at rod with hardware to attach rods to

SPECIFICATIONS speed. Other constant or variable bed joint locations. Specify location for conveyor. Provides 6’ clearance

TREAD ROLLERS: 1.9” dia. x 12 ga. ROLLER CENTERS: 4”, 6”, 8” or 12” MOTOR DRIVE: 1/3 HP, 230/460/3, speeds available. NOTE: CAPACITY undertrussing and desired clearance between ceiling and TOR (furnished in

steel, model 192S with sprockets. centers available. 60 cycle, ODP right angle gear motor. CHANGES WITH SPEED. 100 FPM underneath unit. Consult factory. place of floor supports). See Conveyor

MAX. WITH ROLL-TO-ROLL CHAIN GUARD RAILS: 1-3/4” x 1” formed Accessories.

CHAIN DRIVE: Roll-to-roll no. 40 SPEED: 45 FPM, constant. ELECTRICAL CONTROLS: Optional. DRIVE. channel (model GC), adjusts horizontally ELECTRICAL CONTROLS: Magnetic

roller chain. BEARINGS: Removable type, zinc-plat- MOTORS: Available through 3 HP in to 8” wider than roller and vertically to starter; one direction manual starter;

CENTER DRIVE: Reversible drive either ed, grease packed, labyrinth sealed. TEFC, explosion proof, dirty duty, brake 6” above roller; formed steel fixed (model momentary start/stop push button

side mounted or underside mounted BED: 5-1/2” x 1-1/2” x 10 ga. motor, 115/230/1, 575/3, etc. FSG in 2”, 4” and 6” heights; fixed station; limit switch, photo relay; others

(specify). Main drive roller is supported and 3-1/2” x 1-1/2” x 10 ga. formed FLOOR SUPPORTS: Supports, knee brac- channel (model FC); 1-1/2” angle available.

by precision, heavy duty, lubricated, ball steel channel frame. es, casters and polytier supports avail- (model GA1-1/2). See Conveyor

bearing units.

able. See Conveyor Accessories. Accessories.

CHAIN GUARD: The chain drive is

completely enclosed along the entire

length of the conveyor.

ROLLER TO ROLLER CHAIN DRIVE OPTIONAL TOP ROLLER GUARD MOUNTED DRIVE

(guard removed for clarity)

You might also like

- Chain Driven Live Roller ConveyorDocument13 pagesChain Driven Live Roller ConveyorDiego Fernando AVENDA¥O RODRIGUEZNo ratings yet

- 36crrh PDFDocument2 pages36crrh PDFargaNo ratings yet

- 36-CRRH: H Y T R O L Conveyor Company, INCDocument2 pages36-CRRH: H Y T R O L Conveyor Company, INCargaNo ratings yet

- Out 879690Document3 pagesOut 879690cristiantcs18No ratings yet

- CMS MetalDeck LoadTable 1 5 Composite Deck Grade 40Document4 pagesCMS MetalDeck LoadTable 1 5 Composite Deck Grade 40darwingcamachoNo ratings yet

- Hanger Load TablesDocument1 pageHanger Load TablesRileybrandon constructionNo ratings yet

- CMS MetalDeck LoadTable 1 5 Composite Deck Grade 80Document4 pagesCMS MetalDeck LoadTable 1 5 Composite Deck Grade 80darwingcamachoNo ratings yet

- PH Hydraulic Torque Wrench Instruction ManualDocument23 pagesPH Hydraulic Torque Wrench Instruction ManualLikLiek WahahaNo ratings yet

- MATIERE Unibridge Technical SpecificationsDocument2 pagesMATIERE Unibridge Technical SpecificationsFadel MuhammadNo ratings yet

- Steel Wire Rope: Factors Affecting Rope Life Tensile GradeDocument1 pageSteel Wire Rope: Factors Affecting Rope Life Tensile GradeHUNG NIKKONo ratings yet

- Catalogo Ferraco CompleDocument92 pagesCatalogo Ferraco CompleTIM PECASNo ratings yet

- Ram Spec s-28f9845Document2 pagesRam Spec s-28f9845Justine Kei Lim-OrtegaNo ratings yet

- Major Material Requirement: Ruwanpura Expressway Project - Phase 01Document2 pagesMajor Material Requirement: Ruwanpura Expressway Project - Phase 01Shamitha KanchanaNo ratings yet

- Vornbaeumen - VS 6-11 C TDSDocument1 pageVornbaeumen - VS 6-11 C TDSKonstantinos SynodinosNo ratings yet

- BONT Level GaugeDocument13 pagesBONT Level Gaugeabdul azzam Al BanjariNo ratings yet

- RR KABEL Price List - LT HT Cables - 150322Document4 pagesRR KABEL Price List - LT HT Cables - 150322Hemil PatelNo ratings yet

- Rotary Valve Selector Guide PDFDocument28 pagesRotary Valve Selector Guide PDFtradehouseNo ratings yet

- Roots RAM Rotary Positive Blowers: SpecificationsDocument2 pagesRoots RAM Rotary Positive Blowers: SpecificationsAlberto Velosa RoaNo ratings yet

- Torrex Cable Price List July 2022Document2 pagesTorrex Cable Price List July 2022getztarunNo ratings yet

- Volume of Horizontal Cylindrical TankDocument4 pagesVolume of Horizontal Cylindrical TankAhmedRamadanNo ratings yet

- Asme Ansi b16.9 DimensionDocument13 pagesAsme Ansi b16.9 DimensionarisandiyusufNo ratings yet

- RR KABEL Price List - LT HT Cables - 01st February 2023Document4 pagesRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNo ratings yet

- Videx Sectional Tanks-BrochureDocument8 pagesVidex Sectional Tanks-BrochureRendani VeleNo ratings yet

- IHSERIALNUMBERSDocument26 pagesIHSERIALNUMBERSJasmin DesmaraisNo ratings yet

- A63 A64 CylinderDocument5 pagesA63 A64 CylinderBiswanath LenkaNo ratings yet

- Batt Cables NYYDocument1 pageBatt Cables NYYeplan drawingsNo ratings yet

- KEC RPG Cables List Price 08 December 2021Document7 pagesKEC RPG Cables List Price 08 December 2021Sunny KumarNo ratings yet

- Stainless Steel Pipes PressurDocument4 pagesStainless Steel Pipes PressurGaurav BedseNo ratings yet

- FLOWTITE Handling and StorageDocument13 pagesFLOWTITE Handling and StorageMohammed khaleelNo ratings yet

- 2 22 PDFDocument2 pages2 22 PDFpriecs100% (1)

- Polycab Price ListDocument8 pagesPolycab Price ListSandeep NarayananNo ratings yet

- FREEPHONE: 0800 117882 FREEFAX: 0800 575092: Guide To Lead Flashing Roll Weights To BS EN 12588Document1 pageFREEPHONE: 0800 117882 FREEFAX: 0800 575092: Guide To Lead Flashing Roll Weights To BS EN 12588Adie MorganNo ratings yet

- Product Data Sheet General Data Air Consumption Imperial Hytork en 83216Document1 pageProduct Data Sheet General Data Air Consumption Imperial Hytork en 83216RSalehNo ratings yet

- Price List: High Voltage / Low Voltage Power & Control CablesDocument7 pagesPrice List: High Voltage / Low Voltage Power & Control CablesAnkitNo ratings yet

- 6x36 WS WC: Standard Round Strand RopesDocument2 pages6x36 WS WC: Standard Round Strand RopesBronwynne OctoberNo ratings yet

- CSL - SPM Hawser CatalogDocument14 pagesCSL - SPM Hawser CatalogEkoNo ratings yet

- Cordoaria Sao Leopoldo - CatalogoDocument44 pagesCordoaria Sao Leopoldo - CatalogoKESSLER OFFSHORENo ratings yet

- 250 - GB - 1403 BM 2014Document12 pages250 - GB - 1403 BM 2014silvio ribeiroNo ratings yet

- Table 4D1A PDFDocument1 pageTable 4D1A PDFMadusanka Weebedda100% (1)

- FWW-DA BenefitsDocument2 pagesFWW-DA BenefitsAbed HajjoNo ratings yet

- Tabla de ResistenciasDocument74 pagesTabla de ResistenciasAlexander CalizayaNo ratings yet

- 3 Demag CC2800-1Document6 pages3 Demag CC2800-1Jon Csehi100% (2)

- Table 4. "C" Values For ConductorsDocument1 pageTable 4. "C" Values For Conductorssam_sudanNo ratings yet

- Installation Guide For Solid Wall PVC Sewer PipeDocument20 pagesInstallation Guide For Solid Wall PVC Sewer PipeKaleab TadesseNo ratings yet

- Dimensions and Dimensional Tolerances of Long Radius Elbows 45 and 90 Degrees and 3D Elbows, NPS 1 - 2 To NPS 48, ASME B16.9Document3 pagesDimensions and Dimensional Tolerances of Long Radius Elbows 45 and 90 Degrees and 3D Elbows, NPS 1 - 2 To NPS 48, ASME B16.9sennimalaiNo ratings yet

- Macsteel Exports Product Catalogue 2021Document48 pagesMacsteel Exports Product Catalogue 2021Dude BroNo ratings yet

- Drives F55Document3 pagesDrives F55hernan dueñasNo ratings yet

- 1051 GD 2250tDocument2 pages1051 GD 2250tJunior Francisco QuijanoNo ratings yet

- Horizontal Tank VolumeDocument6 pagesHorizontal Tank VolumeNitin KurupNo ratings yet

- Pages From Dorman Longs - Handbook For Constructional Engineers - 1906-102Document1 pagePages From Dorman Longs - Handbook For Constructional Engineers - 1906-102Fornvald TamasNo ratings yet

- PCC LP NO. 3 DTD 1st August 2018Document8 pagesPCC LP NO. 3 DTD 1st August 2018AteebNo ratings yet

- Openwebsteeljoists,Vhser看Es: Vulcraf丁Loadtable Basedonaiiowabiest「Essoi30,000P.S・1"Document1 pageOpenwebsteeljoists,Vhser看Es: Vulcraf丁Loadtable Basedonaiiowabiest「Essoi30,000P.S・1"GADAL SOLOMONNo ratings yet

- Kap 02 6 KantskruvDocument34 pagesKap 02 6 KantskruvbufabNo ratings yet

- Air Cylinder: Series A23, A24 Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument8 pagesAir Cylinder: Series A23, A24 Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- 1.5 B Wide Rib Roof DeckDocument4 pages1.5 B Wide Rib Roof Deckpaiya92No ratings yet

- KEC - Price List CablesDocument8 pagesKEC - Price List CablesSCM ASA BHANUNo ratings yet

- Polycab Wires Latest Price ListDocument1 pagePolycab Wires Latest Price Listandcha.exe100% (1)

- Battery Calculation - Rocket ExideDocument6 pagesBattery Calculation - Rocket Exidebhavin24uNo ratings yet

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- The Modern Cruising Sailboat: A Complete Guide to its Design, Construction, and OutfittingFrom EverandThe Modern Cruising Sailboat: A Complete Guide to its Design, Construction, and OutfittingRating: 5 out of 5 stars5/5 (4)

- BQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiDocument4 pagesBQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiArie WigunaNo ratings yet

- General: Sample Requisition For The Month of Feb'2021Document3 pagesGeneral: Sample Requisition For The Month of Feb'2021Easy TechNo ratings yet

- Technical Data MQ-6: Gas SensorDocument2 pagesTechnical Data MQ-6: Gas SensorIhwanNo ratings yet

- User's Manual Calibration Unit PGT120: Wolfgang Warmbier Untere Gießwiesen 21 D-78247 Hilzingen/GermanyDocument7 pagesUser's Manual Calibration Unit PGT120: Wolfgang Warmbier Untere Gießwiesen 21 D-78247 Hilzingen/GermanyWuzekNo ratings yet

- Mypricebook 0000062696 1000 2018 04 10Document1,031 pagesMypricebook 0000062696 1000 2018 04 10Yesica SantamariaNo ratings yet

- HME 95 Owner ManualDocument20 pagesHME 95 Owner Manualkennkki0% (1)

- Noble Series New!: Notch-FreeDocument1 pageNoble Series New!: Notch-FreecrlaurenceNo ratings yet

- Transtech Surge Handout Rev2Document44 pagesTranstech Surge Handout Rev2Anonymous 0iYfWI6fNo ratings yet

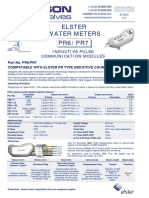

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 pageData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaNo ratings yet

- Data Sheet Daniel Series 700 Model v788 en 6385002Document10 pagesData Sheet Daniel Series 700 Model v788 en 6385002Marcelo PinheiroNo ratings yet

- Hand Tool BestDocument14 pagesHand Tool BestBenjamin FalletNo ratings yet

- WS 54 Tool and Cutter Grinding Machine: Productivity Realised at Tool Cutting EdgeDocument4 pagesWS 54 Tool and Cutter Grinding Machine: Productivity Realised at Tool Cutting Edgejacksonholland8335No ratings yet

- ZTech X3 Product DescriptionDocument3 pagesZTech X3 Product DescriptionDanielle DiazNo ratings yet

- R400BrochureUSA DagorDocument2 pagesR400BrochureUSA Dagor陈旭100% (1)

- Kenwood Dnx8120 Parts and Full Diagrams and LayoutDocument28 pagesKenwood Dnx8120 Parts and Full Diagrams and LayoutEdwin GeeqNo ratings yet

- The Borealis Zombie Saver BackpackDocument4 pagesThe Borealis Zombie Saver BackpackLiz HernandezNo ratings yet

- Intelligent Automatic Water Fount Control System Using High Sensitivity LDRDocument3 pagesIntelligent Automatic Water Fount Control System Using High Sensitivity LDRYellaturi Siva Kishore ReddyNo ratings yet

- FP-01 Front PageDocument1 pageFP-01 Front PageBerlin Andrew SionNo ratings yet

- Muhammad Asif: ResumeDocument5 pagesMuhammad Asif: Resumeasi315No ratings yet

- Mosebach's Pad-Mounted Load Bank, The X100P FamilyDocument2 pagesMosebach's Pad-Mounted Load Bank, The X100P FamilyEduardo Puma AriasNo ratings yet

- TC-48 TC480652 PDFDocument288 pagesTC-48 TC480652 PDFSergeyNo ratings yet

- WeaponsDocument2 pagesWeaponsdirtyharrygulshanNo ratings yet

- MediawebserverDocument52 pagesMediawebserveralgubNo ratings yet

- Centrifugal Pump Types (API-610)Document4 pagesCentrifugal Pump Types (API-610)Иван РадевNo ratings yet

- Compressed Cylinder SafetyDocument31 pagesCompressed Cylinder SafetycarolNo ratings yet

- Basic Guide To Fire Alarm InstallationDocument12 pagesBasic Guide To Fire Alarm InstallationCatrina FedericoNo ratings yet

- Gauge Blocks: Length StandardDocument40 pagesGauge Blocks: Length Standardaraha21No ratings yet

- Technical Manual MKTHDocument30 pagesTechnical Manual MKTHahmed abdoh0% (1)

- 431 Shoppertron Parts ManualDocument88 pages431 Shoppertron Parts ManualskipaduveinowNo ratings yet

- Bit - HalfMoon + Wing ShankDocument3 pagesBit - HalfMoon + Wing ShankaceportgasNo ratings yet