Professional Documents

Culture Documents

Coating FeedMill-8095

Uploaded by

Rifai IndraswariCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coating FeedMill-8095

Uploaded by

Rifai IndraswariCopyright:

Available Formats

7

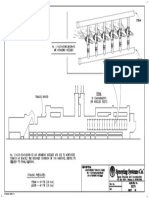

,-,oJLLED IN

HOLES 1./1'' Streaky spray distribution - with

much area untouched by direct im-

pact of spray.

Susceptible to clogging - since

many small orifices are used for

same coverage which is available

from one larger orifice spray

nozzie:-

Wastes water and pump capacity

since so many orifices are re-

quired to provide coverage.

Erosion eventually enlarges holes

so that entire manifold must be

removed and a new one completely

drilled and installed.

Uniform spray distribution - with

direct spray impact on every inch

of surface.

Choice of many nozzle orifices,

S'pray patterns and materials -

and interchangeable to meet any

spray requirement without dis-

turbing manifold.

Projection of nozzle through bottom

of pipe tends to prevent sediment

in manifold from entering nozzle.

Conserves water and pump ca:pacity

by effectively and uniformly dis-

tributing spray over wide area of

coverage.

DESCRIPTION:

COMPARISON OF

DRILLED HOLES IN PIPE

VS. VEEJET NOZZLES IN

INDUSTRIAL WASHING APPLICATION

ftse~~~~e!£0:

P.O. Box 7900 - Wheaton, II. 60189-7900

Rev. No. Application No.

Ref.

8095

SHEET OF

© Spraying Systems Co.

L _J

You might also like

- An Engineers Guide To Spray TechnologyDocument16 pagesAn Engineers Guide To Spray TechnologyViajante_santosNo ratings yet

- W2P Membrane DiffuserDocument1 pageW2P Membrane DiffuserAngirishNo ratings yet

- SIREG - Drainage PipesDocument8 pagesSIREG - Drainage PipesMario RuggieroNo ratings yet

- Conbextra HESEDocument4 pagesConbextra HESEm.elsanee.cubicNo ratings yet

- Guide To Spray Properties: What's in A Spray?Document7 pagesGuide To Spray Properties: What's in A Spray?Anonymous yPWi8p3KkANo ratings yet

- Brochures - Waterproofing SikaFuko - Injection Hose Systems - GCCDocument5 pagesBrochures - Waterproofing SikaFuko - Injection Hose Systems - GCCCharbel GhanemNo ratings yet

- Full Cone NozzlesDocument25 pagesFull Cone NozzlesMinha Mubarok Ibn MasduqiNo ratings yet

- Sprayed Concrete Application GuidelinesDocument6 pagesSprayed Concrete Application GuidelinesUrosNo ratings yet

- Lechler Fachbericht Asme-Power-Conference 2009-07 Van-Durme enDocument6 pagesLechler Fachbericht Asme-Power-Conference 2009-07 Van-Durme enhungleteNo ratings yet

- Eflow Installation Guide - Dec17 v1 0 LRDocument12 pagesEflow Installation Guide - Dec17 v1 0 LRAJ RICCIARDONo ratings yet

- Abrassive Perforating Via Coiled Tubing RevisitedDocument4 pagesAbrassive Perforating Via Coiled Tubing RevisitedRachel PanjaitanNo ratings yet

- HWP CW UC8 Generic IM 0422 PDFDocument12 pagesHWP CW UC8 Generic IM 0422 PDFQuang PhanNo ratings yet

- Vibrating Wire Settlement Systems: 4600 SeriesDocument4 pagesVibrating Wire Settlement Systems: 4600 SeriesKael CabezasNo ratings yet

- Suc DrumsDocument6 pagesSuc DrumsrkoGear100% (1)

- Amistco - KO Drum Demister Options (Mist Eliminator Spacing What To Do For Liquid Carryover)Document6 pagesAmistco - KO Drum Demister Options (Mist Eliminator Spacing What To Do For Liquid Carryover)Mubarik AliNo ratings yet

- Seamless VS Welded TubesDocument1 pageSeamless VS Welded Tubeshirenkumar patelNo ratings yet

- Notes:: Plan End ViewDocument1 pageNotes:: Plan End Viewsowman tungNo ratings yet

- The Benefits of Bulk Emulsion Explosives in Underground PDFDocument5 pagesThe Benefits of Bulk Emulsion Explosives in Underground PDFalvaroaac4No ratings yet

- 442-032 PDF PDFDocument12 pages442-032 PDF PDFCalNo ratings yet

- Pasco Catalog eDocument9 pagesPasco Catalog eClementine JsotoNo ratings yet

- Medium Foam Pod Nozzle - NPB Series Fountain NozzleDocument2 pagesMedium Foam Pod Nozzle - NPB Series Fountain NozzleFachrul Rozi SuriyanaNo ratings yet

- Devilbiss Atomizers/Nebulizers/ Syringes/Powder Blowers Instruction GuideDocument2 pagesDevilbiss Atomizers/Nebulizers/ Syringes/Powder Blowers Instruction GuideStacy WilsonNo ratings yet

- Maxurethane Injection Tube EngDocument4 pagesMaxurethane Injection Tube EngUyên Bùi Thụy TúNo ratings yet

- ESCHandbook Chapter3 3.04Document5 pagesESCHandbook Chapter3 3.04Larry Wayne Sumpter, JrNo ratings yet

- TIEIG Catalog For Heavy Machinary 2022Document10 pagesTIEIG Catalog For Heavy Machinary 2022Hülya Kula ÇİÇEKÇİNo ratings yet

- Pitfalls of Pump PipingDocument3 pagesPitfalls of Pump PipingChris PeramunugamaNo ratings yet

- Spray DryerDocument9 pagesSpray DryerSteve WanNo ratings yet

- 97363-MS Underbalanced PerforatingDocument8 pages97363-MS Underbalanced Perforatinghade wantoNo ratings yet

- Abdf - Novel ApplicationsDocument6 pagesAbdf - Novel ApplicationsVamsee KrishnaNo ratings yet

- Srsa (New) June 2023Document2 pagesSrsa (New) June 2023planningjewarNo ratings yet

- Bosch Rexroth Axial Piston Pump CatalogDocument10 pagesBosch Rexroth Axial Piston Pump CatalogTiagoNo ratings yet

- Pressure Balanced Drilling Bumper Sub: Instruction Manual 4410Document17 pagesPressure Balanced Drilling Bumper Sub: Instruction Manual 4410Foros IscNo ratings yet

- Section 2 Squeeze Cementing Ongc General InformationDocument4 pagesSection 2 Squeeze Cementing Ongc General InformationLenin DiazNo ratings yet

- Sanitation (Toilettes Sèches) - Overview Water Aid 2007Document5 pagesSanitation (Toilettes Sèches) - Overview Water Aid 2007susCities100% (1)

- Large Landslide Stabilization by Deep Drainage WellsDocument8 pagesLarge Landslide Stabilization by Deep Drainage WellsCarlos Eduardo Torres RomeroNo ratings yet

- No Cavitate Orifice PlateDocument2 pagesNo Cavitate Orifice PlateAbhijeet SahuNo ratings yet

- Self-Drilling Anchor: Kuechler-Technik - CHDocument24 pagesSelf-Drilling Anchor: Kuechler-Technik - CH2K19/STE/20 SUGAM JAINNo ratings yet

- Portable Foam Inductor UNI 900 MDocument2 pagesPortable Foam Inductor UNI 900 MForum PompieriiNo ratings yet

- Helical Reinforcement BarsDocument1 pageHelical Reinforcement BarsruwanthaNo ratings yet

- Hand Book - Amphibia Method Statement ENDocument60 pagesHand Book - Amphibia Method Statement ENJose Eduardo GranatoNo ratings yet

- Shield Water Spray NozzleDocument17 pagesShield Water Spray NozzleMd. Asrafujjaman (Livon)No ratings yet

- Tsda Sedimentadores de Tubos PDFDocument4 pagesTsda Sedimentadores de Tubos PDFAndres OsorioNo ratings yet

- Foam-Water Sprinkler-B1Document2 pagesFoam-Water Sprinkler-B1Ahmed Said IbrahimNo ratings yet

- B-1 Foam-Water Sprinkler PDFDocument2 pagesB-1 Foam-Water Sprinkler PDFchangala chilekaNo ratings yet

- Brentwood - CL - Tube Settler DesApp - 2011 - en PDFDocument4 pagesBrentwood - CL - Tube Settler DesApp - 2011 - en PDFagomilNo ratings yet

- EW StepByStep PostCore ENDocument1 pageEW StepByStep PostCore ENharambatchaNo ratings yet

- DL International Cranes 0710Document2 pagesDL International Cranes 0710sangwoo jungNo ratings yet

- 1.3 Types of Nozzles. Calculations For Calibration of Sprayers and Chemical Application RatesDocument10 pages1.3 Types of Nozzles. Calculations For Calibration of Sprayers and Chemical Application RatesManish KumarNo ratings yet

- BilletCooler Oval Cone Techn Datenblatt Lechler GBDocument2 pagesBilletCooler Oval Cone Techn Datenblatt Lechler GBKoushik RayNo ratings yet

- Sika Injectoflex System (Type HP)Document2 pagesSika Injectoflex System (Type HP)Lim Yew KwangNo ratings yet

- NDJ Maintenance Eng 010713FDocument12 pagesNDJ Maintenance Eng 010713Fمؤمن سعيد طلحةNo ratings yet

- Pasco CatalogDocument7 pagesPasco CatalogItx MinhasNo ratings yet

- SIREG - Sleeved Grouting PipesDocument16 pagesSIREG - Sleeved Grouting PipesMario RuggieroNo ratings yet

- Fosroc Concure RB90: High Quality, Resin Based, Concrete Curing CompoundDocument4 pagesFosroc Concure RB90: High Quality, Resin Based, Concrete Curing CompoundBrian MbathaNo ratings yet

- Bubble and MistDocument4 pagesBubble and MistbilalNo ratings yet

- Visual Inspection Care Storage & Handling GuideDocument7 pagesVisual Inspection Care Storage & Handling GuideMelv CookNo ratings yet

- Proven and Reliable: Pump-Line-Nozzle Systems: Ics Industrial Control SystemsDocument3 pagesProven and Reliable: Pump-Line-Nozzle Systems: Ics Industrial Control SystemsKevin TtitoNo ratings yet

- Design: Offsets in Stacks Stub Stacks Branch Pipe GradientsDocument1 pageDesign: Offsets in Stacks Stub Stacks Branch Pipe GradientsBoraNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- CS134A Concrete Forms WebDocument2 pagesCS134A Concrete Forms WebRifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- CS127A Pan Coating Choc Centers WebDocument2 pagesCS127A Pan Coating Choc Centers WebRifai IndraswariNo ratings yet

- Mixing Vat Cleaning-26343Document1 pageMixing Vat Cleaning-26343Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim May 2023Document49 pagesRifai - Claim May 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim May 2023Document49 pagesRifai - Claim May 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Agt 2023Document52 pagesRifai - Claim Agt 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Agt 2023Document52 pagesRifai - Claim Agt 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Rifai - Claim May 2023Document49 pagesRifai - Claim May 2023Rifai IndraswariNo ratings yet

- Mixing Vat Cleaning-26343Document1 pageMixing Vat Cleaning-26343Rifai IndraswariNo ratings yet

- Automatic and Air Atomizing Spray Nozzles CatalogDocument166 pagesAutomatic and Air Atomizing Spray Nozzles CatalogAsad AhmedNo ratings yet

- Rifai - Claim Agt 2023Document52 pagesRifai - Claim Agt 2023Rifai IndraswariNo ratings yet

- Rifai - Claim Agt 2023Document52 pagesRifai - Claim Agt 2023Rifai IndraswariNo ratings yet

- Moisturizing Tobacco 38279Document1 pageMoisturizing Tobacco 38279Rifai IndraswariNo ratings yet

- C20F WindJet Air ProductsDocument28 pagesC20F WindJet Air Productsamicarelli100% (1)

- Distress Manual PDFDocument51 pagesDistress Manual PDFEIRINI ZIGKIRIADOUNo ratings yet

- A Simple and Convenient Synthesis of Pseudo Ephedrine From N-MethylamphetamineDocument2 pagesA Simple and Convenient Synthesis of Pseudo Ephedrine From N-Methylamphetaminedh329No ratings yet

- Gibbs VerBeek CorrespondenceDocument3 pagesGibbs VerBeek CorrespondenceWXMINo ratings yet

- CV KM Roy Supit 01 April 2019Document3 pagesCV KM Roy Supit 01 April 2019Ephanama TehnikNo ratings yet

- Light, Shape & Sound SignalsDocument2 pagesLight, Shape & Sound SignalsMa EL75% (4)

- Sand Cone Test ResultsDocument71 pagesSand Cone Test ResultsGayan Indunil JayasundaraNo ratings yet

- EtamolDocument5 pagesEtamolthonyyanmuNo ratings yet

- Recommended Reads by David PerellDocument3 pagesRecommended Reads by David PerellRonit MandalNo ratings yet

- Huawei Sne Mobile Phone User Guide - (Emui9.0.1 - 01, En-Uk, Normal)Document68 pagesHuawei Sne Mobile Phone User Guide - (Emui9.0.1 - 01, En-Uk, Normal)FarzadNo ratings yet

- PNAPDocument79 pagesPNAPYu chung yinNo ratings yet

- 2course Codes For 1 SEMESTER S.Y. 2021-2022: GE 2/ GE 1: Readings in The PhilippineDocument10 pages2course Codes For 1 SEMESTER S.Y. 2021-2022: GE 2/ GE 1: Readings in The PhilippineRexson Dela Cruz TagubaNo ratings yet

- Eligibility Conditions: Advertisement For Regular Commission in Pakistan Army Through 136 Pma Long CourseDocument5 pagesEligibility Conditions: Advertisement For Regular Commission in Pakistan Army Through 136 Pma Long CourseHusnain IshtiaqNo ratings yet

- Muetd - Session 3 - 2022 - 030716-08-1238 2Document1 pageMuetd - Session 3 - 2022 - 030716-08-1238 2Laila HaliliNo ratings yet

- Autodesk 2016 Product Keys 1Document3 pagesAutodesk 2016 Product Keys 1EfrEn QuingAtuñaNo ratings yet

- COT RPMS Rating Sheet For T I III For SY 2021 2022 JhanzDocument2 pagesCOT RPMS Rating Sheet For T I III For SY 2021 2022 Jhanzjhancelle golosindaNo ratings yet

- The Impact On Digital Marketing During Pandemic Outbreak COVID-19 On Business DevelopmentDocument5 pagesThe Impact On Digital Marketing During Pandemic Outbreak COVID-19 On Business DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Business Tax ReviewerDocument22 pagesBusiness Tax ReviewereysiNo ratings yet

- Case Study-Cereal PartnersDocument5 pagesCase Study-Cereal PartnersTariq MehmoodNo ratings yet

- RAB PLTS Hybrid 1kWp-ScheneiderDocument4 pagesRAB PLTS Hybrid 1kWp-ScheneiderilhamNo ratings yet

- Management Information SystemDocument65 pagesManagement Information SystemMuhammad FaizanNo ratings yet

- PRACTICES AND CHALLENGES IN THE IMPLEMENTATION OF BASIC EDUCATION LEARNING CONTINUITY PLAN-Authored By: Reynaldo C. CruzDocument71 pagesPRACTICES AND CHALLENGES IN THE IMPLEMENTATION OF BASIC EDUCATION LEARNING CONTINUITY PLAN-Authored By: Reynaldo C. CruzInternational Intellectual Online PublicationsNo ratings yet

- Oops MCQ (Unit-1)Document7 pagesOops MCQ (Unit-1)Jee Va Ps86% (14)

- Beyond Investment: The Power of Capacity-Building SupportDocument44 pagesBeyond Investment: The Power of Capacity-Building SupportLaxNo ratings yet

- 6.5 Tectonics and EvidencesDocument28 pages6.5 Tectonics and Evidencesbook wormNo ratings yet

- Psychology - Masters in Psychology Entrance Examination Book (Power Within Psychology, Amit Panwar) (Z-Library)Document414 pagesPsychology - Masters in Psychology Entrance Examination Book (Power Within Psychology, Amit Panwar) (Z-Library)Suraj100% (12)

- NSDADocument1 pageNSDAShallu ManchandaNo ratings yet

- Okuma CL302L Parts List & ManualDocument3 pagesOkuma CL302L Parts List & Manualcoolestkiwi100% (1)

- 2003 Wiley Periodicals, Inc.: Max VisserDocument10 pages2003 Wiley Periodicals, Inc.: Max VisserMariano DomanicoNo ratings yet

- Sample From Cambridge AssessmentDocument2 pagesSample From Cambridge AssessmentVinicius GomesNo ratings yet