Professional Documents

Culture Documents

MSD B

Uploaded by

barrozomariakatrinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSD B

Uploaded by

barrozomariakatrinaCopyright:

Available Formats

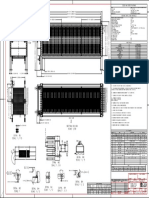

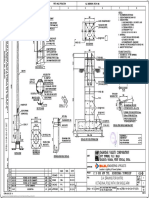

GENERAL NOTES

1. THE WHOLE OPERATION IS IN BATCH PROCESS

2. DWG NUMBER ARE REPRESENTED BY TTT-XXX WHERE "TTT"

DENOTES THE UNIT NUMBER AND "XXX" CORRESPONDS TO

THE PFD STREAM NUMBER

3. LEGEND

CS: CARBOON STEEL

SS: STAINLESS STEEL

PP: POLYPROPYLENE

PVC: POLYVINYL CHLORIDE

PTFE: POLYTETRAFLUOROETHYLENE

CA: CORROSION ALLOWANCE

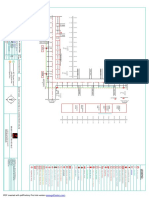

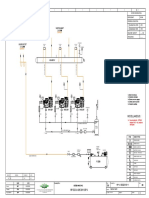

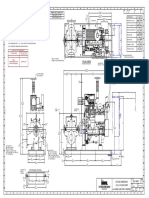

E-201 T-204 E-202 F-201 F-202 PWHT: POST WELD HEAT TREATMENT

LDT: LIMITING DESIGN TEMPERATURE

Depolymerized PET Cooler CW Tank CW Air Fin Cooler

Depolymerized PET Plate PIPING MATERIALS ARE IDENTIFIED ON THE SCHEMES LISTING

Shell PP Shell CS + 3.0 mm CA Depolymerized PET Ultrafiltration

Shell CS + 3.0 mm CA Internals PP Tubes SS 304 and Frame Filter Press USING THE FOLLOWING:

Tubes SS 316L PWHT No LDT 35.4oC PWHT Yes LDT 35.4oC Frame CS + 3.0 mm CA Shell SS 316L SS 304

PWHT No LDT 86.4oC Remarks Remarks Plate SS 316L Tubes PP

SS 316L

PTFE

Remarks PWHT Yes LDT 35.4oC PWHT No LDT 35.4oC CS (+ 3.0 mm CA) PWHT

PP

Remarks Remarks

P-203 A/B P-204 A/B P-205 A/B PVC

CWS Main Charge Pump CWR Main Charge Pump Depolymerized PET Main

Casing PP Casing PP Charge Pump

Impeller PP Impeller PP Casing PP

PWHT No LDT 35.4oC PWHT No LDT 35.4oC Impeller PP

Remarks Remarks PWHT No LDT 35.4oC

Remarks

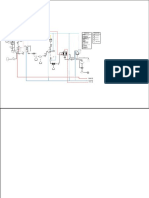

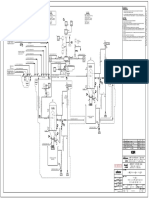

FC

202

FOR CONTINUATION

TC

203

SEE DWG 300-003

FC

E-202 P-204 A/B

201

E-201 PC

201 F-202

PG

204

106

F-201 V-301

TC

202

109 003 NOTES

107

1. THE CONCENTRATE WILL BE COLLECTED USING HOPPER

MADE OF PP

P-205 A/B 110

108

NOTE 1

NOTE 1

PG PG

202 203

7.8327 kg

100% Enzyme

LG

203 (for reuse)

P-203 A/B

T-204 EQUIPMENT NUMBERS

E-201 P-203 A/B

PROCESS FLUID CWR CWS CWS CWS T-204 P-204 A/B

E-202 P-205 A/B

FROM UNIT 100 FROM UNIT 400 TO UNIT 300 TO UNIT 400 TO UNIT 400 F-201

F-202

BR-101 C-401 V-301 E-405 E-403

DRG No. 001 DRG No. 004 DRG No. 003 DRG No. 004 DRG No. 004

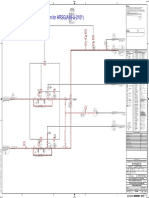

01R ISSUED FOR REVIEW

NO. DESCRIPTION BY CHKD APVD DATE

REVISIONS

TITLE

MATERIAL SELECTION DIAGRAM

PRODUCT RECOVERY

PRETREATMENT UNIT

UNIT: 200

DRG. No.: SIZE: REV.:

002 A3 01R

You might also like

- Oisd - RP - 174 Revision: S.N O. para No. Heading Existing para Proposed Revision Remarks 1Document68 pagesOisd - RP - 174 Revision: S.N O. para No. Heading Existing para Proposed Revision Remarks 1Ravi KantNo ratings yet

- Typ. Detail Section of Service Entrance: LegendDocument1 pageTyp. Detail Section of Service Entrance: LegendLowie Torres TonioNo ratings yet

- Hydrology and Water Resource Systems Analysis (PDFDrive)Document622 pagesHydrology and Water Resource Systems Analysis (PDFDrive)Loo Wei SungNo ratings yet

- Hydraulic Hatch Drawings With Pending ExcelDocument4 pagesHydraulic Hatch Drawings With Pending ExcelTarek TarekNo ratings yet

- Preventing Pulsation ProblemDocument10 pagesPreventing Pulsation Problemfathim1356No ratings yet

- HVAC Rules of ThumbDocument8 pagesHVAC Rules of Thumbsam7sNo ratings yet

- SU 836 Spare Parts Catalogue PDFDocument62 pagesSU 836 Spare Parts Catalogue PDFIgor KotenkoNo ratings yet

- Oily Water Treatment PackageDocument1 pageOily Water Treatment Packagecliffrajjoel100% (1)

- STFFD-P1-006002-D10-1001 Rev B HVAC System - Piping & Instrumentation DiagramDocument4 pagesSTFFD-P1-006002-D10-1001 Rev B HVAC System - Piping & Instrumentation DiagramHiếu NguyênNo ratings yet

- Final Design - Assignment IIIDocument67 pagesFinal Design - Assignment IIIAmilcarwalter75% (4)

- CB3 Me-13Document1 pageCB3 Me-13J-R MERLIN CabatoNo ratings yet

- Alan S Foust Solid Liquid SeparationDocument77 pagesAlan S Foust Solid Liquid SeparationAlfi HendryNo ratings yet

- Eb VRM 01 1040 PDFDocument2 pagesEb VRM 01 1040 PDFLuis GonzalezNo ratings yet

- BB BB: Code and SpecificationsDocument1 pageBB BB: Code and SpecificationsandersonNo ratings yet

- Fortem Digital Air Compressor Instruction GuideDocument12 pagesFortem Digital Air Compressor Instruction GuideAJR365No ratings yet

- Notes: North Field Expansion Feed Project Onshore Facilities FEEDDocument1 pageNotes: North Field Expansion Feed Project Onshore Facilities FEEDAbid AyubNo ratings yet

- (For Wall) : Note: Prior To Backfill of Duct Bank, All Opening Shall Be PluggedDocument1 page(For Wall) : Note: Prior To Backfill of Duct Bank, All Opening Shall Be PluggedAbid AyubNo ratings yet

- MSD DDocument1 pageMSD DbarrozomariakatrinaNo ratings yet

- 011 012 MergedDocument12 pages011 012 MergedAli HusseinNo ratings yet

- General Notes:: Vicinity Map P1Document1 pageGeneral Notes:: Vicinity Map P1Alsean Soriano DetubioNo ratings yet

- P 0 PDFDocument1 pageP 0 PDFSketch UpNo ratings yet

- Keterangan Alat Keterangan Alat Keterangan Simbol Keterangan SimbolDocument2 pagesKeterangan Alat Keterangan Alat Keterangan Simbol Keterangan SimbolPratiwi Putri LimNo ratings yet

- 100 PAT A4AC Model PDFDocument1 page100 PAT A4AC Model PDFAshish ShahNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Ricardo Alberto Zapata BalcazarNo ratings yet

- Section X-X Section Y-Y: Typical Plan of Proposed Construction of Tower Wagon Shed (8-WHEELER)Document1 pageSection X-X Section Y-Y: Typical Plan of Proposed Construction of Tower Wagon Shed (8-WHEELER)Manoj H MNo ratings yet

- A10 A Pid Va 718589 203Document1 pageA10 A Pid Va 718589 203zhangNo ratings yet

- 2544 P502C10 Iso Amn23003003 0007 - 1Document1 page2544 P502C10 Iso Amn23003003 0007 - 1ahmed marieNo ratings yet

- P2202124605 DesignDocument1 pageP2202124605 DesignRochelle Ann MallariNo ratings yet

- Proses Revisi 3Document2 pagesProses Revisi 3Pratiwi Putri LimNo ratings yet

- Aps 1Document1 pageAps 1Akash MohantyNo ratings yet

- Epbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFDocument1 pageEpbu-14-04-Ga-Kt-057a (6M Octagonal Pole) R4-Approval PDFP.MannaNo ratings yet

- Epbu 14 04 Ga KT 057a (6m Octagonal Pole) r4 ApprovalDocument1 pageEpbu 14 04 Ga KT 057a (6m Octagonal Pole) r4 ApprovalP.MannaNo ratings yet

- MRT M&E Drawing4Document1 pageMRT M&E Drawing4qinxuekunNo ratings yet

- Angloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Document1 pageAngloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Pedro ChaucaNo ratings yet

- LS-2361 L2 Jacuzzi-Bed DetailDocument1 pageLS-2361 L2 Jacuzzi-Bed Detailvin ssNo ratings yet

- ELECTRIC LAYOUT-ModelDocument1 pageELECTRIC LAYOUT-Modelmanasa manasaNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Electrical Site Setting Layout Plan: Prop. Ground Floor VillaDocument1 pageElectrical Site Setting Layout Plan: Prop. Ground Floor VillathaenNo ratings yet

- 20100PE-DW02-0007 Rev1 11-SD-2123Document1 page20100PE-DW02-0007 Rev1 11-SD-2123Jovit BeaNo ratings yet

- 2220-PW-6"-C1E2A-21269: Diametro Largo Total (M) ItemDocument1 page2220-PW-6"-C1E2A-21269: Diametro Largo Total (M) ItemAlonso FarfanNo ratings yet

- Sapar-Veraval Route Inpath PDFDocument3 pagesSapar-Veraval Route Inpath PDFvaghasiyagunjanNo ratings yet

- HS523217 51 PR PID 0018 0001rev1Document1 pageHS523217 51 PR PID 0018 0001rev1Nasim MammadovNo ratings yet

- Plan at Canopy Top Level: Detail - ZDocument1 pagePlan at Canopy Top Level: Detail - ZEr navneet jassiNo ratings yet

- SA04C2-03-WP-D-43101-01-2: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-43101-01-2: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Aa 038605 001Document1 pageAa 038605 001hai sunNo ratings yet

- Major1010373x12.2pscslab V5 Approve P12Document1 pageMajor1010373x12.2pscslab V5 Approve P12rushi123No ratings yet

- Uwps-Pmd-02-Ps-21-Mec-Dr-00009Document1 pageUwps-Pmd-02-Ps-21-Mec-Dr-00009pangilbert928No ratings yet

- 2544 P502a20 Iso LPS23056329 0001 - 1Document2 pages2544 P502a20 Iso LPS23056329 0001 - 1ahmed marieNo ratings yet

- 10-5-2023 - Banquet Hall..Document1 page10-5-2023 - Banquet Hall..ds18.albertcastroNo ratings yet

- Coppe R: Suction Inle T 2X 67MMDocument1 pageCoppe R: Suction Inle T 2X 67MMJitto E JoseNo ratings yet

- Detail - 3 Section - L: Infineum JSGP Alliance (Ija) Projects Infineum Singapore LLPDocument1 pageDetail - 3 Section - L: Infineum JSGP Alliance (Ija) Projects Infineum Singapore LLPdharunesh182No ratings yet

- Site PlanDocument1 pageSite PlanNaveen singhNo ratings yet

- Motobomba ACIDocument1 pageMotobomba ACIKEVIN COSTASNo ratings yet

- Ppu Stdaln 1Document1 pagePpu Stdaln 1Alifasyraf HaNo ratings yet

- Section - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas LimitedDocument1 pageSection - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas Limitedsumit kumarNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Mohd KhaidirNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Mohd KhaidirNo ratings yet

- 5-C0003 - Pga1002413340010-02 SH - 1Document2 pages5-C0003 - Pga1002413340010-02 SH - 1Aswindana Ibnu SenaNo ratings yet

- Ga Shealding Mast - AppvdDocument1 pageGa Shealding Mast - AppvdNanik EdaneNo ratings yet

- Construction Notes: D. Notes On Foundation Design CriteriaDocument9 pagesConstruction Notes: D. Notes On Foundation Design CriteriaIrene Ionie Rarangol - TengcoNo ratings yet

- Saudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Document1 pageSaudi Arabian Oil Company: CA-932993 001 A 656 Restricted 00Mohamed Wasim ShaikhNo ratings yet

- PHC Pile Model2Document1 pagePHC Pile Model2Chan ThornNo ratings yet

- Job No. 25800: Quebrada Blanca Fase 2Document1 pageJob No. 25800: Quebrada Blanca Fase 2Ricardo Alberto Zapata Balcazar100% (1)

- Angloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Document1 pageAngloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Pedro ChaucaNo ratings yet

- Telecome MapDocument1 pageTelecome Maploc khaNo ratings yet

- 230510-MS-LS-500-9F-T Detailed Sections R01Document1 page230510-MS-LS-500-9F-T Detailed Sections R01Mateen JawreNo ratings yet

- File - 20220523 - 210015 - Pid FGDDocument11 pagesFile - 20220523 - 210015 - Pid FGDThắng NguyễnNo ratings yet

- Mulimbayan Residence - PL (For Construction)Document7 pagesMulimbayan Residence - PL (For Construction)Jhanchris CortezNo ratings yet

- T-101 Process Water Tank X-101 PET Flakes Extruder X-102 PET Flakes Microgranulator BR-101 PET-Enzyme Batch BioreactorDocument1 pageT-101 Process Water Tank X-101 PET Flakes Extruder X-102 PET Flakes Microgranulator BR-101 PET-Enzyme Batch BioreactorbarrozomariakatrinaNo ratings yet

- Balustrade Detail - 2: Arch. Nathaniel B. Lazona, Lra Proposed Two Storey ApartmentDocument1 pageBalustrade Detail - 2: Arch. Nathaniel B. Lazona, Lra Proposed Two Storey ApartmentbarrozomariakatrinaNo ratings yet

- Arts 7 Week 5Document26 pagesArts 7 Week 5barrozomariakatrinaNo ratings yet

- Adobe Scan Nov 06, 2023Document13 pagesAdobe Scan Nov 06, 2023barrozomariakatrinaNo ratings yet

- Hydraulics Lab Manual - PandemicDocument12 pagesHydraulics Lab Manual - PandemichghvtfNo ratings yet

- Aluswirler Chips en 02 10Document2 pagesAluswirler Chips en 02 10Tuyen NguyenNo ratings yet

- Fortpro Water Pumps PDFDocument1 pageFortpro Water Pumps PDFhebert perezNo ratings yet

- Sambeiro Close Revised Plumbing Bill 2Document7 pagesSambeiro Close Revised Plumbing Bill 2Dapo AlimiNo ratings yet

- CPT 0018 Commissioning Procedure of Fuel Oil System PDFDocument5 pagesCPT 0018 Commissioning Procedure of Fuel Oil System PDFsetiawanaji407No ratings yet

- Pulsafeeder OMNI DC2-DC6 Pump Manual PDFDocument46 pagesPulsafeeder OMNI DC2-DC6 Pump Manual PDFRoberto MejiaNo ratings yet

- 01) Transformer Lecture - 140305Document50 pages01) Transformer Lecture - 140305robert_candra_tarunaNo ratings yet

- Fire Retardant Hydraulic FluidsDocument12 pagesFire Retardant Hydraulic FluidsPRASAD SANAPNo ratings yet

- Air Conditioning and Ventilation System: Batangas State UniversityDocument23 pagesAir Conditioning and Ventilation System: Batangas State UniversityRenee CruzNo ratings yet

- Bernoulli ReportDocument4 pagesBernoulli ReportGabriel VaughnNo ratings yet

- Francis Turbines: - Examples - Losses in Francis Turbines - NPSH - Main DimensionsDocument39 pagesFrancis Turbines: - Examples - Losses in Francis Turbines - NPSH - Main DimensionsAnonymous vFgnnTkDNo ratings yet

- 3D Firefighting: Controlling The EnvironmentDocument29 pages3D Firefighting: Controlling The EnvironmentFagner CarmoNo ratings yet

- Detailed Component Specifications For 3Nm /H Oxygen GeneratorDocument3 pagesDetailed Component Specifications For 3Nm /H Oxygen GeneratorSapna TanejaNo ratings yet

- Lecture 13-Mathematical Modelling of Liquid Level SystemsDocument22 pagesLecture 13-Mathematical Modelling of Liquid Level Systemssdp071660100% (1)

- PT. Transco Energi Utama. POM: Diagram Alir ProsesDocument1 pagePT. Transco Energi Utama. POM: Diagram Alir Prosesharry mahyudiNo ratings yet

- Micromachines 13 00224 v3Document17 pagesMicromachines 13 00224 v3Safdar AbbasNo ratings yet

- Artificial LiftDocument7 pagesArtificial LiftShakerMahmoodNo ratings yet

- Line DefectsDocument4 pagesLine DefectsYugendranNairNo ratings yet

- Eccentric Reducer Dimensions and Weight ChartDocument3 pagesEccentric Reducer Dimensions and Weight Chartrakhikishore143No ratings yet

- Homework 2Document2 pagesHomework 2Tien NgNo ratings yet