Professional Documents

Culture Documents

000-P310-RA-Format-CCTV, ANPR Installation

Uploaded by

MITHUN RAJOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

000-P310-RA-Format-CCTV, ANPR Installation

Uploaded by

MITHUN RAJCopyright:

Available Formats

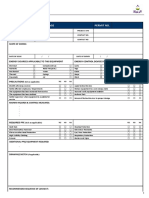

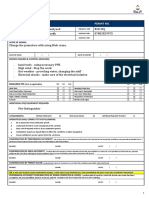

Ref. No.

GEN-WS-HSE-FOR-012

Date: 25-11-2023

RISK ASSESSMENT

MAINACTIVITY: Installation of CCTV camera,ANPR with cabling RA No

AL FURJAN PACKAGE 15

LOCATION: Landscape area, Control room PROJECT: DATE: 25/11/2023

EQUIPMENT TO BE USED SUBSTANCES TO BE USED REVISION STATUS

• Technician Tools Box. REVISED DATE

• Mobile Ladder /Scaffold / Measuring tape

Step Ladders if required. Scaffolding materials,

• Wiring spring.

Ladder

• Screwdriver sets. First Issue

Cat6A and Fiber cables 00

Wire Stripers/cutter

Fluke tester and OTDR

tester equipment’s

POTENTIAL HAZARDS / CONDITIONS CONSIDERED (TICK BOX) PERSONS AT RISK (TICK BOX)

☒WORKING FROM HEIGHT ☒ ELECTRICITY ☒ HAND TOOLS ☒MATERIAL ☒CONFINED SPACE ☒EXCAVATION/BACK FILLING ☒EMPLOYEES ☐PUBLIC

HANDLING

☒FALLING MATERIALS ☒ MANUAL HANDLING ☒PEDESTRIAN ☒NOISE & VIBRATION ☒ HAZARDOUS SUBSTANCES

☒FATIGUE ☒SUBCONTRACTORS ☐VISITORS

☒MACHINERY/EQUIPMENT ☒ SLIPS / TRIPPING ☒ SITE VEHICLE ☐ HEAT EXHAUSTION ☒ENVIRONMENTAL

☒SECURITY (Use Environmental Impact-

☒FIRE RISK ☒ACCESS/EGRESS ☒MATERIAL STORAGE Severity Rating Section for these

☒ADVERSE WEATHER ☐STAKE HOLDERS ☐OTHERS

☐ LIFTING HAZARDS)

OPERATION

MANDATORY HSE REQUIREMENTS (TICK BOX)

☒ ADEQUATE ☒WORK PERMIT

☒SAFETY INDUCTION ☒PROPER TOOLS / EQUIPMENT ☒SUPERVISION

VENTILATION

☒TOOLBOX TALK ☒TASK-SPECIFIC PPE ☒BARRICADES, WARNING SIGNS IN THE AFFECTED AREA

☒DUST CONTROL ☒TASK LIGHTING

PERSONAL PROTECTIVE EQUIPMENT (PPE) REQUIREMENT (TICK BOX)

☒SAFETY HELMET ☒GOGGLES / SAFETY GLASSES ☒RESPIRATORY PROTECTION / BREATHING ☒GLOVES ☒ OVERALLS

APPARATUS

☒SAFETY BOOTS ☒EAR PLUGS / DEFENDER ☒FULL BODY SAFETY HARNESS ☒HIGH VIZ SAFETY JACKET ☐WELDING/METAL CUTTING PPE

TO REFER TO OTHER RISK ASSESSMENTS OR ANY LEGAL REQUIREMENTS

1. Comply with DM CoP Requirements, Trakhees - HSE Requirements and Project HSE Management Plan

RISK ASSESSMENT TEAM OFFICIAL SIGNATORIES FOR THE RISK ASSESSMENT

Sr # Name Designation SIGNATURE: ASSESSED BY (name) Designation SIGNATURE: DATE:

1 MITHUN APPROVED BY (name) Project Director 25/11/2023

Project Manager

2 Waqas Siddiqui APPROVED BY (name) Construction Manager 25/11/2023

HSE dept.

3 REVIEWED BY (name) Project HSE Manager 25/11/2023

HSE Manager

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

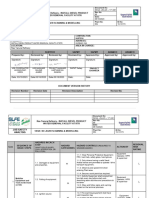

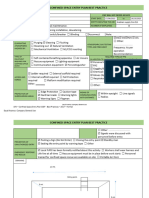

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

Demonstrated

Potential Residual Risk

Risk H / M / H/M/

ALARP

L With no Existing Barrier or L

Cause Consequences controls in with controls

Job Step Hazard Controls Recommended Controls

Sequence of place in place

# Possible causes The harm which Action By

working The potential to cause Describe all existing Describe additional controls that

that will could possibly

activities harm. Health, Injury, barriers /controls for are required

potentially occur

Property damage, each hazard Yes\

release a hazard S P PR S P RR

environment etc. No

1. Fatality, partial or Personnel 3 2 6 • All workers must be • Proper coordination and PE/SE/ 3 1 3 YES

permanent injury, Head adequately HSE necessary permission shall be Sup

disability inducted with proper obtained with concerned prior

Injury, fracture,

Eye injury, Hand TBT and awareness. to bring the vehicle inside the

Vehicle incidents due to Injury • Ensure all vehicles have site.

vehicle forward/ Reverse Major/Minor access pass for entering Restrict the trailer/heavy vehicle

movements. the site. movement inside the project site

injury near duty start / finish times,

Ensure separate way for

vehicles /equipment’s and breaks, restrooms, and main exits,

pedestrians. particularly when the flow of

workers on foot is at a peak (such

as at the end of a shift or during

breaks).

Access to

Personnel • Designated materials • Work area to be kept clear of

Worksite and

injury, Head storage area and non-essential tools &

Work Area

Injury, fracture, pedestrian access. equipment.

, Hand Injury • Sufficient light on traffic • Access to be clear from any

Major/Minor ways and sign boards. obstruction.

injury • Ensure PPE (safety shoes,

Slip, Trip & Fall Minor injury, cut/ helmet, jacket, safety glasses, PE/SE/

2 2 4 2 1 2 YES

bruises. gloves etc.) worn for the Sup

workplace.

• Ensure the method of statement

& risk assessment briefing to all

workers.

Ensure competent supervision and

competent operatives are in place.

Personnel • Ensure Pre – task briefing. YES

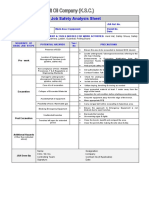

Personal injuries, injury, Head • Vehicle must be • All vehicle/heavy equipment shall

Delivery of Falling of objects. PE/SE/

2. damage to Injury, fracture, 3 2 6 registered and driver be fitted with reverse alarm. 3 1 3

materials. Sup

property Eye injury, Hand license to be ensured. • Follow vehicle routes and speed

Injury limits.

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

Major/Minor • Visitor induction must be • Vehicles to be parked in the

injury delivered and provide all designated parking/unloading

necessary barricades. areas.

. • Permit to work should be • Transport assembly area must be

in place. cordoned off.

• Competent banks man • Only the essential personnel shall

shall control heavy be allowed to approach the

equipment / vehicle working area.

movement inside the • Ensure Plant Equipment

site. checklist.

• Barricade and sign board • TBT must be conducted and

provided. attached with PTW.

• Provided designated • Ensured and advised proper

watchman. material stacking with necessary

Ensured all the workforce support and make sure no any

must be mandatory HSE heavy material stacked above

inducted and job-oriented shoulder level.

TBT delivered by

• Worker should be legally

competent supervisor.

appointed with their valid

company I.Ds.

• Enforced only competent

workforce only.

All crew appointed must be well

known about the standard

operating procedures, types of

potential hazards and as well

actual hazards.

• Start unloading works after

Personnel switching off the engine and YES

• Ensure the availability of providing hand brakes.

injury, Head

Flagman. • Only experienced and trained

Injury, fracture,

• Permit to work must be workmen to be engaged.

Fatality, partial or Eye injury, Hand PE/SE/

Personnel being struck in place. • Use proper access provided in the

permanent Injury • Ensured job-oriented

by vehicle / equipment. 3 3 9 vehicles. 2 2 4

disability, damage Major/Minor Sup

to property training to workforce and • TBT must be conduct regarding

injury mandatory HSE induction job task by competent

for entire crew supervisor.

All area must be barricades with

caution sign boards.

Personal injuries Personnel • Ensured all the work • Per job induction must be YES

Sharp objects PE/SE/

i.e. cut, wounds, injury, Head 3 2 6 crew is trained by conducted by competent 3 1 3

Sup

bruises, laceration Injury, fracture, mandatory HSE induction supervisor.

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

Eye injury, Hand as well job task specific • All sharp object must be covered

Injury training. or eliminate before starting the

Major/Minor Permit to work must be in work.

place • Where the size, surface texture

injury

or nature of a load makes it

difficult to grasp consideration

should be given to the handles.

• TBT must be conducted with

proper manual handling

briefings.

Use EN standard hand gloves.

Personnel • Ensure proper material stacking YES

injury, Head necessary support and make sure

Injury, fracture, • Ensured job-oriented no any heavy material stored

Fall hazards due to Minor injuries, training to workforce and over shoulder level.

Eye injury, Hand PE/SE/

improper material cut, abrasion, mandatory HSE induction All Workers assigned for this task

Injury 3 2 6 must be safety inducted also they Sup 2 1 2

stacking minor or major for entire crew.

Major/Minor will have to attend specific

injuries • Permit to work should be

injury. training which will include the

in place.

standard operating procedures,

types of potential or actual

hazards peasant.

• All Workers assigned for this task YES

must be safety inducted also they

will have to attend specific

Storage of

training which will include the

material, lifting,

standard operating procedures,

shifting

3. Personnel types of potential or actual

(Manually and

mechanically) injury, hazards peasant.

Back pain, • Ensured job-oriented • All work crew assigned for task

Sprain, training to workforce and must be trained with manual

Improper work poster fracture, Hand mandatory HSE induction handling and competent.

Strain, sprain to PE/SE/

during manual handling muscles Injury

3 2 6

for entire crew. • In case mechanical handling Sup

2 1 2

Major/Minor • Permit to work should be rigger to be posted.

injury in place. • Rigger must be competent by

EIAC/OSHAD approved 3rd party

training.

• Proper way of communications

should be follow.

TBT or pre-job task induction must

be conduct by competent

supervisor

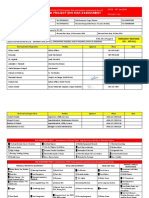

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

• Regular inspection of the area. YES

• All cutting or remaining parts

Personnel

must be packed into one plastic

injury, Head bag and parodically remove from

Slip trip,

Injury, fracture, Ensured all the the site.

, Hand Injury PE/SE/

Improper housekeeping Environmental housekeeping and waste • All small cutting pieces of PVC

3 2 6 Sup 2 1 2

damage, damage Major/Minor material cleared and pipes must keep in one plastic

to property injury properly disposed. bag to avoid any slip trip hazards.

Remove all unsafe or unwanted

material to avoid all fire or other

potential hazards.

• Adequate supervision with clear YES

information and instruction.

Personnel • Uncoil complete length of cable

injury, Head before connecting or switching

Injury, fracture, Ensured the use of

on.

, Hand Injury industrial sockets All the • Competent electrician to provide

Major/Minor electrical distribution temporary electrics to the station

Electrocution injury board supply board of work and ensure proper sound PE/SE/

Electrical hazards

Fatality. 3 3 9 equipped with RCD and connections. Ensure Permit to Sup 3 1 3

Property damage Property ELCB. Appointed Work (PTW) prior to start the

damage competent electrician and

activity.

maintenance records are in

Electric shock place • All the hand-held power tools

can lead to which used in the projects are

Usage of Hand death 110 V

tools and Power In case of any sub sequent use of 220 or

4.

tools (drilling) 415V will be used by the approval and

permission from the engineer.

Personnel YES

injury, Head

Injury, fracture,

• Inspection records are

Deep cut injuries , Hand Injury

available Any defective tools immediately

Improper use of hand to Hands. Major/Minor

Competent person removed from the site. Ensure CH/SE/PE/CM.

tools Injuries to injury 3 2 6 3 1 3

appointed for the competent person and trained for the

another body

inspection and task.

parts. Property

maintenance.

damage

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

• All the work crews are YES

Poor quality of Personnel adequately trained

work, chance for injury, Head through induction,

accident /incident Injury, fracture, awareness and tool box

or property

, Hand Injury trainings

Lack of Supervision

Major/Minor • Permit to work system in CH/SE/PE/CM

injury 3 2 6 place. 3 1 3

All the supervisors are • Ensure the availability of

Property trained and competent to competent supervisor at work

damage conduct the work under place.

the developed safe work Work task instruction should be

procedure. provided to the workers prior to the

commencement of activity

Personnel • Fire risk assessment and YES

• Follow NO SMOKING policy.

injury, Head control measures are

• Provide appropriate fire

Injury, fracture, developed.

extinguishers points for

• Adequate fire points are

, Hand Injury emergency responding.

Fire incidents. provided.

Fire hazard Major/Minor • Don’t store any flammable CH/SE/PE/CM

Burns and injuries 3 2 6 • Fire evacuation routes 3 1 3

injury materials nearby wood cutting

are identified with

area.

Property appropriate sign boards

Sufficient Fire wardens should be

damage Fire assembly points are

appointed.

provided

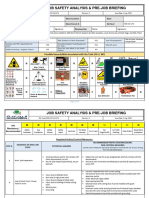

• Competent workmen to be YES

Personnel allowed to perform work.

injury, Ear • Proper Supervision.

injury, • Use of the correct PPE. (helmet,

Dust generation

Major/Minor safety shoes, gloves, goggles, ear

due to drilling Silicosis Noise & dust control PE/SE/

5. Dust Hearing plug, mask, Hi Vi vest)

activities & noise injury 3 2 6 needs to be monitored. Sup 2 1 2

impairment • Regular servicing of the

Noise

Property equipment and maintenance as

damage per operational manual.

Implement proper housekeeping.

Personal injury YES

Working at Height Personal injury

Installation of Fracture • PTW system in place. • Toolbox talks to be given

Fall of persons from Fracture

CCTV & ANPR Fatality • TBT & DSTI procedure in • Ensure safe access and egress.

height. Fatality PE/SE/

Property damage

6. cameras on poles Falling of materials/tools. Property damage 3 2 6 place. • Ensure Podium ladder in good Sup 3 1 3

Falling from

and ceiling with Collapse of Scaffold. Falling from Procedure of for Method condition prior to use.

height

the Toppling of scaffold. height Statement & Risk • Don’t use “A” type ladders.

Falling objects

Poor Platform. Falling objects

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

Use of Hand Tools Assessment, Work • Aluminum ladders are

Scaffolding & Notification in place. prohibited to use in Live

Ladders Energized Electric Facilities Area.

• Ensure to use fiber ladders and

platforms to perform activity

with/ nearby live electric facility.

• Podium Ladders & scaffolds to

be inspected prior to use and

color tag (safe to use) to be on

the ladder.

• Ensure that podium ladder is

free from damage (crack, splits,

holes, etc.).

• Ensure that non-slip base

(rubber shoes) is provided to

Podium ladder.

• Proper supervision on the place.

• Always have two hands free to

climb up and down.

• Scaffold Inspectors must be

certified by the approved third

party and have deep knowledge

of erection/ dismantling.

• Planks/ ledgers shouldn’t be

painted or damaged.

• Mobile Scaffolds must not be

moved while occupied.

• Castor wheels must be locked in

the mobile scaffold.

• Adjacent work activities are

considered before starting the

work.

• Task performing area must be

barricaded and sufficient signage

provided.

• Never overload scaffold.

Never move the scaffold with

person on platform.

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

• TBT must be conducted by

concern supervisor prior to start

the activity.

• Avoid working in extreme

temperature if possible.

• Adequate provisions of cool

drinking water/consuming

drinking water regularly +

electrolyte drinks to replenish

Personnel electrolytes lost due to sweat.

injury, Heat • Keep your body covered with

Stroke,Fainting, long sleeved shirts and trousers.

Head Injury, • Covering of body will stop most

Working in

adverse fracture, , Hand Regular work breaks & job of the Ultra Violet light and

Heat related injuries, Heat Stroke, PE/SE/

Weather Injury rotations must be reduce the possibility of

7. stress Fainting, 3 2 6 Sup 3 1 3 YES

conditions Major/Minor maintained. contracting skin cancer.

injury • Sunburn can be caused by glare

from an overcast sky, there

Property doesn’t need to be direct

damage

sunlight.

• Fair skinned people burn more

easily so avoid work outside

areas.

• Pedestal fans/exhaust fans will

be available all the time if the

working temperature exceeds.

• Avoid lone working.

Adequate supervision must be

available all the times.

• Noise will be limited to less than

• Adequate PPEs must be 80db where possible.

Hearing loss, worn by all.

Hearing loss, • Provide shaded work area as

respiratory

respiratory • Working area to be much as possible.

problem, problem, cordoned off • Provide cool & air-conditioned

Dust, High noise level, coughing, coughing,

Environmental • Waste to be regularly rest areas with water or PM/PE/SE/

poor air quality. sneezing, sneezing, 3 2 6 removed from site. 3 1 3 YES

8. Impacts Excessive heat irritation, Heat electrolyte drinks available. Sup

irritation, Heat Signages will be in place. In

stress, heat • General awareness training

stress, heat area of high noise, ear

exhaustion, exhaustion, related to heat stress to be

Fatigue etc. protection will be required provided for exposed workers.

Fatigue to enter.

• Ensure availability of enough

cold drinking water for all.

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

Provide frequent breaks &

minimize exposure time.

• Ensure enough number of

trained/ certified fire wardens

available at workplace & store

areas.

• Ensure appropriate and enough

number of inspected & color-

coded fire extinguishers are

available.

• Fire prevention preparedness

inspection to be conducted by

competent person.

• Ensure emergency contact

• Ensure DSTI/TBT number is available at all

procedure in place. workplaces.

Personnel • Project emergency plan • Ensure availability of emergency

injury, Head in place & followed alarm system.

Lack of emergency Personnel Injury, Injury, fracture, during emergency, if any • Ensure designated assembly point

Emergency evacuation plan Fire or any , Hand Injury & should be addressed is available. PM/SE/PE

9 3 2 6 2 1 2 YES

Procedures Slip/ Trip emergency Major/Minor through TBT / safety • All activities to be stopped and Sup

injury meetings. area to be evacuated in case of

Ensure all access/egress any emergency.

must be free from • Concerned authority to instruct

obstacles at all times. all personnel to reach the nearest

assembly points as quick as

possible.

• Competent supervisor should be

available at site all times.

• Procedures/ escape routes and

assembly points should be

identified and communicate to all

personnel and maintained.

• Safety personnel should be

available on site.

Periodically inspection of fire

protection system carried out &

record maintained.

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

Ref. No. GEN-WS-HSE-FOR-012

Date: 25-11-2023

000/ P 310/ Risk Assessment for /00-00-2023/Rev0

You might also like

- Concise Encyclopedia of System Safety: Definition of Terms and ConceptsFrom EverandConcise Encyclopedia of System Safety: Definition of Terms and ConceptsNo ratings yet

- RA0128 - Installation of UPS SystemDocument17 pagesRA0128 - Installation of UPS SystemExplore the world TodayNo ratings yet

- Jsa Centrifugal PumpDocument1 pageJsa Centrifugal PumpShubham Gupta50% (2)

- Project Construction EHSS RISK Assessment-1Document11 pagesProject Construction EHSS RISK Assessment-1shoaib akhtarNo ratings yet

- Isolation Permit/ High Voltage Permit NoDocument2 pagesIsolation Permit/ High Voltage Permit NoMohammed KadhimNo ratings yet

- Safe Work Method Statement: Work Activity: General LiftingDocument15 pagesSafe Work Method Statement: Work Activity: General LiftingMazhar Kaleem100% (1)

- Risk Assessment For Using An Excavator As A Lifting ApplianceDocument2 pagesRisk Assessment For Using An Excavator As A Lifting AppliancezaimNo ratings yet

- Job Safety Analysis: SKSA-JSA-23 - 171-001 00 05/10/2023 10-13173Document7 pagesJob Safety Analysis: SKSA-JSA-23 - 171-001 00 05/10/2023 10-13173skmohdmusthafaNo ratings yet

- Jsa Demolish of Existing Armor RockDocument2 pagesJsa Demolish of Existing Armor Rockabdan adly TNo ratings yet

- JSA - Main Turbine Lub Oil Pumps - OHDocument2 pagesJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- Form-Safety-JSA LoggingDocument2 pagesForm-Safety-JSA LoggingMohammed BaderNo ratings yet

- Plant Risk Assessment Form: Auger Drill and Drive AttachmentsDocument12 pagesPlant Risk Assessment Form: Auger Drill and Drive AttachmentsragNo ratings yet

- SGCMC-Tool Box Talk-OSH-FRM-03Document3 pagesSGCMC-Tool Box Talk-OSH-FRM-03rizvidawar221No ratings yet

- TCF & Civil Works - JSADocument42 pagesTCF & Civil Works - JSASiraj Mohamed IkbalNo ratings yet

- 08b Supbook JSADocument1 page08b Supbook JSAMohammed MinhajNo ratings yet

- Jsa MV Cable Pulling, Termination and TestingDocument11 pagesJsa MV Cable Pulling, Termination and TestingMohammad AqilNo ratings yet

- NEWT Area RA Updated 17.11.2020 - TK-105Document11 pagesNEWT Area RA Updated 17.11.2020 - TK-105Sidney Navarro UmaliNo ratings yet

- Pre-Job Hazard AnalysisDocument4 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- JSA-174.Confined Space EntryDocument3 pagesJSA-174.Confined Space Entryghazi4u100% (1)

- 009 ABGJHA009 Concrete WorksDocument4 pages009 ABGJHA009 Concrete WorksALBILAL HSENo ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- Permit To WorkDocument1 pagePermit To WorkMohammed KadhimNo ratings yet

- Module 09 QRA Training PresentationDocument30 pagesModule 09 QRA Training Presentationankitalalwani100% (2)

- JSA Loading & UnloadingDocument2 pagesJSA Loading & UnloadingSodikinNo ratings yet

- Risk Assessment No 01 Anchor Handling in General Rev 03Document5 pagesRisk Assessment No 01 Anchor Handling in General Rev 03Bhaskar AgnihotriNo ratings yet

- Methodology of Work and Sequence of ActivitiesDocument6 pagesMethodology of Work and Sequence of ActivitiesAmitNo ratings yet

- 8.ALFA - 1-11-22-R0 - RA - Instalation of FanDocument9 pages8.ALFA - 1-11-22-R0 - RA - Instalation of Fanfloredex005No ratings yet

- ALFA - 1-11-22-R0 - RA-Lifting ActivityDocument8 pagesALFA - 1-11-22-R0 - RA-Lifting Activityfloredex005No ratings yet

- 7.ALFA - 1-11-22-R0 - RA - Cable Tray IntalationDocument9 pages7.ALFA - 1-11-22-R0 - RA - Cable Tray Intalationfloredex005No ratings yet

- PTW Form PredsolDocument2 pagesPTW Form PredsolNamig BabazadehNo ratings yet

- RA 003 - Sea Outfall Drainage Pipe InstallationDocument8 pagesRA 003 - Sea Outfall Drainage Pipe Installationsedat.cotNo ratings yet

- Csep RC#42Document3 pagesCsep RC#42ashish kumarNo ratings yet

- Daily Safety Inspection ChecklistDocument2 pagesDaily Safety Inspection Checklistarunjith r0% (1)

- Workplace Hazard Identification & Assessment SheetDocument3 pagesWorkplace Hazard Identification & Assessment SheetTawsif Ahmed100% (1)

- Rse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerDocument2 pagesRse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerOws Anish100% (1)

- PTW 0 Certificate Forms WP 2 25-01 Okt 2023 Nopia UpdateDocument301 pagesPTW 0 Certificate Forms WP 2 25-01 Okt 2023 Nopia UpdateRizky Pratama NNo ratings yet

- Sow Lab Mechanical ElectricalDocument18 pagesSow Lab Mechanical Electricalazhar khanNo ratings yet

- SAFETY Work Methodology of Installation of Fire AlarmDocument3 pagesSAFETY Work Methodology of Installation of Fire AlarmAlvin PangilinanNo ratings yet

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- Risk Assessments - PageDocument1 pageRisk Assessments - PageQays YousefNo ratings yet

- Enerfab JSADocument2 pagesEnerfab JSAelvandiNo ratings yet

- JSA Hydro ExcavateDocument3 pagesJSA Hydro Excavatearnel_ado4412100% (3)

- Confined Space Entry Plan Best Practice Form (For QJ-1R Lateral Line-JTF) Upto-07.08.2021Document7 pagesConfined Space Entry Plan Best Practice Form (For QJ-1R Lateral Line-JTF) Upto-07.08.2021Mohammad Anwar Hossain100% (1)

- Imb SH Hse 0024 01Document19 pagesImb SH Hse 0024 0101095902062ahmedNo ratings yet

- Whs f014 Safe Work Method Statement FormDocument9 pagesWhs f014 Safe Work Method Statement FormTamo Kim ChowNo ratings yet

- Carbon Steel PIPE Installation JHA - MTMDocument17 pagesCarbon Steel PIPE Installation JHA - MTMtahir khanNo ratings yet

- Hirarc Form Amirah AmigosDocument1 pageHirarc Form Amirah Amigosڤوتري جنتايوNo ratings yet

- JSA Finishing Temporary FacilitiesDocument6 pagesJSA Finishing Temporary Facilitiesjet Louis Magallones100% (1)

- RA 13 Belle Vue AvenueDocument5 pagesRA 13 Belle Vue AvenueJoshHumphreyNo ratings yet

- JHA ConcretingDocument3 pagesJHA Concretingfatimah beluhi75% (4)

- CHRC SWMS Excavation Activities PDFDocument6 pagesCHRC SWMS Excavation Activities PDFBorislav VulićNo ratings yet

- 12 N9-Job Safety FOR CLEANING CASINGDocument4 pages12 N9-Job Safety FOR CLEANING CASINGkhurramNo ratings yet

- Risk AssessmentDocument3 pagesRisk Assessmenteeetete24No ratings yet

- Job Safety Analysis: Location Date New Revised Jsa No. Task Supervisor Analysis by Approved byDocument2 pagesJob Safety Analysis: Location Date New Revised Jsa No. Task Supervisor Analysis by Approved byDavid GlawsonNo ratings yet

- RA Sandblasting and Painting of SheetsSpoolsDocument3 pagesRA Sandblasting and Painting of SheetsSpoolshashibpervez.shvenergybdNo ratings yet

- WP 0094 2023 06 2792Document2 pagesWP 0094 2023 06 2792killuaNo ratings yet

- Working at HeightDocument2 pagesWorking at HeightMohammed KadhimNo ratings yet

- Manual Excavation JSADocument1 pageManual Excavation JSATausif Khan100% (2)

- Job Safety Analysis Sheet: Manual ExcavationDocument1 pageJob Safety Analysis Sheet: Manual Excavationwahyu nugroho100% (1)

- Risk AssessmentDocument4 pagesRisk Assessmenthaythamabdeldayem100% (1)