Professional Documents

Culture Documents

FD460TH

Uploaded by

dedehamzah225Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FD460TH

Uploaded by

dedehamzah225Copyright:

Available Formats

Cab use box assemb y Chass s use box assemb y

A B

1 2 1 2 3

C E G

D

4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 3 4

1 2 3 1 2

30 30 30 30 30 30 30

86

87a

85 86

87a

85 86

87a

85 86

87a

85 86

87a

85 86

87a

85 86

87a

85 H K L M

87 87 87 87 87 87 87 3 4 7 8 9 10 11 12

5 4 3 2 1

1 2 3 4

1 2 10 9 8 7 6 1 2 3 4 5 6

5 6 7 8

87 87 87 87 87 87 87

87a 87a 87a 87a 87a 87a 87a P Q R

85 86 85 86 85 86 85 86 85 86 85 86 85 86

N T

30 30 30 30 30 30 30 5 6 7 8 3 4 3 4

1 2 3 4 1 2 3 4 1 2 1 2 1 2 3 4 5

V 3722010-92W/C

A.3

CA4251P66K25T1E5_Z00014_01

20161208

CA4251P66K2T1A2E4_Z00002_04

20160922

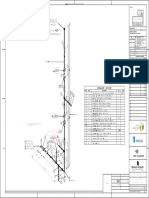

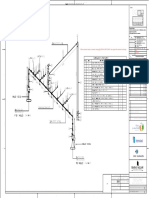

ns rumen assemb y d agram R gh chass s w ng ha ness assemb y

DJ431-6C

CA4250P66K24T1A7E5_Z00008_01

20170223

Le doo ha ness assemb y R gh doo ha ness assemb y

A cond on ng w e ha ness assemb y W ng ha ness assemb y o ea ax e

Evaporator temperature sensor Internal and external loop steering Water valve motor

Side defrost motor Front defrost motor

Ventilator and speed control resistor

Control panel 1

Sheath:

Terminals:

Observation Direction and Measuring Point of Sheath

sheath

Outlet end Inlet end

View Direction Wireway

Dimensional boundaries

Speed regulating module

Dimension measuring point

Semi-overlapping coating of wear-resistant cloth-based tape for conductors

Semi-overlapping tape gluing for wire,Flannel tape according to Q/CAM-371

Unprotected wires

Conductor for surface binding of PVC tape,PVC tape according to JF03-76

(Leave bare line on head over 100 mm, 50 mm on head below 100 mm, 30 mm on head below 100 mm)

Connect the car body with a wire beam.

Except for special requirements for bellows diameter,The filling rate of conductor relative bellows is 70%-80%.

Except for special provisions,Wires wrapped with bellows,The bellows are wrapped in the following way ("L" means the length of the bellows):

1、L〉100mmUse spacer coating,The distance between coatings is 50mm, with at least 3 windings.

2、L≤100mmUse spacer coating,The encapsulation position is in the middle of the dimension, winding at least 3 circles.

Solder joints are the joints of the same functional conductor.

Distribution of line number connectors in corresponding sheaths,Look from the end of the line

Line number

Length measurement refers to the measurement point to the measurement point.,

Or the distance from the measuring point to the conductor terminal Body wire harness Speed regulating module Control panel1

The dimension of the injection is the length dimension of the wire after straightening out., Control panel1 Body wire harness

One end is the connector.,Its length is measured from the root of the socket inlet end.

Body wire harness Speed regulating module Control panel1

Blind plugging is needed for unused holes in waterproof connectors

Speed regulating module Control panel1

At the end of the insulating pipe and the branch of the conductor, tie with tape

Control panel1 Water valve motor

One-point welding of trunk lines and their branches (except CAN lines)

Twisted pair pitch (27-33) twist/m Control panel1 Control panel1 Water valve motor

Conductor and terminal are crimped Control panel1 Control panel1 Body wire harness

Single-layer V-type heat-shrinkable tube for compression joint of single (special) terminal and conductor

Control panel1 Control panel1 Speed regulating module

Double-layer heat-shrinkable pipe protection for wire solder joint in wire harness Control panel1 Control panel1 Water valve motor

Plug in QC/T 417,Among them, the surface of the metal terminal is tin plated, Control panel1 Contro Body wire harness

copper/Ep.Sn9, according to Q/CAYT-4.12.

Control panel1 Body wire harness Body wire harness

Thin-walled polyvinyl chloride conductors are used for all conductors,According to QC/T 730, B

Control panel1 Body wire harness

Technical conditions according to QC/T 29106

Control panel1

Samples must be re-examined by product design department before starting supply.

Control panel1 Water valve motor

Trailer socket harness assembly for ABS Beam Assembly in front of cab

Dashboard wire harness

Line number Core cross sectional area(mm²) colour remarks

(green)

(gray)

Inner core:

Inner core:

Cover Observation Direction and Measurement Point

Cover.

Outlet Line End

View Direction wire

Size Limits

Brake light switch Clutch switch

Dimension measuring point Right door wire harness (gray)

Cover:

Tail protection:

Left door wire harness

Trailer power outlet for ABS Location card: Cover:

Tail protection:

Air-conditioning Location card:

low-voltage switches Scratching motor

Distribution of line number connectors in corresponding sheaths,Look from the end of the line (Shenzhen Jijia Baowei Co. , Ltd. )

Length measurement refers to the measurement point to the measurement point., Water level alarm switch

Or the distance from the measuring point to the conductor terminal Chassis harness

Cover Observation Direction and Measurement Point

The dimension of the injection is the length dimension of the wire after straightening out., Outlet

Cover.

Line End

One end is the connector.,Its length is measured from the root of the socket inlet end. View Direction

wire

Blind plugging is needed for unused holes in waterproof connectors Size Limits

Plug-in feature number(corresponding to the selection relationship list)

No special instructions for plug-in Hebi Tianhai Electric Appliance Co. , Ltd. , Zhengzhou Lianming Electric The wire beam label, the label content is shown in "XXXXX", the label content is clear,

Appliance Co. , Ltd. and Ningbo Zhengyao Automobile Electric Appliance Co. , Ltd. Paste position(30-100) mm away from the end of the branch socket feed

Size measurement point

Single-layer V-type heat-shrinkable tube for compression joint of single (special) terminal and conductor Semi-laminated tape with wear-resistant cloth for wires

Thin-walled polyvinyl chloride conductors are used for all conductors,According to QC/T 730, C After the wire is covered with a semi-overlapping type of wear-resistant cloth base tape,

tie the open corrugated pipe;

Unprotected wires

Plug in QC/T 417,Among them, the surface of the metal terminal is tin plated,

copper/Ep.Sn9, according to Q/CAYT-4.12. Traverse with PVC tape semi-overlapping plastic, more than 100mm head left bare line 50mm,

100mm below the head 30mm Scrubbers

At the end of the insulating pipe and the branch of the conductor, tie with tape Wire bound with PVC sleeve Line number Wire function Conductor cross-sectional area(mm²) colour remarks Line number Wire function Conductor cross-sectional area(mm²) colour remarks code number number remarks

Dashboard wire harness Left door, wire harness. Dashboard wire harness Left door, wire harness.

Bind wires with open bellows Left door, wire harness.

If there is a clear manufacturer's note on the connector,

soldered dot Right door, wire harness. Dashboard wire harness

Dashboard wire harness Right door, wire harness. Dashboard wire harness Right door, wire harness.

After the wire is semi-stacked with wear-resistant cloth base tape, bind the open corrugated pipe,

it should be followed, for example: and use the wear-resistant cloth base tape semi-overlapping tape outside the corrugated pipe. soldered dot Left door, wire harness. Dashboard wire harness Right door, wire harness.

1928 40 4195 (Bosch Company), etc In addition to the special requirements for corrugated tubes and zippered PVC tubes,

the required lead to the corrugated pipe, zippered PVC tube fill rate of more than 50 <UNK>

soldered dot Water level alarm switch Dashboard wire harness Left door, wire harness.

Except for special provisions, wires protected by a bellows or PVC zipper tubes are covered both inside soldered dot Scratching motor Dashboard wire harness Left door, wire harness.

Conductor and terminal are crimped

and outside the bellows or PVC zipper tubes as follows(`` L "indicates the length of the bellows): soldered dot Brake light switch

1, L 〉100Mm with interval plastic, plastic spacing 50mm, at least winding 3 laps;

Left door, wire harness.

Trailer socket harness assembly for ABS

Dashboard wire harness Water level alarm switch Dashboard wire harness

Technical conditions according to QC/T 29106 name 2, L ≤ 100mm with interval adhesive, adhesive position in the middle of the size, winding at least 3 laps

Dashboard wire harness Brake light switch Dashboard wire harness Left door, wire harness.

Welding point refers to the connection point of the same function wire

Dashboard wire harness Left door, wire harness. Dashboard wire harness Right door, wire harness.

The position of each line number socket in the corresponding sheath is viewed from the qualifying end

Samples must be re-examined by product design Length measurement refers to the distance from the point of measurement to the point of measurement,

Dashboard wire harness Left door, wire harness. Dashboard wire harness Right door, wire harness.

Left door, wire harness.

soldered dot Right door, wire harness. Dashboard wire harness

department before starting supply. or the distance from the point of measurement to the end of the wire

The size of the injection is the length of the wire after straightening. When one end is a plug, its length is measured from the end of the plug. Dashboard wire harness Left door, wire harness. soldered dot Right door, wire harness.

Holes not used for waterproof plugs need to be blocked with blind plugs Dashboard wire harness Right door, wire harness. Dashboard wire harness Left door, wire harness.

Security Number Processing Widget Document

At the end and branch of the insulated tube, bind with tape Dashboard wire harness Scrubbers Dashboard wire harness Left door, wire harness.

Drawing matters. of items methods version Version Diagram A total of 1 card

Main line and its branch lines are welded at one point(except CAN lines) soldered dot Scratching motor Dashboard wire harness Left door, wire harness.

Product Flower Drawing The twisted pair pitch is (27~33) twist / m Dashboard wire harness Scratching motor Dashboard wire harness Left door, wire harness.

Design XuiFeng reinspection nonmetal pattern Shade. categories Comparison The wire and terminal are connected by compression Dashboard wire harness Scratching motor Dashboard wire harness Left door, wire harness.

Single V-shaped heat condenser for single(special) terminals and wire compression Dashboard wire harness Scratching motor Dashboard wire harness Left door, wire harness.

heat Surface Drawing

PVC tape is F-PVC / 105 / R-Tx according to the specification in QC/T 29106 Appendix C Dashboard wire harness Scrubbers Dashboard wire harness Left door, wire harness.

Proofreading ZhangJinBo Weight treatment protection software

The bellows are UFW type bellows, according to Category A in Appendix D of QC/T 29106 Dashboard wire harness Air-conditioning low-voltage switches Dashboard wire harness Left door, wire harness.

Change of PVC casing in line with JF03-117 Dashboard wire harness Air-conditioning low-voltage switches Dashboard wire harness Right door, wire harness.

To examine LiGuoHui Notice Number In the abrasion-resistant tape, the tape size is P-PET/105 / R-TP according to the specification in Appendix C of QC/T 29106, Dashboard wire harness Right door, wire harness.

Wear resistance: When a = 10mm, the number of cycles & GT; 2000 times, when a = 5 mm, the number of cycles & GT; 1,000 times, Dashboard wire harness Left door, wire harness. Dashboard wire harness Left door, wire harness.

name Beam Assembly in front of cab

Number

Production

At the time of testing, take a length of about 10cm tape and stick it along the shaft to a steel rod with a diameter. Dashboard wire harness Left door, wire harness. soldered dot Right door, wire harness.

General layout ZhangYanHui material Impact swaps tag of posts date The test method and equipment press 9.3 in GB/T 25085, in which the diameter of the scratch needle is 0.45 mm. Security Number Processing Widget Document

Dashboard wire harness Left door, wire harness. Dashboard wire harness Clutch switch Establishment Tangchao matters. of items methods version Version Diagram A total of 1 card

Double layer heat condensation pipe protection at wire soldering point in wire beam, according to Category C in Appendix B of QC/T 29106 Product Flower Drawing

Correction. reinspection nonmetal pattern Shade. categories Comparison

soldered dot Right door, wire harness. Dashboard wire harness Clutch switch

preparation

Plug pressQC/T 417

Standardization YangChaoYang Review Weight

heat

treatment

Surface

protection

Drawing

software

Dashboard wire harness Left door, wire harness. Dashboard wire harness Brake light switch

China First Automobile Co., Ltd. Technology Center All conductors are PVC thin-walled conductors, press GB/T 25085 B

soldered dot Right door, wire harness.

General layout

Change of

Notice Number

Technical conditions QC/T 29106 standardization material Impact swaps tag

Number

of posts date

Approval JiaoXueMing Subcode Samples must be re-examined by the Product Design Department before starting supply Dashboard wire harness Right door, wire harness.

Jointly sign

FAW Jiefang Qingdao Automobile Co., Ltd

Dashboard wire harness Right door, wire harness. Approval Subcode

Transition harness assembly of

Elevated Box Wire Bundle Assembly 24 V power supply socket

Line number Wire function Cross sectional area of conductor (mm²) colour remarks

Left body wire harness Drive Log

Left body wire harness Drive Log

Left body wire harness Left front profile light

soldered dot Drive Log

Left body wire harness Drive Log

Left body wire harness Drive Log

Left body wire harness

Indoor lighting1

Door, alarm light.

soldered dot

Connected to instrument

Indoor lighting2

Left front profile light

soldered dot

soldered dot

panel wiring harness

Elevated box light1 soldered dot

Elevated box light2 soldered dot

Elevated box light3 soldered dot

Drive Log soldered dot

Left body wire harness Drive Log

Left body wire harness Door, alarm light.

Left body wire harness Door, alarm light.

Left body wire harness Left room light

(green) Left body wire harness Right room light

Left body wire harness Drive Log

Left body wire harness Door, alarm light.

soldered dot Elevated box light1

soldered dot Elevated box light2

soldered dot Elevated Box Light 2

Left body wire harness Drive Log

Left body wire harness Drive Log

Left body wire harness Left body wire harness

Twisted pair

Left body wire harness Left body wire harness

soldered dot Drive Log

Twisted pair

soldered dot Drive Log

Left body wire harness Drive Log

Left front profile light Left body wire harness Drive Log

Left body wire harness Drive Log

code number number remarks

Sheath:

terminal:

24 V power supply socket

Cover Observation Direction and Measurement Point

Cover Observation Direction and Measurement Point

Cover

Outlet

Cover

Outlet Line End Wire Cross sectional area

Line End

View Direction wire

Size Limits number Wire function of conductor (mm²) colour colour

View Direction wire

Door open alarm light Connected to instrument

Interior light on left Indoor light, right

Size measurement point 24 V power supply socket wire harness

Size Limits Connected to instrument

Unprotected wires 24 V power supply socket wire harness

Traverse with PVC tape semi-overlapping plastic, more than 100mm head left bare line 50mm, 100mm below the head 30mm

Bind wires with open bellows Dimension measuring point

In addition to the special requirements for corrugated tubes and zippered PVC tubes, the required lead to the corrugated pipe, zippered PVC tube fill rate of more than 50 <UNK>

Except for special provisions, wires protected by a bellows or PVC zipper tubes are covered both inside and outside the bellows or PVC zipper tubes as follows(`` L "indicates the length of the bellows): Unprotected wires

1, L 〉 100Mm with interval plastic, plastic spacing 50mm, at least winding 3 laps;

2, L ≤ 100mm with interval adhesive, adhesive position in the middle of the size, winding at least 3 laps

Welding point refers to the connection point of the same function wire

For the conductor bound with bellows, the bellows shall be UFW type bellows according to jf03-159 (class B)

The position of each line number socket in the corresponding sheath is viewed from the qualifying end

Length measurement refers to the distance from the point of measurement to the point of measurement, or the distance from the point of measurement to the end of the wire

The size of the injection is the length of the wire after straightening. When one end is a plug, its length is measured from the end of the plug. Except for special requirements for bellows diameter,The filling rate of conductor relative bellows is 70%-80%.

Holes not used for waterproof plugs need to be blocked with blind plugs

At the end and branch of the insulated tube, bind with tape

Main line and its branch lines are welded at one point(except CAN lines) Except for special provisions,Wires wrapped with bellows,The bellows are wrapped in the following way ("L" means the length of the bellows):

The twisted pair is(27 ~ 33) twist / M

The wire and terminal are connected by compression 1、L〉100mmUse spacer coating,The distance between coatings is 50mm, with at least 3 windings.

Single V-shaped heat condenser for single(special) terminals and wire compression

PVC tape is F-PVC / 105 / R-Tx according to the specification in QC/T 29106 Appendix C 2、L≤100mmUse spacer coating,The encapsulation position is in the middle of the dimension, winding at least 3 circles.

Elevated Box Wire Bundle Assembly

name

The bellows are UFW type bellows, according to Category A in Appendix D of QC/T 29106

Double layer heat condensation pipe protection at wire soldering point in wire beam, according to Category C in Appendix B of QC/T 29106 Drawing

Security

matters.

Number

of items

Processing

methods

Widget

version

Document

Version Diagram A total of 1 card Distribution of line number connectors in corresponding sheaths,Look from the end of the line

Plug press QC/T 417

Product Flower Drawing

Establishment Tangchao reinspection nonmetal pattern Shade. categories Comparison

All conductors are PVC thin-walled conductors, press GB/T 25085 B

heat Surface Drawing

Transition harness assembly of 24 V

Correction. Weight treatment protection software

Technical conditions QC/T 29106 Review

Change of

Notice Number Length measurement refers to the measurement point to the measurement point.,Or the distance from the measuring point to the conductor terminal

name

Number

Samples must be re-examined by the Product Design Department before starting supply

General layout Impact swaps tag of posts date

power supply socket

material

standardization

Approval Subcode

FAW Jiefang Qingdao Automobile Co., Ltd

The dimension of the injection is the length dimension of the wire after straightening out.,One end is the connector.,Its length is measured from the root of the socket inlet end.

Conductor and terminal are crimped Security is Number Processing Component Document

Drawing important of items method version version Picture A total of 1 sheet 1

Product ree Decorative Drawing

Plug in QC/T 417,Among them, the surface of the metal terminal is tin plated, copper/Ep.Sn9, according to Q/CAYT-4.12. Design xamination Nonmetal pattern Color Categories Proportion

heat Surface Drawing

Thin-walled polyvinyl chloride conductors are used for all conductors,According to QC/T 730, B Correction. Weight treatment protection software

Change Notice

Review

Technical conditions according to QC/T 29106 Number

Number

General layout Impact swap sign of places date

Material

Samples must be re-examined by product design department before starting supply. Science

standardization

Technology center of China First Automobile Co., Ltd

Approval Code

Wiring harness assembly for air horn Left body wiring harness assembly

Line number Wire function Conductor cross-sectional area(mm²) colour remarks

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Side turn light

soldered dot Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Side turn light soldered dot

Sleeping light soldered dot

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Sleeping light

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

Chassis wire harness Dashboard wire harness Elevated box wire harness

Dashboard wire harness Elevated box wire harness

code number number remarks

Air horn solenoid valve

Dashboard wire harness

(gray)

Cover Observation Direction and Measurement Point

Cover Observation Direction and Measurement Point Outlet

Cover

Line End

(green)

View Direction wire

Cover

Outlet Line End Size Limits

Plug feature number(corresponding to the selection relationship list)

View Direction wire Wire beam label, label content as shown in "XXXXX", label content is clear,

Paste position from branch socket end(30-100) mm

Size Limits Size measurement point

Side turn light

Semi-laminated tape with wear-resistant cloth for wires

After the wire is covered with a semi-overlapping type of wear-resistant cloth base tape, tie the open corrugated pipe;

Wire beam label, label content as shown in "XXXXX", label content is clear,

Paste position from branch socket end(30-100) mm Unprotected wires

Traverse with PVC tape, half laminated plastic, more than 100 mm head left bare line 50mm, 100mm below the left head 30mm

Bind wire with closed bellows Wire bound with PVC sleeve

All connectors connected to the bellows must have rear protection that matches the bellows Bind wires with open bellows

The position of each line number socket in the corresponding sheath is viewed from the qualifying end After the wire is semi-stacked with wear-resistant cloth base tape, bind the open corrugated pipe, and use the wear-resistant cloth base tape semi-overlapping tape outside the corrugated pipe.

Sleeping light

Length measurement refers to the distance from the point of measurement to the point of measurement, In addition to special requirements for corrugated tubes, diameter of zipper PVC tubes, required wire relative corrugated tubes, zipper PVC tube fill rate is more than 50 %

Except for special provisions, wires protected by a bellows or PVC zipper tubes are covered both inside and outside the bellows or PVC zipper tubes as follows(L represents the length of the bellows):

or the distance from the point of measurement to the end of the wire 1、L〉100Mm with spacing plastic, plastic spacing 50mm, winding at least 3 laps;

The size of the injection is the length of the wire after straightening. When one end is a plug, its length is measured from the end of the plug. Line number Wire function Conductor cross-sectional area(mm²) colour remarks 2、L≤100Mm with an interval coating, the adhesive position in the middle of the size, winding at least 3 laps;

Welding point refers to the connection point of the same function wire

At the end and branch of the insulated tube, bind with tape The position of each line number socket in the corresponding sheath is viewed from the qualifying end

Chassis wire harness Air horn solenoid valve

Length measurement refers to the distance from the point of measurement to the point of measurement, or the distance from the point of measurement to the end of the wire

The wire and terminal are connected by compression Chassis wire harness Air horn solenoid valve The size of the injection is the length of the wire after straightening. When one end is a plug, its length is measured from the end of the plug.

Holes not used for waterproof plugs need to be blocked with blind plugs

PVC tape is F-PVC / 105 / R-Tx according to the specification in QC/T 29106 Appendix C At the end and branch of the insulated tube, bind with tape

Air horn wire harness assembly

Main lines and their branch lines are welded at one point(except CAN lines)

The bellows are UFW type bellows, according to Category A in Appendix D of QC/T 29106 Double twisted distance(27 ~ 33) twist / M

name

The wire and terminal are connected by compression

Plug press QC/T 417 Single V-shaped heat condenser for single(special) terminals and wire compression

Security Number Processing Widget Document PVC tape is F-PVC / 105 / R-Tx according to the specification in QC/T 29106 Appendix C

A total of 1 card

All conductors are PVC thin-walled conductors, press GB/T 25085 B Establishment matters. of items methods version Version Diagram

The bellows are UFW type bellows, according to Category A in Appendix D of QC/T 29106

Product Flower Drawing

Correction. reinspection nonmetal pattern Shade. categories Comparison PVC casing in line with JF03-117

Technical conditions QC/T 29106 heat Surface Drawing In the abrasion-resistant tape, the tape size is P-PET/105R-Tp according to the specification in Appendix C of QC/T 29106.

Review Weight treatment protection software Wear resistance: a = 10mm, the number of cycles > 2000 times, a = 5mm, the number of cycles > 1000 times, Left Body Wire Assembly

Samples must be re-examined by the Product Design Department before starting supply

name

Change of At the time of testing, take a length of about 10cm tape and stick it along the shaft to a steel rod with a diameter. The test method and equipment press 9.3 in GB/T 25085, in which the diameter of the scratch needle is 0.45 mm.

General layout Notice Number Drawing

Security

matters.

Number

of items

Processing

methods

Widget

version

Document

Version Diagram A total of 1 card

Number Double layer heat condensation pipe protection at wire soldering point in wire beam, according to Category C in Appendix B of QC/T 29106 Establishment Tangchao

Product

reinspection nonmetal

Flower

pattern Shade.

Drawing

categories Comparison

standardization material Impact swaps tag of posts date Plug press QC/T 417 Correction. Weight

heat

treatment

Surface

protection

Drawing

software

All conductors are PVC thin-walled conductors, press GB/T 25085 B Review

Change of

Notice Number

Jointly sign Technical conditions QC/T 29106 Number

FAW Technology Center

General layout material Impact swaps tag of posts date

Samples must be re-examined by the Product Design Department before starting supply standardization

Faw Jiefang Qingdao automobile co., ltd

Approval Subcode

Approval Subcode

Right body wiring harness assembly Instrument panel wiring harness assembly

Butt connector for

instrument panel

Wire number Wire function Cross sectional area of conductor(mm²) colour remarks wire harness and

Trend diagram of communication CAN lines (E35, E34,C1,C2): the minimum distance between nodes is 100 chassis wire harness Function switch

Instrument cluster

Instrument panel wiring harness Right front end marker lamp Instrument cluster

Instrument panel wire harness Chassis wire harness

Indoor lighting control switch Hydraulic turnover control switch Danger alarm switch Front fog lamp switch Rear fog lamp switch Fuel preheating switch Horn change-over switch Inter axle differential lock switch Inter wheel differential lock switch Multi state switch Work light control switch

fuse box

Engine ECU Yellow Blue

Instrument panel wiring harness Side turn lamp

terminal resistance

terminal resistance

ABS controller

Instrument panel wiring harness Right front end marker lamp

(black)

(brown)

Vehicle information

service terminal Diagnostic socket Body controller Retarder ABS controller NOx sensor

Side turn lamp Solder joint

Instrument panel wire

harness and left

body wire harness

inverter Solder joint Label the hydraulic turnover Attach the front fog lamp Attach the rear fog Label the fuel Label the horn Label the inter axle Label the inter wheel Label the work light

Butt connector Label the interior lighting symbol control switch symbol Label the hazard switch symbol switch symbol label lamp switch symbol label preheating switch symbol transfer switch symbol differential lock switch symbol differential lock switch symbol Label the multi state switch symbol control switch symbol

Instrument panel wiring harness inverter

Oil saving

The terminals are:

Left body electric

Instrument panel wiring harness inverter

(green)

wire harness

(Orange)

(blue)

(gray)

Connect to

H connector Connect to

Connect to

E connector

G connector

Code name number number remarks

Left body wire harness and Cab fuse box 1

Overhead box wire harness (green)

Butt connector Attach the parking power take-off switch symbol label

Attach the power take-off switch symbol label

Cover Observation Direction and Measurement Point

Right front end marker lamp Vehicle information service terminal

Cover Overhead box wire harness

Outlet Line End (injection cable)

Instrument panel wiring harness

(yellow) (green) (blue)

Driving recorder Power take-off switch

OBD diagnostic socket Park power take-off switch

View Direction wire The connector is installed on the connector bracket according to the position

shown in the figure, and the outlet direction is shown in the figure

The tightening torque of dj431-8e is 11 ± 1n · M

Door controller

Size Limits

Radio player

Connector feature number (list of corresponding optional relations)

Black PVC tape is tightly wrapped and The size is the cable length, When leaving the factory, C1, C2, C3 connectors are connected to each other and locked firmly

Wiring harness label, the label content is shown as "xxxxx", the label content is clear,

water is not allowed to penetrate The length of connector and rear protection is not included 24 V power socket

The cigarette lighter

The pasting position is (30-100) mm away from the inlet end of branch connector

Dimension measuring point

Automatic air conditioning

(green)

Body controller x1

Semi laminated coating of wear resistant cloth base tape for conductor

Cover Observation Direction and Measurement Point

Cover

After the conductor is wrapped with wear-resistant cloth base tape, the open bellows are bound;

Outlet

Line End

(yellow)

View Direction wire

Body controller x2

Size Limits

accelerator pedal

(black) (brown)

Unprotected conductor Connector feature number (list of corresponding optional relations)

Wire harness length (list of corresponding optional relations) Body controller x3-a

Wiring harness label, the label content is shown as "xxxxx", the label content is clear,

The conductor is bound with PVC sleeve The pasting position is (30-100) mm away from the inlet end of branch connector

The branch line shall be buried in the trunk line of the arrow by 100 mm, and then the PVC tape shall be used for semi stack coating

Dimension measuring point Body controller x3-b

Opening wire binding Conductor durable ground cloth base tape semi laminated coating

The ignition switch

After the conductor is wrapped with wear-resistant cloth base tape, the open bellows are bound;

The size here is shown in the package method shown in the figure, and the outer half stacked adhesive tape is used Right body wiring harness

After the wire is semi-laminated with wear-resistant duct tape, the open corrugated pipe is bundled, Headlamp and dimmer switch Wiper and auxiliary brake switch Cruise switch

90 degree elbow

and the corrugated pipe is semi-laminated with wear-resistant duct tape

Multifunction steering wheel switch

Wrap the mark with green PVC tape (gray)

In addition to the special requirements for the diameter of corrugated pipe and zipper PVC pipe, the filling rate of wire relative to corrugated pipe and zipper PVC pipe is required to be more than 50% Direction mark of lead wire in connector

Left body wiring harness

Unless otherwise specified, the wires protected by corrugated pipe or PVC zipper pipe shall be coated with the following

inverter

The conductor shall be wrapped with open braided polyester sleeve, and the external part shall be wrapped with PVC tape.

(green) (gray) (Orange) (blue)

The PVC tape shall be f-pvc / 105 / r-tx according to Appendix C of QC / T 29106

glue inside and outside the corrugated pipe or PVC zipper pipe ("L" indicates the length of the corrugated pipe):

Chassis wiring harness

1. when l > 100mm, use interval encapsulation, the encapsulation interval is 50mm, and at least three turns are wound; Wire Cross sectional Wire Cross sectional Wire Cross sectional Wire Cross sectional Code

Wire Cross sectional Wire Cross sectional Wire Cross sectional Wire Cross sectional

Unprotected conductor

number Wire function area of conductor(mm²) colour remarks number Wire function area of conductor(mm²) colour remarks number Wire function area of conductor(mm²) colour remarks number Wire function area of conductor(mm²) colour remarks number Wire function area of conductor(mm²) colour remarks number Wire function area of conductor(mm²) colour remarks number Wire function area of conductor(mm²) colour remarks number Wire function area of conductor(mm²) colour remarks name number number remarks

2. When L≤100mm, it shall be coated at intervals, and the coating position shall be in the middle of this size, and it shall be wound at least 3 times. Side turn lamp The conductor shall be semi laminated with PVC tape, and the bare wire shall be reserved by

Chassis wiring harness

The ignition switch

fuse box

fuse box

Function switch

Solder joint

fuse box

Body controller × 3

Function switch

Function switch

Solder joint

Solder joint

Solder joint

fuse box

Vehicle information service terminal

Automatic air conditioning

fuse box

Solder joint

Function switch

Right body wiring harness

fuse box

fuse box

Door controller

Door controller

accelerator pedal

Function switch

Chassis wiring harness

Chassis wiring harness

50 mm at the head exceeding 100 mm and 30 mm below 100 mm

Solder joint refers to the connection point of the same functional wire Solder joint fuse box Chassis wiring harness fuse box Multi function steering wheel Solder joint fuse box Solder joint Solder joint Body controller × 3 fuse box Door controller×1 accelerator pedal Chassis wiring harness

The conductor is bound with PVC sleeve Chassis wiring harness fuse box fuse box Chassis wiring harness Function switch Solder joint Chassis wiring harness Automatic air conditioning Solder joint fuse box fuse box Chassis wiring harness accelerator pedal Chassis wiring harness

The distribution position of connectors of each wire number in the corresponding sheath is viewed from the outlet end Solder joint fuse box1 Chassis wiring harness Vehicle information service terminal Function switch Solder joint fuse box fuse box OBD diagnostic socket fuse box Function switch Chassis wiring harness accelerator pedal Chassis wiring harness On demand Strapping antenna

The conductor shall be wrapped with wear-resistant cloth base tape, and then the closed bellows shall be bound Starting switch fuse box Combination switch Body controller × 3-A Function switch Solder joint Solder joint Left body wiring harness Function switch Body controller × 3 Instrument cluster Chassis wiring harness Combination switch Chassis wiring harness

Length measurement refers to measuring point or the distance between measuring point and wire terminal Starting switch Chassis wiring harness Body controller × 1 Chassis wiring harness Function switch Solder joint Automatic air conditioning fuse box Function switch Chassis wiring harness fuse box1 Chassis wiring harness Function switch Solder joint Supplied with electrical harness

Opening wire binding Chassis wiring harness Instrument cluster Right body wiring harness Solder joint Instrument cluster Chassis wiring harness Instrument cluster ABS controller Function switch Multi function steering wheel? Yingxia? Instrument cluster Chassis wiring harness accelerator pedal Chassis wiring harness

The noted dimensions are all the length dimensions of the wire after straightening. When one end is a connector, its length is measured from the root of the incoming end of the connector Combination switch fuse box Left body wiring harness Solder joint ABS controller Chassis wiring harness Chassis wiring harness Instrument cluster fuse box Chassis wiring harness Instrument cluster Chassis wiring harness Instrument cluster Chassis wiring harness

The conductor is bound with closed bellows Solder joint Body controller × 3 Combination switch Body controller×3-A The cigarette lighter Chassis wiring harness Chassis wiring harness Instrument cluster Solder joint Left body wiring harness Function switch fuse box Instrument cluster Chassis wiring harness

The unused holes of waterproof connectors need to be blocked with blind plugs fuse box Chassis wiring harness 24 V power socket Solder joint Chassis wiring harness Instrument cluster Solder joint Body controller×2 Function switch Solder joint Cab fuse box1 Chassis wiring harness

Wire shall be covered with flannel tape according to QC / t29106 Function switch Solder joint Body controller × 1 Chassis wiring harness Automatic air conditioning Chassis wiring harness Chassis wiring harness Instrument cluster Function switch fuse box Function switch Chassis wiring harness

At the end of the insulating tube and the branch of the conductor, tie it with adhesive tape fuse box Chassis wiring harness Left body wiring harness Solder joint Automatic air conditioning Solder joint fuse box Chassis wiring harness fuse box Chassis wiring harness Function switch Chassis wiring harness Left body wiring harness Chassis wiring harness

Twisted pair

After the conductor is wrapped with wear-resistant cloth base tape, Solder joint Left body wiring harness The ignition switch fuse box Instrument cluster Chassis wiring harness fuse box Chassis wiring harness Function switch Chassis wiring harness Solder joint Fleet Management Left body wiring harness Chassis wiring harness

the open corrugated pipe is bound, and then PVC tape is used to wrap the corrugated pipe

Main line and its branch line are welded at one point (except CAN line) Combination switch fuse box Instrument cluster Chassis wiring harness Chassis harness meter Solder joint Automatic air conditioning Door controller Chassis wiring harness Body controller×1 Chassis wiring harness OBD diagnostic socket Solder joint

Twisted pair

After the wire is semi-laminated with wear-resistant duct tape, the open corrugated pipe is bundled, Solder joint Body controller × 3 Instrument cluster Chassis wiring harness Chassis harness Power take-off switch Instrument cluster Chassis wiring harness Door controller Chassis wiring harness Body controller×1 Chassis wiring harness OBD diagnostic socket Solder joint

and the corrugated pipe is semi-laminated with wear-resistant duct tape

The twist of twisted pair is (27~33) twist/m. fuse box Chassis wiring harness ABS controller Chassis wiring harness Chassis harness Park power take-off switch fuse box ABS controller Door controller Chassis wiring harness

Vehicle information

service terminal

fuse box

Vehicle information

service terminal

Solder joint

In addition to the special requirements for the diameter of corrugated pipe and zipper PVC pipe, Twisted pair

Vehicle information

the filling rate of wire relative to corrugated pipe and zipper PVC pipe is required to be more than 50% fuse box Chassis wiring harness Body ground Chassis wiring harness Chassis wiring harness Body controller×1 fuse box ABS controller Door controller Chassis wiring harness Left body wiring harness Solder joint Solder joint

service terminal

List of optional relationships

Wires and terminals are connected by crimping List of optional relationships Unless otherwise specified, the wires protected by corrugated pipe or PVC zipper pipe shall be coated

Instrument cluster Solder joint fuse box1 Chassis wiring harness Chassis wiring harness Chassis wiring harness Instrument cluster Chassis wiring harness Door controller Chassis wiring harness Door controller Chassis wiring harness Team management of Jiefang bank Solder joint

with the following glue inside and outside the corrugated pipe or PVC zipper pipe ("L" indicates the length of the corrugated pipe): Twisted pair

Connector feature number

1. when L>100mm, use interval encapsulation, the encapsulation interval is 50mm, and at least three turns are wound; Left body wiring harness Solder joint Solder joint Body controller×3-B fuse box Chassis wiring harness Door controller Chassis wiring harness Door controller Chassis wiring harness Team management of Jiefang bank Solder joint

Single-layer V-shaped heat shrinkable tube is used at the pressure joint between single (special) terminal and wire 2. When L≤100mm, it shall be coated at intervals, and the coating position shall be in the middle of this size, and it shall be wound at least 3 times. Combination switch fuse box OBD diagnostic socket Solder joint Solder joint Left body wiring harness ABS controller Chassis wiring harness Chassis wiring harness Chassis wiring harness Door controller Chassis wiring harness X3 body controller Solder joint

Twisted pair

Solder joint refers to the connection point of the same functional wire Solder joint Body controller × 3 OBD diagnostic socket Solder joint Door controller Body controller×3 ABS controller Chassis wiring harness Door controller Chassis wiring harness Door controller Chassis wiring harness X3 body controller Solder joint Wire number

The PVC tape is F-PVC/105/R-Tx according to the specification in appendix c of QC/T 29106 Connector feature number

fuse box Chassis wiring harness Vehicle information service terminal Solder joint Door controller Body controller×3 ABS controller Chassis wiring harness Door controller Chassis wiring harness Door controller Chassis wiring harness OBD diagnostic socket Chassis wiring harness

The distribution position of connectors of each wire number in the corresponding sheath is viewed from the outlet end

Part version Twisted pair

Instrument cluster Solder joint Fleet Management Solder joint Body controller×1 Left body wiring harness ABS controller Chassis wiring harness Chassis wiring harness Chassis wiring harness Door controller Chassis wiring harness OBD diagnostic socket Chassis wiring harness

Length measurement refers to measuring point or the distance between measuring point and wire terminal

UFW corrugated pipe is used as corrugated pipe, which is classified as class a in appendix d of QC/T 29106 Wire number

Vehicle information service terminal Solder joint Body controller×1 Solder joint Body controller×1 Left body wiring harness ABS controller Chassis wiring harness Door controller Chassis wiring harness Door controller Chassis wiring harness Fleet management module Solder joint

The noted dimensions are all the length dimensions of the wire after straightening. When one end is a connector,

Right body wiring harness assembly

Twisted pair

its length is measured from the root of the incoming end of the connector Left body wiring harness Solder joint Chassis wiring harness Chassis wiring harness Door controller Chassis wiring harness ABS controller Chassis wiring harness Door controller Chassis wiring harness Door controller Chassis wiring harness Fleet management module Solder joint

PVC casing shall comply with JF03-117 Drawing No Description of options The unused holes of waterproof connectors need to be blocked with blind plugs Car entertainment

Function switch Solder joint Combination switch Solder joint Door controller Chassis wiring harness ABS controller Chassis wiring harness Multifunction steering wheel switch Analog input Door controller Chassis wiring harness X3 body controller Solder joint

terminal

ABS line Twisted pair Drawing No Description of options

At the end of the insulating tube and the branch of the conductor, tie it with adhesive tape Car entertainment

Without power take-off

In the wear-resistant duct tape, the duct tape specification is P-PET/105/R-Tp according to the specification in appendix c of QC/T 29106.

Automatic air conditioning Solder joint Combination switch Solder joint Left body wiring harness Chassis wiring harness ABS controller Chassis wiring harness terminal Multifunction steering wheel switch Door controller Chassis wiring harness X3 body controller Solder joint

With power supply of 200V Ground wire

Main line and its branch line are welded at one point (except CAN line) Function switch Solder joint Function switch Solder joint Solder joint Body controller×3 ABS controller Chassis wiring harness Vehicle information service terminalChassis wiring harness Door controller Chassis wiring harness Installation of power take-off

No power supply 220 V The twist of twisted pair is (27 ~ 33) twist/m. Note: "X" means no selection

Function switch Solder joint Left body wiring harness Solder joint fuse box Function switch ABS controller Chassis wiring harness Vehicle information service terminalChassis wiring harness The ignition switch Chassis wiring harness

Wear resistance: when a=10mm, the cycle times are more than 2000 times; when a=5mm, the cycle times are more than 1000 times. Wires and terminals are connected by crimping

Note: "x means no selection"

Left body wiring harness assembly

name Function switch Solder joint Right body wiring harness Solder joint Solder joint Function switch ABS controller Chassis wiring harness Vehicle information service terminalChassis wiring harness The ignition switch Solder joint

Single-layer V-shaped heat shrinkable tube is used at the pressure joint between single (special) terminal and wire Vehicle information

During the test, an adhesive tape with a length of about 10cm was taken and adhered to a steel bar with a diameter along the axial direction. The PVC tape is F-PVC/105/R-Tx according to the specification in appendix c of QC/T 29106

Function switch Solder joint Brake light switch Solder joint Left body wiring harness Chassis wiring harness ABS controller Chassis wiring harness Vehicle information service terminalChassis wiring harness service terminal Left body wiring harness

The test method and equipment were in accordance with 9.3 in GB/T 25085, in which the diameter of the scraping needle was 0.45 mm. Function switch Solder joint Door controller Solder joint Solder joint Body controller×3 ABS controller Chassis wiring harness Instrument cluster fuse box fuse box Body controllerX1 Combination switch Chassis wiring harness

UFW corrugated pipe is used as corrugated pipe, which is classified as class a in appendix d of QC/T29106

Function switch Solder joint Door controller Solder joint fuse box Chassis wiring harness ABS controller Chassis wiring harness Instrument cluster Chassis wiring harness Chassis wiring harness Body controllerX1

Security Number Processing Widget Document PVC casing shall comply with JF03-117

Wire welding spots in wire harness shall be protected by double-layer heat shrinkable tube, according to Class C in Appendix B of QC/T 29106 Establishment matters. of items methods version Version Diagram A total of 1 card Function switch Solder joint Function switch Solder joint fuse box Chassis wiring harness ABS controller Chassis wiring harness Instrument cluster Chassis wiring harness Body controllerX3 Function switch Cab fuse box Chassis wiring harness

In the wear-resistant duct tape, the duct tape specification is P-PET/105/R-Tp according to the specification in appendix c of QC/T 29106.

Function switch Solder joint Function switch Solder joint Solder joint Body controller×3 ABS controller Chassis wiring harness Vehicle information service terminal Instrument cluster Body controllerX3 Function switch Chassis wiring harness Chassis wiring harness Part

Product Flower Drawing version

Press QC/T 417 for connector Correction. reinspection nonmetal pattern Shade. categories Comparison Wear resistance: when a=10mm, the cycle times are more than 2000 times; when a=5mm, the cycle times are more than 1000 times.

Multi function steering wheel Solder joint Function switch Solder joint fuse box Chassis wiring harness Solder joint Left body wiring harness Body controllerX3 fuse box Combination switch Chassis wiring harness

During the test, an adhesive tape with a length of about 10cm was taken and adhered to a steel bar with a diameter along the axial direction. Instrument panel wiring harness assembly

heat Surface Drawing The test method and equipment were in accordance with 9.3 in GB/T25085, in which the diameter of the scraping needle was 0.45 mm. Chassis wiring harness Solder joint Function switch Solder joint fuse box Chassis wiring harness ABS controller OBD diagnostic socket fuse box Right body wiring harness Body controllerX3 Function switch Combination switch Chassis wiring harness

The wires are made of PVC thin-walled wires according to GB/T 25085 Grade B. Review Weight treatment protection software Vehicle information

Technical conditions of cables for ABS solenoid valves and sensors shall be in accordance with GB/T 25087 Function switch Solder joint Function switch Solder joint Combination switch Body controller×3-A Solder joint Chassis wiring harness fuse box Chassis wiring harness Left body wiring harness service terminal Combination switch Chassis wiring harness

Change of Vehicle information

Technical conditions are in accordance with QC/T 29106 General layout Notice Number

The wire core in the cable shall be in accordance with GB/T 25085, Grade B. Function switch Solder joint Function switch Solder joint Combination switch fuse box ABS controller OBD diagnostic socket Left body wiring harness service terminal Combination switch Chassis wiring harness name

Instrument panel wiring harness assembly

Vehicle information

The connector size of ABS solenoid valve shall meet the requirements of code 1 in ISO 15170.1, and the test and requirements shall meet the requirements of ISO 15170.2 Function switch Solder joint Function switch Solder joint Combination switch fuse box fuse box Chassis wiring harness fuse box1 fuse box1 Left body wiring harness service terminal Cab fuse box Chassis wiring harness

Number

standardization material tag date

Before starting the supply, the samples must be reinspected by the product design department

Security Number Processing Widget

Impact swaps

Document

of posts Wire welding spots in wire harness shall be protected by double-layer heat shrinkable tube, according to Class C in Appendix B of QC/T 29106 Chassis wiring harness fuse box Function switch Solder joint Body controller×3-A Solder joint Chassis wiring harness Instrument cluster fuse box Chassis wiring harness Independent warm air fuse box Establishment Tang Chao matters. of items methods version Version Diagram A total of 1 card

Product Flower Drawing

Correction. reinspection pattern Shade. Comparison

Press QC/T 417 for connector Right body wiring harness Solder joint Function switch Solder joint Combination switch Body controller×3-B fuse box Function switch fuse box Body controller x3-b Instrument cluster Chassis wiring harness nonmetal categories

Jointly sign Weight

heat Surface Drawing

Review treatment protection

FAW Technology Center

software

The wires are made of PVC thin-walled wires according to GB/T 25085B Grade B. Function switch fuse box Function switch Solder joint Solder joint Chassis wiring harness Chassis wiring harness Function switch fuse box Door controller Function switch fuse box

Change of

General layout

Notice Number

Approval Subcode Technical conditions are in accordance with QC/T 29106 Function switch Solder joint Function switch Solder joint fuse box Automatic air conditioning Chassis wiring harness Function switch fuse box Left body wiring harness Chassis wiring harness fuse box Number

standardization material Impact swaps tag of posts date

Before starting the supply, the samples must be reinspected by the product design department Function switch Solder joint fuse box 24 V power socket Chassis wiring harness Function switch fuse box Left body wiring harness Cab fuse box1 Chassis wiring harness Jointly sign

FAW Jiefang Qingdao Automobile Co., Ltd

Function switch Solder joint fuse box The cigarette lighter Chassis wiring harness Function switch Solder joint Fleet Management accelerator pedal Chassis wiring harness Approval Subcode

You might also like

- 02C-1 Lin Xlraem4100g211062Document1 page02C-1 Lin Xlraem4100g211062Daniel PricopNo ratings yet

- Oh Susana: Popular Norteamericana 120Document1 pageOh Susana: Popular Norteamericana 120HECTOR VASQUEZ ZELADANo ratings yet

- Hassan AllamDocument1 pageHassan AllammohsinqcqaNo ratings yet

- Greensleeves (Piano, Arr. Paul de Senneville & Gerard Salesses)Document3 pagesGreensleeves (Piano, Arr. Paul de Senneville & Gerard Salesses)jaetanoNo ratings yet

- In Your Own Sweet WayDocument4 pagesIn Your Own Sweet WaySebastian Mendez Siem100% (1)

- Diagrama Elétrico GA132-160VSD PK & FF 1028888981-01Document32 pagesDiagrama Elétrico GA132-160VSD PK & FF 1028888981-01Marcio100% (2)

- A - Song - For - Slug Snails SongDocument1 pageA - Song - For - Slug Snails SongretconnNo ratings yet

- Hassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglyDocument1 pageHassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglymohsinqcqaNo ratings yet

- KDocument27 pagesKcristianNo ratings yet

- El Noy de La Mare: A Catalan Folk SongDocument3 pagesEl Noy de La Mare: A Catalan Folk SongYermia NugrohoNo ratings yet

- SEL SN-1 POINT - 1 Reference DrawingsDocument2 pagesSEL SN-1 POINT - 1 Reference DrawingsKs MuraliNo ratings yet

- Spilway Aeng MerahDocument1 pageSpilway Aeng MerahChopys As ShidiqiNo ratings yet

- 01 Full Score Pasiwali 2Document8 pages01 Full Score Pasiwali 2Tina LeeNo ratings yet

- Amb-Agcc02-Tun Ce 1002 - P0Document1 pageAmb-Agcc02-Tun Ce 1002 - P0Sugam JainNo ratings yet

- 1SBB505165D3501Document2 pages1SBB505165D3501sara ramadanNo ratings yet

- Flats Floor PlansDocument1 pageFlats Floor Planslenganji simwandaNo ratings yet

- TweeterDocument4 pagesTweeterRicardo RamosNo ratings yet

- 2 Ton Hurricane Hook MountDocument1 page2 Ton Hurricane Hook MountVitor OlivettiNo ratings yet

- UDocument8 pagesUcristianNo ratings yet

- Diagram - XAS 57-97 DD WUXDocument1 pageDiagram - XAS 57-97 DD WUXCovid 55100% (1)

- Quy Trinh 2Document1 pageQuy Trinh 2HOÀNG LÊ PHẠMNo ratings yet

- Autocad 1:100: Corte A - A'Document1 pageAutocad 1:100: Corte A - A'Luz RestrepoNo ratings yet

- A. Carrillos Caridad Guardiola: PasodobleDocument1 pageA. Carrillos Caridad Guardiola: PasodobleDamian Magallon FerrandezNo ratings yet

- AKELARREDocument1 pageAKELARREOrquestina anarco yeyeNo ratings yet

- Stand by Me - TenorSxDocument3 pagesStand by Me - TenorSxAlessandro SalaroliNo ratings yet

- Quy Trinh DKDocument1 pageQuy Trinh DKKHÁNH VÕ ĐĂNGNo ratings yet

- StatusDocument9 pagesStatusadrienspinozziNo ratings yet

- Boquillas C2000Document2 pagesBoquillas C2000LIZANA QUISPE ELMER ARSENIONo ratings yet

- Chega de Saudade - CompleteDocument15 pagesChega de Saudade - CompleteMarco LamiNo ratings yet

- LICENCIA ALBAN-Plano 1Document1 pageLICENCIA ALBAN-Plano 1Ana Maria ValbuenaNo ratings yet

- CS 4944 - JCT A B & C - CH5 SHAFT EX. DRAWING - R00 (Sheet 1of6)Document1 pageCS 4944 - JCT A B & C - CH5 SHAFT EX. DRAWING - R00 (Sheet 1of6)محمد طولانNo ratings yet

- McErlain E Blues With FillsDocument1 pageMcErlain E Blues With FillsbohemianNo ratings yet

- Vendavais30-Trompa em FDocument2 pagesVendavais30-Trompa em FDeivid Cordeiro dos SantosNo ratings yet

- My Life Is Going On GUITARRADocument3 pagesMy Life Is Going On GUITARRAByePawellNo ratings yet

- Polka Dziadek NamyslowskiDocument2 pagesPolka Dziadek Namyslowskihte14558No ratings yet

- Elevation of Tower - 1 (Facing West) Part 2 of 3: LegendsDocument1 pageElevation of Tower - 1 (Facing West) Part 2 of 3: LegendsHozien OnofreNo ratings yet

- To Know Him Is To Love Him (Versie Voor Twee Met Vingerzetting)Document2 pagesTo Know Him Is To Love Him (Versie Voor Twee Met Vingerzetting)tedskesNo ratings yet

- Cielito Lindo Ukulele TabDocument1 pageCielito Lindo Ukulele TabJames Leandro0% (1)

- Runaway - Jefferson Starship - Bass TabDocument4 pagesRunaway - Jefferson Starship - Bass TabLawrence GouldNo ratings yet

- Runaway - Jefferson Starship - Bass TabDocument4 pagesRunaway - Jefferson Starship - Bass TabLawrence GouldNo ratings yet

- C STR DWG 000 40010 0001 5Document1 pageC STR DWG 000 40010 0001 5HUSSEIN FNEISHNo ratings yet

- DR-CST-800-0014 - Rev ADocument1 pageDR-CST-800-0014 - Rev APinak ProjectsNo ratings yet

- CABLE TRENCH & FOUNDATION LAYOUT - SitaburdiDocument1 pageCABLE TRENCH & FOUNDATION LAYOUT - Sitaburdisayanti.koley18No ratings yet

- Carol Medley: TraditionalDocument3 pagesCarol Medley: TraditionalAlessandro MandariniNo ratings yet

- Kitchen SpecDocument1 pageKitchen SpecabebaNo ratings yet

- 6 Pu PSHC WIDocument1 page6 Pu PSHC WIJhamil GonzalesNo ratings yet

- Snap Rosa LinnDocument1 pageSnap Rosa LinnblabladusquareNo ratings yet

- Terrace Floor: A B C DDocument1 pageTerrace Floor: A B C DS KarthikeyanNo ratings yet

- Faith ADocument1 pageFaith ADelos Santos, John Marquin S.No ratings yet

- Instalaciones Electricas PlanoDocument1 pageInstalaciones Electricas PlanoAnthony Arias SottecNo ratings yet

- Ala Est Ep 02 For r00Document1 pageAla Est Ep 02 For r00Thaise OliveiraNo ratings yet

- COLINA Piso 3 - RUTA-1 2Document1 pageCOLINA Piso 3 - RUTA-1 2jonathan Stiven HenaoNo ratings yet

- Genshin Impact Main ThemeDocument4 pagesGenshin Impact Main Themeaboliver27No ratings yet

- Caution: MODEL 201 Single Line Diagram Electrical Drawing Package OverviewDocument11 pagesCaution: MODEL 201 Single Line Diagram Electrical Drawing Package OverviewjoseNo ratings yet

- Carcassi Op60 No7Document2 pagesCarcassi Op60 No7Kaja PecnikNo ratings yet

- Eleve 2Document1 pageEleve 2sadafNo ratings yet

- Sunset Lover: 100 A B C D M FDocument4 pagesSunset Lover: 100 A B C D M FDavid CabreraNo ratings yet

- KEELE Map ColourDocument1 pageKEELE Map ColourHotCatonablankblankNo ratings yet

- Upc6gx RC11 B0600 DD030 - 001 - 00Document1 pageUpc6gx RC11 B0600 DD030 - 001 - 00Viet NguyenNo ratings yet

- Dge 169Document6 pagesDge 169Krittika ChandranNo ratings yet

- Development of Groundwater Monitoring Wells in Granular AquitmentsDocument16 pagesDevelopment of Groundwater Monitoring Wells in Granular AquitmentsJose Luis Nava HernandezNo ratings yet

- Biodegradable and Non Bio-Degradable SubstancesDocument12 pagesBiodegradable and Non Bio-Degradable SubstancessdfkjklsdfNo ratings yet

- Absolute LYFT Pulsed Eddy CurrentDocument2 pagesAbsolute LYFT Pulsed Eddy CurrentgulmuhrNo ratings yet

- Datasheet SKHI 22A PDFDocument12 pagesDatasheet SKHI 22A PDFGlauber GoncalvesNo ratings yet

- Bulk Carrier InspectionsDocument3 pagesBulk Carrier InspectionsmetallourgosNo ratings yet

- Dream Residences - Water Supply & Fire Protection BOMDocument1 pageDream Residences - Water Supply & Fire Protection BOMPatrick LlenaresNo ratings yet

- Cooling Tower ReportDocument11 pagesCooling Tower Reportbae zazNo ratings yet

- Lesson 11 Activity 1 Thermal ExpansionDocument18 pagesLesson 11 Activity 1 Thermal ExpansionEthel WenceslaoNo ratings yet

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pages3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNo ratings yet

- 690+ ParkerDocument148 pages690+ Parkerjohxav10No ratings yet

- 2-Basic Concepts of Corrosion Science and EngineeringDocument31 pages2-Basic Concepts of Corrosion Science and EngineeringMarwin G CrispinoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALNo ratings yet

- 6 Big Losses in Manufacturing-2Document3 pages6 Big Losses in Manufacturing-2izzudinrozNo ratings yet

- Minor Project RoboticsDocument10 pagesMinor Project RoboticsAnonymous 1S0lIEY100% (1)

- Reported by ACI/TMS Committee 216Document26 pagesReported by ACI/TMS Committee 216DIDIER ANGEL LOPEZ RINCONNo ratings yet

- RepAnltg ZF Wandler W390MSDocument42 pagesRepAnltg ZF Wandler W390MSFadil100% (1)

- Plant Commissioning & Start Up ProcedureDocument18 pagesPlant Commissioning & Start Up Procedureaamirapi100% (7)

- EFI BasicsDocument168 pagesEFI BasicsBryanMaes100% (1)

- Rock Tunneling Methods: 1. Drill and Blast MethodDocument14 pagesRock Tunneling Methods: 1. Drill and Blast MethodAnish Pathak100% (1)

- Operation and Maintenance Manual: C7.1 Industrial EngineDocument100 pagesOperation and Maintenance Manual: C7.1 Industrial Engineivan50% (2)

- Tempstar N9MP1 InstallDocument70 pagesTempstar N9MP1 InstallTokyNo ratings yet

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityDocument93 pages1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelNo ratings yet

- A Guide For Preservation of Mud Houses in Village Folk, Waterproof Mud PlasteringDocument4 pagesA Guide For Preservation of Mud Houses in Village Folk, Waterproof Mud PlasteringKratiNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- Emd NotesDocument182 pagesEmd Notesvpzfaris0% (1)

- MEISER Grating PDFDocument122 pagesMEISER Grating PDFabdulloh_99No ratings yet

- Dept of Chemistry 18CHE12/22 Sai Vidya Institute of TechnologyDocument22 pagesDept of Chemistry 18CHE12/22 Sai Vidya Institute of TechnologyshreyaNo ratings yet