Professional Documents

Culture Documents

ZHIHUA FM Certification Specifications

Uploaded by

bryan charles arbieto martinezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZHIHUA FM Certification Specifications

Uploaded by

bryan charles arbieto martinezCopyright:

Available Formats

Pipe Fittings

These fittings are suitable for interconnecting piping, valves and other components in both wet and dry automatic sprinkler systems.

Installation should be according to applicable sprinkler system fabrication rules. These rules limit the minimum size of sprinkler piping

to 1 in., nominal. FM Approved pipe fittings of smaller sizes are intended for use as valve trim, gauge connections, and for other

peripheral service. The water flow path of the sprinkler system cannot be designed using smaller sizes than 1 in., nominal. Unless

otherwise noted in the listing, these fittings have 175 psi (1205 kPa) rated working pressure.

Threaded connections on fittings can be made to FM Approved threadable thinwall pipe or to Schedule 40 pipe. Refer to the "Steel

Pipe" listings for a summary of the various types of FM Approved steel pipe suitable for threading or grooving."

The fittings manufacturer's installation instructions must be observed in all cases. When connections are made to FM Approved pipe,

the pipe manufacturer's installation instructions must also be followed.

Unless otherwise stated below, the maximum ambient temperature to which these fittings should be subjected is 225°F (107°C).

Pipe Fittings

Shandong Zhihua Pipe Industry, Pipe Fittings

Rated Working

Product Fitting

Nominal Pipe Size, in. Pressure, Remarks

Designation Description

psi (kPa)

33.7, 42.4, 48.3, 60.3, 73.0, 76.1, 88.9, 108,

114.3,

XGQT01 90° Elbow 300 (2070) c

133, 139.7, 159, 165.1, 168.3, 219.1, 273.0,

323.9

33.7, 42.4, 48.3, 60.3, 73.0, 76.1, 88.9, 108,

XGQT02 45° Elbow 114.3, 300 (2070) c

133, 139.7, 159, 165.1, 168.3, 219.1

XGQT09 22.5° Elbow 114.3, 165.1, 219.1 300 (2070) c

XGQT9 11.25° Elbow 114.3, 165.1, 219.1 300 (2070) c

33.7, 42.4, 48.3, 60.3, 73.0, 76.1, 88.9, 108,

114.3,

XGQT03 Equal Tee 300 (2070) c

133, 139.7, 159, 165.1, 168.3, 219.1, 273.0,

323.9

60.3 x 33.7, 42.4, 48.3

73.0 x 42.4, 48.3, 60.3

76.1 x 48.3, 60.3

88.9 x 48.3, 60.3, 73.0, 76.1

108 x 76.1, 88.9

Reducing Tee (Grooved

XGQT04 114.3 x 60.3, 73.0, 76.1, 88.9 300 (2070) c

Outlet)

139.7 x 60.3, 76.1, 88.9, 114.3

159 x 76.1, 88.9, 108, 114.3

165.1 x 60.3, 76.1, 88.9, 114.3, 139.7

168.3 x 60.3, 73.0, 76.1, 88.9, 114.3

219.1 x 114.3, 139.7, 159, 165.1, 168.3

60 x 33.7, 42.4, 48.3

73.0 x 42.4, 48.3, 60.3

76.1 x 33.7, 42.4, 48.3, 60.3

88.9 x 33.7, 42.4, 48.3, 60.3, 76.1

108 x 76.1, 88.9

Reducing Tee (Threaded

XGQT04S 114.3 x 33.7, 42.4, 48.3, 60.3, 73.0, 76.1, 88.9 300 (2070) b, c

Outlet)

139.7 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

159 x 76.1, 88.9

165.1 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

168.3 - 33.7, 42.4, 48.3, 60.3, 73.0, 88.9

219.1 x 76.1, 88.9

60.3, 73.0, 76.1, 88.9, 114.3, 139.7, 159,

XGQT07 Equal Cross 165.1, 300 (2070) c

168.3, 219.1

Reducing Cross 139.7 x 114.3

XGQT7 300 (2070) c

(Grooved Outlet) 165.1 x 114.3

© 2007-2020 FM Approvals. All rights reserved. Page 1 of 2

114.3 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

Reducing Cross

XGQT7S 139.7 x 42.4, 48.3, 60.3, 76.1, 88.9 300 (2070) b, c

(Threaded Outlet)

165.1 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

33.7, 42.4, 48.3, 60.3, 76.1, 88.9, 114.3,

XGQT06 End Cap 139.7, 300 (2070) c

165.1, 168.3, 219.1

60.3 x 33.7, 42.4, 48.3

73.0 x 33.7, 42.4, 48.3

76.1 x 33.7, 42.4, 48.3, 60.3

88.9 x 33.7, 42.4, 48.3, 60.3, 73.0, 76.1

108 x 76.1, 88.9

114.3 x 60.3, 73.0, 76.1, 88.9

XGQT5 Concentric Reducer 133 x 108, 114.3 300 (2070) c

139.7 x 60.3, 76.1, 88.9, 114.3

159 x 60.3, 76.1, 88.9, 108, 114.3, 133

165.1 x 60.3, 76.1, 88.9, 114.3, 139.7

168.3 x 60.3, 73.0, 76.1, 88.9, 114.3, 139.7

219.1 x 60.3, 76.1, 88.9, 114.3, 139.7, 165.1,

168.3

60.3 x 33.7, 42.4, 48.3

73.0 x 33.7, 42.4, 48.3, 60.3

76.1 x 33.7, 42.4, 48.3, 60.3

88.9 x 33.7, 42.4, 48.3, 60.3, 73.0, 76.1

108 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

Concentric Reducer 114.3 x 33.7, 42.4, 48.3, 60.3, 73.0, 76.1, 88.9

XGQT5S 300 (2070) b, c

(Threaded Outlet) 139.7 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

159 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

165.1 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

168.3 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9

219.1 x 33.7, 42.4, 48.3, 60.3, 76.1, 88.9,

114.3

165.1 x 88.9, 114.3

XGQT05 Eccentric Reducer 300 (2070) c

219.1 x 114.3, 139.7, 165.1

60.3, 73.0, 76.1, 88.9, 108, 114.3, 133, 139.7,

Flange Adapter (Grooved

XGQT8 159, 300 (2070) a, c

Outlet)

165.1, 168.3, 219.1

Remarks:

a. Supplied with Class 125 Flanges

b. Threads per ANSI B1.20.1 - 1983

c. Available with Cut Grooves

Company Name: Shandong Zhihua Pipe Industry Co Ltd

Zhang Jia Village, Fang an Subdistrict , Fangzi District , Weifang City, Shandong Province 262113

Company Address:

, China

Company Website: http://wfzhihua.com

New/Updated Product

No

Listing:

Listing Country: China

Certification Type: FM Approved

Class of Work: 1920-Coupling & Fitting, All Type

© 2007-2020 FM Approvals. All rights reserved. Page 2 of 2

Grooved Couplings or Fittings

Grooved couplings are used to join pipe and fittings in both wet and dry sprinkler systems. Unless otherwise noted, these couplings are intended to provide some flexibility in piping systems. Typical applications are in sprinkler risers, in feed mains passing through walls from one building area to another, in

locations subject to earthquakes, in the discharge line from aboveground pump suction tanks, in new connections to existing feed mains and in air or water fire service lines subject to excessive vibration or difficult alignment.

Unless otherwise noted, these couplings are limited to use with rolled or cut groove-ended pipe, valves and fittings, at a minimum rated working pressure of 175 psi (1205 kPa) and are suitable for aboveground service. Higher rated pressures are noted in the text of the listing. Selection of pipe schedules

for use with grooved pipe couplings should be made according to applicable FM Global Property Loss Prevention Data Sheets installation standards. These pipe schedules determine system pressure ratings and may take precedence over the higher rated working pressures listed for some couplings.

Installation must be made according to the manufacturer's instructions and requirements. Where couplings are used to join FM Approved pipe, the pipe manufacturer's installation instructions and requirements must also be observed. Grooves should be made according to ANSI/AWWA C606 (latest

edition), "Grooved and Shouldered Joints", unless otherwise specified.

FM Approved grooved pipe couplings joining steel pipe may be used in underground service, subject to the installation restrictions placed upon the pipe and to the coupling manufacturer's recommendations and requirements.

Unless otherwise stated in the listing, these couplings have been evaluated for a maximum ambient temperature of 225°F (107°C), suitable for use in normal warehouse protection. For special applications, temperatures, or environments, the manufacturer's recommendations and requirements are to be

followed.

Grooved Couplings, Standard-Flexible

These couplings join pipe, valves or fittings having equal nominal-sized diameters.

Model XGQT1N

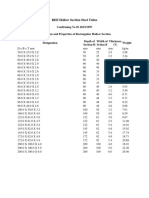

Rated Working Pressures for Model XGQT1N Flexible Coupling by Pipe a, b, c

Pipe Description

Nominal Pipe Size

1 1-1/4 1-1/2 2 2-1/2 3 4 5 6 8 10 12

(33.7) (42.7) (48.3) (60.3) (73.1) (76.1) (88.9) (108) (114.3) (133) (139.7) (141.3) (159) (165.1) (168.3) (216.3) (219.1) (267.4) (273) (318.5) (323.9)

Schedule 40, 300 300 300 300 300 300 300 300 300 300 300 300

Cut Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Schedule 40, 300 300 300 300 300 300 300 300 300 300 300 300

Roll Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Schedule 10, 300 300 300 300 300 300 300 300 300

Rolled Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

0.188” Wall, 300 300

Rolled Groove (2070) (2070)

0.250” Wall, 300

Rolled Groove (2070)

GB/T 3091, 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300

Cut Groove d (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

GB/T 3091, 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300

Rolled Groove d, e (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Remarks:

a.) Minimum schedule cut groove pipe to be joined: 6 inch or smaller, Schedule 40; 8 inch or larger, Schedule 30

b.) Minimum schedule rolled groove pipe to be joined: 6 inch or smaller, Schedule 10; 8 or 10 inch - 0.188 inch (5 mm) wall; 12 inch – 0.250 in. wall

c.) All couplings in table above, Approved when supplied with a Grade E EDPM gasket using standard gasket lubricant

d.) FM Approved for use with rolled or cut groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 40 steel sprinkler pipe per ASME B36.10-2004 specifications

e.) FM Approved for use with rolled groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 10 steel sprinkler pipe per ASME B36.10-2004 specifications

Company Name: Shandong Zhihua Pipe Industry Co Ltd

Company Address: Zhang Jia Village, Fang an Subdistrict , Fangzi District , Weifang City, Shandong Province 262113 , China

Company Website: http://wfzhihua.com

New/Updated Product Listing: No

Listing Country: China

Certification Type: FM Approved

Class of Work: 1920-Coupling & Fitting, All Type

© 2007-2020 FM Approvals. All rights reserved. Page 1 of 1

Grooved Couplings or Fittings

Grooved couplings are used to join pipe and fittings in both wet and dry sprinkler systems. Unless otherwise noted, these couplings

are intended to provide some flexibility in piping systems. Typical applications are in sprinkler risers, in feed mains passing through

walls from one building area to another, in locations subject to earthquakes, in the discharge line from aboveground pump suction

tanks, in new connections to existing feed mains and in air or water fire service lines subject to excessive vibration or difficult

alignment.

Unless otherwise noted, these couplings are limited to use with rolled or cut groove-ended pipe, valves and fittings, at a minimum

rated working pressure of 175 psi (1205 kPa) and are suitable for aboveground service. Higher rated pressures are noted in the text

of the listing. Selection of pipe schedules for use with grooved pipe couplings should be made according to applicable FM Global

Property Loss Prevention Data Sheets installation standards. These pipe schedules determine system pressure ratings and may take

precedence over the higher rated working pressures listed for some couplings.

Installation must be made according to the manufacturer's instructions and requirements. Where couplings are used to join FM

Approved pipe, the pipe manufacturer's installation instructions and requirements must also be observed. Grooves should be made

according to ANSI/AWWA C606 (latest edition), "Grooved and Shouldered Joints", unless otherwise specified.

FM Approved grooved pipe couplings joining steel pipe may be used in underground service, subject to the installation restrictions

placed upon the pipe and to the coupling manufacturer's recommendations and requirements.

Unless otherwise stated in the listing, these couplings have been evaluated for a maximum ambient temperature of 225°F (107°C),

suitable for use in normal warehouse protection. For special applications, temperatures, or environments, the manufacturer's

recommendations and requirements are to be followed.

Grooved Couplings, Reducing-Flexible

These couplings join pipe, valves or fittings having different nominal pipe diameters.

Model XGQT1B

Max Working

Product Nominal Pipe Size,

Groove Type Pressure, Remarks

Designation mm

psi (kPa)

73 x 60

76 x 60

89 x 60, 73

Rolled Groove, 300

XGQT1B 114 x 60, 73, 76, 89 a, b, c, d, e

Cut Groove (2070)

165 x 114

168 x 89, 114

219 x 165, 168

Remarks:

a. Minimum schedule cut groove pipe to be joined: 6 inch or smaller, Schedule 40; 8 inch or larger, Schedule 30

b. Minimum schedule rolled groove pipe to be joined: 6 inch or smaller, Schedule 10; 8 inch or larger, 0.188 inch (5 mm) wall

c. Approved when supplied with a Grade E EPDM gasket.

d. FM Approved for use with rolled or cut groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 40

steel sprinkler pipe per ASME B36.10-2004 specifications.

e. FM Approved for use with rolled groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 10 steel

sprinkler pipe per ASME B36.10-2004 specifications.

Company Name: Shandong Zhihua Pipe Industry Co Ltd

Zhang Jia Village, Fang an Subdistrict , Fangzi District , Weifang City, Shandong Province 262113

Company Address:

, China

Company Website: http://wfzhihua.com

New/Updated Product

No

Listing:

Listing Country: China

Certification Type: FM Approved

Class of Work: 1920-Coupling & Fitting, All Type

© 2007-2020 FM Approvals. All rights reserved. Page 1 of 1

Grooved Couplings or Fittings

Grooved couplings are used to join pipe and fittings in both wet and dry sprinkler systems. Unless otherwise noted, these couplings are intended to provide some flexibility in piping systems. Typical applications are in sprinkler risers, in feed mains passing through walls from one building area to another, in

locations subject to earthquakes, in the discharge line from aboveground pump suction tanks, in new connections to existing feed mains and in air or water fire service lines subject to excessive vibration or difficult alignment.

Unless otherwise noted, these couplings are limited to use with rolled or cut groove-ended pipe, valves and fittings, at a minimum rated working pressure of 175 psi (1205 kPa) and are suitable for aboveground service. Higher rated pressures are noted in the text of the listing. Selection of pipe schedules

for use with grooved pipe couplings should be made according to applicable FM Global Property Loss Prevention Data Sheets installation standards. These pipe schedules determine system pressure ratings and may take precedence over the higher rated working pressures listed for some couplings.

Installation must be made according to the manufacturer's instructions and requirements. Where couplings are used to join FM Approved pipe, the pipe manufacturer's installation instructions and requirements must also be observed. Grooves should be made according to ANSI/AWWA C606 (latest

edition), "Grooved and Shouldered Joints", unless otherwise specified.

FM Approved grooved pipe couplings joining steel pipe may be used in underground service, subject to the installation restrictions placed upon the pipe and to the coupling manufacturer's recommendations and requirements.

Unless otherwise stated in the listing, these couplings have been evaluated for a maximum ambient temperature of 225°F (107°C), suitable for use in normal warehouse protection. For special applications, temperatures, or environments, the manufacturer's recommendations and requirements are to be

followed.

Grooved Couplings, Standard-Rigid

These couplings join pipe, valves or fittings having equal diameters.

Model XGQT1

Rated Working Pressures for Model XGQT1 Rigid Coupling by Pipe a, b, c

Pipe Description

Nominal Pipe Size

1 1-1/4 1-1/2 2 2-1/2 3 4 5 6 8 10 12

(33.7) (42.7) (48.3) (60.3) (73.1) (76.1) (88.9) (108) (114.3) (133) (139.7) (141.3) (159) (165.1) (168.3) (216.3) (219.1) (267.4) (273) (318.5) (323.9)

Schedule 40, 300 300 300 300 300 300 300 300 300 300 300 300

Cut Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Schedule 40, 300 300 300 300 300 300 300 300 300 300 300 300

Roll Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Schedule 10, 300 300 300 300 300 300 300 300 300

Rolled Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

0.188” Wall, 300 300

Rolled Groove (2070) (2070)

0.250” Wall, 300

Rolled Groove (2070)

GB/T 3091, 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300

Cut Groove d (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

GB/T 3091, 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300

Rolled Groove d, e (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Remarks:

a.) Minimum schedule cut groove pipe to be joined: 6 inch or smaller, Schedule 40; 8 inch or larger, Schedule 30

b.) Minimum schedule rolled groove pipe to be joined: 6 inch or smaller, Schedule 10; 8 or 10 inch - 0.188 inch (5 mm) wall; 12 inch – 0.250 in. wall

c.) All couplings in table above, Approved when supplied with a Grade E EDPM gasket using standard gasket lubricant

d.) FM Approved for use with rolled or cut groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 40 steel sprinkler pipe per ASME B36.10-2004 specifications

e.) FM Approved for use with rolled groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 10 steel sprinkler pipe per ASME B36.10-2004 specifications

Company Name: Shandong Zhihua Pipe Industry Co Ltd

Company Address: Zhang Jia Village, Fang an Subdistrict , Fangzi District , Weifang City, Shandong Province 262113 , China

Company Website: http://wfzhihua.com

New/Updated Product Listing: No

Listing Country: China

Certification Type: FM Approved

Class of Work: 1920-Coupling & Fitting, All Type

© 2007-2020 FM Approvals. All rights reserved. Page 1 of 1

Grooved Couplings or Fittings

Grooved couplings are used to join pipe and fittings in both wet and dry sprinkler systems. Unless otherwise noted, these couplings are intended to provide some flexibility in piping systems. Typical applications are in sprinkler risers, in feed mains passing through walls from one building area to another, in

locations subject to earthquakes, in the discharge line from aboveground pump suction tanks, in new connections to existing feed mains and in air or water fire service lines subject to excessive vibration or difficult alignment.

Unless otherwise noted, these couplings are limited to use with rolled or cut groove-ended pipe, valves and fittings, at a minimum rated working pressure of 175 psi (1205 kPa) and are suitable for aboveground service. Higher rated pressures are noted in the text of the listing. Selection of pipe schedules

for use with grooved pipe couplings should be made according to applicable FM Global Property Loss Prevention Data Sheets installation standards. These pipe schedules determine system pressure ratings and may take precedence over the higher rated working pressures listed for some couplings.

Installation must be made according to the manufacturer's instructions and requirements. Where couplings are used to join FM Approved pipe, the pipe manufacturer's installation instructions and requirements must also be observed. Grooves should be made according to ANSI/AWWA C606 (latest

edition), "Grooved and Shouldered Joints", unless otherwise specified.

FM Approved grooved pipe couplings joining steel pipe may be used in underground service, subject to the installation restrictions placed upon the pipe and to the coupling manufacturer's recommendations and requirements.

Unless otherwise stated in the listing, these couplings have been evaluated for a maximum ambient temperature of 225°F (107°C), suitable for use in normal warehouse protection. For special applications, temperatures, or environments, the manufacturer's recommendations and requirements are to be

followed.

Grooved Couplings, Standard-Rigid

These couplings join pipe, valves or fittings having equal diameters.

Model XGQT2

Rated Working Pressures for Model XGQT2 Rigid Angle Coupling by Pipe a, b, c

Pipe Description

Nominal Pipe Size

1 1-1/4 1-1/2 2 2-1/2 3 4 5 6 8 10 12

(33.7) (42.7) (48.3) (60.3) (73.1) (76.1) (88.9) (108) (114.3) (133) (139.7) (141.3) (159) (165.1) (168.3) (216.3) (219.1) (267.4) (273) (318.5) (323.9)

Schedule 40, 300 300 300 300 300 300 300 300 300 300 300 300

Cut Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Schedule 40, 300 300 300 300 300 300 300 300 300 300 300 300

Roll Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Schedule 10, 300 300 300 300 300 300 300 300 300

Rolled Groove (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

0.188” Wall, 300 300

Rolled Groove (2070) (2070)

0.250” Wall, 300

Rolled Groove (2070)

GB/T 3091, 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300

Cut Groove d (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

GB/T 3091, 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300 300

Rolled Groove d, e (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070) (2070)

Remarks:

a.) Minimum schedule cut groove pipe to be joined: 6 inch or smaller, Schedule 40; 8 inch or larger, Schedule 30

b.) Minimum schedule rolled groove pipe to be joined: 6 inch or smaller, Schedule 10; 8 or 10 inch - 0.188 inch (5 mm) wall; 12 inch – 0.250 in. wall

c.) All couplings in table above, Approved when supplied with a Grade E EDPM gasket using standard gasket lubricant

d.) FM Approved for use with rolled or cut groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 40 steel sprinkler pipe per ASME B36.10-2004 specifications

e.) FM Approved for use with rolled groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 10 steel sprinkler pipe per ASME B36.10-2004 specifications

Company Name: Shandong Zhihua Pipe Industry Co Ltd

Company Address: Zhang Jia Village, Fang an Subdistrict , Fangzi District , Weifang City, Shandong Province 262113 , China

Company Website: http://wfzhihua.com

New/Updated Product Listing: No

Listing Country: China

Certification Type: FM Approved

Class of Work: 1920-Coupling & Fitting, All Type

© 2007-2020 FM Approvals. All rights reserved. Page 1 of 1

Grooved Couplings or Fittings

Grooved couplings are used to join pipe and fittings in both wet and dry sprinkler systems. Unless otherwise noted, these couplings

are intended to provide some flexibility in piping systems. Typical applications are in sprinkler risers, in feed mains passing through

walls from one building area to another, in locations subject to earthquakes, in the discharge line from aboveground pump suction

tanks, in new connections to existing feed mains and in air or water fire service lines subject to excessive vibration or difficult

alignment.

Unless otherwise noted, these couplings are limited to use with rolled or cut groove-ended pipe, valves and fittings, at a minimum

rated working pressure of 175 psi (1205 kPa) and are suitable for aboveground service. Higher rated pressures are noted in the text

of the listing. Selection of pipe schedules for use with grooved pipe couplings should be made according to applicable FM Global

Property Loss Prevention Data Sheets installation standards. These pipe schedules determine system pressure ratings and may take

precedence over the higher rated working pressures listed for some couplings.

Installation must be made according to the manufacturer's instructions and requirements. Where couplings are used to join FM

Approved pipe, the pipe manufacturer's installation instructions and requirements must also be observed. Grooves should be made

according to ANSI/AWWA C606 (latest edition), "Grooved and Shouldered Joints", unless otherwise specified.

FM Approved grooved pipe couplings joining steel pipe may be used in underground service, subject to the installation restrictions

placed upon the pipe and to the coupling manufacturer's recommendations and requirements.

Unless otherwise stated in the listing, these couplings have been evaluated for a maximum ambient temperature of 225°F (107°C),

suitable for use in normal warehouse protection. For special applications, temperatures, or environments, the manufacturer's

recommendations and requirements are to be followed.

Grooved Split Flanges-Flexible

Split Flanged-These fittings join pipe, valves or fittings having equal diameters.

Model XGQT08

Max Working Pressure,

Product Nominal Pipe Size, Bolt

Remarks psi

Designation mm Pattern

(kPa)

60, 73, 76, 89, 108, 114, 133, 140, 141, 159, 165, 168, 219, a, b, c, d, 300

XGQT08 ANSI 150

273, 325 e, (2070)

Remarks:

a. Minimum schedule cut groove pipe to be joined: 6 inch or smaller, Schedule 40; 8 inch or larger, Schedule 30

b. Minimum schedule rolled groove pipe to be joined: 6 inch or smaller, Schedule 10; 8 or 10 inch - 0.188 inch (5 mm) wall; 12 inch –

0.250 inch (6.35 mm) wall

c. Approved when supplied with a Grade E EPDM gasket.

d. FM Approved for use with rolled or cut groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 40

steel sprinkler pipe per ASME B36.10-2004 specifications

e. FM Approved for use with rolled groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 10 steel

sprinkler pipe per ASME B36.10-2004 specifications

Company Name: Shandong Zhihua Pipe Industry Co Ltd

Zhang Jia Village, Fang an Subdistrict , Fangzi District , Weifang City, Shandong Province 262113

Company Address:

, China

Company Website: http://wfzhihua.com

New/Updated Product

No

Listing:

Listing Country: China

Certification Type: FM Approved

Class of Work: 1920-Coupling & Fitting, All Type

© 2007-2020 FM Approvals. All rights reserved. Page 1 of 1

Pipe Fittings

These fittings are suitable for interconnecting piping, valves and other components in both wet and dry automatic sprinkler systems.

Installation should be according to applicable sprinkler system fabrication rules. These rules limit the minimum size of sprinkler piping

to 1 in., nominal. FM Approved pipe fittings of smaller sizes are intended for use as valve trim, gauge connections, and for other

peripheral service. The water flow path of the sprinkler system cannot be designed using smaller sizes than 1 in., nominal. Unless

otherwise noted in the listing, these fittings have 175 psi (1205 kPa) rated working pressure.

Threaded connections on fittings can be made to FM Approved threadable thinwall pipe or to Schedule 40 pipe. Refer to the "Steel

Pipe" listings for a summary of the various types of FM Approved steel pipe suitable for threading or grooving."

The fittings manufacturer's installation instructions must be observed in all cases. When connections are made to FM Approved pipe,

the pipe manufacturer's installation instructions must also be followed.

Unless otherwise stated below, the maximum ambient temperature to which these fittings should be subjected is 225°F (107°C).

Fittings, Side Outlet, Rigid

These fittings allow installation of a perpendicular branch line of reduced size, while joining inline pipes of equal diameters. These

fittings bolt over a hole in the run pipe, and allow installation of a perpendicular branch line of reduced size. The maximum branch

line size is one pipe size reduced from the run pipe size.

Models XGQT3, XGQT3S and XGQT3U

Nominal Run by Max Working

Product Fitting

Outlet Sizes, Remarks Pressure,

Designation Description

mm psi (kPa)

60 x 42, 48

73 x 42, 48

76 x 42, 48

89 x 42, 48, 60

108 x 76, 89

Mechanical Tee, 300

XGQT3 114 x 33, 42, 48, 60, 73, 76, 89 a, b, c, e, f

Grooved Outlet (2070)

140 x 42, 48, 60, 76, 89

141 x 42, 48, 60, 76

165 x 42, 48, 60, 76, 89, 114

168 x 42, 48, 60, 73, 76, 89, 114

219 x 60, 76, 89, 114

60 x 33, 42

73 x 33, 42, 48

76 x 33, 42, 48

89 x 33, 42, 48, 60

108 x 33, 42, 48, 60, 73, 76, 89

114 x 33, 42, 48, 60, 73, 76, 89

Mechanical Tee, 300

XGQT3S 133 x 33, 42, 48, 60, 76, 89 a, b, c, d, e, f

Threaded Outlet (2070)

140 x 33, 42, 48, 60, 76, 89

141 x 33, 42, 48, 60, 76, 89

159 x 33, 42, 48, 60, 76, 89

165 x 33, 42, 48, 60, 76, 89

168 x 33, 42, 48, 60, 73, 76, 89

219 x 33, 42, 48, 60, 76, 89, 114

33 x 21

42 x 21, 26, 33

48 x 21, 26, 33

Mechanical Tee, 300

XGQT3U 60 x 21, 26, 33, 42 a, b, c, d, e, f

Threaded Outlet (2070)

73 x 21, 26

76 x 21, 26, 33

89 x 33

Remarks:

a. Minimum schedule cut groove pipe to be joined: 6 inch or smaller, Schedule 40; 8 inch or larger, Schedule 30

b. Minimum schedule rolled groove pipe to be joined: 6 inch or smaller, Schedule 10; 8 inch or larger, 0.188 inch (5 mm) wall

c. Approved when supplied with a Grade E EPDM gasket.

d. Approved when supplied with NPT female threads.

e. FM Approved for use with rolled or cut groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 40

steel sprinkler pipe per ASME B36.10-2004 specifications

f. FM Approved for use with rolled groove GB/T 3091 steel sprinkler pipe with wall thicknesses comparable to Schedule 10 steel

sprinkler pipe per ASME B36.10-2004 specifications

© 2007-2020 FM Approvals. All rights reserved. Page 1 of 2

Company Name: Shandong Zhihua Pipe Industry Co Ltd

Zhang Jia Village, Fang an Subdistrict , Fangzi District , Weifang City, Shandong Province 262113

Company Address:

, China

Company Website: http://wfzhihua.com

New/Updated Product

No

Listing:

Listing Country: China

Certification Type: FM Approved

Class of Work: 1920-Coupling & Fitting, All Type

© 2007-2020 FM Approvals. All rights reserved. Page 2 of 2

You might also like

- Codes Standards For Structural Steel Fabrication ErectionDocument7 pagesCodes Standards For Structural Steel Fabrication Erectionelangorenga67% (3)

- Schema Generator Curent Kipor Id6000Document1 pageSchema Generator Curent Kipor Id6000Generatoare de Curent ElectricNo ratings yet

- SP00976 OMM For CPPDocument414 pagesSP00976 OMM For CPPCidhin NairNo ratings yet

- Shape by Shape, Collection 2: Free-Motion Quilting with Angela Walters - 70+ More Designs for Blocks, Backgrounds & BordersFrom EverandShape by Shape, Collection 2: Free-Motion Quilting with Angela Walters - 70+ More Designs for Blocks, Backgrounds & BordersRating: 5 out of 5 stars5/5 (1)

- Shand - Jurs Conservation Vent 94020-3CDocument8 pagesShand - Jurs Conservation Vent 94020-3CRuban PaulNo ratings yet

- Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument19 pagesSteel Castings, Welding, Qualifications of Procedures and PersonnelDavidNo ratings yet

- Certificados de Calidad PDFDocument4 pagesCertificados de Calidad PDFAlexander Alvarez VegaNo ratings yet

- Design CalculationsDocument50 pagesDesign CalculationsSandi ApriandiNo ratings yet

- API Round-Thread Casing Coupling - Dimensions, Tolerance and MassesDocument3 pagesAPI Round-Thread Casing Coupling - Dimensions, Tolerance and MassesEsteban NeutoNo ratings yet

- J-30 MODEL SJ-300F RESILIENT SEATED BUTTERFLY VALVE - Rev.NDocument5 pagesJ-30 MODEL SJ-300F RESILIENT SEATED BUTTERFLY VALVE - Rev.NMichel De Souza CorreaNo ratings yet

- Grinnell Mechanical Products Rigid Coupling General Description Technical DataDocument2 pagesGrinnell Mechanical Products Rigid Coupling General Description Technical DataСергей КолесниковNo ratings yet

- Design CalculationsDocument50 pagesDesign CalculationsMohammed AltafNo ratings yet

- Evaluation of External Loads On Welding Neck Flanges As Per Code Case 2901Document6 pagesEvaluation of External Loads On Welding Neck Flanges As Per Code Case 2901NirmalNo ratings yet

- Tenar Is Hydri LWTDocument1 pageTenar Is Hydri LWTIng BernsteinNo ratings yet

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsDocument2 pagesCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimNo ratings yet

- Astm A500-3Document1 pageAstm A500-3asnawi89No ratings yet

- Dimensions of Cut Ring GasketDocument2 pagesDimensions of Cut Ring GaskethibhavuNo ratings yet

- Catalog SMT Series Transformers Solahd en Us 7438562Document1 pageCatalog SMT Series Transformers Solahd en Us 7438562ale348hotmail.comNo ratings yet

- UF-pHt SeriesDocument4 pagesUF-pHt SeriesLalit VashistaNo ratings yet

- Pipes b16.25 PDFDocument11 pagesPipes b16.25 PDFAsep DarojatNo ratings yet

- Retrofitting Columns 20JAN09Document4 pagesRetrofitting Columns 20JAN094geniecivilNo ratings yet

- 720.0 32.0 31.3 Total Number of Stations (N) Sum of Internal Angles Closing Error Reduced BearingDocument8 pages720.0 32.0 31.3 Total Number of Stations (N) Sum of Internal Angles Closing Error Reduced BearingjkhsiugNo ratings yet

- Stability CheckDocument3 pagesStability Checkmario milanoreNo ratings yet

- Bolt Capacities: Non-Preloaded Ordinary BoltsDocument1 pageBolt Capacities: Non-Preloaded Ordinary BoltsSelvasathaNo ratings yet

- Red. Conc y ExcDocument10 pagesRed. Conc y Excventura.curayNo ratings yet

- FC80617Document2 pagesFC80617Khalid ZaeemNo ratings yet

- FM JUNT AccesoriosDocument3 pagesFM JUNT AccesoriosFIRE RL SYSTEMSNo ratings yet

- Piping ElementsDocument53 pagesPiping ElementsHemant ShindeNo ratings yet

- Rangka Atap Baja - Tipe 1Document43 pagesRangka Atap Baja - Tipe 1Afif NurhidayatNo ratings yet

- Design For ShearDocument2 pagesDesign For ShearThomas John Doblas AgrabioNo ratings yet

- 6.1 Flanges ASME B16.5Document9 pages6.1 Flanges ASME B16.5GEORGENo ratings yet

- UB UC Steel SectionsDocument10 pagesUB UC Steel SectionsMuhammad HasanNo ratings yet

- Pipe Abstract of Chatarpura ID OD Length (M)Document5 pagesPipe Abstract of Chatarpura ID OD Length (M)Anil SainiNo ratings yet

- Column DesignDocument22 pagesColumn DesignMuhammad Atif IqbalNo ratings yet

- Tws 600 S Pump Flyer - 0910Document2 pagesTws 600 S Pump Flyer - 0910santanuaNo ratings yet

- Riduzioni Concentriche Ed Eccentriche Cod. RFW402 RFW409: Concentric and Eccentric ReducersDocument4 pagesRiduzioni Concentriche Ed Eccentriche Cod. RFW402 RFW409: Concentric and Eccentric ReducersAHMED AMIRANo ratings yet

- Tabel Marshal AC Base PDFDocument1 pageTabel Marshal AC Base PDFgheanifaNo ratings yet

- Laporan Harian ACBCDocument7 pagesLaporan Harian ACBCmandor gedorNo ratings yet

- EN 10061-2003 - Extracto - Tolerancias HexagonaisDocument2 pagesEN 10061-2003 - Extracto - Tolerancias HexagonaisQualidadeTFNo ratings yet

- Ficha Tecnica Canales en UDocument1 pageFicha Tecnica Canales en UDavidVegaNo ratings yet

- TSH W563Document4 pagesTSH W563AHMED BAKRNo ratings yet

- CalculationDocument4 pagesCalculationCR001No ratings yet

- Column DesignDocument20 pagesColumn DesignSaman AdelNo ratings yet

- Max Bolt Loads Refer To BS5950Document1 pageMax Bolt Loads Refer To BS5950Eko Pulianto ZESBNo ratings yet

- Bolt Load Tables To BS5950 01.01.03 PDFDocument1 pageBolt Load Tables To BS5950 01.01.03 PDFjakeer70% (1)

- Capacity of Bolt - BS5950Document1 pageCapacity of Bolt - BS5950Eko Pulianto ZESBNo ratings yet

- Bolt Capacity Refer To BS5950Document1 pageBolt Capacity Refer To BS5950Eko Pulianto ZESBNo ratings yet

- Tubos de Aço: Tubos de Condução Com e Sem Costura - NBR 5590 (ASTM A-53) /A106 A/API 5L BDocument2 pagesTubos de Aço: Tubos de Condução Com e Sem Costura - NBR 5590 (ASTM A-53) /A106 A/API 5L BDiovane SantosNo ratings yet

- UF-FS SeriesDocument2 pagesUF-FS SeriesLalit VashistaNo ratings yet

- Accessories: Flanges According To DIN - EN - ASME - JIS - GOSTDocument24 pagesAccessories: Flanges According To DIN - EN - ASME - JIS - GOSTTero LaukkanenNo ratings yet

- FR Codo de 90 Ac Ced80 Astm A234 Gr. WPBDocument1 pageFR Codo de 90 Ac Ced80 Astm A234 Gr. WPBSERVICIOS INTEGRALES OSDANo ratings yet

- Tabel BajaDocument14 pagesTabel Bajadudududu lalalalaNo ratings yet

- CIV 4013-Assignment 2010Document8 pagesCIV 4013-Assignment 2010Virtual RealityNo ratings yet

- Design CalculationsDocument54 pagesDesign CalculationsFrank MtetwaNo ratings yet

- ECO - B - PRO - BDocument2 pagesECO - B - PRO - BRajkishore NayakNo ratings yet

- Table 3.3-3 Section Properties To Calculate Member StabilityDocument1 pageTable 3.3-3 Section Properties To Calculate Member StabilityshazanNo ratings yet

- All Aluminum Conductor Steel Reinforced (Acsr)Document48 pagesAll Aluminum Conductor Steel Reinforced (Acsr)Satadal DashNo ratings yet

- Compdump - K6101ADocument41 pagesCompdump - K6101AJOSE LUIS RATTIANo ratings yet

- RHS Hollow Section Steel TubesDocument3 pagesRHS Hollow Section Steel TubesNurquiz Jhon VillagonzaloNo ratings yet

- Rhs Shs Hollow Section Pipes PDFDocument3 pagesRhs Shs Hollow Section Pipes PDFplanningNo ratings yet

- Tubos de Aço Com e Sem Constura: Normas AtendidasDocument1 pageTubos de Aço Com e Sem Constura: Normas AtendidasRaufe SouzaNo ratings yet

- RD RigidsteelconduitimcDocument1 pageRD RigidsteelconduitimcRitaban222No ratings yet

- Rd-Rigid Steel Conduit ImcDocument1 pageRd-Rigid Steel Conduit ImcSGQNo ratings yet

- DUCT CalculationDocument13 pagesDUCT CalculationMark SorianoNo ratings yet

- Gaylord List Parts 20062Document18 pagesGaylord List Parts 20062kskadryNo ratings yet

- A Project of Volunteers in AsiaDocument98 pagesA Project of Volunteers in AsiaMbah DukNo ratings yet

- MSS SP53Document9 pagesMSS SP53nile_asterNo ratings yet

- 10 WB140-2 Shop ManualDocument406 pages10 WB140-2 Shop ManualMarcos Calderon ReynaNo ratings yet

- Research On The Springback of Thin-Walled Tube NC Bending Based On The Numerical Simulation of The Whole ProcessDocument13 pagesResearch On The Springback of Thin-Walled Tube NC Bending Based On The Numerical Simulation of The Whole ProcessYasser BouktirNo ratings yet

- INSTA SBC EN 13589-2 Sep 2009Document17 pagesINSTA SBC EN 13589-2 Sep 2009Kipodim100% (1)

- Piping Specialties Rev 4Document25 pagesPiping Specialties Rev 4gigiphi100% (1)

- PVC Pipes and Fittings State of The Art of Thermoplastic Pipe Technology in North AmericaDocument94 pagesPVC Pipes and Fittings State of The Art of Thermoplastic Pipe Technology in North Americavmi_dudeNo ratings yet

- Platso WatDocument37 pagesPlatso WatAshoka NarayananNo ratings yet

- Quality ConsultantDocument4 pagesQuality Consultantapi-77897032No ratings yet

- Shear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsDocument6 pagesShear Wave Velocity: Comparison Between Centrifuge and Triaxial Based MeasurementsLuciano JuniorNo ratings yet

- (GRE) Installation Manual For MarineDocument37 pages(GRE) Installation Manual For MarineQuy RomNo ratings yet

- External Coatings For Corrosion Protection of Steel Pipes and ComponentsDocument120 pagesExternal Coatings For Corrosion Protection of Steel Pipes and ComponentsadelNo ratings yet

- JIS B.0203.e.1982Document14 pagesJIS B.0203.e.1982Angel Alvarez CarrilloNo ratings yet

- Project ProposDocument24 pagesProject ProposKrishnendu PramanikNo ratings yet

- Rotary Positive Displacement PumpsDocument16 pagesRotary Positive Displacement Pumpsalexmuchmure2158No ratings yet

- Rapp-It CatalogueDocument12 pagesRapp-It CatalogueJose Martinez MillaNo ratings yet

- An Analysis of Failures in Coiled TubingDocument8 pagesAn Analysis of Failures in Coiled TubingDavid OtálvaroNo ratings yet

- PKG List (Submit To Mr. Jeong)Document6 pagesPKG List (Submit To Mr. Jeong)Tuấn PhạmNo ratings yet

- Takeuchi Tb175 Workshopmanual Sec WatDocument20 pagesTakeuchi Tb175 Workshopmanual Sec Wattanya100% (56)

- Fastparts SprayersDocument46 pagesFastparts Sprayerseverywhere4645No ratings yet

- Electrobomba Centrifuga Vertical CRIDocument28 pagesElectrobomba Centrifuga Vertical CRICristianSalazarRamirezNo ratings yet

- Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesDocument12 pagesSeamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesemadNo ratings yet

- 4.0 S-135 Drill Pipe W Xt39Document1 page4.0 S-135 Drill Pipe W Xt39rdos14No ratings yet

- Astm Designation of Materials: SK Corporation H. BaeDocument4 pagesAstm Designation of Materials: SK Corporation H. BaeNeelam AhmadNo ratings yet