Professional Documents

Culture Documents

5 Innovative Materials For The Future of Design A

Uploaded by

vinay chinniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 Innovative Materials For The Future of Design A

Uploaded by

vinay chinniCopyright:

Available Formats

SUSTAINABILITY

5 experimental materials

for the future of design

and architecture

Text by Salvatore Peluso

Add to bookmarks

Turning polluted soil into bricks

A selection of material innovations for

integration into buildings and products:

micro-algae capable of absorbing CO2

like tall trees, fossil-free metals,

photovoltaic membranes, bricks that

sequester toxins from the land and

biological textiles

Updated on 12 June 2023. There are many

independent experimental research projects that

could soon be harnessed at industrial level. These

projects and glimmers of hope for sustainable

development can help us imagine a future in which

Man’s impact on the planet is significantly reduced.

PhotoSyntetica – CO2-

absorbing micro-algae

Through the urban cultivation of micro-algae,

EcoLogic Studio produces oxygen and reduces air

pollutants. PhotoSyntetica is a research project

that the London-based studio has been working on

for several years, by means of a number of

experiments, prototypes and installations that turn

buildings into air pollution filters. The architects

have developed a curtain that functions as a

photobioreactor, in which a 2m2 module has the

same efficiency as a tall tree. It combines the

qualities of EFTE sheeting – a light, robust,

translucent and chemically inert material – with the

algae’s ability to capture solar radiation and absorb

CO2 ten times more effectively than trees.

Ecologic Studio, PhotoSynthetica, urban curtains in Dublin and

Helsinki. Ph Tuomas Uusheimo

AuREUS – photovoltaic film

The inventor of the AuREUS system garnered the

first ever James Dyson Sustainability Award 2020 in

the Sustainability category. It is a plastic material

derived from agricultural waste that converts UV

light into electric energy, developed by Carvey Ehren

Maigue, an electrical engineering student at Mapua

University in Manila. It is also very flexible and easy

to use, as well as highly effective, regardless of

weather conditions. Current tests indicate that it is

capable of producing electricity 48% of the time,

compared with 10-25% from photovoltaic cells.

AuREUS has the merit not just of tackling one of the

most pressing issues of our times – energy shortage

– it could also potentially be used in different fields

and by a large number of people.

Carvey Ehren Maigue, AuREUS JDA Imagery Sustainability Winner

Claybens – bricks from

polluted clay soil

Per- and polyfluoroalkyl substances (PFAS) are

chemical products that are difficult to degrade. Used

for decades in various industrial processes – textile

production, electronics, paper coatings, paint, fire

retardant foam and wax for skis – they persist at

length in the environment and in the food chain.

With her start up Claybens

Claybens, Dutch designer Emy

Bensorphas come up with a solution to the problem:

heating PFAS contaminated clay soil to very high

temperatures allows the chemical pollutants to be

destroyed, creating a clean ceramic material.

Claybens turns this into bricks that can be produced

in bulk, allowing large quantities of soil to be

cleansed rapidly.

Turning polluted soil into bricks

HYBRIT – fossil-free steel

Steel is far from being considered a sustainable

material. The industry that rotates around steel

generates huge CO2 emissions - 1.85 tonnes of CO2

for every tonne of material produced. Between 12%

and 14% of global CO2 emissions are associated with

the steel industry. However, the Swedish firm SSAB

Oxelösund has come up with what they say is the

world’s first fossil-free steel, produced using green

hydrogen rather than coking coal, by harnessing

HYBRIT (Hydrogen Breakthrough Ironmaking

Technology), created by the company along with

LKAB and Vattenfall in 2016. Only small objects for

demonstration purposes, such as a candlestick by

the designer Lena Bergström have been produced

thus far. The aim is to start using it in complex

industrial processes over the next few years, and the

Volvo Group is the company’s first large-scale client.

Biotic – biological textiles

Dutch studio Lionne van Deursen is researching

the properties and potential of biologically grown

materials. Biotic is a series of biological textiles,

made from bacterial cellulose, dyed using natural

pigments. The bacteria feed off sugared green tea

and spin nano fibres of cellulose. Once the surface

layer solidifies it acquires qualities comparable to

those of leather: the material produced by the

microorganisms is biodegradable, extremely tough

and highly flexible. The experiments carried out by

Lionne van Deursen have yielded a collection of

textiles of different colours, degrees of translucency

and textures. The studio has designed a collection of

table lamps using this material.

SSAB Oxelösund, iron fossil-

free with HYBRIT technology (Hydrogen Breakthrough Ironmaking Technology

19 October 2021

SHARE

See Also

Other Articles

STORIES

A 60-year milestone looking towards the

challenges of the future. We talk to Pedrali

Patrizia Malfatti

EXHIBITIONS

SaloneSatellite and Rinascente: design starts over

from young people

Marilena Sobacchi

SALONE SELECTION

Milan Digital Week between paradigm shifts and

the development of limits

C. S. Bontempi Sciama

STORIES

What we saw at Fashion Weeks

Elisa Carassai

Institutional partner

Official Time Keeper

Officials partner

Media Partner

In collaboration with

As part of the Smart 365 Fair

Stay up with our news,

subscribe to our

newsletter

Email Address*

Subscribe

The Salone Internazionale del Mobile was founded in

1961 as a vehicle for promoting Italian furniture and

furnishings exports and soon became the most

keenly awaited event in the world of furniture.

Foro Buonaparte 65

20121, Milano

Tel. 02 725941 Fax 02 89011563

About us Contact us

Privacy Disclaimer

D. Lgs. 231/01 Cookies

Reg.Impr. / CF e P.IVA 06987590152 ®

2022 Federlegno Arredo Eventi SpA

You might also like

- Resilience in Heritage Conservation and Heritage Tourism A Dissertation by ... (Pdfdrive)Document217 pagesResilience in Heritage Conservation and Heritage Tourism A Dissertation by ... (Pdfdrive)ristya arintaNo ratings yet

- Garbage Management Plan-2021 (Rev 2023)Document41 pagesGarbage Management Plan-2021 (Rev 2023)Afig DzhafarovNo ratings yet

- EIA Guidelines For Drainage IrrigationDocument252 pagesEIA Guidelines For Drainage Irrigationwilson celexNo ratings yet

- Bajaj Allianz General Insurance Company Limited: Presented by Shreya Jiya Sailatha AkhilDocument13 pagesBajaj Allianz General Insurance Company Limited: Presented by Shreya Jiya Sailatha AkhilShreyaNo ratings yet

- Unit 1 - Heritage Tourism1Document48 pagesUnit 1 - Heritage Tourism1mikee albaNo ratings yet

- Case Study-5 Title: - Acoem Eagle, Enocean Push Button, Nest Sensor, Ninja Blocks - Focusing On Wearable ElectronicsDocument6 pagesCase Study-5 Title: - Acoem Eagle, Enocean Push Button, Nest Sensor, Ninja Blocks - Focusing On Wearable ElectronicsTushar NepaleNo ratings yet

- Technical and Economic Feasibility Analysis of An Industrial Plant For Producing Acrylo Nitril To Be Used For The Production of Acrylic Fiber PDFDocument95 pagesTechnical and Economic Feasibility Analysis of An Industrial Plant For Producing Acrylo Nitril To Be Used For The Production of Acrylic Fiber PDFMarvil Raul Cieza CastilloNo ratings yet

- SEM I To IV B.arch Syllabus 2021Document74 pagesSEM I To IV B.arch Syllabus 2021Vigneshkumar RamanathanNo ratings yet

- BIO NEET BOOK-2 - (ENG) - Ch-6-J-Done-1Document64 pagesBIO NEET BOOK-2 - (ENG) - Ch-6-J-Done-1Prajapati HarishNo ratings yet

- SDS NITOFLOR SL1000 IndiaDocument29 pagesSDS NITOFLOR SL1000 IndiaMaha MuflehNo ratings yet

- Bihar Public Service Commision ASSISTANT PDFDocument1 pageBihar Public Service Commision ASSISTANT PDFFunmaniaNo ratings yet

- The Maritime Pilot at WorkDocument167 pagesThe Maritime Pilot at WorkÇağlayan TopNo ratings yet

- Owner'S Manual: Signals. A Little Practice Is Required To Understand When and HowDocument20 pagesOwner'S Manual: Signals. A Little Practice Is Required To Understand When and HowMama SpittaNo ratings yet

- T Ilc 03Document31 pagesT Ilc 03Tomáš TóthNo ratings yet

- Chamberlink - October 2014Document24 pagesChamberlink - October 2014Imelda V. MulcahyNo ratings yet

- Mathrubhumi Yearbook 2019 Digital Update November 2018Document21 pagesMathrubhumi Yearbook 2019 Digital Update November 2018Bimal MadathilNo ratings yet

- Final Signed Audited Accounts 21-22 - Updated Draft 5Document34 pagesFinal Signed Audited Accounts 21-22 - Updated Draft 5Martin AllenNo ratings yet

- Bucks County v. TikTok, Et Al.Document109 pagesBucks County v. TikTok, Et Al.Kristina KoppeserNo ratings yet

- Energy Efficiency and Comfort of Historic Buildings - Proceedings - EECHBDocument342 pagesEnergy Efficiency and Comfort of Historic Buildings - Proceedings - EECHBHumbertoNo ratings yet

- NRCEP Announcement of CPD Requirement For Competent PersonsDocument3 pagesNRCEP Announcement of CPD Requirement For Competent PersonsAku Lah100% (2)

- J Fajardo - PortfolioDocument10 pagesJ Fajardo - PortfolioJonathan FajardoNo ratings yet

- Marketing ProjectDocument31 pagesMarketing ProjectSai KashidNo ratings yet

- SimilolaDocument32 pagesSimilolaekundayo ojoNo ratings yet

- NOAA-Hydro Division Field Procedure Manua-L2014Document635 pagesNOAA-Hydro Division Field Procedure Manua-L2014Jimmy LeeNo ratings yet

- Basic Understanding Cloud ComputingDocument7 pagesBasic Understanding Cloud ComputingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Q-Pack and Global BrandsDocument37 pagesQ-Pack and Global BrandsCălin Rareș-MihaiNo ratings yet

- Carbon Fibres: Production, Properties and Potential Use: Pooja Bhatt and Alka GoelDocument6 pagesCarbon Fibres: Production, Properties and Potential Use: Pooja Bhatt and Alka GoelResego PhiriNo ratings yet

- Iso 21009-2-2015Document20 pagesIso 21009-2-2015ali kajbafNo ratings yet

- My Final Thesis AchyutaDocument60 pagesMy Final Thesis AchyutaTek R OjhaNo ratings yet

- Ista 6 Amazon OverboxDocument19 pagesIsta 6 Amazon OverboxMarcoNo ratings yet

- Environment FairfieldDocument51 pagesEnvironment FairfieldWdymNo ratings yet

- Leaching 2Document11 pagesLeaching 2Prasanjit DasNo ratings yet

- 11 07 18Document22 pages11 07 18WoodsNo ratings yet

- TMT4145 Ceramics EngineeringDocument26 pagesTMT4145 Ceramics EngineeringAngga Yogi PrasetiaNo ratings yet

- The Dual Management of Innovation by The DecathlonDocument18 pagesThe Dual Management of Innovation by The DecathlonYashas KumarNo ratings yet

- Does Green Environmental Policy Promote Renewable Energy Consumption in BRICST Fresh Insights From Panel Quantile RegressionDocument18 pagesDoes Green Environmental Policy Promote Renewable Energy Consumption in BRICST Fresh Insights From Panel Quantile RegressionAbdur RehmanNo ratings yet

- Fast Food Competition-3-29Document27 pagesFast Food Competition-3-29Thanh Hà TrầnNo ratings yet

- STS Chapter 3Document5 pagesSTS Chapter 3krung krung biNo ratings yet

- Tutorial Letter 101/3/2023: Engaging With Society Meeting The Challenges of A Changing WorldDocument13 pagesTutorial Letter 101/3/2023: Engaging With Society Meeting The Challenges of A Changing WorldFeroza Angamia100% (1)

- Pavlik HarnessDocument16 pagesPavlik HarnessSunny100% (1)

- Pediatric OptometryDocument63 pagesPediatric OptometryRAJA the GREAT100% (1)

- Exemplu CVDocument2 pagesExemplu CVAdrian CapatinaNo ratings yet

- Alcohol Concentration in The Preparation of Mother Tinctures of Vegetable OriginDocument4 pagesAlcohol Concentration in The Preparation of Mother Tinctures of Vegetable OriginDr. Kazy Habibur RahmanNo ratings yet

- Engineering and Applied Science Research Kinetics Study of Biodiesel Production at Room Temperature Based On Eggshell Derived Cao As Basic Heterogeneous CatalystDocument14 pagesEngineering and Applied Science Research Kinetics Study of Biodiesel Production at Room Temperature Based On Eggshell Derived Cao As Basic Heterogeneous CatalysthmneNo ratings yet

- Kata LogDocument106 pagesKata LogOscarNo ratings yet

- Uolexamcentres WorldwideDocument16 pagesUolexamcentres WorldwidekennethNo ratings yet

- CPP - Triple Airway ManoeuvreDocument3 pagesCPP - Triple Airway ManoeuvreRyan ReNo ratings yet

- Hillstone E-Pro Series: Next-Generation FirewallDocument6 pagesHillstone E-Pro Series: Next-Generation FirewallRaul Spada OrlandiniNo ratings yet

- NZ Coast Guard MOSS Module (Maritime Operator Safety System)Document6 pagesNZ Coast Guard MOSS Module (Maritime Operator Safety System)alejoNo ratings yet

- 01 - 1 - Minimize SLA Violation and Power Consumption in Cloud Data Center Using Adaptive Energy Aware AlgorithmDocument15 pages01 - 1 - Minimize SLA Violation and Power Consumption in Cloud Data Center Using Adaptive Energy Aware AlgorithmhasniNo ratings yet

- BSECE 4A Environmental Laws ReportDocument9 pagesBSECE 4A Environmental Laws ReportCatherine BalanoNo ratings yet

- Flex STP LeafletDocument2 pagesFlex STP LeafletvinorpatilNo ratings yet

- The Newton2Document32 pagesThe Newton2Cynthia HtbNo ratings yet

- SOLASDocument26 pagesSOLASAnu Sugathan oe22d015No ratings yet

- Vaxa - UltraNanno+ Product Data Sheet FFDocument3 pagesVaxa - UltraNanno+ Product Data Sheet FFLuan NguyenNo ratings yet

- Breast Implant-Associated Anaplastic Large Cell Lymphoma e A Systematic Review With Pooled AnalysisDocument8 pagesBreast Implant-Associated Anaplastic Large Cell Lymphoma e A Systematic Review With Pooled AnalysisGiancarlos GuzmanNo ratings yet

- Ramdump Modem 2022-06-21 17-00-01 PropsDocument15 pagesRamdump Modem 2022-06-21 17-00-01 PropsAung Kyaw HtayNo ratings yet

- Statia Information Bulletin March PDFDocument12 pagesStatia Information Bulletin March PDFlyritzaNo ratings yet

- Material Safety Data Sheet: Nitric Acid, 65% MSDSDocument7 pagesMaterial Safety Data Sheet: Nitric Acid, 65% MSDSFikreslasie LemaNo ratings yet

- Level 2 Stage 1Document101 pagesLevel 2 Stage 1liriridiumNo ratings yet

- Estimation Templates For CalculationDocument15 pagesEstimation Templates For CalculationSyed MohammedNo ratings yet

- 220720221747-Boq Interior WorkDocument6 pages220720221747-Boq Interior WorkGelanWelaboNo ratings yet

- Study and Characterization of PP-R/Polyolefin Elastomer and PP-R/EPDM Blend: Effect of Chlorinated Water On Blend PerformanceDocument11 pagesStudy and Characterization of PP-R/Polyolefin Elastomer and PP-R/EPDM Blend: Effect of Chlorinated Water On Blend PerformanceNiku SamarthNo ratings yet

- Gallagher Polyurethane GuideDocument34 pagesGallagher Polyurethane Guidefeltofsnake100% (4)

- Solvent Extraction - Literature Review PDFDocument18 pagesSolvent Extraction - Literature Review PDFProcess EngineerNo ratings yet

- Piedmont StyleDDocument1 pagePiedmont StyleDBenjamin MillerNo ratings yet

- Section 4 - Chip SealsDocument18 pagesSection 4 - Chip SealsFranklinNo ratings yet

- Experimental Analysis of The Addition of Rice Husk Ash To The Clayey Subgrade of A Road Stabilized With LimeDocument6 pagesExperimental Analysis of The Addition of Rice Husk Ash To The Clayey Subgrade of A Road Stabilized With LimeAngelo Anthony AllenaNo ratings yet

- Copper PRDocument17 pagesCopper PRSaadAminNo ratings yet

- Forthress Lightweight Precast Panel Methodology Latest Revision 08062020Document24 pagesForthress Lightweight Precast Panel Methodology Latest Revision 08062020LA Boiser100% (1)

- Investigation of The Microstructures, Properties, and Toughening Mechanism of Polypropylene/calcium Carbonate Toughening Masterbatch CompositesDocument16 pagesInvestigation of The Microstructures, Properties, and Toughening Mechanism of Polypropylene/calcium Carbonate Toughening Masterbatch CompositesHatchi KouNo ratings yet

- Single-Round High Flow Cartridge Filter Housings: Fiberglass Reinforced Plastic (FRP)Document2 pagesSingle-Round High Flow Cartridge Filter Housings: Fiberglass Reinforced Plastic (FRP)saradhi sravan kumarNo ratings yet

- Aws C5.5 (2003) Rp-GtawDocument131 pagesAws C5.5 (2003) Rp-GtawIsmail Karmana100% (2)

- MSM R19 - Unit-2Document28 pagesMSM R19 - Unit-2Madheswaran DharmapuriNo ratings yet

- Wall Panelling SystemsDocument70 pagesWall Panelling SystemsNicole Francis100% (1)

- Saggar Works at Caughley 2004Document24 pagesSaggar Works at Caughley 2004digitalpast100% (2)

- Ciclo Di Verniciatura: Proprietà TecnicheDocument9 pagesCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- Types of Pipe Fittings in Plumbing SystemDocument7 pagesTypes of Pipe Fittings in Plumbing SystemJoanne DawangNo ratings yet

- Reverse Osmosis: Boiler Water Operator Training NotesDocument6 pagesReverse Osmosis: Boiler Water Operator Training NotesSheikh SahabNo ratings yet

- Steve Treese Petroleum Technology Quarterly PDFDocument9 pagesSteve Treese Petroleum Technology Quarterly PDFSami AhmadNo ratings yet

- DBHT PHB 5805 LaddTrayFATreport Rev 0Document23 pagesDBHT PHB 5805 LaddTrayFATreport Rev 0Ahmad DagamsehNo ratings yet

- KMC Schedule of Rates For 2018 - DescriptionDocument32 pagesKMC Schedule of Rates For 2018 - DescriptionKalyan GaineNo ratings yet

- Hbe Oil Tanks Welded Steel en 0220Document14 pagesHbe Oil Tanks Welded Steel en 0220Emir EsimNo ratings yet

- Structural Screw Design Guide: Myticon Timber ConnectorsDocument52 pagesStructural Screw Design Guide: Myticon Timber ConnectorsciviliiiNo ratings yet

- Ba 5 PDFDocument24 pagesBa 5 PDFhakNo ratings yet

- Midland Brick Technical Manual 2013 PDFDocument116 pagesMidland Brick Technical Manual 2013 PDFNhuVan NguyenNo ratings yet

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDocument11 pagesColloids and Surfaces A: Physicochemical and Engineering AspectsFernando HenriqueNo ratings yet

- Parts Manual: 2013-12-04 Manual TP-P001 Revision 07Document21 pagesParts Manual: 2013-12-04 Manual TP-P001 Revision 07Nesreen Ahmed NaoumNo ratings yet

- Design Loadbearing Masonry StructuresDocument9 pagesDesign Loadbearing Masonry StructuresthushtikaNo ratings yet

- Ac 7000 F Blowing AgentDocument1 pageAc 7000 F Blowing AgentFraz Ahmad100% (1)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffFrom Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffRating: 5 out of 5 stars5/5 (21)

- The Storyteller: Expanded: ...Because There's More to the StoryFrom EverandThe Storyteller: Expanded: ...Because There's More to the StoryRating: 5 out of 5 stars5/5 (13)

- Bare Bones: I'm Not Lonely If You're Reading This BookFrom EverandBare Bones: I'm Not Lonely If You're Reading This BookRating: 4 out of 5 stars4/5 (11)

- Ikigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessFrom EverandIkigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessRating: 5 out of 5 stars5/5 (91)

- Twelve Caesars: Images of Power from the Ancient World to the ModernFrom EverandTwelve Caesars: Images of Power from the Ancient World to the ModernRating: 3.5 out of 5 stars3.5/5 (9)

- The Gardner Heist: The True Story of the World's Largest Unsolved Art TheftFrom EverandThe Gardner Heist: The True Story of the World's Largest Unsolved Art TheftNo ratings yet

- To Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryFrom EverandTo Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryRating: 4 out of 5 stars4/5 (26)

- I Didn't Come Here to Make Friends: Confessions of a Reality Show VillainFrom EverandI Didn't Come Here to Make Friends: Confessions of a Reality Show VillainRating: 3 out of 5 stars3/5 (47)

- Storytelling: A Guide on How to Tell a Story with Storytelling Techniques and Storytelling SecretsFrom EverandStorytelling: A Guide on How to Tell a Story with Storytelling Techniques and Storytelling SecretsRating: 4.5 out of 5 stars4.5/5 (72)

- The Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisFrom EverandThe Hotel on Place Vendôme: Life, Death, and Betrayal at the Hotel Ritz in ParisRating: 3.5 out of 5 stars3.5/5 (49)

- They Can't Kill Us Until They Kill UsFrom EverandThey Can't Kill Us Until They Kill UsRating: 4.5 out of 5 stars4.5/5 (40)

- Twilight of the Gods: A Journey to the End of Classic RockFrom EverandTwilight of the Gods: A Journey to the End of Classic RockRating: 3.5 out of 5 stars3.5/5 (28)

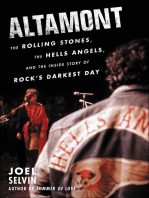

- Altamont: The Rolling Stones, the Hells Angels, and the Inside Story of Rock's Darkest DayFrom EverandAltamont: The Rolling Stones, the Hells Angels, and the Inside Story of Rock's Darkest DayRating: 4 out of 5 stars4/5 (25)