Professional Documents

Culture Documents

RM Stock

RM Stock

Uploaded by

materialOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RM Stock

RM Stock

Uploaded by

materialCopyright:

Available Formats

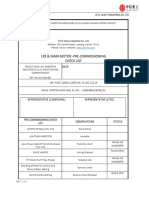

Existing Source of R.M.

Supply Suggested

RM Grade RM Suggested

Make of Rate Per

Supplied Sizes Process Risk Factor Make of

R.M Kg

Vendor R.M

Upto 25

80

mm

26-100 mm Vivan, 78 Once a while

chances of JSW,

A to Z Sky-Way Normal

getting Center JaiLaxmi,

Steelloys, 105-120 mm VD, Inductio

EN-19 81 Crack in Ultra Tata

Shreenathji Balaram n

Test, Ecentric

Steel Yard Furnace.

125-150 84-85 Cracks Open after

Hardening.

Calcutta,

160-200 90-94 JSW, China

China

Upto 25 mm 102

Vivan,

British,

A to Z Sky-Way

26-100 100 Center Crack

Steelloys, VD, Normal

Balaram Inductio Observed in Ultra JSW,

Shreenathji

EN-24 Test, Ecentric JaiLaxmi,

Steel Yard, 105-120 n 106 Cracks Open after Tata

Sachin Furnace.

Hardening.

Steel.

125-150 118-120

Calcutta,

China

160-200 128-132

Ultra OK, But

Original

Local Surface Cracks

Vascomax Forging rolled or

Plus Metal All Sizes Scrap 2250 Observed after

(C-300) Process forged

Forged Hardening

Material

process

Suggested Parameter For good R.M Procurement

Rate per Planning For Stock /

Process Benefits

Kg Suggestion

85

Preference process- One/ Two Months

1)LRF- Ladle 86 advance planning., 100% OK

Refining Furnace, Preference process- material

2)EMS- 88 1)LRF- Ladle Refining Without Cracks

Electronics Furnace, with Vendor

Manufacturing 2)EMS- Electronics assurity up to

Services, 88-90 Manufacturing Services, finish product.

3)V.D Route. 3)V.D Route.

92-94

108

Preference process- One/ Two Mounths

1)LRF- Ladle 110 advance planning., 100% OK

Refining Furnace, Preference process- material

2)EMS- 1)LRF- Ladle Refining Without Cracks

Electronics 118 Furnace, with Vendor

Manufacturing 2)EMS- Electronics assurity up to

Services, Manufacturing Services, finish product.

3)V.D Route. 118 3)V.D Route.

135

100% OK

Original imported One/ Two Mounths material

rolled or forged advance planning., Without Cracks

5500

material with Mill Holled raw material with Vendor

TC. availability for Rachet. assurity up to

finish product.

You might also like

- Implementation of Marketing Plan and StrategiesDocument40 pagesImplementation of Marketing Plan and StrategiesJanniele Dela PeñaNo ratings yet

- CAVSMA1Document2 pagesCAVSMA1Bill MurrayNo ratings yet

- Appian Traing Pdf7Document3 pagesAppian Traing Pdf7Svr Ravi100% (1)

- Hammad - PresentationDocument19 pagesHammad - PresentationRehan SadiqNo ratings yet

- ITT Cannon D Subminiature Products-1869325Document62 pagesITT Cannon D Subminiature Products-1869325asepNo ratings yet

- Cu ZN 10Document1 pageCu ZN 10Sara RiddleNo ratings yet

- Welding Super Duplex SSDocument11 pagesWelding Super Duplex SSmuarabadak100% (1)

- VSKT106 16S90P VishayDocument9 pagesVSKT106 16S90P VishayjoseNo ratings yet

- LOTHERME Ready Reckoner PDFDocument40 pagesLOTHERME Ready Reckoner PDFAmit DuttaNo ratings yet

- LGI Scrap Lifting MagnetDocument2 pagesLGI Scrap Lifting MagnetAlan RossNo ratings yet

- Kiln Inlet Section Casting Procedure LafargeDocument8 pagesKiln Inlet Section Casting Procedure LafargeKhaled BOUALINo ratings yet

- RAYCLAD 80/120: Heat Shrinkable Two Layer Pipeline CoatingDocument2 pagesRAYCLAD 80/120: Heat Shrinkable Two Layer Pipeline CoatingHamza GhaniNo ratings yet

- Qap Final Clamp and HardwareDocument13 pagesQap Final Clamp and HardwareGnanavel GNo ratings yet

- Arcelormittal Pressure VesselDocument12 pagesArcelormittal Pressure VesselAnonymous UoHUagNo ratings yet

- Series: 5yearsDocument2 pagesSeries: 5yearsmamidivinay kumarNo ratings yet

- Apar Conductor PDFDocument47 pagesApar Conductor PDFSourav BhattacharyaNo ratings yet

- Paper - Comminution Case Study - ST - Ives PDFDocument7 pagesPaper - Comminution Case Study - ST - Ives PDFdarwin_huaNo ratings yet

- WorkshopDocument2 pagesWorkshopCERS Oil LabNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: 1200V 60A APT60D120B APT60D120S APT60D120BG APT60D120SGDocument4 pagesUltrafast Soft Recovery Rectifier Diode: 1200V 60A APT60D120B APT60D120S APT60D120BG APT60D120SGWilson LlumanNo ratings yet

- GE DisconnectDocument1 pageGE DisconnectdeepaksolarNo ratings yet

- Precision Thin Film Chip ResistorsDocument3 pagesPrecision Thin Film Chip ResistorsJaPan LifeNo ratings yet

- China Steel PDFDocument38 pagesChina Steel PDFKalpeshNo ratings yet

- Low-Profile SMT Header: TMM 1 SMDocument1 pageLow-Profile SMT Header: TMM 1 SMRaghav AdhikariNo ratings yet

- SHD-GC - 2019Document2 pagesSHD-GC - 2019S Adriano CiriacoNo ratings yet

- Crompton DC MotorsDocument6 pagesCrompton DC MotorsAzed-dine BoughmarNo ratings yet

- 4G Fcaw WPSDocument3 pages4G Fcaw WPSdjafourNo ratings yet

- AUIRG7CH80K6B-M: Automotive GradeDocument3 pagesAUIRG7CH80K6B-M: Automotive GradeMiguel GonzalezNo ratings yet

- H.T BRAUTEK LITHIUM EP SeriesDocument2 pagesH.T BRAUTEK LITHIUM EP SeriesALFREDO CANTOS CORNEJONo ratings yet

- Diversion 165 and 180: Quick SpecsDocument4 pagesDiversion 165 and 180: Quick SpecsГуставо Аранда МендосаNo ratings yet

- Schott KyDocument7 pagesSchott KysateeshNo ratings yet

- DatasheetDocument66 pagesDatasheetJorge Martínez100% (1)

- (W) Gc2208ledgv-Tjl - 1603Document1 page(W) Gc2208ledgv-Tjl - 1603Mohamad SannanNo ratings yet

- PDS - Na - Klon-KlnnDocument2 pagesPDS - Na - Klon-Klnndemi bajakanNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Aws Journal Sep-12Document231 pagesAws Journal Sep-12Sankar MukaNo ratings yet

- Arcelormittal Pressure Vessel PDFDocument10 pagesArcelormittal Pressure Vessel PDFImmanuel SNo ratings yet

- Skyware Global 1.2m Standard RX/TX Ka-Band SFL AntennaDocument2 pagesSkyware Global 1.2m Standard RX/TX Ka-Band SFL AntennaKmiSzNo ratings yet

- Repair and Maintenance Weld Overlay Solutions For Steel MillsDocument28 pagesRepair and Maintenance Weld Overlay Solutions For Steel MillsMike CheNo ratings yet

- Welding Superintendent: Curriculm VitaeDocument5 pagesWelding Superintendent: Curriculm VitaeMuhammad WarisNo ratings yet

- Aurora: AE MD-108BS SeriesDocument2 pagesAurora: AE MD-108BS SeriestasoNo ratings yet

- REPORTDocument9 pagesREPORTVinod GuptaNo ratings yet

- Protec Z Technical Data Rev 7 2015Document4 pagesProtec Z Technical Data Rev 7 2015OperaçãoNo ratings yet

- Diamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsDocument2 pagesDiamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsRMNo ratings yet

- Aurora: AE MC-120BD SeriesDocument2 pagesAurora: AE MC-120BD SeriestasoNo ratings yet

- WPS Mig 2Document1 pageWPS Mig 2rafetguzelsoyNo ratings yet

- Annex 1-Form E - Format of Technical BidDocument37 pagesAnnex 1-Form E - Format of Technical Bidhosam shokriNo ratings yet

- Summary Battery SpecificationsDocument12 pagesSummary Battery Specificationssewot00No ratings yet

- X65 Flange Steel: Corus Engineering SteelsDocument3 pagesX65 Flange Steel: Corus Engineering SteelsestudiemosNo ratings yet

- NEC Offshore Technical Specifications v1 Mei2012 TKFDocument8 pagesNEC Offshore Technical Specifications v1 Mei2012 TKFVladimir SanovicNo ratings yet

- CatalogueDocument58 pagesCatalogueGanesh DuraisamyNo ratings yet

- VAM® RiserDocument8 pagesVAM® RiserVíctor Eduardo Salas OlguínNo ratings yet

- Composition % Combination of Properties: The Benefits of Cal Wrought CNCDocument6 pagesComposition % Combination of Properties: The Benefits of Cal Wrought CNCAshesh MokidiNo ratings yet

- RCA-HP E3: Vishay DraloricDocument10 pagesRCA-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- (AWS A5.20 E71T-9J) : Technical ReportDocument2 pages(AWS A5.20 E71T-9J) : Technical Reportzendaoui amineNo ratings yet

- Welder Qualification Flow Chart (Updated)Document7 pagesWelder Qualification Flow Chart (Updated)Rajesh KannanNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- DTS Oil Dielectric Test SetsDocument2 pagesDTS Oil Dielectric Test SetsMuhammad KashifNo ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- AgInquirer Data Seet - USADocument2 pagesAgInquirer Data Seet - USApratikgv_1No ratings yet

- SE25998 Reject Shop ReportDocument6 pagesSE25998 Reject Shop ReportBidulaNo ratings yet

- Computer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- MARKETING PLAN 2.1 - SummaryDocument24 pagesMARKETING PLAN 2.1 - SummarybirukNo ratings yet

- Oromia Credit & Saving Share Company (OCSSCO)Document46 pagesOromia Credit & Saving Share Company (OCSSCO)endaleNo ratings yet

- Dr. Amor Lazzez: Overview of Systems Integration: Challenges and DrivesDocument20 pagesDr. Amor Lazzez: Overview of Systems Integration: Challenges and DrivesArsenia DuldulaoNo ratings yet

- First Page PDFDocument1 pageFirst Page PDFmadersesherilynNo ratings yet

- Project Concept Paper Activity1 1Document8 pagesProject Concept Paper Activity1 1B2 Laza Justine PeterNo ratings yet

- Principles of Microeconomics Canadian 6th Edition Mankiw Test BankDocument25 pagesPrinciples of Microeconomics Canadian 6th Edition Mankiw Test BankAustinSmithpdnq100% (41)

- Iso 17020 Accreditation of Cnetsten NDT Laboratory: AbsractDocument6 pagesIso 17020 Accreditation of Cnetsten NDT Laboratory: Absractsafeer ahmadNo ratings yet

- Literature Review On Sales Promotion StrategiesDocument8 pagesLiterature Review On Sales Promotion Strategiesea4c954q100% (1)

- KFC in International Market: Presentation OnDocument9 pagesKFC in International Market: Presentation OnRaeesa WaqarNo ratings yet

- Oracle Bi Sample App Content GuideDocument174 pagesOracle Bi Sample App Content Guideavinashworld100% (1)

- CSR Renault Group Nov - 2023Document10 pagesCSR Renault Group Nov - 2023Aymen SioudNo ratings yet

- Cost AccountingDocument59 pagesCost AccountingMuhammad UsmanNo ratings yet

- Metallurgy 5th Ed 1977 PDFDocument483 pagesMetallurgy 5th Ed 1977 PDFanon_435115635No ratings yet

- Marketing Management Module 4Document8 pagesMarketing Management Module 4Sharon Cadampog MananguiteNo ratings yet

- CMA Exam Module-2021Document19 pagesCMA Exam Module-2021Tri EvelinaNo ratings yet

- Introduction To Six Sigma: UNIT-4Document20 pagesIntroduction To Six Sigma: UNIT-4Seif CharafNo ratings yet

- IATF What Is It - R1Document3 pagesIATF What Is It - R1Edward LibrianusNo ratings yet

- Kashif Ali: House # 392 Sector 15/A Orangi Town, Karachi +92-332-2437464Document3 pagesKashif Ali: House # 392 Sector 15/A Orangi Town, Karachi +92-332-2437464Candle thread TurkeyNo ratings yet

- Smu 3rd Sem Operation Management AssignmentsDocument12 pagesSmu 3rd Sem Operation Management AssignmentsProjectHelpForuNo ratings yet

- 3D PrintingDocument18 pages3D PrintingkishanNo ratings yet

- Market Logistics & Supply Chain Management: SDM - CH 15Document53 pagesMarket Logistics & Supply Chain Management: SDM - CH 15Shubham DixitNo ratings yet

- Explanation:: Chapter 2 Study QuestionsDocument14 pagesExplanation:: Chapter 2 Study QuestionsChi Iuvianamo0% (1)

- GTM BrochureDocument12 pagesGTM BrochureDouglas MontozaNo ratings yet

- Procurement Processes and Master DataDocument60 pagesProcurement Processes and Master Datalaurablue96No ratings yet

- Activity DiagramDocument1 pageActivity DiagramSmit JoshiNo ratings yet