Professional Documents

Culture Documents

ALGAITH PU&LD Machine Property Damage

Uploaded by

osama nasrOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ALGAITH PU&LD Machine Property Damage

Uploaded by

osama nasrCopyright:

Available Formats

Pickup & Laydown Machine Property Damage

Rig T-562, December 25, 2023

Preliminary investigation

Incident Description:

On 25th December 2023, the operation was picking up and running in the hole with 9-5/8” casing with

CRT equipment and PU/LD machine.

The rig had run 95 joints. On joint 96, the PU/LD machine operator lowered the trough to the catwalk to

load a joint of casing by the machine’s hydraulic arms and into the trough. The loaded trough was then

hoisted by the PU/LD machine operator towards V-door when at approximately three-quarters of the

distance from the rig floor, the hoisting line attached to the trough by 4-parts shackle disconnected from

its mounting position causing the trough to descend backwards beyond operator’s control towards the

PU/LD machine stopper. The trough impacted against the PU/LD machine stopper, while the loose end

of the hoisting line jammed into the top snatch block and came to a halt.

Immediate Recovery Actions:

1. Stopped the operation, had stand up meeting with the crew. Developed JSA to recover the casing

joint in the trough, to release the tension in the fast line and rigged down the PU/LD machine

accessories.

2. Resumed the RIH 9 5/8” casing by crane.

3. Al-Gaith representative arrived on location for investigation.

4. KCA rig manager and HSE supervisor arrived on location for support.

Significant Findings during the preliminary investigation:

1. Rig had two PU/LD machines on location.

2. 1st unit (Unit A) was previously utilized for 13-3/8” casing job and was parked at the rig main camp

side. Unit A was not returned to Al-Gaith yard after 13-3/8” casing job completion.

3. A 2nd unit (Unit B) was dispatched to the rig upon Aramco Foreman equipment request. The Al-Gaith

crew decided upon confirming with their base coordinator to utilize Unit A that was on standby at

the rig site. Al-Gaith coordinator confirmed that both units are in good working condition and the

crew selected Unit A due to its better hoisting capability comparing it with Unit B.

- Unit A trough capable of handling casing sizes between 4-½” and 18-3/8”. Hoisting line 16mm;

Guy line 22mm

- Unit B trough capable of handling casing sizes between 4-½” and 13-3/8”. Hoisting line 16mm;

Guy line 22mm

4. Both PU/LD machines were not provided with the SWAP checklist for Casing/Tubing Running

Operation upon their dispatch to the rig from Al-Gaith base.

5. Split safety pin of the 4-parts shackle attaching the hoisting line to the trough broke off allowing the

shackle’s nut and pin to loosen up, detaching the hoisting line from the trough releasing it towards

the end of the catwalk (PU/LD machine side).

Saudi Aramco: Company General Use

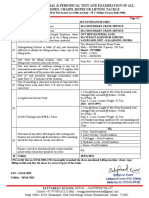

Fig. 1

6. Several split safety pins installed at other places of the PU/LD machine observed to be improperly

installed, only one side of the split pin was bent around the shackles bolt.

Fig. 2 Fig. 3

7. Al-Gaith crew was formed out of two operators. 1st operator who rigged up the unit worked till

24:00 hrs, then he was relieved by the 2nd operator. The 2nd operator confirmed during the

interview that he had visually checked the equipment condition during the crew change.

8. Al-Gaith inspection procedure does not clearly specify if the unit needs to be inspected periodically

during operation.

Saudi Aramco: Company General Use

9. The design of the trough anchor point (pad eye) to fasten the hoisting line is making the swivel and

shackles to rub against the trough. A dent was observed on the trough side edge where the swivel-

shackle assembly are rubbing.

Fig. 4

Fig. 5

Saudi Aramco: Company General Use

10. Deviation from the OEM unit design by installing the additional “horizontal” pad eye.

Fig. 6

Fig. 7

Saudi Aramco: Company General Use

Timeline:

23rd Dec 23 During the working day the RSTC completed the 3rd party equipment checklist.

24th Dec 23 19:20:00 Rig up of the casing running equipment completed.

19:30:00 Crew held PJSM and started running casing operations.

19:45:00 Run in casing operation commenced.

24:00:00 PU/LD machine operator tour change (60 jts in the hole).

25th Dec 23 00:05:00 2nd PU/LD machine operator completed the equipment check and

resumed operation.

02:32:00 Crew managed to run 95 jts in the hole.

02:33:00 PU/LD machine operator lowered the trough on the catwalk on its

loading position and the 96 JT was loaded in the trough.

02:34:00 PU/LD machine operator started hoisting the trough loaded with the

casing JT towards the rig floor.

02:34:30 The suspended trough reached 3/4 from its initial position to the rig

floor when the hoisting line detached from the trough and started descending

towards the PU/LD machine.

02:34:35 The trough contacted the stopper plate and the trolling wire rope

jammed into the top anchor snatch block stopping the descending trough.

Potential Causal Factors:

Inappropriate equipment design / hazard introduced by the design.

Failure to identify the hazard.

Inadequate equipment checks performed.

Improper equipment installation (split safety pins)

Inadequate risk assessment.

Preliminary corrective actions:

In coordination with OEM for the troughs Al Gaith to verify all pad eyes installation/design for

further assessment for introduced hazards and correct similar set-ups.

Al Gaith to implement OEM recommended intervals equipment checks to be performed by

competent person into their procedure.

The inspections interval to be discussed during the PJSM and properly documented in the

combined JSA.

KCA to update their “Third Party Equipment Inspection Checklist” to include the split safety pins

inspection for their condition and proper installation.

Al Gaith to implement SWAP checklist for all their units.

Saudi Aramco: Company General Use

Written Statement:

Off-duty operator statement

Saudi Aramco: Company General Use

On-duty operator statement:

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Site equipment inspections:

Unit-A PU/LD Machine

Saudi Aramco: Company General Use

Unit-B PU/LD Machine

Saudi Aramco: Company General Use

Al Gaith inspection procedure.

Saudi Aramco: Company General Use

Revised JSA of Al Gaith including periodical inspection of all lifting accessories.

PU/LD machine OEM design

Saudi Aramco: Company General Use

Operators competency certificates:

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- Recommended Practice For Machinery Installation and Installation Design Chapter 2-Rigging and LiftingDocument2 pagesRecommended Practice For Machinery Installation and Installation Design Chapter 2-Rigging and LiftingshbaeerNo ratings yet

- On Working With LHD Practical Problems and SolutionsDocument62 pagesOn Working With LHD Practical Problems and SolutionsSrikanth SriNo ratings yet

- Rig Move Procedures HSE 008Document12 pagesRig Move Procedures HSE 008Martahan Manurung100% (8)

- HSE Alert 16-16 Violation To Rig Move Procedure Results in Power Line IncidentDocument2 pagesHSE Alert 16-16 Violation To Rig Move Procedure Results in Power Line Incident曹庆园No ratings yet

- Crane Truck ManualDocument19 pagesCrane Truck ManualepsaNo ratings yet

- Bored Pile Drilling Machine and Work InstructionDocument6 pagesBored Pile Drilling Machine and Work Instructionmiraç burak navruzNo ratings yet

- Audit Report Century 14 Rev 1Document51 pagesAudit Report Century 14 Rev 1agusnurcahyo66No ratings yet

- Bridge Crane & Hoist InstallationDocument7 pagesBridge Crane & Hoist Installationnike_y2kNo ratings yet

- Irector General Border Roads General Maintenance Instruction No. 241 On Operation and Maintenance of Concrete Mixer Gamzen 750 RDDocument8 pagesIrector General Border Roads General Maintenance Instruction No. 241 On Operation and Maintenance of Concrete Mixer Gamzen 750 RDBrajnandan AryaNo ratings yet

- Boeing 747-436 Landing Gear FailureDocument5 pagesBoeing 747-436 Landing Gear FailureAlejandra QuirozNo ratings yet

- Dynamic Compaction Operation Safety Training - ECTDocument4 pagesDynamic Compaction Operation Safety Training - ECTgayanNo ratings yet

- 4.3 Towing ProcedureDocument3 pages4.3 Towing Procedurejohnson OlubiNo ratings yet

- G.I. 1010.007 Safe Practices For Towing EquipmentDocument7 pagesG.I. 1010.007 Safe Practices For Towing EquipmentbryanNo ratings yet

- Requirement Lifting EquipmentDocument11 pagesRequirement Lifting EquipmentALI BEN AMOR100% (1)

- General Method Statement Ras Gara PhaseDocument21 pagesGeneral Method Statement Ras Gara Phaseyaser elgohary100% (2)

- JCB 3DX Maintenance ManualDocument12 pagesJCB 3DX Maintenance ManualDavid Palash100% (2)

- Department Pre Rig Move ChecklistsDocument11 pagesDepartment Pre Rig Move ChecklistsNagendra Singh Ranawat100% (1)

- Catalyst Loading by Dense Method (SingleBed) in Inert AtmosphereDocument5 pagesCatalyst Loading by Dense Method (SingleBed) in Inert Atmospherevishal bailurNo ratings yet

- AAC 3 of 2004 CVR ReadoutDocument4 pagesAAC 3 of 2004 CVR Readoutpathy_ameNo ratings yet

- HSE Alert 21-16 Mast Collapse During Rig Move OperationsDocument2 pagesHSE Alert 21-16 Mast Collapse During Rig Move Operations曹庆园No ratings yet

- Dropped Object - Fatale AccidentDocument9 pagesDropped Object - Fatale Accidentvikrant911No ratings yet

- E:/GMI 224 TO 246/GMI No 243Document13 pagesE:/GMI 224 TO 246/GMI No 243Priyadharshan BalanNo ratings yet

- 100-Yer-Pm-Ppm-0258 (Pile Driving)Document14 pages100-Yer-Pm-Ppm-0258 (Pile Driving)Armando AballeNo ratings yet

- A1F9V8 - CP Rail and Cargill HDD Execution PlanDocument17 pagesA1F9V8 - CP Rail and Cargill HDD Execution PlanSbitNo ratings yet

- 01.05.2021 Method Statement For Modular Skid InstallationDocument6 pages01.05.2021 Method Statement For Modular Skid InstallationPangky AbasoloNo ratings yet

- Zoomlion 80 Ton - 011Document2 pagesZoomlion 80 Ton - 011Susil Kumar SahooNo ratings yet

- Aac3 2004Document4 pagesAac3 2004Anandan PonnusamyNo ratings yet

- Cat Load by Sock Method in Normal AtmosphereDocument4 pagesCat Load by Sock Method in Normal Atmospherevishal bailurNo ratings yet

- Jsa For LiftingDocument4 pagesJsa For Liftingshaibaz chafekarNo ratings yet

- 20110812-42 Use of Hydraulic Jack-In Piling ("JIP") MachinesDocument3 pages20110812-42 Use of Hydraulic Jack-In Piling ("JIP") MachinesLee TaiNo ratings yet

- HSE Alert 07-16 Damage To Drilling Mast IncidentDocument1 pageHSE Alert 07-16 Damage To Drilling Mast IncidentSajid HussainNo ratings yet

- Cps Crane MaintenanceDocument13 pagesCps Crane MaintenanceTarek HareedyNo ratings yet

- Saudi ARAMCO - Lifting Instruction ManualDocument10 pagesSaudi ARAMCO - Lifting Instruction Manualmubeennavaz100% (2)

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- Tab 2b - Fatality PDODocument2 pagesTab 2b - Fatality PDOMohamed BensmailNo ratings yet

- 2607 S 85 Rev 0 ENDocument3 pages2607 S 85 Rev 0 ENJuan Carlos Ladino VegaNo ratings yet

- 4-3 Towing ProcedureDocument3 pages4-3 Towing ProcedureOlubi FemiNo ratings yet

- CPCS A56 Dump Truck Articulated Chassis Theory Test AnswersDocument7 pagesCPCS A56 Dump Truck Articulated Chassis Theory Test AnswersAdam Adrian80% (30)

- SWP - DPC Bucket Installation BTW Reject & Clinker SiloDocument2 pagesSWP - DPC Bucket Installation BTW Reject & Clinker Siloshahhussain1031No ratings yet

- Saudi Aircon Method StatementDocument12 pagesSaudi Aircon Method StatementSavad AlwyeNo ratings yet

- Risk Assessment Pc4dp-A (Draft)Document11 pagesRisk Assessment Pc4dp-A (Draft)HSE PULAI ANo ratings yet

- HSE Alert # 53-14 High Potential Crane Drops IncidentDocument1 pageHSE Alert # 53-14 High Potential Crane Drops IncidentaswinNo ratings yet

- SSW MEWP Cherry PickerDocument2 pagesSSW MEWP Cherry Pickerrossiwidnes78No ratings yet

- MANUAL FOR REACTORS - v2Document7 pagesMANUAL FOR REACTORS - v2narendradounde143No ratings yet

- Saudi Aramco StandardsDocument23 pagesSaudi Aramco Standardsbalaji100% (3)

- RP 205Document30 pagesRP 205Vasant Kumar VarmaNo ratings yet

- SOP For Hydra RepairingDocument13 pagesSOP For Hydra RepairingMD AbdullahNo ratings yet

- MOS-09-Generator Set Installation-Rev-0 (05, Jan)Document42 pagesMOS-09-Generator Set Installation-Rev-0 (05, Jan)Muhammad IrfanNo ratings yet

- 0007 028Document16 pages0007 028Mohamed Ibrahim100% (2)

- Cat d8tDocument8 pagesCat d8tAlex I FBNo ratings yet

- 01 Rigging and Lifting Plan GTG-2 GeneratorDocument2 pages01 Rigging and Lifting Plan GTG-2 GeneratorHamzaNoumanNo ratings yet

- Excavation Backfilling MosDocument22 pagesExcavation Backfilling Mosabrahmanjazbi100% (3)

- Mid Group Black White Building 74 Rivington ST Shoreditch London Raptor 184 Erect RAMS Rev 3Document40 pagesMid Group Black White Building 74 Rivington ST Shoreditch London Raptor 184 Erect RAMS Rev 3RADHE SHYAMNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Air Crash Investigations - The Crash Of Embraer 500 (N100EQ) Gaithersburg, MarylandFrom EverandAir Crash Investigations - The Crash Of Embraer 500 (N100EQ) Gaithersburg, MarylandNo ratings yet

- Components of Emotional IntelligenceDocument5 pagesComponents of Emotional IntelligenceSteven AdongoNo ratings yet

- BerengerDocument2 pagesBerengerSomenath DeyNo ratings yet

- Assignment 4Document5 pagesAssignment 4SnehaNo ratings yet

- 71 SubmissionDocument4 pages71 Submissionmohamed aliNo ratings yet

- Estadistica MultivariableDocument360 pagesEstadistica MultivariableHarley Pino MuñozNo ratings yet

- Weekly Progress Report PDFDocument7 pagesWeekly Progress Report PDFHeak Hor50% (2)

- Data Sheets Bulletin Electric Actuators Model Epi 2 Keystone Us en 2721364Document16 pagesData Sheets Bulletin Electric Actuators Model Epi 2 Keystone Us en 2721364Nag RajNo ratings yet

- Henning ResumeDocument1 pageHenning Resumeapi-341110928No ratings yet

- PH G12 S1Document9 pagesPH G12 S1mahmoudNo ratings yet

- ECE - 1551 Digital Logic Lecture 15: Combinational Circuits: Assistant Prof. Fareena SaqibDocument19 pagesECE - 1551 Digital Logic Lecture 15: Combinational Circuits: Assistant Prof. Fareena SaqibAll aboutNo ratings yet

- A Review of Charging Algorithms For Nickel Andlithium - BattersehDocument9 pagesA Review of Charging Algorithms For Nickel Andlithium - BattersehRaghavendra KNo ratings yet

- 20years Cultural Heritage Vol2 enDocument252 pages20years Cultural Heritage Vol2 enInisNo ratings yet

- Automobile Engineering NotesDocument120 pagesAutomobile Engineering Notesakshay2992No ratings yet

- MIT15 093J F09 Rec04Document4 pagesMIT15 093J F09 Rec04santiago gonzalezNo ratings yet

- Installation Manual - Chain Link FenceDocument2 pagesInstallation Manual - Chain Link FenceChase GietterNo ratings yet

- T2 Homework 2Document3 pagesT2 Homework 2Aziz Alusta OmarNo ratings yet

- YaskawaDocument54 pagesYaskawaPer Sverre DacolNo ratings yet

- Topic 1: Introduction To Telecommunication: SPM1012: Telecommunication and NetworkingDocument22 pagesTopic 1: Introduction To Telecommunication: SPM1012: Telecommunication and Networkingkhalfan athmanNo ratings yet

- Elecntron Interference: Institución Universitaria ITSADocument14 pagesElecntron Interference: Institución Universitaria ITSAYuliana RicoNo ratings yet

- Financial and Economic Texts' Translation - 2 PGDocument2 pagesFinancial and Economic Texts' Translation - 2 PGbia1209No ratings yet

- 8 GraphsFundamentalsDocument28 pages8 GraphsFundamentalsguptharishNo ratings yet

- Les Lac Inset Monitoring FormDocument57 pagesLes Lac Inset Monitoring FormKim Sang AhNo ratings yet

- Electrostatics DPPDocument10 pagesElectrostatics DPPhimesh2006hNo ratings yet

- Ethiopian Geology 2&3 2015Document51 pagesEthiopian Geology 2&3 2015amanuel buzunaNo ratings yet

- Analisis Perencanaan Strategis Sebagai Determinan Kinerja Perusahaan Daerah Air Minum PDAM Kota Gorontalo PDFDocument19 pagesAnalisis Perencanaan Strategis Sebagai Determinan Kinerja Perusahaan Daerah Air Minum PDAM Kota Gorontalo PDFMuhammat Nur SalamNo ratings yet

- Bahasa Inggris Teknik Individual Assignment 3Document5 pagesBahasa Inggris Teknik Individual Assignment 3Khaiza SyNo ratings yet

- SYLLABUSDocument1 pageSYLLABUSUadNo ratings yet

- Bulk MicromachiningDocument14 pagesBulk MicromachiningSrilakshmi MNo ratings yet

- Green Bill: Easypa Y Scan & PayDocument4 pagesGreen Bill: Easypa Y Scan & Paymohamed elmakhzniNo ratings yet

- TMS TAdvPolyList Quick Start Guide PDFDocument5 pagesTMS TAdvPolyList Quick Start Guide PDFwilkerNo ratings yet