Foundation Construction Guidelines

Uploaded by

johnkarl.bentingFoundation Construction Guidelines

Uploaded by

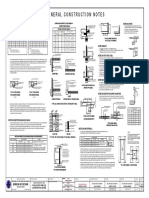

johnkarl.bentingGENERAL NOTES: TYP TOP M

1.0 GENERAL : 5.0 FOUNDATIONS : @ BOT. FLG.

3 SIDES 45°

1.1 ALL DIMENSIONS ARE SHOWN IN MILLIMETERS, ELEVATIONS ARE IN METERS, 3.2. REINFORCING BARS : 5.1 FOOTINGS WERE DESIGNED USING AN ALLOWABLE SOIL BEARING CL 1

UNLESS NOTED OTHERWISE. CAPACITY OF 144 KPa (3000 PSF) AT DEPTHS INDICATED IN THE DRAWING. 1

3.2.1 UNLESS OTHERWISE SPECIFIED ON PLANS, ALL REINFORCING BARS SHALL BE CONFIRMATION OF ACTUAL SOIL BEARING CAPACITY SHALL BE DONE PRIOR TO

1.2 THE CONTRACTOR SHALL VERIFY ALL DIMENSIONS AND CONDITIONS AT THE

0-2

tf

DEFORMED WITH A MINIMUM YIELD STRENGTH, fy = 30000 PSI CONSTRUCTION OF FOUNDATION, INCREASE IN FOUNDATION SIZE SHALL BE DONE "k" AS PER AISC

SITE, AND SHALL NOTIFY THE ENGINEER OF DISCREPANCIES BETWEEN ACTUAL MANUAL

CONDITIONS AND INFORMATION SHOWN ON THE DRAWINGS BEFORE PROCEEDING FOR Ø12 AND BELOW, AND fy = 40000 PSI FOR Ø16 AND ABOVE. WHEN ACTUAL SOIL BEARING CAPACITY, CONFIRMED DURING EXCAVATION, WARRANTS

WITH THE WORK. THIS SHALL INCLUDE THE LOCATION AND DIMENSIONS OF REVISION OF FOUNDATION SIZES. BACKING

3.2.2 ALL REINFORCING BARS SHALL BE CLEANED OF RUST, GREASE OR OTHER BAR

GROOVES, REGLETS, SLEEVES, CURBS, OPENINGS, EMBEDDED OR ATTACHED

MATERIALS WHICH TEND TO IMPAIR BOND. 5.2 WHERE LOOSE/SOFT MATERIAL IS ENCOUNTERED AT DEPTH OF FOOTING/FOUNDATION

ITEMS, ETC. REFER TO ARCHITECTURAL, MECHANICAL, ELECTRICAL AND PLUMBING 6

ALL FIGURED DIMENSIONS SHALL TAKE PRECEDENCE OVER SCALE SHOWN ON PLANS, 3.2.3 ALL REINFORCING BARS SHALL BE ACCURATELY AND SECURELY PLACED INDICATED, EXCAVATE TO FIRM LAYER AND REPLACE LOOSE/SOFT MATERIALS

DRAWINGS. UNDERNEATH THE FOOTING WITHIN THE FOOTING AREA PLUS 1/2 DEPTH OF SOIL

BEFORE POURING CONCRETE OR APPLYING MORTAR OR GROUT. "k" AS PER AISC

MATERIAL ON ALL SIDES WITH SELECTED BACKFILL. COMPACT SELECTED BACKFILL MANUAL

1.3 SECTIONS OR DETAILS. SPECIFIC NOTES AND DETAILS ON DRAWINGS SHALL TAKE 3.2.4 LAPPED SPLICES SHALL BE STAGGERED WHERE POSSIBLE. WELDING SYMBOL

PRECEDENCE OVER GENERAL NOTES AND TYPICAL DETAILS. TO 95% MAXIMUM DRY DENSITY ( ASTM D1557).

3.2.5 UNLESS INDICATED OTHERWISE, SPLICING OF REINFORCEMENT SHALL BE IN 16MMØ ERECTION BOLT.

5.3 ALL COLUMN FOOTINGS SHALL REST ON 50MM THK COMPACTED GRAVEL

1.4 THE CONTRACT STRUCTURAL DRAWINGS AND SPECIFICATIONS REPRESENT THE ACCORDANCE WITH ACI- 318-95. TOP & BOT. PLATES FOR SHEAR PL (OPTIONAL)

BASE COURSE, UNLESS OTHERWISE STATED. SHALL MATCH BEAM FLANGE 10 SEE NOTE 1

FINISHED STRUCTURES. THEY DO NOT INDICATE THE METHOD OF CONSTRUCTION 3.2.6 UNLESS SHOWN OTHERWISE ON PLANS, SPLICES SHALL BE AS FOLLOWS :

UNLESS SO STATED. THE CONTRACTOR SHALL PROVIDE ALL NECESSARY

THICKNESS AND SHALL BE 40 6

A. 5.4 FILL/BACKFILL SHALL BE PLACED IN 200 MM LAYERS AND EACH LAYER SHALL BE

BEAMS AND FOOTING TIE BEAMS : TOP AND BOTTOM BARS SHALL NOT 12MM THK. MINIMUM

MEASURES TO PROTECT THE STRUCTURES, ADJACENT PROPERTIES, WORKMEN COMPACTED TO 95% MAXIMUM DRY DENSITY BEFORE SUBSEQUENT LAYERS REINFORCING PLATE

BE SPLICED WITHIN THE COLUMN OR WITHIN A DISTANCE OF TWICE THE 80 TOP & BOT. (SEE DETAIL) 45°

AND OTHER PERSONS DURING ALL PHASES OF CONSTRUCTION. ARE TO BE LAID.

MEMBER DEPTH FROM THE FACE OF THE COLUMN ; AT LEAST TWO EXTRA

1.5 THE CONTRACTOR SHALL IMMEDIATELY NOTIFY THE OWNER AND/OR THE STIRRUP - TIES SHALL BE PROVIDED AT ALL SPLICES. THE SPLICE LENGTH

THE ENGINEER OF ANY CONDITION WHICH IN HIS OPINION MIGHT ENDANGER SHALL NOT BE LESS THAN THE LENGTH IN ITEM 4.2.9 BELOW.

0-2

tf

THE STABILITY OF THE STRUCTURES OR CAUSE DISTRESS IN THE STRUCTURES. B. COLUMNS : SPLICES WHEN PERMITTED SHALL BE MADE WITHIN THE CENTER

HALF OF COLUMN HEIGHT, AND LAP SPLICE SHALL NOT BE LESS THAN

FILLET WELD TABLE

1.6 CONSTRUCTION MATERIALS SHALL NOT BE STORED ON POURED FLOORS. IT BACKING

40 BAR DIAMETERS. THE USE OF APPROVED MECHANICAL DEVICES MAY BE

IS THE GENERAL CONTRACTOR'S RESPONSIBILITY TO ENSURE THAT THE WELD SIZE, S SCALLOP NOTCH BAR

SUB-CONTRACTORS ARE INFORMED AND DO NOT VIOLATE THIS IMPORTANT PERMITTED PROVIDED THAT NOT MORE THAN ALTERNATE BARS ARE PLATE THICKNESS, t

BEAM TO COLUMN FLANGE

(MM) (MM)

REQUIREMENT. SPLICED AT ANY LEVEL AND THE MINIMUM VERTICAL DISTANCE 4 (EXTERIOR)

BETWEEN TWO ADJACENT BAR SPLICES SHALL BE 600MM. (MM) WELDING SYMBOL

S-1 SCALE: N.T.S.

1.7 THE CONTRACTOR SHALL PROVIDE TEMPORARY ERECTION BRACINGS AND T JOINTS LAP JOINTS R

SHORINGS FOR ALL THE STRUCTURAL MEMBERS AS REQUIRED FOR STRUCTURE C. CMU WALLS : VERTICAL BARS SHALL BE SPLICED AT THE TOP OF WALL

STABILITY DURING ALL PHASES OF CONSTRUCTION. FOOTING OR TIE BEAM AND AT THE BOTTOM OF RC LINTEL LESS THAN 6 S=t S=t 25

BEAM OR BEAMS. SPLICE LENGTHS SHALL BE 600MM MIN.

1.8 THE CONTRACTOR SHALL TAKE ALL STEPS NECESSARY TO ENSURE THE

PROPER ALIGNMENT OF THE STRUCTURES DURING AND AFTER THE INSTALLATION

3.2.7 UNLESS INDICATED OTHERWISE ALL BEAMS TERMINATING AT THE COLUMN 6 TO 8 6 4 25 SINGLE BEVEL

SHALL HAVE TOP AND BOTTOM BARS EXTENDING TO THE FAR FACE OF 80 40 CP

OF ALL STRUCTURAL AND FINISH MATERIALS. THE COLUMN, TERMINATING IN A STANDARD 90° HOOK LENGTH OF 9 TO 11 6 6 25 TYP.

5 GROOVE WELD

ANCHORAGE NOT LESS THAN 600MM. T&B S-1 SCALE: N.T.S.

1.9 TYPICAL DETAILS AND GENERAL NOTES ON S-1 APPLY TO ALL PARTS OF THE

WORKS UNLESS OTHERWISE SHOWN ON THE DRAWINGS. 3.2.8 SHOP DRAWINGS FOR BENDING AND CUTTING OF REINFORCEMENT SHALL 12 TO 15 9 9 35

STIFFENER PLATE 3 SIDES

BE SUBMITTED FOR APPROVAL TO THE ENGINEER PRIOR TO FABRICATION.

16 TO 18 9 9 35 ALIGN WITH CONN.

2.0 STANDARDS AND REFERENCES : 3.2.9 SPLICE LENGTH OF REINFORCING BARS SHALL BE AS SHOWN IN THE PLATE. THICKNESS "k" AS PER AISC

TABLE BELOW: TO MATCH BEAM

19 OR OVER 12 12 35 MANUAL

THE FOLLOWING SHALL GOVERN THE DESIGN, FABRICATION AND CONSTRUCTION 3.3 STRUCTURAL STEEL/ANCHOR BOLTS/BOLTS/WELDS & WELDMENTS WEB THK.

OF THE PROJECT :

3.3.1 ALL STRUCTURAL STEEL SHALL HAVE A MINIMUM YIELD STRENGTH, 16MMØ ERECTION

L

2.1 AMERICAN CONCRETE INSTITUTE ( ACI PUBLICATIONS ) ; Fy = 248 MPa (36 KSI) AND SHALL CONFORM TO ASTM A 36 S BOLT FOR SHEAR PL

ACI 318-95 BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE (OPTIONAL).

t1

SPECIFICATIONS.

ACI 315-80 MANUAL OF STANDARD PRACTICE FOR DETAILS AND DETAILING SEE NOTE 1

3.3.2 ALL STRUCTURAL STEEL SHALL BE FABRICATED AND ERECTED IN WELD ALL AROUND

OF CONCRETE REINFORCEMENT. ACCORDANCE WITH THE AISC SPECIFICATIONS (9TH EDITION) AND WELD ALL AROUND

PLATE TO MATCH "k" AS PER AISC

2.2 AMERICAN INSTITUTE OF STEEL CONSTRUCTION (AISC) PUBLICATION: CODE OF STANDARD PRACTICE AS AMENDED TO DATE. MANUAL

t1

MANUAL OF STEEL CONSTRUCTION, NINTH EDITION. CANTILEVER BEAM BEAM

3.3.3 ALL COLD FORMED STEEL SHALL HAVE A MINIMUM STRENGTH,

t2

"ALLOWABLE STRESS DESIGN" (ASD) FLANGE THICKNESS

Fy = 230 MPa (33 KSI)

t2

3.3 AND WIDTH GIRDER

2.3 AMERICAN WELDING SOCIETY (AWS) PUBLICATION D.1.1-90. 3.3.4 NO STEEL SHALL BE FABRICATED OR ERECTED UNTIL SHOP DRAWINGS S

HAVE BEEN APPROVED BY THE STRUCTURAL ENGINEER.

2.4 AMERICAN SOCIETY FOR TESTING MATERIALS (ASTM)

3.3.5 ALL SHOP AND FIELD WELDING SHALL BE IN ACCORDANCE WITH AWS t=t1 OR t2, WHICHEVER IS THINNER BEAM TO BEAM C.P.

2.5 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (NSCP) VOL. 1, D.1.1-2000 AND PERFORMED BY QUALIFIED WELDERS.

FIFTH EDITION, 2001.

3 (MOMENT CONNECTION)

3.3.6 UNLESS INDICATED OTHERWISE, WELDING ELECTRODES SHALL BE E70XX, NOTE: SCALE: N.T.S.

S-1

2.6 ASSOCIATION OF STRUCTURAL ENGINEERS OF THE PHILIPPINES (ASEP) MINIMUM THICKNESS OF WELD SHALL BE 3MM.

UNLESS OTHERWISE SPECIFIED, SIZE OF FILLET WELDS SHALL BE PROVIDED

HANDBOOK OF STRUCTURAL STEEL SHAPES AND SECTIONS, 1987

3.3.7 UNLESS OTHERWISE INDICATED ALL ANCHOR AS SHOWN ABOVE. THE WELD SIZE NEED NOT EXCEED THE THICKNESS OF

2.7 UNIFORM BUILDING CODE (UBC), VOL. 2 1997 EDITION BOLTS SHALL CONFORM TO ASTM A307 SPECIFICATIONS. THE THINNER MATERIAL BEING JOINT.

3.3.8 BOLTS FOR MEMBER CONNECTIONS SHALL BE HIGH STRENGTH BOLTS,

CONFORM TO ASTM A325 FRICTION TYPE WITH WASHERS. CL

3.0 MATERIALS

3.1. NORMAL WEIGHT CONCRETE : 3.4 CONCRETE MASONRY UNITS (CMU) C.P.

TYP TOP M 3 SIDES C.P. 200

3.1.1 CONCRETE USED IN THIS WORK SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH 3.4.1 CMU USED IN THESE WORKS SHALL HAVE A MINIMUM ULTIMATE

120 @ BOT. FLG.

@ 28 DAYS AS FOLLOWS: COMPRESSIVE STRENGTH @ 28 DAYS AS FOLLOWS : 1

100MM THICK NON-LOAD BEARING CMU, f'm = 6.9 MPa (350 PSI) 1

80 40 16MMØ ERECTION BOLT.

FOOTINGS, AND SLABS (3000 PSI) 100MM THICK NON-LOAD BEARING CMU, f'm = 6.9 MPa (350 PSI) FOR SHEAR PL (OPTIONAL) "k" AS PER AISC SINGLE BEVEL

COLUMNS, PEDESTAL AND BEAMS (3000 PSI) 3.4.2 ALL CELLS SHALL BE SOLIDLY FILLED WITH GROUT. CONCRETE SHALL SEE NOTE 1 MANUAL 6 GROOVE WELD

STIFFENER PLATE

HAVE A MINIMUM COMPRESSIVE STRENGTH OF 13.80 MPa S-1 SCALE: N.T.S.

3.1.2 ALL CONCRETE SHALL BE DEPOSITED, VIBRATED AND CURED IN ACCORDANCE ALIGN WITH CONN.

(2000 PSI) @ 28 DAYS.

L

WITH ACI STANDARD 318-95 PLATE. THICKNESS "k" AS PER AISC

3.4.3 UNLESS INDICATED OTHERWISE, CMU REINFORCEMENT SHALL BE 10MMØ TO MATCH BEAM MANUAL

3.1.3 MINIMUM CONCRETE COVER FOR REINFORCING BARS SHALL BE AS FOLLOWS: WEB THK.

HOR. BARS @ 600 AND 10MMØ VERT. BARS @ 400.

"k" AS PER AISC

A. FOOTINGS = 75MM (CAST AGAINST EARTH)

L

3.4.4 ALL WALLS SHALL BE CONSTRUCTED IN CONVENTIONAL RUNNING BOND MANUAL

B. BEAMS AND COLUMNS = 40MM (TO STIRUPS AND TIES)

UNLESS NOTED OTHERWISE.

C. SLABS AND WALLS = 20MM (CAST AGAINST FORMS)

3.4.5 GROUT MASONRY IN 2.4M MAXIMUM LIFTS. REINFORCING SHALL BE TOP & BOT. PLATES 16MMØ ERECTION BOLT.

D. BOTTOM SLAB AND WALLS = 50MM (INSIDE SURFACE OF WATER RETAINING STRUCTURE) "k" AS PER AISC

SECURED AGAINTS DISPLACEMENT PRIOR TO GROUTING BY WIRE SHALL MATCH BEAM FLANGE FOR SHEAR PL (OPTIONAL)

MANUAL

10

PLATE TO MATCH THICKNESS AND SHALL BE 40 SEE NOTE 1

3.1.4 BEFORE CONCRETE IS POURED, CHECK WITH ALL TRADES TO ENSURE PROPER POSITIONERS AT INTERVALS NOT EXCEEDING 200 BAR DIAMETERS CANTILEVER BEAM 12MM THK. MINIMUM

PLACEMENT OF ALL OPENINGS, SLEEVES, CURBS, CONDUITS, ETC. RELATIVE TO NOR 3M. FLANGE THICKNESS 3 SIDES 80 REINFORCING PLATE

THE WORK. 3.4.6 IF WORK IS STOPPED ONE (1) HOUR OR LONGER, PROVIDE HORIZONTAL AND WIDTH

TOP & BOT. (SEE DETAIL)

3.1.5 WHEN CONCRETE WILL BE EXPOSED TO EXTERNAL SOURCES OF CHLORIDES IN

SERVICES, SUCH AS DEICING SALTS, BRACKISH WATER, SEAWATER OR SPRAY FROM 4.0 CONSTRUCTION JOINTS:

THESE SOURCES, CONCRETE MUST BE PROPORTIONED TO SATISFY THE SPECIAL 4.1 CONTRUCTION JOINTS NOT INDICATED ON PLANS SHALL BE MADE SO AS

EXPOSURE REQUIREMENTS OF ACI 318-95. TO LEAST IMPAIR THE STRENGTH OF THE STRUCTURE AND SHALL BE SUBJECT

3.1.6 ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF 7 CONSECUTIVE DAYS TO APPROVAL OF THE ENGINEER. BEAM TO BEAM BEAM TO COLUMN FLANGE

1 (NON-MOMENT CONNECTION) 2 (INTERIOR) NOTE:

IMMEDIATELY AFTER POURING BY THE USE OF WET BURLAP. 4.2 UNLESS SHOWN OTHERWISE, SLAB ON GRADE SHALL HAVE CONTROL JOINTS

S-1 SCALE: N.T.S. S-1 SCALE: N.T.S. 1. SHEAR PLATE THICKNESS SHALL

@ 6.00M MAXIMUM CENTER TO CENTER.

NOT BE LESS THAN WEB THICKNESS

AND 10MM, WHICHEVER IS GREATER.

REPUBLIC ACT 9266

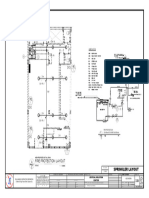

PROJECT TITLE: PROJECT OWNER: PREPARED BY: SHEET CONTENT SHEET NO.

ART IV, SECTION 33

DRAWINGS AND SPECIFICATIONS DULY AS SHOWN

CIVIL ENGINEER SIGNED AND SEALED AS INSTRUMENT DRAWN BY: BENTING, JOHN KARL M.

OF SERVICE ARE INTELLECTUAL

PROPOSED TWO-STOREY BUILDING

S 1.00

PROPERTY.IT SHALL BE UNLAWFUL

FOR ANY PERSON TO DUPLICATE OR MR. HENRY NG LIO

PRC REG. NO: PTR NO: TO MAKE COPIES FOR USED IN APPROVED BY:

REPETITION, WETHER EXECUTED

DATE: ISSUED ON: PARTLY OR WHOLE, WITHOUT THE

WRITTEN CONSENT OF THE AUTHOR LOCATION: NO. 441 LT., ARTIAGA, SAN JUAN CITY

ISSUED AT: DATE: MAY 20 2023

You might also like

- Bridge Design and Construction GuidelinesNo ratings yetBridge Design and Construction Guidelines2 pages

- Construction Notes for Structural DesignNo ratings yetConstruction Notes for Structural Design14 pages

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3No ratings yetGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 31 page

- Foundation Plan and Details: Foundation Legend: General Foundation NotesNo ratings yetFoundation Plan and Details: Foundation Legend: General Foundation Notes6 pages

- STR - 670 GB - Rev-3-Rvt (Edicion para Rev 3) - MariaNo ratings yetSTR - 670 GB - Rev-3-Rvt (Edicion para Rev 3) - Maria17 pages

- XP 1050AE DSN V01 DWG W02 Structural DrawingsNo ratings yetXP 1050AE DSN V01 DWG W02 Structural Drawings8 pages

- 7710 Muirfield DR - DB-2023-01257 - StructuralNo ratings yet7710 Muirfield DR - DB-2023-01257 - Structural4 pages

- 07 152502 4800000647 RTC STR DRG 010003 - ANo ratings yet07 152502 4800000647 RTC STR DRG 010003 - A1 page

- Shoring and Design Guidelines for StructuresNo ratings yetShoring and Design Guidelines for Structures1 page

- General Construction Notes: Bureau of DesignNo ratings yetGeneral Construction Notes: Bureau of Design1 page

- Proposed Three-Storey Building: General Structural / Construction Notes and SpecificationsNo ratings yetProposed Three-Storey Building: General Structural / Construction Notes and Specifications1 page

- Concrete Slab and Block Reinforcement GuideNo ratings yetConcrete Slab and Block Reinforcement Guide5 pages

- Building Code Compliance for ConstructionNo ratings yetBuilding Code Compliance for Construction1 page

- Construction Notes for Reinforced ConcreteNo ratings yetConstruction Notes for Reinforced Concrete1 page

- Construction Notes for Concrete StructuresNo ratings yetConstruction Notes for Concrete Structures1 page

- Hardy Frame "STK" Washers Are Required in The Top of Panels WhenNo ratings yetHardy Frame "STK" Washers Are Required in The Top of Panels When1 page

- Dalino Commercial Building - Structural PlanNo ratings yetDalino Commercial Building - Structural Plan4 pages

- 4" Floor Slab & Tie Beam SpecificationsNo ratings yet4" Floor Slab & Tie Beam Specifications15 pages

- General Construction Notes: Bureau of DesignNo ratings yetGeneral Construction Notes: Bureau of Design15 pages

- Iloilo City Gymnasium Construction NotesNo ratings yetIloilo City Gymnasium Construction Notes1 page

- Roof Trellis Framing: Existing StructureNo ratings yetRoof Trellis Framing: Existing Structure1 page

- Two-Storey Building Construction DetailsNo ratings yetTwo-Storey Building Construction Details1 page

- Digital Marketing TR Plan 2021 Q3 September 12.Pptx 1No ratings yetDigital Marketing TR Plan 2021 Q3 September 12.Pptx 1113 pages

- STADIO Assignment Template TGEF701 - FIS 2025No ratings yetSTADIO Assignment Template TGEF701 - FIS 20255 pages

- Exam Practice Question - Tesla WZ AnswersNo ratings yetExam Practice Question - Tesla WZ Answers4 pages

- Electric Vehicles in India: Challenges AheadNo ratings yetElectric Vehicles in India: Challenges Ahead5 pages

- Highest Integrity Hand-Held Coiled Tubing Handling Tools: Features and Benefits of CoillokNo ratings yetHighest Integrity Hand-Held Coiled Tubing Handling Tools: Features and Benefits of Coillok2 pages

- Henry VIII: Monarchy, Ministers, and PowerNo ratings yetHenry VIII: Monarchy, Ministers, and Power42 pages

- CreditReport Piramal - AMRIK SINGH - 2024 - 10 - 06 - 16 - 24 - 08.pdf 31-Dec-2024No ratings yetCreditReport Piramal - AMRIK SINGH - 2024 - 10 - 06 - 16 - 24 - 08.pdf 31-Dec-20246 pages

- Round Robin DNS Load Balancing - WebsiteGearNo ratings yetRound Robin DNS Load Balancing - WebsiteGear2 pages

- Fuels and Combustion Marion L. Smith, Karl W. Stinson.67% (3)Fuels and Combustion Marion L. Smith, Karl W. Stinson.366 pages

- Lesson 5: Gathering Information From SurveysNo ratings yetLesson 5: Gathering Information From Surveys18 pages

- Kedokteran Pariwisata: by Imam Syahrul Fatoni PutraNo ratings yetKedokteran Pariwisata: by Imam Syahrul Fatoni Putra48 pages