Professional Documents

Culture Documents

S-1 General Notes

Uploaded by

Engr. Robnick PaduaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S-1 General Notes

Uploaded by

Engr. Robnick PaduaCopyright:

Available Formats

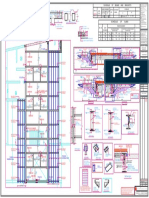

GENERAL :

A. MATERIALS AND WORKMANSHIP SHALL CONFORM WITH THE

REQUIREMENTS OF THE FOLLOWING BUILDING CODES.

1. ACI 318 - 14

2. ASEP SEISMIC DESIGN GUIDE

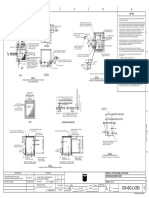

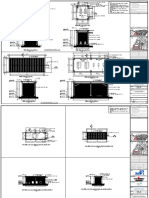

CONSTRUCTION NOTES

3. NSCP - 2015 EDITION

4. UBC 1997 STRUCTURAL STEEL :

BEAM

B. ALL DRAWINGS SHALL NOT BE SCALED FOR CONSTRUCTION lb1 lb2

PURPOSES UNLESS OTHERWISE INDICATED. 1. ALL STUCTURAL STEEL SHALL CONFORM TO ASTM A-36. SEE NOTE A SEE NOTE A

5-10MMØ BARS 150MM

BAR SPACES DIA.

C. FOR ALL OTHER REQUIREMENTS , REFER TO ARCHITECTURAL , SPACED AT 200 MM O.C.

SANITARY , ELECTRICAL AND MECHANICAL WORKING DRAWINGS.

2. WELDING SHALL CONFORM TO AWS STANDARDS. 1 2

NOT LESS THAN

20MM

3. FABRICATOR SHALL SUBMIT SHOP DRAWINGS FOR APPROVAL BY LAPS SEE

100MM

50MM

FOOTINGS : CALCULATED BOND

LENGTH BUT

NOTE E

30Ø OR 600MM

1. FOOTINGS ARE DESIGNED TO REST ON FIRM SUBGRADE

WITH MINIMUM BEARING CAPACITY OF 3, 000 psf THE ENGINEER AND THE OWNER.

2. NO FOOTING SHALL REST ON FILL. 2h 2h 5-10MMØ BARS

SPACED AT 200 MM O.C.

3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENT SHALL NO LAPS ZONE

1

SEE NOTES

D,F&G 2 SEE NOTE D FOR ALL TYPICAL SLAB DEPRESSION DETAIL

BE 70 MM CLEAR FOR CONCRETE DEPOSITED AGAINST THE SEE NOTE D MINIMUM STEEL LAPS CALCULATED

SEE NOTE B LAP LENGTH

FORMWORK. BUT 300MM

40MM CLEAR

DISTANCE (MINIMUM)

END SPAN INTERNAL

CONCRETE MIXES & PLACINGS : DETAIL - 3 SUPPORT SUPPORT

1. UNLESS OTHERWISE SPECIFIED , THE MINIMUM 28-DAY CYLINDER h 500MM

40MM CLEAR DIST.

10

40MM CLEAR

00

COMPRESSIVE STRENGTH ARE AS FOLLOWS : (MINIMUM) FOR DISTANCE (MINIMUM)

FOOTINGS AND BEAMS ON GRADE 3, 000 psi

BEAMS & GIRDERS

SEE NOTE - A SEE NOTE - A 10 A. CURTAILMENT OF TOP BARS TO BE TENSION BOND LENGTH BEYOND THE POINT OF

TRIMMERS MAY BE 00

COLUMNS 3, 000 psi DETAIL - 1 OMITTED WHERE CONTRAFLEXURE BUT NOT LESS THAN lb/4 FROM SUPPORT , IF SOME BARS ARE 50MM

OPENING IS FRAMED

SLABS , BEAMS AND GIRDERS 3, 000 psi BY BEAMS CURTAILED AT SHORTER DISTANCES AT LEAST A THIRD OF TOTAL STEEL MUST

BEARING AND RETAINING WALLS 3, 000 psi EXTEND THIS DISTANCE.

C h

BEDDED SLABS , CATCH BASINS AND SIDEWALK 2,500 psi

2. ALL CONCRETE MUST BE DEPOSITED , VIBRATED AND CORED IN 2-16MMØ AT MINIMUM 1-16MMØ

B. THE AREA OF BOTTOM OF STEEL PROVIDED AT THE SUPPORTS MUST EQUAL AT

TYPICAL BEAM-COLUMN EACH CORNER

ACCORDANCE WITH ACI STANDARD 318-89. INTERCONNECTION

TOP & BOTTOM FOR LEAST HALF THE AREA OF THE TOP STEEL AT THAT SECTION.

NOTE : SLABS 125MM THK.

AND OVER

50MM

3. STRIPPING FORMS AND SHORES SHALL BE AS FOLLOWS : A. STIRRUP SPACING IN PLASTIC HINGE ZONE OF LENGTH 2h OPENING C. A MIN. OF 1/4 OF THE LARGER AMOUNT OF TOP STEEL REQUIRED AT EITHER END 500MM 10MMØ TIES AT 150MM O.C.

FOUNDATION 1 DAY SHALL BE THE LEAST OF ; 1. D/4 2. 6Ø 3. 150MM. HOOK SLAB MUST CONTINUE FOR THE WHOLE LENGTH OF THE SPAN.

EXTENDED TRIMMER BAR

COLUMNS & WALLS 3 DAYS B. Ø = DIAMETER OF MAIN LONGITUDINAL BAR FOR DISTANCE REINFORCEMENT 1000MM BEYOND SIDES

OVER TRIMMER BAR OF OPENING OR AS FAR

BEAMS & GIRDERS 21 DAYS D. NO LAPS IN TOP & BOTTOM TO OCCUR WITHIN A DISTANCE OF 2h FROM FACE OF

UNDER CONSIDERATION IN TOP OR BOTTOM WHICHEVER IS AS POSSIBLE & HOOK.

SLABS 17 DAYS SUPPORT .

SMALLER.

4. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT

SEGREGATION RE-HANDLING OR FLOWING. PLACING SHALL BE

C. THIS STIRRUP SPACING CONTINUES WITHIN THE INTERMEDIATE E. LAPS ARE TO BE KEPT TO A MINIMUM AND CRANKS IF REQUIRED TO BE AS FOR TYP. BEAM DEPRESSION DETAIL

DONE PREFERABLY WITH BUGGIES , BUCKET OR WHEELBARROWS. ZONE. COLUMNS.

NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE SCHEDULE - 1 PROVIDE EXTRA BAR

(NOT SHOWN) PARALLEL 1000

FROM HOPPERS TO BUGGIES , WHEELBARROWS OR BUCKETS IN TO SIDES OF EQUAL AREA F. IF h > 750MM PROVIDE EXTRA LONGITUDINAL BARS FOR 2/3 OF THE BEAM DEPTH

OF INTERRUPTED SLAB

WHICH CASE THEY SHALL NOT EXCEED SIX (6.0) IN METER IN CONCRETE HOLLOW BLOCK REINFORCEMENT REINFORCEMENT LESS FROM THE TENSION FACE WITH SPACING > 250MM.

AGGREGATE LENGHT. NO DEPOSITING OF CONCRETE SHALL BE BLOCK REINFORCEMENT NOTES AREA TRIMMER BARS.

ALLOWED WITHOUT THE USE OF VIBRATORS. UNLESS AUTHORIZED THICK HORIZONTAL VERTICAL A. MINIMUM SPLICE AT LAP = 300MM

G. LAPS IN FRAMING BARS TO BE STAGGERED RELATIVE TO LAPS IN MAIN TOP AND

B. PROVIDE RIGHT ANGLE REINF. t

75 MM 10MM AT 600MM O.C. 10MM AT 600MM O.C. DETAIL - 4

IN WRITING BY THE DESIGNERS AND ONLY FOR USUAL CONDITIONS 100MM 10MM AT 600MM O.C. 10MM AT 600MM O.C.

AT CORNERS 1000MM LONG.

C. WHERE CHB WALLS ADJOINING COLS.

BOTTOM BARS.

WHERE VIBRATORS IS EXTREMELY DIFFICULT TO ACCOMPLISH. R.C. BEAMS. WALL DOWELS W/ SAME b b ANCHORAGE OUTSIDE

150MM 12MM AT 600MM O.C. 12MM AT 600MM O.C. PANEL ZONE PQRS

SIZE AS VERT. REINF. SHALL BE

200MM

BEAMS AND GIRDERS : 12MM AT 600MM O.C. 12MM AT 600MM O.C. PROVIDED.

P Q TYP. SLAB CONSTRUCTION JOINT

1. CAMBER ALL BEAMS AND GIRDERS AT LEAST 6.50 MM FOR EVERY

3.0 M. OF SPAN. SCHEDULE - 2

h

2. FOR TWO OR MORE LAYERS OF REINFORCING BARS USE SEPARATORS

WALL REINFORCEMENT VERTICAL

SPACED AT 1.0 M. O.C. AND IN NO CASE SHALL BE LESS THAN REMARKS

THK. HORIZONTAL VERTICAL SECTION S R

TWO (2) SEPARATORS. 10MM AT 250MM O.C. 10MM AT 300MM O.C.

HORIZONTAL & CENTER VERTICAL 1-1 2-2

100MM BARS STAGGERED OUTSIDE.

125MM 10MM AT 250MM O.C. 10MM AT 250MM O.C. - DO -

3. NO SPLICE SHALL BE PERMITTED ON BEAMS AND GIRDERS WHERE BOTH FACES HORIZONTAL BEAMS FORMING PART OF A ALTERNATIVE PREFERRED b

150MM 12MM AT 250MM O.C. 12MM AT 300MM O.C

CRITICAL BENDING STRESSES IS OCCUR. TENSION SPLICE SO PERMI-

SHALL BE INSIDE.

DUCTILE MOMENT RESISTING END SUPPORT DETAIL

175MM 12MM AT 200MM O.C. 12MM AT 250MM O.C. - DO -

TTED SHALL BE 60 DIAMETER FOR PLAIN BARS AND 40 DIAMETER 200MM 12MM AT 300MM O.C. E.F. 12MM AT 300MM O.C. BOTH FACES HORIZONTAL FRAMEWORK

SHALL BE OUTSIDE.

12Ø

FOR DEFORMED BARS. 225MM 12MM AT 200MM O.C. E.F. 12MM AT 250MM O.C. E.F. - DO -

COMPRESSION SPLICE SHALL BE 40 DIAMETERS FOR PLAIN BARS

AND 30 DIAMETERS FOR DEFORMED BARS. LAP SPLICES SHALL BE

250MM

275MM

300MM

12MM AT 300MM O.C. E.F.

12MM AT 250MM O.C. E.F.

12MM AT 200MM O.C. E.F.

12MM AT 300MM O.C. E.F.

12MM AT 300MM O.C. E.F.

12MM AT 275MM O.C. E.F.

- DO -

- DO -

- DO -

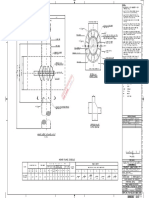

CONCRETE COLUMNS : PLAN

CONF'T

WIRED TOGETHER UNLESS OTHERWISE SPECIFIED. TOP BARS AT MID-

ZONE

L1

325MM 12MM AT 200MM O.C. E.F. 12MM AT 250MM O.C. E.F. - DO -

SPAN , BOTTOM BARS AT SUPPORT , BEND BARS AT BED POINTS IN

SUPERSTRUCTURE. WELDED SPLICES SHALL DEVELOP IN TENSION AT

350MM 16MM AT 250MM O.C. E.F. 12MM AT 300MM O.C. E.F. - DO -

A. Li = LARGEST OF :

LEAST 125% OF THE SPECIFIED YIELD STRENGTH OF THE BAR. NOT 1. h (h>b)

INTERMEDIATE ZONE

MORE THAN 50% OF THE BARS AT ANY ONE SECTION SHALL BE

PERMITTED TO BE SPLICED.

200

1

200 2. Lo/6 1000MM

Lo

LINTEL BEAM STIFFENER

4. IF BEAM REINFORCING BARS END IN A WALL THE CLEAR DISTANCE

COLUMN

1 1

3. 450 MM

FROM THE BAR TO THE FARTHER FACE OF THE WALL SHALL NOT B. FOR COLUMNS REQUIRING SPECIAL CONFINEMENT STEEL.

BE LESS THAN 50 MM EMBEDMENT LENGTH SHALL BE 40 DIAMETER Shi = SPACING OF ALL CONFINEMENT ZONE USING A

CONF'T

FOR TENSION AND 20 DIAMETER FOR COMPRESSION BARS.

ZONE

L1

MAXIMUM SPACING OS 0.20 b , 6Ø OR 200MM. h

5. MINIMUM CONCRETE PROTECTION OF REINFORCING BARS OR SHAPES

CONNECTION

THE AREA OF CONFINEMENT LINKS SHOULD BE DE-

SEE NOTE

BEAM-COL

SHALL BE AS SHOWN ON DETAIL-1.

D&E

6. UNLESS OTHERWISE NOTED IN PLANS OR SPECIFICATIONS , CAMBER

TERMINED.

Sh1/2

1 - 16MMØ

SEE NOTE

C. Sh : = SPACING FOR ALL LINKS & TIES IN INTERMEDIATE 10MMØ TIES 2-12MMØ ON

CONF'T

ALL BEAMS AND GIRDERS AT LEAST 6.5 MM FOR EVERY 3.0 M OF

ZONE

VERTICAL BAR

L1

B&C

AT 150MM O.C. BOTH SIDES

(TYPICAL)

SPAN EXCEPT CANTILEVERS FOR WHICH THE CAMBERS SHALL BE AS

NOTED IN PLANS OR AS ORDERED BY THE DESIGNER , BUT IN CASE

ZONE. SPACING TO BE THE LEAST OF :

SECTION

INTERMEDIATE ZONE

LESS THAN 7.5 MM FOR EVERY 3.0 M OF FREE SPAN. 1. 12Ø

SEE NOTE C

Lo

2. 400MM

Sh2 LAP SEE

NOTE F

CONCRETE SLABS : TYPICAL BEAM CONSTRUCTION JOINT

3. 0.40b

1. ALL REINFORCEMENT SHALL BE 20 MM CLEAR MINIMUM FROM TOP AND

0.2 Sh1

Ø = DIAMETER OF SMALLEST LONGITUDINAL BAR

CONF'T

ZONE

BOTTOM OF SLAB.

L1

2. FOR TWO-WAY SLAB BARS ALONG SHORTER SPAN SHALL BE PLACED IN COLUMN.

Sh

100-150MMØ PIPE

BELOW THOSE ALONG THE LONGER SPAN AT CENTER AND OVER THE D. SPACING AND TOTAL CROSS-SECTIONAL AREA OF HOOPS

LONGER SPAN BARS NEAR THE SUPPORT. UNLESS OTHERWISE INDICA- ELEVATION ELEVATION

b

TED OR SHOWN IN DETAILS THE SPACING OF THE BARS AT THE a

& TIES THROUGH THE BEAM COLUMN CONNECTION

COLUMN STRIPS CAN BE APPROXIMATELY 1-1/3 TIMES OF THE MIDDLE CHB WALL

STRIP BUT IN NO CASE GREATER THAN 2-1/3 TIMES THE SLAB THICK-

(OR ANY OTHER CONNECTING MEMBER). h

SUPPLEMENTARY

NESS. 300MM DOWEL(SAME DIAMETER

CROSS TIES (SEE

NOTE H)

E. ALL HOOP ARRANGEMENTS MUST ALSO BE CAPABLE

AS CHB VERTICAL REINF.)

3. UNLESS OTHERWISE DETAILED IN CONTINOUS SLABS HAVING SAME REIN- 300MM h

OF RESISTING THE APPLIED SHEARS THROUGHOUT

b

HOOPS 12MMØ ON

FORCEMENT RUNNING IN ONE DIRECTION REINFORCING SHALL BE BENDED

2-12MMØ TOP BAR b/a > 10 THE WHOLE COLUMN LENGTH INCLUDING THE BEAM BOTH SIDES

150MM

EXTENDED OR CUT AS SHOWN ON THE SCHEDULE OF SLABS 1000MM

100MM

b > 300MM

20MM

4. TEMPERATURE BARS SHALL BE GENERALLY PLACED NEAR THE TENSION

10MMØ, 1 AT 50

REST AT 250MM O.C.

1-1 COLUMN CONNECTION ZONE.

FACE AND SHALL NOT BE LESS THAN 0.0025 BT. BARS : 6-12MMØ BARS : 3-12MMØ

2-12MMØ BOTTOM BAR CRANK DETAIL F. IN MEDIUM AND HIGH RISK EARTHQUAKE ZONES NOTE :

TIES : 10Ø, 1 AT 50 TIES : 10Ø, 1 AT 50

5. UNLESS OTHERWISE NOTED ALL BEDDED SLABS SHALL REINFORCED WITH 3 AT 100, 3 AT 150

REST AT 250MM

3 AT 100, 3 AT 150

REST AT 250MM

135° (Ø) SPLICES SHOULD BE MADE OUTSIDE OF PLASTIC A. CONDUITS , PIPES & SLEEVES PASSING THROUGH

6Ø

10MMØ AT 400MMØ O.C. E.W. AT CENTER OF SLAB CONSTRUCTION

JOINTS FOR SAME SHALL NOT BE MORE THAN 3.0 M APART.

SECTION - 1 HINGE ZONES AND ARE TO BE LARGER OF : A SLAB , WALL OR BEAM SHALL NOT IMPAIR

SIGNIFICANTLY THE STRENGTH OF THE CONSTRUC-

STIFFENER COLUMN STIFFENER COLUMN 1. CALCULATED BOND LENGTH

6. PROVIDE EXTRA REINFORCEMENT AT CORNER SLABS (TWO ADJACENT FOR 6" CHB FOR 4" CHB ØM

r = 2ØM (MILD STEEL)

4ØM (HT. STEEL)

TION.

DISCONTINOUS EDGE ) AS SHOWN ON DETAIL-3. 2. 30Ø , FOR Fy = 415 MPa

B. THEY SHALL NOT BE PLACED CLOSER THAN 3 DIA-

7. PROVIDE SUPPLEMENTARY REINFORCEMENT AT SMALL UNFRAMED OPENING TYPICAL DETAIL OF LINTEL BEAM AND STIFFENER COLUMN DETAIL OF HOOP AND 3. 20Ø , FOR Fy = 275 MPa METER OR WIDTHS ON CENTER.

IN FLOOR SLABS AS SHOWN ON DETAIL-4. TIE ANCHORAGE DIMENSIONS

I. DIAMETER OF HOOPS AND CROSS - TIES :

CONCRETE HOLLOW BLOCKS : MILD STEEL REINFORCEMENT : DETAIL - 5

6MM , IF ØM < 20MM

REINFORCEMENT AS TABULATED IN SCHEDULE SHALL BE PROVIDED UNLESS 1. ALL MILD STEEL REINFORCEMENT SHALL CONFORM TO ASTM A-1562 -2T 10MM , IF 20MM <ØM<28MM TYPICAL PIPE SLEEVE DETAIL

OTHERWISE SPECIFIED IN THE PLAN . SEE SCHEDULE -1. AND DEFORMATIONS TO A-305-56 OR LATEST REVISIONS.

2. DEVELOPMENT LENGTH FOR ALL BARS SHALL BE A MINIMUM OF 40 BARS 12MM , IF ØM>28MM

CONCRETE WALLS : DIAMETERS UNLESS OTHERWISE SPECIFIED. ØM = THE DIAMETER OF LONGITUDINAL BAR.

UNLESS OTHERWISE INDICATED IN THE PLANS , WALL REINFORCEMENT SHALL SEE DETAIL - 5.

BE FOLLOWED AS TABULATED IN SCHEDULE -2. SEE SCHEDULE -2.

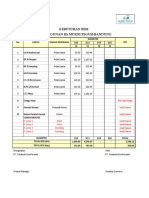

FOR PERMIT

ARCHITECT: ENGINEER: PROJECT NAME: CLIENT NAME: SHEET CONTENTS: SHEET NO:

CONSTRUCTION NOTES

Proposed 3-Storey Residence w/ Deck & 2-Storey

DEBBIE ANN S. LUA JEFFERSON M. VILLARAZA

Multipurpose Bldg.

Mr. Kirk Chester Dy S-1

ARCHITECT ENGINEER

NOTE: ANY DISCREPANCIES ON ALL DRAWINGS OR

PRC: 0022594 DATE: Feb. 08, 2022 PRC: 118310 DATE: Jan. 07, 2022 Location: Dorotea St, Quezon City RA 545: THIS DRAWING AS AN INSTRUMENT OF SERVICE IS THE PROPERTY OF THE DESIGNER DRAWN BY: CHECKED BY: DATE: SPECIFICATIONS SHALL BE VERIFIED WITH THE

ARCHITECT PRIOR TO IMPLEMENTATION.

AND AS SUCH MUST NOT BE REPRODUCED IN PART OR WHOLE WITHOUT CONSENT.

PTR: 1580136 PLACE: San Juan City, Manila PTR: 9036680 PLACE: Marikina City

You might also like

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Batching Plant Architectural DrawingDocument1 pageBatching Plant Architectural DrawingTaposh Paul100% (1)

- Section Z-Z Section X-X: 8T12-150-T1 10T12-150-T1Document1 pageSection Z-Z Section X-X: 8T12-150-T1 10T12-150-T1inno musiimeNo ratings yet

- E0.52 ELECTRICAL SITE PLAN Rev.0Document1 pageE0.52 ELECTRICAL SITE PLAN Rev.0Abdul RahmanNo ratings yet

- Structural PlanDocument1 pageStructural PlanGenevieve GayosoNo ratings yet

- Uci Mce Stru D S-20.6Document1 pageUci Mce Stru D S-20.6Thanh Đạt NguyễnNo ratings yet

- Construction Notes: D. Notes On Foundation Design CriteriaDocument9 pagesConstruction Notes: D. Notes On Foundation Design CriteriaIrene Ionie Rarangol - TengcoNo ratings yet

- 01 - Foundation LayoutDocument1 page01 - Foundation LayoutSolomon Ndugwa BalemeziNo ratings yet

- Rta Drawings Vol1Document215 pagesRta Drawings Vol1Aboalmaail AlaminNo ratings yet

- 66 SSD 0005 BDocument1 page66 SSD 0005 BMbalekelwa MpembeNo ratings yet

- Foundations and Column Pedestals: General NotesDocument3 pagesFoundations and Column Pedestals: General NotesMaher ElabdNo ratings yet

- Asace Department of Defense Cut and Cover StandardsDocument104 pagesAsace Department of Defense Cut and Cover StandardsNANA ADDONo ratings yet

- Weld SymbolDocument1 pageWeld SymbolblithevincentNo ratings yet

- 1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLDocument1 page1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLMANOJTRIVEDI100% (1)

- Civ GC L1253 1Document2 pagesCiv GC L1253 1Adhe L ShethiadyNo ratings yet

- Terminal 2: Level 4 - Retail Mezzanine - Part Plan - 53Document1 pageTerminal 2: Level 4 - Retail Mezzanine - Part Plan - 53waz ahmedNo ratings yet

- Issued For Construction: Section A-A Anchor FlangeDocument1 pageIssued For Construction: Section A-A Anchor FlangeFahadNo ratings yet

- Stair CaseDocument5 pagesStair CaseAjay KunduNo ratings yet

- Type-1 - Structural Plan - 2013-02-16 PDFDocument3 pagesType-1 - Structural Plan - 2013-02-16 PDFjremptymak0% (1)

- WH2 GaDocument5 pagesWH2 GaRaveendra Babu CherukuriNo ratings yet

- Plot Stamp - A1 - Adv 20-01-20-Electrical.Document1 pagePlot Stamp - A1 - Adv 20-01-20-Electrical.nadeem UddinNo ratings yet

- Zoleta Residence - Structural PlansDocument5 pagesZoleta Residence - Structural PlansJc SulitNo ratings yet

- Issued For Construction: Detail Detail Section SectionDocument1 pageIssued For Construction: Detail Detail Section SectionFahadNo ratings yet

- GAs - BOUNDARY WALL-S77 BOUNDARY WALLSDocument1 pageGAs - BOUNDARY WALL-S77 BOUNDARY WALLSSamitha SoysaNo ratings yet

- Floor Layout PlanDocument1 pageFloor Layout PlanDereck W MarieNo ratings yet

- A A A A: Saudi Arabian Oil CompanyDocument1 pageA A A A: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Water TankDocument1 pageWater TankProject ManagerStructuresNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument9 pagesNotes:: Saudi Arabian Oil CompanykdpmansiNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- Sheet - 6 - Terrace Beam-22-08-22-A1-Terrace BeamDocument1 pageSheet - 6 - Terrace Beam-22-08-22-A1-Terrace BeamThrk TwrNo ratings yet

- RA611709002P0A1Document1 pageRA611709002P0A1Asad MaherNo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3TOM YEENo ratings yet

- Balustrade Type 1: Insaat Pasha PashaDocument1 pageBalustrade Type 1: Insaat Pasha PashaMirze QuluzadeNo ratings yet

- RFQ PebDocument28 pagesRFQ Pebxhzk7p97r8No ratings yet

- 17 1197 Column LayoutDocument1 page17 1197 Column LayoutKeise AliNo ratings yet

- Aaaa PDFDocument1 pageAaaa PDFAhgcjNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFVikramjit SinghNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFSumantrra ChattopadhyayNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFIraj Farooq100% (1)

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFMadhavNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFVikramjit Singh100% (1)

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFSyed Abdul Rawoof100% (2)

- Pipe - Culvert Design PDFDocument1 pagePipe - Culvert Design PDFDarshan M TNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFAhgcjNo ratings yet

- Terminal 2: E36 E38 E40 E33 E35 E37 E39 H34Document1 pageTerminal 2: E36 E38 E40 E33 E35 E37 E39 H34waz ahmedNo ratings yet

- 2Document1 page2Tarun SinghalNo ratings yet

- (R4) Details of Mother Slab PDFDocument1 page(R4) Details of Mother Slab PDFsurya prakashNo ratings yet

- Cater Catering-Layout1Document1 pageCater Catering-Layout1Fadi AlatrashNo ratings yet

- Sa-0224311 0001 0000Document1 pageSa-0224311 0001 0000Bilal ChohanNo ratings yet

- Sheet - 1 - Pile Cap-09-08-22-A1-Pile LayoutDocument1 pageSheet - 1 - Pile Cap-09-08-22-A1-Pile LayoutThrk TwrNo ratings yet

- Sheet 2 Column 23-08-22 A1 ColumnDocument1 pageSheet 2 Column 23-08-22 A1 ColumnThrk TwrNo ratings yet

- Bridge No.136Document1 pageBridge No.136RajeshNo ratings yet

- C-1 Mark C-2: Stair Detail 2 Stair Detail 3Document1 pageC-1 Mark C-2: Stair Detail 2 Stair Detail 3Ysabelle TagarumaNo ratings yet

- GC ST 09 RevisedDocument1 pageGC ST 09 Revisedmhazarath murariNo ratings yet

- Mis PDFDocument32 pagesMis PDFMohamed ELrasheedNo ratings yet

- S5-00A - WOOD WALL SCHEDULE AND DETAILS Rev.2 MarkupDocument1 pageS5-00A - WOOD WALL SCHEDULE AND DETAILS Rev.2 MarkupjhamiralexNo ratings yet

- 23lg0043 - Plans Set 2 of 5Document9 pages23lg0043 - Plans Set 2 of 5Sherwin NatinoNo ratings yet

- S-5 Schedule of Footings and ColumnsDocument1 pageS-5 Schedule of Footings and ColumnsEngr. Robnick PaduaNo ratings yet

- S-4 Third and Roof Framing PlanDocument1 pageS-4 Third and Roof Framing PlanEngr. Robnick PaduaNo ratings yet

- Second Floor Framing Plan: For PermitDocument1 pageSecond Floor Framing Plan: For PermitEngr. Robnick PaduaNo ratings yet

- S-2 Foundation PlanDocument1 pageS-2 Foundation PlanEngr. Robnick PaduaNo ratings yet

- IS 817 - Part1 - Training of Welders PDFDocument26 pagesIS 817 - Part1 - Training of Welders PDFDeepak RajanNo ratings yet

- Jis G 3505-2004Document17 pagesJis G 3505-2004wasatiah05No ratings yet

- MSDS ChlorineDocument8 pagesMSDS ChlorineZaman AzimiNo ratings yet

- 2 AnchorageDocument16 pages2 AnchorageAditi GuptaNo ratings yet

- Top 300 Companies of PakistanDocument8 pagesTop 300 Companies of PakistanadnanbwNo ratings yet

- Teijin-Aramid-Ballistics-Material-Handbook-English1 - Copiar PDFDocument11 pagesTeijin-Aramid-Ballistics-Material-Handbook-English1 - Copiar PDFBarbara SanNo ratings yet

- Textile Industries in India-1-1Document3 pagesTextile Industries in India-1-1S Noor TaufeeqNo ratings yet

- WaterWolf Data Sheet PDFDocument2 pagesWaterWolf Data Sheet PDFcarlosfariasfakeNo ratings yet

- Acids, Bases and Salt Preparations QPDocument5 pagesAcids, Bases and Salt Preparations QPdana hadadNo ratings yet

- BS 4479-9-1990Document11 pagesBS 4479-9-1990윤규섭No ratings yet

- Lubwama 2018Document13 pagesLubwama 2018Richard Solis ToledoNo ratings yet

- Plovak Supertec-DrinkDocument3 pagesPlovak Supertec-DrinkMite TodorovNo ratings yet

- Minor Project On Compressed Earth BlocksDocument7 pagesMinor Project On Compressed Earth BlocksRajendra Singh Panwar100% (1)

- ASTM C55 - 01aDocument3 pagesASTM C55 - 01aMarco Soto100% (3)

- Chapter 1 - Modeling The ConstitutionDocument50 pagesChapter 1 - Modeling The ConstitutionDaniel Vindex Kwabla Domeh100% (1)

- 7 Dry Sand MoldingDocument3 pages7 Dry Sand MoldingFahri RamadhanNo ratings yet

- Row Schott Technical Glasses View 2020-04-14Document80 pagesRow Schott Technical Glasses View 2020-04-14Oleg ChernovNo ratings yet

- CH1 - Cement - Part1Document22 pagesCH1 - Cement - Part1EilmohNo ratings yet

- DynaPrep MDSF Tooling Chart Rev A 04154Document2 pagesDynaPrep MDSF Tooling Chart Rev A 04154Andres NavarroNo ratings yet

- Mac NDT Catalog 2018 1Document20 pagesMac NDT Catalog 2018 1Amar MohammedNo ratings yet

- Prodinfo Gardacid-P-4414 Eng FinalDocument2 pagesProdinfo Gardacid-P-4414 Eng FinalChinawut KhaisilpNo ratings yet

- Engineered Wood13 PDFDocument96 pagesEngineered Wood13 PDFartika sembiringNo ratings yet

- Product Information Flyer: CIMSTAR® 10-700VLCDocument2 pagesProduct Information Flyer: CIMSTAR® 10-700VLCsobheysaidNo ratings yet

- Bbs Pot. Besi RS MTDocument8 pagesBbs Pot. Besi RS MTAmudNo ratings yet

- Mechanical Behavior of Multiwalled Carbon Nanotube Reinforced 7075 Aluminum Alloy Composites Prepared by Mechanical Milling and Hot ExtrusionDocument9 pagesMechanical Behavior of Multiwalled Carbon Nanotube Reinforced 7075 Aluminum Alloy Composites Prepared by Mechanical Milling and Hot ExtrusionAdalberto G MirandaNo ratings yet

- Mobil Cross RefDocument2 pagesMobil Cross RefpaniyaNo ratings yet

- Characterization of The Morphological, Physical, and Mechanical PropertiesDocument6 pagesCharacterization of The Morphological, Physical, and Mechanical Propertieskuhan moganNo ratings yet

- Interline 850 PDFDocument4 pagesInterline 850 PDFaqeelNo ratings yet

- Ufgs 03 42 13.00 10Document20 pagesUfgs 03 42 13.00 10jackcan501No ratings yet

- Section 4 - Chip SealsDocument18 pagesSection 4 - Chip SealsFranklinNo ratings yet