Professional Documents

Culture Documents

User Manual Bosch GSB 20-2 RET Professional (English - 89 Pages) T

Uploaded by

mikeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User Manual Bosch GSB 20-2 RET Professional (English - 89 Pages) T

Uploaded by

mikeCopyright:

Available Formats

OBJ_BUCH-129-002.

book Page 11 Tuesday, October 23, 2007 2:57 PM

English | 11

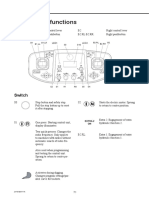

Mounting the Drill Chuck (see figure F) Gear Selection, Mechanical

The keyless chuck is mounted in reverse order. f The gear selector 10 can be actuated at

f Remove the steel pin from the drill hole on standstill or when the machine is running.

the spindle neck after mounting is complet- However, this should not be done while op-

ed. erating at full load or maximum speed.

The drill chuck must be tightened with a Two speed ranges can be preselected with the

tightening torque of approx. 35–40 Nm. gear selection lever 10.

Gear I:

Low speed range; for working with

large drilling diameter or for driving

Operation in screws.

Gear II:

Starting Operation High speed range; for working with

f Observe correct mains voltage! The voltage small drilling diameter.

of the power source must agree with the

voltage specified on the type plate of the If the gear selection lever 10 cannot be fully en-

power tool. gaged, lightly rotate the drill bit by twisting the

Reversing the Rotational Direction drill chuck.

(see figures G–H) (GSB 20-2 RE/

Switching On and Off

GSB 20-2 RCE/GSB 20-2 RET)

To start the power tool, press the On/Off switch

f Actuate the rotational direction switch 5

7 and keep it pressed.

only when the power tool is at a standstill.

To lock the pressed On/Off switch 7, press the

The rotational direction switch 5 is used to re-

lock-on button 9.

verse the rotational direction of the machine.

However, this is not possible with the On/Off To switch off the power tool, release the On/Off

switch 7 actuated. switch 7 or when it is locked with the lock-on but-

ton 9, briefly press the On/Off switch 7 and then

Right rotation: For drilling and driving in screws, release it.

push the rotational direction switch 5 downward

on the left side and at the same time upward on Overload Clutch

the right side. To limit dangerous reaction torque,

Left rotation: For loosening and unscrewing the machine is equipped with a safe-

screws and nuts, push the rotational direction ty clutch (anti-rotation).

switch 5 upward on the left side and at the same

time downward on the right side.

Setting the Operating Mode

Drilling and Screwdriving f If the tool insert becomes caught or jammed,

Set the selector switch 2 to the “Drill- the drive to the drill spindle is interrupted.

ing” symbol. Because of the forces that occur, always

Hammer Drilling hold the power tool firmly with both hands

and provide for a secure stance.

Set the selector switch 2 to the “Ham-

mer drilling” symbol. f If the power tool jams, switch the machine

off and loosen the tool insert. When switch-

The selector switch 2 engages noticeably and can ing the power tool on with the drilling tool

also be actuated with the machine running. jammed, high reaction torques can occur.

Bosch Power Tools 1 609 929 M40 | (23.10.07)

You might also like

- Manual Cortadora de DiscoDocument14 pagesManual Cortadora de DiscoMartha JaquelinNo ratings yet

- Manual Operation XQ114-6BDocument33 pagesManual Operation XQ114-6BrogerNo ratings yet

- Model LM410 Manual PDFDocument31 pagesModel LM410 Manual PDFJahir GolbemNo ratings yet

- Series 70 Electric Actuators: Quick Start GuideDocument2 pagesSeries 70 Electric Actuators: Quick Start GuideTrio Adi PamungkasNo ratings yet

- Lift Chart: KR-20H-L KATO Rough Terrain Mobile CraneDocument7 pagesLift Chart: KR-20H-L KATO Rough Terrain Mobile CraneChristopher Ong100% (1)

- MAKITA - Llave Impacto 6905H - ManualDocument64 pagesMAKITA - Llave Impacto 6905H - Manualmarco antonio talavera salazarNo ratings yet

- Telehandler 2Document50 pagesTelehandler 2GERSON DAVID RODRIGUEZ TORRESNo ratings yet

- Instruction Book A N D Parts List: Reid Brothers Company, IncDocument22 pagesInstruction Book A N D Parts List: Reid Brothers Company, IncElionex ValdezNo ratings yet

- MV Switchgear Operation Procedure and Interlock Condition: Unit 4Document58 pagesMV Switchgear Operation Procedure and Interlock Condition: Unit 4sherifmoussaNo ratings yet

- K Ninja H2 Owner's & Service Manuals 05Document21 pagesK Ninja H2 Owner's & Service Manuals 05njkawasakiNo ratings yet

- HR5201CDocument60 pagesHR5201Cjokin mendiolaNo ratings yet

- Er Drilling Machine Operating Procedure Er 022Document4 pagesEr Drilling Machine Operating Procedure Er 022Ak PallNo ratings yet

- Yt 1000R 20081Document2 pagesYt 1000R 20081Ion CimirinschiNo ratings yet

- SD Operation SD Operation: SEP. 2012 Ce, Ap/E, Am Product Support TeamDocument21 pagesSD Operation SD Operation: SEP. 2012 Ce, Ap/E, Am Product Support Teamcarlos andres salazar sanchezNo ratings yet

- Instruction Manual For Multi Head Drilling Machine LZD12-17Document22 pagesInstruction Manual For Multi Head Drilling Machine LZD12-17tommy.noelNo ratings yet

- HP2070 HP2070F HP2071 HP2071FDocument40 pagesHP2070 HP2070F HP2071 HP2071FAnonymous lSEnEklZ7No ratings yet

- Targa Electric Projection Screen by Draper: Installation/Operating InstructionsDocument2 pagesTarga Electric Projection Screen by Draper: Installation/Operating InstructionsLuisRaulJaquezPeñaNo ratings yet

- 5.5 Derricking Mechanism: Stop in NeutralDocument2 pages5.5 Derricking Mechanism: Stop in NeutralRwan MarymNo ratings yet

- Panasonic Ey7440 Manual de Usuario Páginas 7 9Document3 pagesPanasonic Ey7440 Manual de Usuario Páginas 7 9Mr. Gonza M.No ratings yet

- 5.5 Derricking Mechanism: Stop in NeutralDocument2 pages5.5 Derricking Mechanism: Stop in NeutralRwan MarymNo ratings yet

- Operation Manual - YX51 Decking - FINAL PDFDocument16 pagesOperation Manual - YX51 Decking - FINAL PDFAl Haba Ahmad Zaki Abdul HamidNo ratings yet

- DynaQuip Comoso de Manual LowresDocument12 pagesDynaQuip Comoso de Manual Lowresluis angelNo ratings yet

- Makita HP1631K Impact DrillDocument36 pagesMakita HP1631K Impact DrillAnonymous vQewJPfVXaNo ratings yet

- Operating Instruction Underbody ClampDocument2 pagesOperating Instruction Underbody ClampBe HappyNo ratings yet

- Control Unit Functions GBDocument4 pagesControl Unit Functions GBKevin Elias MujikaNo ratings yet

- Demag Eindschakelaar Dgs - 3en4Document4 pagesDemag Eindschakelaar Dgs - 3en4bsb.edhoeNo ratings yet

- ZF Double H Shift Pattern PDFDocument4 pagesZF Double H Shift Pattern PDFAnonymous 2JNPJ2aXNo ratings yet

- PS2 Positioner Calibration ProcedureDocument6 pagesPS2 Positioner Calibration ProcedureSakthi Sekar Cbi100% (1)

- Benchmark MC-12 - ManualDocument6 pagesBenchmark MC-12 - ManualWatch ShamsNo ratings yet

- Manual Singer 518 538 TextDocument58 pagesManual Singer 518 538 TextGaby Zarabanda100% (1)

- Owner'S Manual Hướng Dẫn Sử Dụng: Air Conditioner (Split Type)Document5 pagesOwner'S Manual Hướng Dẫn Sử Dụng: Air Conditioner (Split Type)Tai NguyenNo ratings yet

- Oi psm630 en in PDFDocument8 pagesOi psm630 en in PDFCosty45No ratings yet

- Prensa de 15 Ton PGC1500Document16 pagesPrensa de 15 Ton PGC1500abdielNo ratings yet

- Royal Sovereign RSC 6500h 65 Professional Wide Format Heat Assist Laminator ManualDocument15 pagesRoyal Sovereign RSC 6500h 65 Professional Wide Format Heat Assist Laminator ManualchristiandabbousNo ratings yet

- Orange PDI GN128-1201 - EDocument2 pagesOrange PDI GN128-1201 - ENazrul IslamNo ratings yet

- Electrovane FiltreDocument39 pagesElectrovane FiltrepvflorinNo ratings yet

- 55 Lbs Trolling Motor: MODEL: 9000200Document15 pages55 Lbs Trolling Motor: MODEL: 9000200Richárd SchmidtNo ratings yet

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocument12 pagesInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146No ratings yet

- c9372 - Manual RECTIFICADORA DISCOS Y TAMBORES PDFDocument28 pagesc9372 - Manual RECTIFICADORA DISCOS Y TAMBORES PDFmarcelo ustarezNo ratings yet

- W13 GR EX 4 OpCraningDocument31 pagesW13 GR EX 4 OpCraningbayu septianNo ratings yet

- PM 1236 v4 1 2017 Indd PDFDocument45 pagesPM 1236 v4 1 2017 Indd PDFwiiiNo ratings yet

- GN128-Piston 0Document3 pagesGN128-Piston 0Nazrul IslamNo ratings yet

- 101NDXFGLUUU1Document2 pages101NDXFGLUUU1John OigbochieNo ratings yet

- Stonel Limit Switch InstructionsDocument2 pagesStonel Limit Switch InstructionsgenibraNo ratings yet

- 4WNA & 4WFA Winch Operations ManualDocument14 pages4WNA & 4WFA Winch Operations Manualsukri arjunaNo ratings yet

- 501 Positioner OperatDocument1 page501 Positioner Operatwifino2470No ratings yet

- Porton DKSDocument52 pagesPorton DKSHugo GarciaNo ratings yet

- Tabla de Conversión de TorquesDocument2 pagesTabla de Conversión de TorquesLuis TorresNo ratings yet

- HM0871CDocument40 pagesHM0871CMarjoe BianagaNo ratings yet

- Dixon ZTR 428-429 Technical DataDocument10 pagesDixon ZTR 428-429 Technical DatatecsbrainNo ratings yet

- Section E Section E: HydraulicsDocument1 pageSection E Section E: HydraulicsNikNo ratings yet

- For Safe Operation: Description of Error DetectedDocument1 pageFor Safe Operation: Description of Error DetectedAmjad HossenNo ratings yet

- Robart Electric Retract Series Instruction Manual: Thank YouDocument2 pagesRobart Electric Retract Series Instruction Manual: Thank YourobNo ratings yet

- curvadora hidráulico 液压打拱机说明书Document6 pagescurvadora hidráulico 液压打拱机说明书Alfredo BerrocalNo ratings yet

- Instructions For Operating Bale Bug Feed Out Wagon With Elsema Wireless SystemDocument2 pagesInstructions For Operating Bale Bug Feed Out Wagon With Elsema Wireless SystemJack NorhyNo ratings yet

- Máy SliceDocument15 pagesMáy SliceHoang NguyenNo ratings yet

- Manual Operation Maintenance Vibration SwitchDocument20 pagesManual Operation Maintenance Vibration SwitchPitipong SunkhongNo ratings yet

- Rev7 WigLBugsDFU J3yuie2 en 1501 PHPDWFN en 1506Document2 pagesRev7 WigLBugsDFU J3yuie2 en 1501 PHPDWFN en 1506pucherosNo ratings yet

- FORTRUST 6110D and 6120D User ManualDocument27 pagesFORTRUST 6110D and 6120D User Manualjean sanchezNo ratings yet

- Product A1089 FDocument1 pageProduct A1089 FmikeNo ratings yet

- DK 3.0mm HDPE Geomembrane Mill CertificateDocument2 pagesDK 3.0mm HDPE Geomembrane Mill CertificatemikeNo ratings yet

- Grinding WheelsDocument1 pageGrinding WheelsmikeNo ratings yet

- Bond Breaker Tape-Nz SDSDocument6 pagesBond Breaker Tape-Nz SDSmikeNo ratings yet

- HDPE All ThicnkenssDocument2 pagesHDPE All ThicnkenssmikeNo ratings yet

- EP11750497NWB1Document43 pagesEP11750497NWB1mikeNo ratings yet

- Section 90: Pedal and Pedal Switch AdjustmentsDocument24 pagesSection 90: Pedal and Pedal Switch Adjustmentsjeffrey pelletierNo ratings yet

- FACTS Technologies SVCDocument9 pagesFACTS Technologies SVCSalah SouidNo ratings yet

- Cummins: Fault Code: 245 PID: S033 SPN: 647 FMI: 4Document6 pagesCummins: Fault Code: 245 PID: S033 SPN: 647 FMI: 4Enrrique LaraNo ratings yet

- AC Voltage Single Function Transducer TAV-311DG/TAV-321DG: Data SheetDocument7 pagesAC Voltage Single Function Transducer TAV-311DG/TAV-321DG: Data Sheetflash_90697638No ratings yet

- DMW 3305 30116 1 3305 602 - Is00Document1 pageDMW 3305 30116 1 3305 602 - Is00nuramirah2023No ratings yet

- Ariens Model 921013 Deluxe 30 Snow Blower Operator ManualDocument46 pagesAriens Model 921013 Deluxe 30 Snow Blower Operator ManualTim MckennaNo ratings yet

- TM PDFDocument183 pagesTM PDFalexNo ratings yet

- MEC 410 Chapter 7 Spring 2017Document67 pagesMEC 410 Chapter 7 Spring 2017Frederick KooNo ratings yet

- A100 DIN BrochureDocument2 pagesA100 DIN BrochureMunteanu LucianNo ratings yet

- Loop Breaker ManualDocument62 pagesLoop Breaker ManualmchrupaloNo ratings yet

- Manual D12RDocument179 pagesManual D12RHennis Alfonzo100% (1)

- HubbellDocument68 pagesHubbellReginald D. De GuzmanNo ratings yet

- Design and Fabrication of An AUTOMATIC BLACK BOARD CleanerDocument21 pagesDesign and Fabrication of An AUTOMATIC BLACK BOARD CleanerNAGARAJNo ratings yet

- Control Cabinet Industrial PC C6640, C6650: Installation and Operating Instructions ForDocument30 pagesControl Cabinet Industrial PC C6640, C6650: Installation and Operating Instructions ForjoeNo ratings yet

- Thales Fiches EZ 2 HD Range - Uk - 0Document2 pagesThales Fiches EZ 2 HD Range - Uk - 0ANo ratings yet

- AUTOMATIC RAILWAY GATE CONTROLLER-reportDocument57 pagesAUTOMATIC RAILWAY GATE CONTROLLER-reportAnarsinh Solanki75% (8)

- Kit Installation Instruction: Siemens Industry, IncDocument12 pagesKit Installation Instruction: Siemens Industry, IncKiaraNo ratings yet

- The Case of Failed TransformerDocument84 pagesThe Case of Failed Transformerlbk50100% (1)

- ATX Power Supply Pinout TablesDocument4 pagesATX Power Supply Pinout TablesElectrical EEENo ratings yet

- Inverter - Solaredge - Installation-Manual - SE3800A-US InstallationDocument7 pagesInverter - Solaredge - Installation-Manual - SE3800A-US InstallationAl0% (1)

- Catalogue SDocument8 pagesCatalogue SSHINOS 3SNo ratings yet

- Partlist GX8250-GX6750-AX475-SX4000 PDFDocument28 pagesPartlist GX8250-GX6750-AX475-SX4000 PDFrina ordonoNo ratings yet

- Quick Manual Solar 260 v1.0Document6 pagesQuick Manual Solar 260 v1.0andrejcerneNo ratings yet

- Samsung Ue32f4000 Ue32f4800 Ue32f5000 Ue32f5070 Ue39f5070 Ue42f5070s Ue46f5070s Ue50f5070ss Chassis U85b U85c PDFDocument80 pagesSamsung Ue32f4000 Ue32f4800 Ue32f5000 Ue32f5070 Ue39f5070 Ue42f5070s Ue46f5070s Ue50f5070ss Chassis U85b U85c PDFGoohee Rk Teesh Kumar0% (2)

- Projeto Antena Direcional PXDocument4 pagesProjeto Antena Direcional PXalissonalexNo ratings yet

- Bosch BODAS Electronics For Mobile HydraulicsDocument28 pagesBosch BODAS Electronics For Mobile HydraulicsJanne PuhakkaNo ratings yet

- 741-0006 Model 2010 Immunoassay System Connected To Clas1 For JapanDocument46 pages741-0006 Model 2010 Immunoassay System Connected To Clas1 For JapanDaniel Martinez CollazoNo ratings yet

- Build Guide - Ender 5 Exoslide Xy Motion KitDocument6 pagesBuild Guide - Ender 5 Exoslide Xy Motion KitGreg RobertsonNo ratings yet

- Novasina Produkt KatalogDocument34 pagesNovasina Produkt Katalogbadmike71No ratings yet