Professional Documents

Culture Documents

Design of Monorail 2

Design of Monorail 2

Uploaded by

CyrilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Monorail 2

Design of Monorail 2

Uploaded by

CyrilCopyright:

Available Formats

Design of Monorail Systems

Tomas H Orihuela Jr, PE

Local Bending of Bottom Flange

The local bending of the bottom flange of the beam or girder due to the wheel load

is an often overlooked design check. S-beams are the most common shape used for

monorails; however, I-beams are sometimes used. Since the flange thickness of an

I-beam is thinner than an equivalent S-beam, the local bending of the bottom flange

of the I-beam could control the design of the monorail beam.

The wheel load is determined using basic static analysis, where in many cases it is

one-fourth (1/4) the lift load with load factor applied. The wheel load is generally

considered to be a concentrated load applied at the center of the wheel contact with

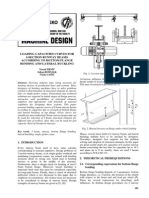

the flange (see Figure 1).

Figure 1: Wheel Contact on Bottom Flange

The CMAA code provides guidance for checking the wheel load on both an S-beam

and I-beam. In addition to checking the stress caused by one wheel load, the stress

between the wheels on one side of the beam should be checked. In many cases,

the wheel spacing longitudinally is short so the stress from the two wheels may be

high between the two contact points. Roark’s Formula for Stress and Strain is a

good reference for determining this stress.9

Fatigue Design

Fatigue problems occur in monorails due to the repeated loading and unloading of

the system. A Class A monorail will likely not have fatigue problems due to

infrequent usage. On the other hand, a Class D monorail design could possibly be

governed by fatigue since its usage is very frequent.

www.pdhengineer.com Page 12 of 20

You might also like

- Frame Design GuidelinesDocument30 pagesFrame Design GuidelinesAnbazhagan Deenadhayalan91% (23)

- Advanced Seat Suspension Control System Design for Heavy Duty VehiclesFrom EverandAdvanced Seat Suspension Control System Design for Heavy Duty VehiclesNo ratings yet

- Chassis Frame Torsional Stiffness Analysis PDFDocument4 pagesChassis Frame Torsional Stiffness Analysis PDFYãbeçk MâmNo ratings yet

- Design of Formula SAE Suspension ComponentsDocument13 pagesDesign of Formula SAE Suspension ComponentsYasser Rohom0% (1)

- Rail WheelDocument8 pagesRail WheelAbdulhmeed MutalatNo ratings yet

- Engineering Failure Analysis: Li-Hui Zhao, Song-Lin Zheng, Jin-Zhi FengDocument10 pagesEngineering Failure Analysis: Li-Hui Zhao, Song-Lin Zheng, Jin-Zhi FengShivNo ratings yet

- Rod End Stress CalculationsDocument3 pagesRod End Stress CalculationsRahul JainNo ratings yet

- Ijfatigue S 07 00263Document40 pagesIjfatigue S 07 00263ekremNo ratings yet

- Vehicle Chassis FrameDocument57 pagesVehicle Chassis FrameRajanikantJadhav100% (2)

- Journal PDFDocument16 pagesJournal PDFankit5088No ratings yet

- A Literature Review On Design of Overhead Monorail CraneDocument3 pagesA Literature Review On Design of Overhead Monorail CraneSuneesh PNo ratings yet

- Fsae Design Suspension Components PDFDocument13 pagesFsae Design Suspension Components PDFKingsley AyascaNo ratings yet

- Literature ReviewDocument12 pagesLiterature Reviewsimonebogetti.sbNo ratings yet

- Dissertation IIDocument54 pagesDissertation IIRaj MandloiNo ratings yet

- Vehicle Dynamics NotesDocument116 pagesVehicle Dynamics NotesJagadesh AbbuNo ratings yet

- Bridge Chapt. 4Document19 pagesBridge Chapt. 4Shita AlemieNo ratings yet

- 181-186 For Web PDFDocument6 pages181-186 For Web PDFdiego.peinado8856100% (1)

- Chassis DesignDocument35 pagesChassis DesignArjun H Nambiar100% (1)

- 05-Chapter 11-BearingsDocument30 pages05-Chapter 11-BearingsOk SokNo ratings yet

- Design Consideration of Ladder Chassis Frame For Hyundai TruckDocument12 pagesDesign Consideration of Ladder Chassis Frame For Hyundai TruckWatt Pauk LayNo ratings yet

- Milovan Ov IDocument14 pagesMilovan Ov ISaturnus PlutoNo ratings yet

- 15.rolling Bearings in Bulk ConveyorsDocument17 pages15.rolling Bearings in Bulk ConveyorsPrashant DinkarNo ratings yet

- Propulsion Shafting AlignmentDocument26 pagesPropulsion Shafting AlignmentAbolfath AskariankhoobNo ratings yet

- RVS 15.45 Englisch KomplettDocument44 pagesRVS 15.45 Englisch KomplettSlavisa PanticNo ratings yet

- The Influence of Wheel Profile On Safety Index: G. F. M. Dos Santos L. A. S. Lopes E. J. Kina John TunnaDocument6 pagesThe Influence of Wheel Profile On Safety Index: G. F. M. Dos Santos L. A. S. Lopes E. J. Kina John TunnaSivaneswaran SabaratnamNo ratings yet

- Ada 219397Document34 pagesAda 219397jai2009No ratings yet

- Dump Truck SimulationDocument26 pagesDump Truck SimulationIdwandi FedoriNo ratings yet

- Chapter 4 BearingsDocument50 pagesChapter 4 BearingsewfsdNo ratings yet

- Traffic Loading Analysis For Highway PavementsDocument15 pagesTraffic Loading Analysis For Highway PavementsBernadette Abanto100% (1)

- TractionDocument5 pagesTractionПавле КрстевскиNo ratings yet

- Simulation and Static Analysis of An Off-Road Vehicle Roll CageDocument8 pagesSimulation and Static Analysis of An Off-Road Vehicle Roll CageIJMERNo ratings yet

- Static Analysis On A Vehicle Tie Rod To PDFDocument9 pagesStatic Analysis On A Vehicle Tie Rod To PDFRyadh OtmaneTelbaNo ratings yet

- Laminated Elastomeric Rubber Bearings For BridgesDocument15 pagesLaminated Elastomeric Rubber Bearings For BridgesPatrick AugustinNo ratings yet

- 1 5024108Document7 pages1 5024108GamerNo ratings yet

- Bearing Selection CriteriaDocument6 pagesBearing Selection CriteriaarunjacobnNo ratings yet

- Axle ShaftsDocument14 pagesAxle ShaftsAnonymous QiMB2lBCJLNo ratings yet

- A Study of Modeling and Finite Element Analysis of Automotive Vehicle Wheel Rim Assembly For The Deformation and Various Stress DistributionDocument6 pagesA Study of Modeling and Finite Element Analysis of Automotive Vehicle Wheel Rim Assembly For The Deformation and Various Stress DistributionHakim SakibNo ratings yet

- ARB DesignDocument4 pagesARB Designtamilselvan33No ratings yet

- 3-A.k. Snghal Rajeev VermaDocument16 pages3-A.k. Snghal Rajeev VermajonnypremNo ratings yet

- Crane Beam DesignDocument23 pagesCrane Beam DesignVignesh RamalingamNo ratings yet

- Camber Crane PDFDocument3 pagesCamber Crane PDFErc Nunez VNo ratings yet

- Automotive SuspensionsDocument16 pagesAutomotive SuspensionsRohit BishtNo ratings yet

- Design of Plate GirdersDocument109 pagesDesign of Plate GirdersTASNIA SIRAJ OISHBYNo ratings yet

- Plate Girder DesignDocument109 pagesPlate Girder Designhasib100% (3)

- Design of Plate GirderDocument109 pagesDesign of Plate GirderFAR_A_DAYNo ratings yet

- Strut Technical DataDocument15 pagesStrut Technical DataJOFRANo ratings yet

- Trusses and Lattice GirdersDocument17 pagesTrusses and Lattice GirdersMisgun Samuel50% (2)

- Pub77 Bulkcarriermodifications OpDocument43 pagesPub77 Bulkcarriermodifications OpJACKNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignFrom EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignRating: 3.5 out of 5 stars3.5/5 (3)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- The Dual Wheel Journey Motorcycle Terms Dictionary and Phrasebook: DWJ Dictionary, #2From EverandThe Dual Wheel Journey Motorcycle Terms Dictionary and Phrasebook: DWJ Dictionary, #2No ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Aisc 1Document2 pagesAisc 1CyrilNo ratings yet

- Aisc 2Document5 pagesAisc 2CyrilNo ratings yet

- AASHTO AluminumDocument5 pagesAASHTO AluminumCyrilNo ratings yet

- AASHTO BoltsDocument5 pagesAASHTO BoltsCyrilNo ratings yet

- ACE BoltsDocument5 pagesACE BoltsCyrilNo ratings yet

- AASHTO Parts Wind MapDocument6 pagesAASHTO Parts Wind MapCyrilNo ratings yet

- Aashto Excerpt Specification CH7Document5 pagesAashto Excerpt Specification CH7CyrilNo ratings yet

- Aashto Part Site ClassificationDocument5 pagesAashto Part Site ClassificationCyrilNo ratings yet

- MakseLife Ideal WeekDocument1 pageMakseLife Ideal WeekCyrilNo ratings yet

- Old Grove Online BrochureDocument7 pagesOld Grove Online BrochureCyrilNo ratings yet