Professional Documents

Culture Documents

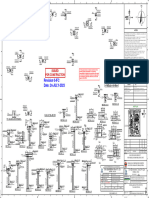

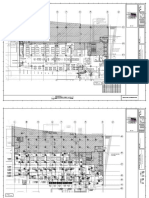

S230 - Column & Base Plate Plan - R2

Uploaded by

Reza MohseniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S230 - Column & Base Plate Plan - R2

Uploaded by

Reza MohseniCopyright:

Available Formats

1 2 3 4 5 6 7 8

NOTE:

1 1.1 2 3 4 5 6 7 8 9 10 11 12 13 13.9 14 15 1. FOR GENERAL NOTES, SEE DWG S011.

2. FOR DOOR JAMBS AND DOOR POSTS, SEE GIRT ELEVATIONS, SEE DWG S340

3. PROVIDE 10 THK FULL DEPTH STIFF PLATES SHOP FILLET WELD EA SIDE

OF COL WEB @ 3000 o.c. OR LESS SPACING. STIFF PLATE SHALL HAVE 10

5280 14240 6760 14240 6760 14240 6760 14240 6760 14240 6760 14240 5880 1000

DEGREE SLOPE AWAY FROM WEB, OR HORIZONTAL WHERE NECESSARY.

600 STIFF PLATE MAY HAVE UP TO 50 DIA HOLES SPACED EQUALLY @ 150 o.c.

FOR PIPES AND/OR CONDUITS. SC1 MAY MAX (2)-HOLES EA SIDE SC2 MAY

1

__________________________ HAVE MAX (4)-HOLES EA SIDE.

S320 4. PROVIDE 10 THK CAP PLATE AT TOP OF ALL COLUMNS, POSTS TYP. CAP

PLATE SHALL BE SLOPED TO MATCH DECK SLOPE. CAP PLATE SHALL BE

SHOP FILLET WELD TO COL FLANGE AND WEB, TYP.

600

E STEEL COLUMN SCHEDULE

S330 S340

MARK DESCRIPTION REMARKS

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

1

650

S

1

1

B B.1

1 SC1

SC2

W690x152

W360x162

1200

SC3 HSS254x203x9.5

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

2

2

B

B

B.2

4520

4520

BP C 2

S

2

SC P1

1

B

8630

23500

BP C 2

S

2

S331

3

7300

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

S

S

2

2

D.9

1200

E 3

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

1

1

B

B

S330

S340 S331

1

D

56000

9000

S331

280

S331

3 2 5

BP C3 BP C3

S

3

515 1930

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

BP C 1

3A

S

S

1

1

S

S

1

1

F

BP C 1

1200

4

S

1

F.1

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

SC P2

2

2

B

B

S331

2

__________________________

2

__________________________

S320 S320

S340

4

10225

BP C 2

S

2

23500

10225

BP C 1

S

1

4515

H.8

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

BP C 2

S

S

2

2

1200

C J H.9

650

2

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

SC P1

1

1

B

B

1

2

B

S330 S340

1

__________________________

S320

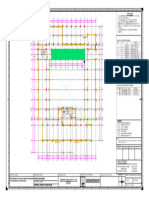

COLUMN & BASE PLATE PLAN

1 : 200

2

GL GL

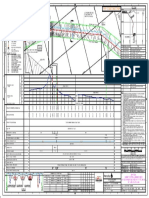

400 400

220

80 x 80 x19 THK 200 200 200 200 400

PLATE W/ HOLE

DIA = ANCHOR +

B 125 125 125 125 110 110

2mm TYP FOR 150 150 4-AR-2 ADHESIVE

ALL ANCHORS 80 x 80 x19 THK 50 TYP ANCHORS

PL 40mm PLATE W/ HOLE IN STANDARD HOLES

EA WAY

DIA = ANCHOR +

8-AR-1 2mm TYP FOR PL 40mm PL 25mm PL 25mm

25 PROJECTION MIN

IN STANDARD HOLES ALL ANCHORS

ABOVE NUT

375

TYP UNO

180

GUSSET PL AT BRACED 6-AR-2 ADHESIVE

4-AR-1 DIA

FRAME LOCATION, ANCHORS

230

225

IN STANDARD HOLES COLUMN

DESIGNED BY SPECIALTY IN STANDARD HOLES

150

SIZE, TYPE, AND

100

CONNECTION DESIGNER,

90

ORIENTATION VARIES

TYP

GL GL

750

450

400

460

THREADED

100

90

BASE PLATE

150

DOUBLE NUT

ALL

TYPE VARIES

225

230

AND WASHER

10 8 8 TOC PEDESTAL

180

375

10 SEE DWG S211 TO S212

40 GROUT

ANCHOR ROD SCHEDULE

HSS 254x203 HSS 254x203

MARK DIA EMBED PROJ WASHER GRADE

EMBED

AR-1 32 850 170 OR 12x150x150 ASTM F1554

GREATER GRADE 105 ANCHOR RODS

NUT EACH SIDE

BP1 BP2 BP3 BP3A AR-2 20 250 170 OR - ASTM A193 B7

GREATER PLATE

50

ADDITIONAL NOTES:

.

NOTE: TACK WELD

1. CENTERLINE OF BASE PLATE SHALL BE CONCENTRIC TO CENTRELINE OF COLUMN AND GUSSET PL, TYP AR-2 TO BE FULLY THREADED ANCHOR ROD 3 PLACES

2. CENTERLINE OF COLUMNS SHALL BE CONCENTRIC TO CENTERLINE OF BEAMS AND CRANE RAILS, TYP EA SIDE

3. SEE TOLERANCE REQUIREMENTS IN DWG S011

A 1 BASE PLATES DETAILS 2 ANCHOR ROD DETAIL 3 COLUMN BASE PLATE DETAIL

- 1 : 10 - 1 : 10 - 1 : 10

TRUE

NORTH

Notes 7200 Permit/Seal Consultant Client/Project Logo Client/Project Agreement Number: Title

ELECTRICAL

1. BUILDING HAS BEEN DESIGNED FOR WIND LOADS SUBSTATION EXISTING

7500

Teck Coal Limited CM00006 8305 HEAVY TRUCK SHOP

PER "BRITISH COLUMBIA BUILDING CODE" TIRE PAD

DEFINITION OF AN "ENCLOSED" BUILDING. THIS FACILITY FUELING FACILITY

REQUIRES THAT ALL EXTERIOR DOORS REMAIN 7400

20

CLOSED EXCEPT DURING LOADING/UNLOADING. SANITARY

COLUMN & BASE PLATE PLAN

73

ALL EXTERIOR DOORS/OPENINGS SHALL REMAIN TREATMENT SYSTEM

CLOSED IN THE EVENT OF A MINING BLAST AND/OR

MINE MAINTENANCE

Stantec Consulting Ltd. Teck EVO AMC

HIGH WIND EVENT (WINDS EXCEEDING OR WATER HEAVY VEHICLE 1100-111 Dunsmuir Street

5 FACILITY

<Pick location in Project Information>

EXPECTED TO EXCEED 80 KMPH [50 MPH] SPEEDS). 8317 Vancouver, BC V6B 6A3 Contractor Partner

TREATMENT & 831 TRUCK SHOP

STORAGE LIGHT VEHICLE Tel: (604) 696-8000

8310

TRUCK WASH BUILDING 8305 WASH BUILDING 2 IFC-SI 0005 CH TVG 2023-05-05 ISSUED FOR CONSTRUCTION - SI 0005 CH TVG 2023-05-05

Stantec Project No. Scale

TRUE

8340 8320 1 IFC CH/GM TVG 2023-02-09 ISSUED FOR CONSTRUCTION CH/GM TVG 2023-02-09

NORTH Sparwood, BC, CANADA V0B 2G1 115622088 As indicated

5/5/2023 4:28:57 PM

0 IFC - STEEL CH/GM TVG 2022-11-16 STEEL PACKAGE - ISSUED FOR CONSTRUCTION CH/GM TVG 2022-11-16 Copyright Reserved

WAREHOUSE B IFR - 60% CH/GM TVG 2022-10-04 60% DESIGN - ISSUED FOR REVIEW CH/GM TVG 2022-10-04

The Copyrights to all designs and drawings are the property of Stantec. Reproduction

Drawing No. Revision No. Teck File No.

8370

0 REPRODUCTION SCALE 50mm BULK LUBE A IFQ-30% CH/GM TVG 2022-08-26 30% DESIGN - ISSUED FOR QUOTATION CH/GM TVG 2022-08-26 or use for any purpose other than that authorized by Stantec is forbidden. File Name: ISSUED FOR CONSTRUCTION - SI GM RX TVG 2023-04-21

ADMINISTRATION 0005

SHOWN STORAGE BUILDING Revision By Appd YYYY-MM-DD Issued By Appd YYYY-MM-DD

The Contractor shall verify and be responsible for all dimensions. DO NOT scale the

drawing - any errors or omissions shall be reported to Stantec without delay. Dwn. Dsgn. Chkd. YYYY-MM-DD S230 2 EVO008-8305-15-DWG-61230

ORIGINAL SHEET - ISO A0

You might also like

- KENR5951Document2 pagesKENR5951vova0lopuxNo ratings yet

- Demin Water SystemDocument1 pageDemin Water Systemmohamed abourayaNo ratings yet

- Issue For Relay Panel Construction PDFDocument119 pagesIssue For Relay Panel Construction PDFallanng30No ratings yet

- Nawcpf Msbi Ca01 950 HV DRW 59249 - 003 - Acoserv Nac Cob Hvac General Arrangement1Document2 pagesNawcpf Msbi Ca01 950 HV DRW 59249 - 003 - Acoserv Nac Cob Hvac General Arrangement1Mlayeh MohamedNo ratings yet

- Pump Room & Hot and Cold Water Sump Codination Dwg.01.08.23-A1Document1 pagePump Room & Hot and Cold Water Sump Codination Dwg.01.08.23-A1Tanzil HassanNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 07Document1 pageEpcc05 MDR 421 STR DWG 000 0072 07RANJEET PRATAP SINGHNo ratings yet

- Road From Palugaswewa To HabaranaDocument2 pagesRoad From Palugaswewa To HabaranaRenga Ramanujan CNo ratings yet

- Dicom Cmpsa 2022 049 PL E05 - 0Document1 pageDicom Cmpsa 2022 049 PL E05 - 0NYLER RODRÍGUEZ BARRUETONo ratings yet

- 25635-220-M6-0210-00001-R2 Chancadora 1Document1 page25635-220-M6-0210-00001-R2 Chancadora 1Victor Guzman PretellNo ratings yet

- Flauta I.encDocument1 pageFlauta I.encMaranatha CentroNo ratings yet

- General Piping and Instrumentation NotesDocument25 pagesGeneral Piping and Instrumentation NotesItz GyyyNo ratings yet

- Sec C Ió N: Vicepresidenciadeproyectos Minachuquicamatasubterránea IngenieríadedetalleDocument1 pageSec C Ió N: Vicepresidenciadeproyectos Minachuquicamatasubterránea IngenieríadedetalleCR ConductorNo ratings yet

- IQ360-000-M6-SG-00003 Rev03Document1 pageIQ360-000-M6-SG-00003 Rev03mustafa1989ocNo ratings yet

- HP 840 G1 - Mec1322Document1 pageHP 840 G1 - Mec1322Ramdas KambleNo ratings yet

- Road "A": PC PCDocument1 pageRoad "A": PC PCRachane NuanyaiNo ratings yet

- SGH D900 SchematicsDocument7 pagesSGH D900 Schematicsaruna-1No ratings yet

- View 1-1: Total Number of Rows:1 Anchor Row:A4Document1 pageView 1-1: Total Number of Rows:1 Anchor Row:A4Vignesh VenkatasubramanianNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Fire Safety Control PlanDocument1 pageFire Safety Control PlanALPHA OMEGANo ratings yet

- Dry-Street Lighting Network Layout-Ci-Sl-Lp-100Document1 pageDry-Street Lighting Network Layout-Ci-Sl-Lp-100Ahmed BoraeyNo ratings yet

- BJ Existing SchematicsDocument7 pagesBJ Existing SchematicsNassif Abi AbdallahNo ratings yet

- WD Centre Line PlanDocument1 pageWD Centre Line PlanRaj GuptaNo ratings yet

- S19a401 Pes001 02 187Document1 pageS19a401 Pes001 02 187construcionesingenieria2022No ratings yet

- Material list for assembly A01-W-23Document1 pageMaterial list for assembly A01-W-23HasmukhNo ratings yet

- Stop/ Control Valves: 1X-M6-AB-00006Document1 pageStop/ Control Valves: 1X-M6-AB-00006wael zakariaNo ratings yet

- PressedDocument6 pagesPressedVijay KumarNo ratings yet

- Polar 37CTV3160 54CTV3160 U21AXTDocument1 pagePolar 37CTV3160 54CTV3160 U21AXTalexmaster073No ratings yet

- ADA Bathroom LayoutDocument1 pageADA Bathroom LayoutCristo BglezNo ratings yet

- Skyworth 6t19 Chassis - njw1180f, fscq1565, Stv8172a, Ta8 SCHDocument1 pageSkyworth 6t19 Chassis - njw1180f, fscq1565, Stv8172a, Ta8 SCHq.electronica.9No ratings yet

- Top View Section X-X: Design DataDocument1 pageTop View Section X-X: Design DatakishoreNo ratings yet

- Master Plan PHASE 1pdfDocument1 pageMaster Plan PHASE 1pdfNaimuddinNo ratings yet

- SCHOOL BUILDING TERRACE MUMTY FLOOR PLAN - ModelDocument1 pageSCHOOL BUILDING TERRACE MUMTY FLOOR PLAN - ModelAATVIK SHRIVASTAVANo ratings yet

- ZONING_REV1_25-AUG-20Document1 pageZONING_REV1_25-AUG-20ahmed yaqoobNo ratings yet

- 3418-ID2-AR-DW-401-01-B (Machine)Document1 page3418-ID2-AR-DW-401-01-B (Machine)Jorge GutierrezNo ratings yet

- 3W-200697-01 R12-AREA-01 Roquette India Pvt. Ltd. Belgaum (200502) COFFE...Document1 page3W-200697-01 R12-AREA-01 Roquette India Pvt. Ltd. Belgaum (200502) COFFE...Dk WatranaNo ratings yet

- Caterpillar 3500B and 3500C. SchematicDocument2 pagesCaterpillar 3500B and 3500C. SchematicАлексейNo ratings yet

- T17m202-02300-205mi-00002 (Im8-65519-4)Document1 pageT17m202-02300-205mi-00002 (Im8-65519-4)Rodrigo RaddatzNo ratings yet

- D027/D029 Point To Point Diagram (1/2)Document24 pagesD027/D029 Point To Point Diagram (1/2)alejandro lopezNo ratings yet

- 3R MB 008 021 1214 E (SA13) Layout1Document1 page3R MB 008 021 1214 E (SA13) Layout1samwail siddiquiNo ratings yet

- P Ple Als 220 30002 0Document1 pageP Ple Als 220 30002 0BadiNo ratings yet

- Capacity PlanDocument1 pageCapacity Planjaishanakar100% (1)

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- T-4.002.788_A_1_publicationDocument1 pageT-4.002.788_A_1_publicationNadeem AkramNo ratings yet

- 3516 s2x1 - Up - Petra & RumDocument2 pages3516 s2x1 - Up - Petra & RumHamza AbuRayyaNo ratings yet

- 3516 S2X1 - UpDocument2 pages3516 S2X1 - UpHamza AbuRayyaNo ratings yet

- 3516 S2X1 - Up - RUMDocument2 pages3516 S2X1 - Up - RUMHamza AbuRayyaNo ratings yet

- 005 Minibrute 05 MetalizerDocument1 page005 Minibrute 05 MetalizerCristobal Nicolás100% (1)

- Coo 4Document1 pageCoo 4Jok PrasNo ratings yet

- Street 25M Street 25M: 02 GF - F.F.L +1.90 1Document1 pageStreet 25M Street 25M: 02 GF - F.F.L +1.90 1Khaled AshrafNo ratings yet

- Main Kitchen Power System Layout r00 O02m06 Acc XX XX SDW El 05008Document1 pageMain Kitchen Power System Layout r00 O02m06 Acc XX XX SDW El 05008SUNDAR TNo ratings yet

- Paras Ventures - (Ground Floor)Document1 pageParas Ventures - (Ground Floor)AriyanNo ratings yet

- GCP 1001 01 CS 0138 0391 M Pid 00002Document1 pageGCP 1001 01 CS 0138 0391 M Pid 00002Leonel Gamero CardenasNo ratings yet

- Site Plan: R 0 A D 60' (34C)Document1 pageSite Plan: R 0 A D 60' (34C)BatWing ZNo ratings yet

- IMSLP815142-PMLP1045449-Chaconne A Minor - de Visée - OriginalDocument1 pageIMSLP815142-PMLP1045449-Chaconne A Minor - de Visée - Originalcarl.geracimoNo ratings yet

- De-Visee-Chaconne_A_minor_trDocument1 pageDe-Visee-Chaconne_A_minor_trValerioNo ratings yet

- Acmv - Piping Laoyut - Dlsu Fit-Out - Rev.04Document2 pagesAcmv - Piping Laoyut - Dlsu Fit-Out - Rev.04Orly L. AlmerinoNo ratings yet

- FinalDocument1 pageFinalredNo ratings yet

- R420-P-2130A R420-P-2130B R420-P-2130C R420-P-2130D: NotesDocument1 pageR420-P-2130A R420-P-2130B R420-P-2130C R420-P-2130D: NotesMubashir fareedNo ratings yet

- Cold-Formed Steel and Mid-Rise ConstructionDocument46 pagesCold-Formed Steel and Mid-Rise ConstructionJose Leonardo Quintero GüellNo ratings yet

- Esquisse #1Document8 pagesEsquisse #1Besada BryanNo ratings yet

- The Paramount Medical Center Malolos PDFDocument5 pagesThe Paramount Medical Center Malolos PDFEd Macusi AsuncionNo ratings yet

- Lecture Notes - Structural Analysis For Trusses - 50126Document30 pagesLecture Notes - Structural Analysis For Trusses - 50126Alvin DeliroNo ratings yet

- Xianghua Wu's Resume: Award-Winning Singapore Architect With Over 15 Years Of ExperienceDocument34 pagesXianghua Wu's Resume: Award-Winning Singapore Architect With Over 15 Years Of ExperienceXianghua WuNo ratings yet

- 3.bom-Civil-Meghana Aac Blocks IndustryDocument15 pages3.bom-Civil-Meghana Aac Blocks IndustrytechnopreneurvizagNo ratings yet

- Load Distribution 1q 2014-15Document6 pagesLoad Distribution 1q 2014-15Macky Cary CabalquintoNo ratings yet

- A Good Place To Start: Tip 2: For ASD, Consider Using The 2011 MSJC ProvisionsDocument12 pagesA Good Place To Start: Tip 2: For ASD, Consider Using The 2011 MSJC ProvisionsconstrucciontotalNo ratings yet

- Catalogue 2008 - Chapter 06 - FTW TechnologyDocument14 pagesCatalogue 2008 - Chapter 06 - FTW TechnologyakajsiNo ratings yet

- BQ (Rev1) - Gading Kencana Office@Shah Alam - 2021!03!31Document66 pagesBQ (Rev1) - Gading Kencana Office@Shah Alam - 2021!03!31BL GroupNo ratings yet

- 14 A Check Lists - AACDocument3 pages14 A Check Lists - AACVaibhav PatilNo ratings yet

- Building & Road SpecsDocument493 pagesBuilding & Road Specssangey111No ratings yet

- Footing J17218 (Recovered)Document9 pagesFooting J17218 (Recovered)eco protectionNo ratings yet

- Rapid Visual Screening MethodDocument15 pagesRapid Visual Screening MethodsmpetrasNo ratings yet

- Resume of Keneshia - DunnDocument2 pagesResume of Keneshia - Dunnapi-24090317No ratings yet

- Footings and FoundationsDocument7 pagesFootings and FoundationsJenina LogmaoNo ratings yet

- Fill in the gaps exercise about places in New York CityDocument2 pagesFill in the gaps exercise about places in New York CityEnderson MendozaNo ratings yet

- Detailed EstimateDocument6 pagesDetailed EstimatePamela Joanne Falo AndradeNo ratings yet

- PlumberDocument8 pagesPlumberKristin MatubisNo ratings yet

- 08 - Chapter 2 PDFDocument21 pages08 - Chapter 2 PDFSunny TuvarNo ratings yet

- Lewiston Greenway PathDocument1 pageLewiston Greenway PathScott TaylorNo ratings yet

- Facilities Standards Service (003C2B) : Contact ListDocument2 pagesFacilities Standards Service (003C2B) : Contact ListasdthuNo ratings yet

- Hydrophilic Rubber Waterstop SpecificationDocument6 pagesHydrophilic Rubber Waterstop Specificationwafikmh4No ratings yet

- Article: Vernacular Architecture Compatible With Environment of Stepped Villages Case Study: Palangan Village, IranDocument9 pagesArticle: Vernacular Architecture Compatible With Environment of Stepped Villages Case Study: Palangan Village, IranAli jeffreyNo ratings yet

- Kanad Kumar's concise resumeDocument21 pagesKanad Kumar's concise resumeKanad Kumar GhoshNo ratings yet

- AATS Technical Services ProfileDocument6 pagesAATS Technical Services Profileimzee25No ratings yet

- Peter EisenmanDocument26 pagesPeter EisenmanVivek PuniNo ratings yet

- JU Floor System...Document34 pagesJU Floor System...kaafiNo ratings yet

- Characteristic Performance of PEB Vs CSBDocument19 pagesCharacteristic Performance of PEB Vs CSBAyon SenguptaNo ratings yet

- Shaik Palace/Villa - Al Dafna:: Sub: Detail Design Verification - HVAC - Brief Scope of WorkDocument3 pagesShaik Palace/Villa - Al Dafna:: Sub: Detail Design Verification - HVAC - Brief Scope of Worka769No ratings yet