Professional Documents

Culture Documents

Current Transformer

Uploaded by

lkt_pestechOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Current Transformer

Uploaded by

lkt_pestechCopyright:

Available Formats

CURRENT TRANSFORMER

TABLE OF CONTENTS

No. Contents Page

1.0 Scope 2

2.0 Standards 2

3.0 Performance Requirements 2

4.0 Design and Constructions 3

4.1 Primary Terminal 3

4.2 Housing 4

4.3 Insulation System 4

4.3.1 Insulation Oil 4

4.3.2 Sampling Valve 4

4.3.3 Provision for Measurement of Dielectric Dissipation 4

Factor

4.3.4 Oil Preservation System 5

4.3.5 Bellow/Oil Indicator 5

4.4 Base 5

4.5 Grounding Terminal 5

4.6 Primary Winding 5

4.7 Secondary Winding 6

4.8 Rating & Schematic Diagram Plate 6

4.9 Corona Ring 6

4.10 Secondary Assembly Box 6

4.11 Secondary Termination 7

4.12 Protective Device 7

5.0 Tests 7

6.0 Drawings and Documents 7

7.0 Special Tools & Spare Parts 7

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 1 of 8

Printed from EDMS System

CURRENT TRANSFORMER

1.0 SCOPE

This document defines the technical requirements for current transformers

connected to TNB Transmission Grid System at 132, 275 and 500 kV. It also covers

Neutral Current Transformers (NCT) to be connected to the neutral point of

transformers for the voltage mentioned. NCTs for capacitor unbalanced protection

used in capacitor banks shall also comply with this document.

Current transformers furnished shall be complete with all accessories ready for

mounting, assembly, connection and immediate service suitable for outdoor

installations.

2.0 STANDARDS

The equipment shall conform to the following Standards:-

IEC 61869-1 Instrument Transformers – Part 1: General

IEC 61869-2 Instrument Transformers – Part 2: Additional Requirement

for Current Transformers.

IEC 60296 Specification for unused mineral insulation oils for

transformers and switchgear

IEC 60156 Dielectric Breakdown Voltage - Method for the

determination of the electric strength of insulating oils

NEMA CC1 National Electrical Manufacturing Association: Electric

Power Connection for Substations

IEC 60529 Degree of Protection Provided By Enclosures (IP-Code)

3.0 PERFORMANCE REQUIREMENTS

Each current transformer shall be designed and constructed for operation on a 3-

phase, 50 hertz, solidly earthed system, at an environmental condition stated in

TTS-SS-GEN document without corrosion, deterioration or degradation of

performance characteristics.

The current transformer shall be designed for operation at the following primary

system voltages and rated insulation levels:

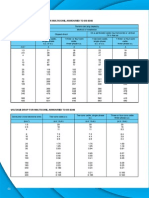

System Voltage : 132kV 275kV 500kV

The rated short time thermal current and duration of the current transformer, and

the required nominal specific creepage distance shall be as specified in Schedule H.

Measuring current transformers of accuracy classes 0.1 to 1 shall have an

extended current rating as below:

132kV 275kV 500kV

Bus 120% 120% 120%

Feeder bays 150% 120% 120%

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 2 of 8

Printed from EDMS System

The details of primary time constant and duty cycle are as follows:

• Primary Time Constant: 100 ms Max

• Duty Cycle: C – 40 ms – O – 500 ms – C - 60 ms – O Max

Outdoor type NCT for 132, 275 and 500kV system transformer neutrals shall be

designed for operation at short time current and duration equivalent to that of the

related Phase Voltage and withstand the following minimum primary system voltages

and rated insulation levels:

System Voltage : kV

• Nominal, rms. (kV) 33

• Highest Voltage, rms, (kV) 36

Rated Insulation Level of Primary Winding, 1.2 / 50 µs 170

to Earth, peak

Rated Power Frequency Withstand, rms. 70

Unbalanced Neutral CT for use in 132kV capacitor banks shall be rated at short

circuit

current withstand of 0.2kA, 3 seconds minimum and withstand the following

minimum

primary system voltages and rated insulation levels.

System Voltage : kV

• Nominal, rms. (kV) 132

• Highest Voltage, rms, (kV) 145

Rated Insulation Level of Primary Winding, 1.2 / 50 µs 650

to Earth, peak

Rated Power Frequency Withstand, rms. 275

4.0 DESIGN AND CONSTRUCTIONS

GENERAL

Current transformers shall be furnished with all field connection hardware suitable

for field mounting on steel supports of pedestal type described in TTS-SS-GEN

document. All hardware shall be hot-dip galvanized or aluminum or stainless steel.

The energized parts shall be made of corrosion-resistant material such as

galvanized steel, aluminum or stainless steel.

4.1 PRIMARY TERMINAL

Each current transformer shall be equipped with suitable terminal pads. The

terminal pads shall be in accordance with the standard NEMA CC1 4-hole

arrangement.

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 3 of 8

Printed from EDMS System

The terminal pads shall be of high conductivity aluminum or bronze or

copper. If bronze or copper, pads shall be plated with hot flowed electro-tin to

a thickness of not less than 0.0127 mm. Whenever larger terminal pads are

required for a higher current rating, the mounting holes shall conform to

NEMA Standards, and details of the mounting holes shall be submitted for

approval.

4.2 HOUSING

The current transformer insulator housing shall be of porcelain or ceramic.

The requirements for the housing shall be referred to TTS-SS-GEN document.

Porcelain housings shall have adequate mechanical and electrical strength.

Porcelain housings shall be wet processed, homogeneous and free from

cavities or other flaws. The glazing shall be uniform in color and free from

blisters, burns and other defects.

The porcelain color shall be dark brown for 132 and 275kV system voltage

and grey for 500kV.

There shall be suitable markings on the porcelain to identify the

manufacturer, date of Manufacture and identification number.

4.3 INSULATION SYSTEM

Current transformer shall be oil filled and hermetically sealed. Outdoor NCTs for

transformer neutrals shall be of the cast resin or porcelain post type.

4.3.1 INSULATION OIL

The current transformer shall be filled with mineral oil type.

This insulating oil shall meet all the requirements as defined by IEC

60296 standards and shall be tested to at least 60kV at the factory. If

the dielectric strength of the oil is less than 60kV when tested in

accordance with IEC 60156 (Dielectric Breakdown Voltage - Method for

the determination of the electric strength of insulating oils), then the

current transformer insulation system shall be unacceptable. A

certified copy of the oil characteristics shall be furnished to the

Employer prior to delivery.

4.3.2 SAMPLING VALVE

Current transformers shall have a special provision for taking a

sample of the oil. Such sample shall be truly representative of the oil

in contact with the primary insulation in respect of moisture content,

dissolved gases and degradation products. The oil sampling facility

shall be of ball valve type and located at the bottom of the CT. The oil-

sampling valve should be designed to prevent gushing out of oil,

when the valve is opened.

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 4 of 8

Printed from EDMS System

4.3.3 PROVISION FOR MEASUREMENT OF DIELECTRIC DISSIPATION

FACTOR

Where the insulation of the current transformer consists mainly of

organic material, provision shall be made for measurement of the

dielectric dissipation factor (DDF) of the insulation system. This is

also known as Dielectric Loss Angle (DLA) or Tangent Delta. A

suitable earthing terminal and link shall be provided for the purpose of

dielectric dissipation factor measurement. The link shall be made of

tinned brass or copper (Aluminum is NOT Acceptable) and shall carry

a suitable engraved warning against removal when in service.

4.3.4 OIL PRESERVATION SYSTEM

A sealed oil preservation system using a stainless steel or teflon

bellow to absorb oil volume changes due to variation in oil

temperature shall be provided. Air or gas cushion in direct or indirect

contact with the oil is not acceptable. The bellows or expansion

chamber shall be of materials which is non-permeable to water, or

oxygen. Rubber bellows shall not be used.

4.3.5 BELLOW/OIL INDICATOR

A diaphragm/bellow displacement indicator shall be provided to

indicate oil level changes due to either gas build up or oil leakage. The

indicator shall clearly show the current transformer normal and

abnormal working range.

Where floater or side glass type indication is also provided to monitor

the oil level, this should be easily readable from ground level. Pointer

type indicators shall not be accepted.

4.4 BASE

The base support assembly shall be of weatherproof welded steel or

aluminum, fabricated to support and mount the current transformer and to be

equipped with grounding terminal.

Outdoor NCTs for transformer neutrals shall be complete with suitable

mounting steelwork and complete with cable box for secondary connections.

4.5 GROUNDING TERMINAL

Grounding terminal shall be copper, stainless steel, tinned copper, tinned

aluminium or tinned bronze of bolted clamp type for earthing downlead

conductor.

The clamp shall be suitable for copper tape of dimension 50mm x 6mm,

except where otherwise specified in Schedule H.

4.6 PRIMARY WINDING

Primary winding conductors shall withstand the required short-time current

rating and duration as specified in Schedule H.

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 5 of 8

Printed from EDMS System

The test to prove conformance to short-time current rating shall be made at a

2 2

current I for a time t, so that (I t) is not less than (I th) and provided t has a

value between 0.5s and 5s, as specified by the standard.

Temperature rise test and thermal stability test shall have been performed at

the relevant continuous thermal current rating of the measurement cores.

4.7 SECONDARY WINDING

Instrument Security Factor FS for the measuring cores should be as low as

possible and shall be less than or equal to 5.

Current transformers for balanced protection schemes shall have identical

turns ratio and adequate magnetization characteristic.

Where an existing balanced protective scheme is being extended, the

Contractor shall ensure that the magnetization characteristic (excitation

current and minimum knee point voltage) of the current transformer provided

is matched and adequate for operation of the associated protective devices.

Accuracy, class, rated burden and turns ratio shall be provided for each type

and rating of current transformers. For class PX current transformer; the

magnetization characteristic, turns ratio, accuracy class and secondary

resistance shall be provided.

The required characteristics of current transformers shall be as stated in

Schedule H and shall be confirmed during design process prior to

manufacturing subject to approval by the Engineer.

4.8 RATING & SCHEMATIC DIAGRAM PLATE

Each current transformer shall have permanently attached to it in a

conspicuous position a rating plate of non corrosive material upon which

shall be engraved with markings as specified in the IEC. Additional rating and

diagram plates shall be provided at eye-level on the steel structure. In

addition, the rating plate shall also have the following information:

• Total oil volume

• Design standard for insulation oil

• Total weight of current transformer

• Design standard and revision year of current transformer

• TNB contract number

• Index of Protection (IP) value of secondary assembly box

• Total and nominal specific creepage distance

• Customer’s name

4.9 CORONA RING

Corona rings shall be supplied where required on current transformers to

prevent corona at rated line-to-line voltage and meet specified Radio and

Television Interference Voltage levels according to IEC Standard.

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 6 of 8

Printed from EDMS System

4.10 SECONDARY ASSEMBLY BOX

For 500kV, 275kV and 132kV current transformers, the cable gland plate

located at the bottom of each secondary terminal box shall be adequately

sized for installing all cables and glands necessary. The enclosure of the

terminal boxes shall be protected to IP54 minimum.

4.11 SECONDARY TERMINATION

The requirements for secondary terminations relevant to the current

transformer shall be referred to TTS-SS-PROTECTION document.

4.12 PROTECTIVE DEVICE

The requirements for protective devices relevant to the current transformer

shall be referred to TTS-SS-PROTECTION document.

Where the open-circuited secondary voltage would exceed 3.5 kV, suitable

protection shall be provided at the secondary terminals to limit the voltage

such as by the provision of a spark gap.

5.0 TESTS

Refer to the document - TTS-SS-TEST.

6.0 DRAWINGS AND DOCUMENTS

Table 1 shows the required drawings and documents to be furnished

subsequent to tender award. The list is the minimum required. The Contractor

should furnish further drawings or documents as deemed fit and as required by

the Engineer.

No. Title

1. COMPONENT LIST

2. GENERAL ARRANGEMENT

3. SECONDARY WIRING ARRANGEMENT

4. NAME PLATE

5. INSULATOR/BUSHING

6. BASE & GROUND PAD

7. PRIMARY TERMINAL DETAIL

8. SECONDARY BOX ASSEMBLY&

DETAIL

9. OIL SAMPLING AND METHOD OF DRAWING

10. FACTORY ACCEPTANCE TEST PLAN & PROCEDURE

11. SUMMARY OF TEST

12. LIST OF NON-COMPLIANCE

Table 1 List of Minimum Required Drawings and Documents

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 7 of 8

Printed from EDMS System

7.0 SPECIAL TOOLS & SPARE PARTS

The proposal shall include the special tools as specified in Schedule K.

TRANSMISSION TECHNICAL SPECIFICATION

TENAGA NASIONAL BERHAD

CURRENT TRANSFORMER

Doc. No. TTS-SS-CT Revision No. 2 Date 18 Dec 2014 Page Page 8 of 8

Printed from EDMS System

You might also like

- Capacitor Voltage TransformerDocument7 pagesCapacitor Voltage Transformerlkt_pestechNo ratings yet

- 51 Sdms 01rev022 For Distribution TransformerDocument20 pages51 Sdms 01rev022 For Distribution Transformernadeem UddinNo ratings yet

- Outdoor Disconnectors & Earthing SwitchesDocument12 pagesOutdoor Disconnectors & Earthing Switcheslkt_pestechNo ratings yet

- CEB Specification 006:2008 Combined Metering TransformersDocument13 pagesCEB Specification 006:2008 Combined Metering TransformerskotiniNo ratings yet

- PDFDocument28 pagesPDFRaheem_kaNo ratings yet

- Spec No. TI/SPC/PSI/TRNPWR/3201 Traction Power Transformer SpecificationDocument86 pagesSpec No. TI/SPC/PSI/TRNPWR/3201 Traction Power Transformer Specificationraj sekhar100% (1)

- EDC-DTS-MV001 - Pole Mounted Three-Phase and Two-Phase Outdoor Distribution TransformersDocument69 pagesEDC-DTS-MV001 - Pole Mounted Three-Phase and Two-Phase Outdoor Distribution TransformersJoe bilouteNo ratings yet

- 10kva 25 Kva Dist - Transformer Spec Revision Dtd. 20.04.2018Document45 pages10kva 25 Kva Dist - Transformer Spec Revision Dtd. 20.04.2018Ritesh DhawaleNo ratings yet

- Transformers SpecificationDocument57 pagesTransformers SpecificationGardell100% (2)

- EDC DTS MV009 Surge ArrestersDocument18 pagesEDC DTS MV009 Surge ArrestersJoe bilouteNo ratings yet

- KAVR Series - Manual PDFDocument214 pagesKAVR Series - Manual PDFtunghtdNo ratings yet

- Low Voltage Power Distribution and Motor Control Center Technical SpecificationDocument25 pagesLow Voltage Power Distribution and Motor Control Center Technical Specificationalstom100% (1)

- En LB566 Manual 41986BA2 07Document207 pagesEn LB566 Manual 41986BA2 07JustinNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 53TMSS02R1Document57 pages53TMSS02R1Abdulaziz AlmutiriNo ratings yet

- April 02, 2011 Transmission Materials Standard SpecificationDocument57 pagesApril 02, 2011 Transmission Materials Standard SpecificationNauman Habib KhanNo ratings yet

- Surge ArresterDocument5 pagesSurge Arresterlkt_pestechNo ratings yet

- Trans HandbkDocument213 pagesTrans HandbkRubal Kathait100% (1)

- Enclosure 6150 Derscription PDF FreeDocument85 pagesEnclosure 6150 Derscription PDF FreeHua NasroNo ratings yet

- 1200531-01 PROFINET PxE 900 Rev.02 Manual enDocument92 pages1200531-01 PROFINET PxE 900 Rev.02 Manual enGustavo CarvalhoNo ratings yet

- MRF2800Document17 pagesMRF2800aaNo ratings yet

- EEAM-Q-017 MEDIUM VOLTAGE SWITCHGEAR AND CONTROL GEAR FOR SUBSTATIONS (HE8-2-5Ver6)Document15 pagesEEAM-Q-017 MEDIUM VOLTAGE SWITCHGEAR AND CONTROL GEAR FOR SUBSTATIONS (HE8-2-5Ver6)史海云No ratings yet

- Substation ComponentDocument62 pagesSubstation ComponentaangjaelaniNo ratings yet

- OMV E&P Philosophy: TitleDocument29 pagesOMV E&P Philosophy: TitleamdatiNo ratings yet

- SEC Automatic Transfer Switch SpecificationsDocument27 pagesSEC Automatic Transfer Switch SpecificationsI CNo ratings yet

- 11kV Dist Xfmr SpecDocument33 pages11kV Dist Xfmr SpecKarthikNo ratings yet

- Small PowerDocument25 pagesSmall PowerAlhassan MahmoudNo ratings yet

- EDC-DTS-MV006 - 35 KV and 22 KV Pole Mounted Auto ReclosersDocument27 pagesEDC-DTS-MV006 - 35 KV and 22 KV Pole Mounted Auto ReclosersJoe bilouteNo ratings yet

- SHPP GL Ch3.FullDocument417 pagesSHPP GL Ch3.FullLuis Faustino Rodriguez LopezNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument83 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardDocument160 pages3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardFarid Ahmad Shalahuddin100% (1)

- 53-TMSS-01-R0-unlockedDocument57 pages53-TMSS-01-R0-unlockedGanesh DuraisamyNo ratings yet

- BX Concentration ControlDocument205 pagesBX Concentration ControlnghiNo ratings yet

- MSP 90Document128 pagesMSP 90FredericoNo ratings yet

- Transductor Lineal Balluff Perfil Ethernet IP PDFDocument19 pagesTransductor Lineal Balluff Perfil Ethernet IP PDFGerardo Cruz EspinosaNo ratings yet

- RTS 2nd Generation SERVO AMPLIFIER Technical ManualDocument65 pagesRTS 2nd Generation SERVO AMPLIFIER Technical ManualJose LopezNo ratings yet

- 7907 Ela80-3000 Rev - 7 PDFDocument54 pages7907 Ela80-3000 Rev - 7 PDFDavid デビッドブエノ BuenoNo ratings yet

- LCL Filters: Instructions ManualDocument10 pagesLCL Filters: Instructions ManualHasib PeyalNo ratings yet

- Elect Dev Cir Capitulo 5 Part1Document63 pagesElect Dev Cir Capitulo 5 Part1Jaime VargasNo ratings yet

- Elect Dev Cir Capitulo 7Document69 pagesElect Dev Cir Capitulo 7Jaime VargasNo ratings yet

- Elect Dev Cir Capitulo 8Document74 pagesElect Dev Cir Capitulo 8Jaime VargasNo ratings yet

- Water Supplies Department: E-60-05 Sept. 2008Document33 pagesWater Supplies Department: E-60-05 Sept. 2008Ricardo QueirogaNo ratings yet

- Danfoss VLT HVAC FC 102 Manual PDFDocument74 pagesDanfoss VLT HVAC FC 102 Manual PDFFernando QueirozNo ratings yet

- VFD ManualDocument186 pagesVFD ManualelengineerNo ratings yet

- SafeGear SpecificationDocument18 pagesSafeGear SpecificationvjrNo ratings yet

- SDMS 01rev01Document27 pagesSDMS 01rev01AkhilNo ratings yet

- 56-SDMS-02 Rev.01 13.8kV Pakage SubstationsDocument17 pages56-SDMS-02 Rev.01 13.8kV Pakage Substations张勇No ratings yet

- CEB Specification for Outdoor Combined Metering TransformersDocument13 pagesCEB Specification for Outdoor Combined Metering TransformersSmit SoniNo ratings yet

- Manual - Conversor CACC - WNTCDocument148 pagesManual - Conversor CACC - WNTCRafael GarciaNo ratings yet

- HD 10/25 S and HD 13/18 S Service ManualDocument30 pagesHD 10/25 S and HD 13/18 S Service ManualFabri GutyNo ratings yet

- C R Panel (With Automation) Nov 2016 - 17.03.2017Document88 pagesC R Panel (With Automation) Nov 2016 - 17.03.2017Ratheesh KumarNo ratings yet

- EDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersDocument33 pagesEDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersJoe bilouteNo ratings yet

- bs7671 Iee On Site GuideDocument184 pagesbs7671 Iee On Site Guidemigzx95% (19)

- Practical Industrial Data Networks: Design, Installation and TroubleshootingFrom EverandPractical Industrial Data Networks: Design, Installation and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Metering Panel & PQMDocument1 pageMetering Panel & PQMlkt_pestechNo ratings yet

- Brochure - PESTECH OCPP Charging Management Platform.v3Document1 pageBrochure - PESTECH OCPP Charging Management Platform.v3lkt_pestechNo ratings yet

- IV Curve RT Diagnosis Function Test Report ENDocument73 pagesIV Curve RT Diagnosis Function Test Report ENlkt_pestechNo ratings yet

- Surge ArresterDocument5 pagesSurge Arresterlkt_pestechNo ratings yet

- Southern Cable Group BHDDocument12 pagesSouthern Cable Group BHDlkt_pestechNo ratings yet

- SCADA Config PDFDocument1 pageSCADA Config PDFlkt_pestechNo ratings yet

- Adarsh Product CatalogueDocument68 pagesAdarsh Product Cataloguelkt_pestechNo ratings yet

- Catalogue SEDIVER PDFDocument28 pagesCatalogue SEDIVER PDFKhalifa Aldila PutraNo ratings yet

- Nedal Busbars For High-Voltage StationsDocument7 pagesNedal Busbars For High-Voltage Stationslkt_pestechNo ratings yet

- MCAGDocument5 pagesMCAGariptrNo ratings yet

- Sarawak Electricity Supply Corporation OrdinanceDocument32 pagesSarawak Electricity Supply Corporation Ordinancelkt_pestechNo ratings yet

- Surge Arrester Details Huawei Sun 20000Document8 pagesSurge Arrester Details Huawei Sun 20000lkt_pestechNo ratings yet

- Surge protection for DC and AC sides of PV systemsDocument3 pagesSurge protection for DC and AC sides of PV systemslkt_pestech100% (1)

- Benefits of SVC and STATCOM Sept 2003 W TaylorDocument8 pagesBenefits of SVC and STATCOM Sept 2003 W Taylornagaraju0204No ratings yet

- Abnormal System VoltagesDocument58 pagesAbnormal System Voltageslkt_pestechNo ratings yet

- Outdoor Solid Core Post Insulators GuideDocument32 pagesOutdoor Solid Core Post Insulators GuidetholgasenelNo ratings yet

- 3.2 Overexcitation and Overvoltage ProtectionDocument6 pages3.2 Overexcitation and Overvoltage Protectionlkt_pestechNo ratings yet

- BS6346-MULTICORE-CURRENT-CAPACITYDocument1 pageBS6346-MULTICORE-CURRENT-CAPACITYlkt_pestechNo ratings yet

- PPC Insulator - Solid CoreDocument16 pagesPPC Insulator - Solid CoreAriel Ghigliotto100% (1)

- Clean Agent PDFDocument4 pagesClean Agent PDFlkt_pestechNo ratings yet

- General ParametersDocument5 pagesGeneral Parameterslkt_pestechNo ratings yet

- IEC 60071 Insulation Coordination Abb LiteratureDocument8 pagesIEC 60071 Insulation Coordination Abb Literaturereza515hei100% (2)

- Temperature Rise 50sqmmDocument2 pagesTemperature Rise 50sqmmlkt_pestechNo ratings yet

- Design Guide Past 1Document1 pageDesign Guide Past 1lkt_pestechNo ratings yet

- 2010.06.21 3AP1 DTC-Reference Excluding ChinaDocument2 pages2010.06.21 3AP1 DTC-Reference Excluding Chinalkt_pestechNo ratings yet

- IEC 1597 1995 SlideDocument1 pageIEC 1597 1995 Slidelkt_pestechNo ratings yet

- CHAPTER 2 Fundamental Requirements for Safety in DesignDocument1 pageCHAPTER 2 Fundamental Requirements for Safety in Designlkt_pestechNo ratings yet

- Chapter 1Document9 pagesChapter 1lkt_pestechNo ratings yet

- 11 Ways To Encourage Stakeholder Participation:: Writing Good Consultation QuestionsDocument1 page11 Ways To Encourage Stakeholder Participation:: Writing Good Consultation QuestionsLuz Alinsunurin DulogNo ratings yet

- Penetron Admix FlyerDocument2 pagesPenetron Admix Flyernght7942No ratings yet

- ACL Reconstruction BookDocument18 pagesACL Reconstruction BookSergejs JaunzemsNo ratings yet

- Cameron VBR-II (Variable Bore Ram) PackerDocument2 pagesCameron VBR-II (Variable Bore Ram) Packerjuan olarteNo ratings yet

- Simulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysysDocument7 pagesSimulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysyseduryuNo ratings yet

- Execution and Documentation Requirements For Life Cycle Cost AnalysesDocument20 pagesExecution and Documentation Requirements For Life Cycle Cost AnalysessmetNo ratings yet

- Agni Free PDF - 2 For Sbi Clerk Mains 2024Document18 pagesAgni Free PDF - 2 For Sbi Clerk Mains 2024supriyo248650No ratings yet

- Advance Corporate StrategyDocument2 pagesAdvance Corporate StrategyPassionate_to_LearnNo ratings yet

- ISLAND SAILING CLUB COWES 2012 ROUND THE ISLAND RACE RESULTSDocument64 pagesISLAND SAILING CLUB COWES 2012 ROUND THE ISLAND RACE RESULTSmatthias_25No ratings yet

- Huawei Tecal RH2288 V2 Server Compatibility List PDFDocument30 pagesHuawei Tecal RH2288 V2 Server Compatibility List PDFMenganoFulanoNo ratings yet

- Editable Classroom Officers TemplateDocument6 pagesEditable Classroom Officers TemplateRachelle AbalosNo ratings yet

- Tutorial MagIC Net 2.XDocument99 pagesTutorial MagIC Net 2.XJuan Diego Aznar Fernández100% (1)

- Demethanizer OperationDocument6 pagesDemethanizer OperationHoustonAbducteeNo ratings yet

- Lb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDocument2 pagesLb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDaniel Oliveira Freitas RochaNo ratings yet

- Live Sound 101: Choosing Speakers and Setting Up a Sound SystemDocument14 pagesLive Sound 101: Choosing Speakers and Setting Up a Sound Systemohundper100% (1)

- Natural Fibres For Composites in EthiopiaDocument12 pagesNatural Fibres For Composites in EthiopiaTolera AderieNo ratings yet

- RELATED STUDIES AND LITERATURE ON EGGSHELL POWDER USE IN CONCRETEDocument5 pagesRELATED STUDIES AND LITERATURE ON EGGSHELL POWDER USE IN CONCRETEReiBañez100% (2)

- 5 Basic Model of PorterDocument6 pages5 Basic Model of PorterJahanvi PandyaNo ratings yet

- Day 1 What Is Phased Array How Phased Array Works? Beam Forming Beam Focusing Beam Streeing Sectorial Scan and Linear ScanDocument64 pagesDay 1 What Is Phased Array How Phased Array Works? Beam Forming Beam Focusing Beam Streeing Sectorial Scan and Linear ScanvibinkumarsNo ratings yet

- Auditing Case 3Document12 pagesAuditing Case 3Kenny Mulvenna100% (6)

- Abdulbasit MohammedDocument170 pagesAbdulbasit MohammedGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Bangladesh Premier League 2024 Schedule, Live Scores and ResultsDocument5 pagesBangladesh Premier League 2024 Schedule, Live Scores and Resultsmoslahuddin2022No ratings yet

- Feasibility ReportDocument10 pagesFeasibility ReportAdityaNo ratings yet

- COURSE Strucure - M.tech (S.E) I & II Sem (Autonomous)Document40 pagesCOURSE Strucure - M.tech (S.E) I & II Sem (Autonomous)Fresherjobs IndiaNo ratings yet

- Operating Instructions MA 42 - Maico Diagnostics PDFDocument28 pagesOperating Instructions MA 42 - Maico Diagnostics PDFJuan PáezNo ratings yet

- DNV Casualty Info 2011 #3Document2 pagesDNV Casualty Info 2011 #3Sureen NarangNo ratings yet

- Standards in Nursing Education ProgrammeDocument13 pagesStandards in Nursing Education ProgrammeSupriya chhetryNo ratings yet

- Designing An AirshipDocument100 pagesDesigning An AirshipFrik van der Merwe100% (2)

- F404-15 Standard Consumer Safety Specification For High ChairsDocument19 pagesF404-15 Standard Consumer Safety Specification For High ChairsAhmed AlzubaidiNo ratings yet