Professional Documents

Culture Documents

List Gear Motor

Uploaded by

Suyanto0 ratings0% found this document useful (0 votes)

4 views1 pageThis document lists the gear motors required for a palm oil mill with a capacity of 45-60 tons of fresh fruit bunches per hour. It includes 36 items ranging from gear motors for conveyor belts to motors that power thresher drums, elevators, and stirrers. The list specifies the power, speed, quantity, and dimensions of each gear motor.

Original Description:

3 phase

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document lists the gear motors required for a palm oil mill with a capacity of 45-60 tons of fresh fruit bunches per hour. It includes 36 items ranging from gear motors for conveyor belts to motors that power thresher drums, elevators, and stirrers. The list specifies the power, speed, quantity, and dimensions of each gear motor.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageList Gear Motor

Uploaded by

SuyantoThis document lists the gear motors required for a palm oil mill with a capacity of 45-60 tons of fresh fruit bunches per hour. It includes 36 items ranging from gear motors for conveyor belts to motors that power thresher drums, elevators, and stirrers. The list specifies the power, speed, quantity, and dimensions of each gear motor.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

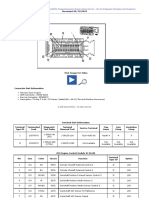

LIST OF GEAR MOTOR

PROJECT : PALM OIL MILL CAP. 45 - 60 TONS FFB/HR

OWNER : PT. KAMPARINDO AGRO INDUSTRI - II DK/KAI2/GEARMOTOR/05.05.21

POWER SPEED DIAMETER TINGGI LEBAR PANJANG

NO. MACHINERIES UNIT QTY REMARK

KW RPM SHAFT SEPI SEPI SEPI

1 Gear Motor Capstand GM 22 24 5 3 Single Drum & 2 Double Drum

2 Sterilizing Fruit Bunch Scraper Conveyor GM 15 24 1 110 8.5 28 180

3 Thresher Drum :

- Electro Motor EM 18,5 1450 3

- Fluid Coupling c/w Pulley & V-Belt FC 18,5 1450 3 Fluid coupling Pulley type

- Gear Box GB 18,5 24 3

4 Under Thresher Screw Conveyor GM 5,5 50 3 60 5 18 100

5 Horizontal Empty Fruit Bunch Scraper Conveyor GM 7.5 42 1 60 5 18 100

6 Inclined Recycle Empty Fruit Bunch Scraper Conveyor GM 11 42 1 60 5 18 100

7 Inclined Empty Fruit Bunch Scraper Conveyor GM 11 42 2 70 6 20 110

8 Bottom Cross Screw Conveyor GM 7,5 50 1 60 5 18 100

9 Fruit Elevator GM 11 42 2 Back Stop Type

10 Fruit Distributing Screw Conveyor GM 7.5 50 1 60 5 18 100

11 Cake Breaker Conveyor No. 1 GM 18.5 65 1

12 Cake Breaker Conveyor No. 2 GM 22 65 1

13 Nut Polishing Drum GM 7,5 80 1 60 5 18 100

14 Fibre Cyclone Air Lock GM 7,5 38 1 60 5 18 100

15 Inclined Fibre & Shell Scrapper Conveyor GM 7,5 42 1 60 5 18 100

16 Nut Augher Conveyor GM 4 50 1 50 5 14 80

17 Destoner Air Lock GM 2,2 38 2 50 5 14 80

18 Wet Nut Distributing Screw Conveyor GM 3 50 1 40 3.5 10 70

19 Air Lock Feeding Ripple Mill GM 2.2 38 4 40 3.5 10 70

20 Bottom Cracked Mixture Screw Conveyor GM 3 50 1 40 3.5 10 70

21 Cracked Mixture Elevator GM 4 42 1 Back Stop Type 50 5 14 80

22 Cracked Mixture Split Airlock GM 2,2 50 1 40 3.5 10 70

23 LTDS Column Air Lock for 2 Stage GM 2,2 38 2 40 3.5 10 70

24 LTDS Cyclone Air Lock for 2 Stage GM 2,2 38 2 40 3.5 10 70

25 Cracked Mixture Feeding Conveyor GM 3 50 1 40 3.5 10 70

26 Claybath Separator :

- Gear Motor Stirrer GM 1,5 11 1 Stirrer ( Helical ) 50 5 14 80

- Electro Motor Vibrating Screen EM 2,2 980 1

27 Wet Shell Screw Conveyor 3 50 2 40 3.5 10 70

28 Bottom Wet Kernel Screw Conveyor GM 3 50 2 40 3.5 10 70

29 Wet Kernel Elevator GM 4 42 1 Back Stop Type 40 3.5 10 70

30 Wet Kernel Distributing Screw Conveyor GM 3 50 1 50 5 14 80

31 Dried Kernel Collecting Screw Conveyor Under Kernel Silo GM 3 50 1 40 3.5 10 70

32 Dry Kernel Distributing Screw Conveyor Above KBS GM 3 50 1 40 3.5 10 70

33 Continious Settling Tank GM 4 3,4 1 Stirrer ( Vertical ) 100 10 30 180

34 Inclined Fibre & Shell Scraper Conveyor GM 7,5 42 1 60 5 18 100

35 Fuel Distributing Screw Conveyor GM 15 50 1 70 6 20 110

36 Fuel Recycling Scraper Conveyor GM 7,5 42 1 60 5 18 100

37 Gate GM 0,31 28 1

Note: - Electro Motor & Gear Motor, 380 V - 50 Hz

- GB = Gear Box - EM = Electro Motor

- GM = Gear Motor - FC = Fluid Coupling

You might also like

- Standard Productivity of MachineryDocument7 pagesStandard Productivity of MachineryAtther Javeed90% (42)

- Cascadia Maintenance Manual Models: CA113DC CA113SLP CA125DC CA125SLPDocument121 pagesCascadia Maintenance Manual Models: CA113DC CA113SLP CA125DC CA125SLPCao LanNo ratings yet

- Oil FilterDocument2 pagesOil FilterAndry PriyantoNo ratings yet

- Prevention of Reflective Cracking in Pavements - Vanelstraete PDFDocument136 pagesPrevention of Reflective Cracking in Pavements - Vanelstraete PDFTran Huynh Nam100% (3)

- Gear BoxDocument6 pagesGear Boxprashant mishra100% (1)

- Parts Catalogue - MDIDocument47 pagesParts Catalogue - MDIsengottaiyan83% (6)

- Catalog 2Document44 pagesCatalog 2Enrique HortaNo ratings yet

- 2 Boiler AalborgDocument15 pages2 Boiler AalborgAlexey PlekhanovNo ratings yet

- Royal Enfield 2010 Thunderbird TwinsparkDocument65 pagesRoyal Enfield 2010 Thunderbird TwinsparkSheeraz Ahmad100% (3)

- 13 - Basic Engine CulataDocument3 pages13 - Basic Engine CulataMARIO DEL PINO MUÑOZNo ratings yet

- General Catalog: Midco Petroleum PartsDocument44 pagesGeneral Catalog: Midco Petroleum PartsabdulNo ratings yet

- DC Motors, Speed Controls, Servo Systems: An Engineering HandbookFrom EverandDC Motors, Speed Controls, Servo Systems: An Engineering HandbookRating: 5 out of 5 stars5/5 (3)

- LH Timetable 2016Document80 pagesLH Timetable 2016AerokosmonautikaNo ratings yet

- Figure 29-00-00-13400-00-U / SHEET 5/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Document1 pageFigure 29-00-00-13400-00-U / SHEET 5/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaNo ratings yet

- Ata 100 CodeDocument11 pagesAta 100 CodeEli Granados100% (2)

- PREPARATIONS FOR Load Line Survey and Safety Equipment SurveyDocument3 pagesPREPARATIONS FOR Load Line Survey and Safety Equipment SurveyjagandeepNo ratings yet

- 031 - Mass Balance - AnswersDocument48 pages031 - Mass Balance - AnswersEASA ATPL Question Bank0% (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Allcan300 V1-1 PDFDocument1 pageAllcan300 V1-1 PDFChris BelgaNo ratings yet

- Fabrication DetailsDocument28 pagesFabrication DetailsPatel MishalNo ratings yet

- FiltersDocument4 pagesFiltersESRANo ratings yet

- Cebu Pacific Print Itinerary Randale PDFDocument5 pagesCebu Pacific Print Itinerary Randale PDFRhyngelNo ratings yet

- 5FG10 30, 5FD10 30 Inspection&AdjustmentDocument89 pages5FG10 30, 5FD10 30 Inspection&AdjustmentSuharto Zuhri100% (2)

- 铖通 562件 BCANC23003082Document4 pages铖通 562件 BCANC23003082Thar NgeNo ratings yet

- Ushio ReinetsuDocument1 pageUshio Reinetsuironite100% (2)

- 50TPD Soybean Oil Batch Type Solvent Extraction PlantDocument4 pages50TPD Soybean Oil Batch Type Solvent Extraction PlantKenan KardasNo ratings yet

- 250ffmcrrcgl1 (Alimentacion A Ciclones)Document8 pages250ffmcrrcgl1 (Alimentacion A Ciclones)Adrian PeraltaNo ratings yet

- International Maritime Solid Bulk Cargoes (IMSBC) CodeDocument18 pagesInternational Maritime Solid Bulk Cargoes (IMSBC) CodeJasper Abrantes100% (1)

- Daftar Gear Motor MAS - R0 (IOLA)Document1 pageDaftar Gear Motor MAS - R0 (IOLA)yptd9nyhntNo ratings yet

- Data Gearmotor Gearbox DMILDocument1 pageData Gearmotor Gearbox DMILDedi Arisman SaputraNo ratings yet

- Electrical Matrial Purchasing ListDocument9 pagesElectrical Matrial Purchasing ListBilla PraveenNo ratings yet

- Revised ListDocument10 pagesRevised List5paisaNo ratings yet

- APPMS Maintenance 2024Document12 pagesAPPMS Maintenance 2024EdwardNo ratings yet

- 11.electric Motor DetailDocument3 pages11.electric Motor Detailrp63337651No ratings yet

- Ies-Industrial Engineering Services: Ultrasonic Thickness Test ReportDocument3 pagesIes-Industrial Engineering Services: Ultrasonic Thickness Test ReportMD Shadikul Huq ShezanNo ratings yet

- Green Machine Parts Manual 1900EDocument24 pagesGreen Machine Parts Manual 1900Ekhans.martinNo ratings yet

- Etansare PompaDocument16 pagesEtansare PompaGeneraltrustargesNo ratings yet

- Contents - V: DimensionsDocument18 pagesContents - V: DimensionspepanlopesNo ratings yet

- Sistema Turbo CargadorDocument3 pagesSistema Turbo CargadorRamón ManglesNo ratings yet

- Data Motor Spare Di Gudang Sparepart 1-1Document3 pagesData Motor Spare Di Gudang Sparepart 1-1anfasa91No ratings yet

- Lamps And Lanterns 井电: Parts List 8-A)Document7 pagesLamps And Lanterns 井电: Parts List 8-A)waleedNo ratings yet

- Despiece Aspirador WVD900-2Document7 pagesDespiece Aspirador WVD900-2pmunozNo ratings yet

- Water Manifold WM5021-05Document2 pagesWater Manifold WM5021-05Dat TranNo ratings yet

- Paginas 4,46,47 TP-6395 10 - 20REOZD KOHLER Parts CatalogDocument3 pagesPaginas 4,46,47 TP-6395 10 - 20REOZD KOHLER Parts CatalogGalindez JoséNo ratings yet

- 2019 Chevrolet Blazer X3 (LGX) PDFDocument6 pages2019 Chevrolet Blazer X3 (LGX) PDFPANHA MENNo ratings yet

- Bearing ListDocument1 pageBearing ListPANKAJ JAISWALNo ratings yet

- 14 Bolt Axle Parts List1Document1 page14 Bolt Axle Parts List1api-36964180% (1)

- Requisition No. ITEM No. Description: Automiser Shaft SS ATM 160Document2 pagesRequisition No. ITEM No. Description: Automiser Shaft SS ATM 160Vaibhav KapadiNo ratings yet

- 7 - Basic Engine Conjunto BalancinesDocument3 pages7 - Basic Engine Conjunto BalancinesMARIO DEL PINO MUÑOZNo ratings yet

- AKAPPDocument6 pagesAKAPPmuhamad.badar9285No ratings yet

- Simplex Infrastructures LTD List of Equipment Available For HireDocument1 pageSimplex Infrastructures LTD List of Equipment Available For HireSurajPandeyNo ratings yet

- Motors Connecting Loads Update On 04.03.2016Document4 pagesMotors Connecting Loads Update On 04.03.2016Durgesh MauryaNo ratings yet

- Parts Catalog - Option DetailDocument3 pagesParts Catalog - Option DetailChardy Jarith Piragua Alvarado100% (1)

- Interlock Protection DiaryDocument79 pagesInterlock Protection Diaryv.aravindharajan7No ratings yet

- Radiador y Sus Partes, Motor Diesel 504BDTDocument3 pagesRadiador y Sus Partes, Motor Diesel 504BDTRamón ManglesNo ratings yet

- Cantidad de Aceite X MarcaDocument1 pageCantidad de Aceite X MarcarodriguezalejandrotucNo ratings yet

- Itams ListDocument32,767 pagesItams Listmangesh guptaNo ratings yet

- List Motor 30-07-15 - Update 2Document61 pagesList Motor 30-07-15 - Update 2heru satriaNo ratings yet

- Kuhne K70D-25DDocument2 pagesKuhne K70D-25DAlkis PapadasNo ratings yet

- Manpower Schedule FL-8 Post O2 & BS DD Washer ProjectDocument2 pagesManpower Schedule FL-8 Post O2 & BS DD Washer ProjectAnonymous VZdnU3l265No ratings yet

- 1.5 SQ - MM 3 Core Cu - Armoud Cable: Total LengthDocument4 pages1.5 SQ - MM 3 Core Cu - Armoud Cable: Total LengthVikram Singh BisthNo ratings yet

- Update Close FindingDocument5 pagesUpdate Close FindingRahmad DaniNo ratings yet

- New Plant Split MEP ADocument1 pageNew Plant Split MEP AHEMANT RAMJINo ratings yet

- FiltersDocument4 pagesFiltersESRANo ratings yet

- Mục 145,146,147,148,149,150,153 (Phần xupap)Document2 pagesMục 145,146,147,148,149,150,153 (Phần xupap)Trường Bửu TrầnNo ratings yet

- Vac10004 SF01Document8 pagesVac10004 SF01Jim JonesjrNo ratings yet

- DMP 230224Document1 pageDMP 230224Ali JafferyNo ratings yet

- Shah Bhogilal Jethalal & Bros. Shah Bhogilal Jethalal & BrosDocument1 pageShah Bhogilal Jethalal & Bros. Shah Bhogilal Jethalal & BrosMeet JaniNo ratings yet

- Parts Catalog - Option Detail: Option Group Graphic Film Card Date FA5025-01 08.03 Fa500gj E 27-MAY-88 Engines G28, V28Document2 pagesParts Catalog - Option Detail: Option Group Graphic Film Card Date FA5025-01 08.03 Fa500gj E 27-MAY-88 Engines G28, V28Dat TranNo ratings yet

- Motor Diesel 186FD 9HP 10NOVIEMBRE2017Document18 pagesMotor Diesel 186FD 9HP 10NOVIEMBRE2017Poncho ConsueloNo ratings yet

- Part & Consumable ReportDocument6 pagesPart & Consumable ReportGuruh SuprayitnoNo ratings yet

- T-SB-0143-10 MIL On DTC P261B or P261C Coolant Pump Control MalfunctionDocument3 pagesT-SB-0143-10 MIL On DTC P261B or P261C Coolant Pump Control MalfunctionHumberto LojanNo ratings yet

- Preliminary Design Report (Group 5)Document10 pagesPreliminary Design Report (Group 5)Shubhankit MohanNo ratings yet

- TirupurDocument6 pagesTirupursaravana0210No ratings yet

- PNR UffiqsDocument1 pagePNR UffiqsNsonkwa AsabaNo ratings yet

- Aircraft StabilityDocument5 pagesAircraft StabilityvenkateshNo ratings yet

- Pavely Adel RofaelDocument1 pagePavely Adel RofaelPavelyNo ratings yet

- 1 The Seller's ObligationsDocument2 pages1 The Seller's ObligationsNguyễn Quốc QuangNo ratings yet

- Nissan ApplicationDocument2 pagesNissan ApplicationmisternikiNo ratings yet

- The Role of Leadership On Employee Performance in Singapore AirlinesDocument42 pagesThe Role of Leadership On Employee Performance in Singapore Airlineskeshav sabooNo ratings yet

- Plan & Development Commission - TOD - 15.5.15Document17 pagesPlan & Development Commission - TOD - 15.5.15Jaspergroup 15No ratings yet

- Esquematico 512-812-12v Lite v1 PDFDocument1 pageEsquematico 512-812-12v Lite v1 PDFzeljkogrNo ratings yet

- 07 Wiring Sprinter 2500Document72 pages07 Wiring Sprinter 2500wladwolfNo ratings yet

- Linear DiffuserDocument52 pagesLinear Diffusermohamed adelNo ratings yet

- Bus TimingsDocument10 pagesBus TimingsGOVINDHARAJU PALANINo ratings yet

- List of Chennai City Pincode (Madras Postal Code / Zip Code)Document7 pagesList of Chennai City Pincode (Madras Postal Code / Zip Code)selvamNo ratings yet

- UD PPT 2Document43 pagesUD PPT 2Vidhisha Bhargava100% (2)

- Railway Reservation FormDocument1 pageRailway Reservation Formapi-26893185100% (4)

- FF2021-46 Traffic Congestion in Metro ManilaDocument2 pagesFF2021-46 Traffic Congestion in Metro ManilaJohn Steven GanitanoNo ratings yet