Professional Documents

Culture Documents

Dfls1200: Powerdi 123

Uploaded by

skyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dfls1200: Powerdi 123

Uploaded by

skyCopyright:

Available Formats

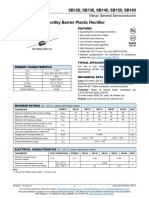

DFLS1200

1.0A HIGH VOLTAGE SCHOTTKY BARRIER RECTIFIER

PowerDI®123

Please click here to visit our online spice models database.

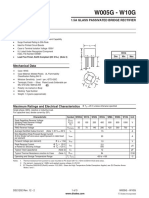

Features Mechanical Data

• •

®

Guard Ring Die Construction for Transient Protection Case: PowerDI 123

• Low Power Loss, High Efficiency • Case Material: Molded Plastic, "Green" Molding Compound.

• Patented Interlocking Clip Design for High Surge Current UL Flammability Classification Rating 94V-0

Capacity • Moisture Sensitivity: Level 1 per J-STD-020D

• Lead Free Finish, RoHS Compliant (Note 4) • Terminal Connections: Cathode Band

• "Green" Molding Compound (No Br, Sb) • Terminals: Finish – Matte Tin annealed over Copper Leadframe.

• Qualified to AEC-Q101 Standards for High Reliability Solderable per MIL-STD-202, Method 208

• Marking Information: See Page 2

• Ordering Information: See Page 2

• Weight: 0.01 grams (approximate)

Top View

Maximum Ratings @TA = 25°C unless otherwise specified

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitance load, derate current by 20%.

Characteristic Symbol Value Unit

Peak Repetitive Reverse Voltage VRRM

Working Peak Reverse Voltage VRWM 200 V

DC Blocking Voltage VR

RMS Reverse Voltage VR(RMS) 141 V

Average Forward Current IF(AV) 1.0 A

Non-Repetitive Peak Forward Surge Current 8.3ms

IFSM 40 A

Single Half Sine-Wave Superimposed on Rated Load

Thermal Characteristics

Characteristic Symbol Typ Max Unit

Thermal Resistance Junction to Ambient (Note 1) RθJA 132 ⎯ °C/W

Thermal Resistance Junction to Soldering Point (Note 2) RθJS ⎯ 7 °C/W

Operating and Storage Temperature Range TJ, TSTG -65 to +175 °C

Electrical Characteristics @TA = 25°C unless otherwise specified

Characteristic Symbol Min Typ Max Unit Test Condition

Reverse Breakdown Voltage (Note 3) V(BR)R 200 ⎯ ⎯ V IR = 8μA

Forward Voltage VF ⎯ ⎯ 0.85 V IF = 1.0A

Leakage Current (Note 3) IR ⎯ ⎯ 2 μA VR = 200V, TA = 25°C

Total Capacitance CT ⎯ 23 ⎯ pF VR = 5VDC, f = 1MHz

Notes: 1. Part mounted on FR-4 board with 2 oz., minimum recommended copper pad layout, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf. TA = 25°C

2. Theoretical RθJS calculated from the top center of the die straight down to the PCB/cathode tab solder junction.

3. Short duration pulse test used to minimize self-heating effect.

4. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied, see EU Directive 2002/95/EC Annex Notes.

PowerDI is a registered trademark of Diodes Incorporated.

DFLS1200 1 of 3 October 2008

Document number: DS30628 Rev. 6 - 2 www.diodes.com © Diodes Incorporated

DFLS1200

IF, INSTANTANEOUS FORWARD CURRENT (A) 10

0.1

0.01

0.001

0.0001

0 0.2 0.4 0.6 0.8 1 1.2 1.4 0 20 40 60 80 100 120 140 160 180 200

VF, INSTANTANEOUS FORWARD VOLTAGE (V)

VR, INSTANTANEOUS REVERSE VOLTAGE (V)

Fig. 1, Typical Forward Characteristics

Fig. 2, Typical Reverse Characteristics

IF(AV), AVERAGE FORWARD CURRENT (A)

1.8

CT, TOTAL CAPACITANCE (pF)

1.6

1.4

1.2

0.8

0.6

0.4

0.2

0

0 5 10 15 20 0 25 50 75 100 125 150 175 200

VR, DC REVERSE VOLTAGE (V)

TA, AMBIENT TEMPERATURE (ºC)

Fig. 3, Typical Total Capacitance vs. Reverse Voltage

Fig. 4, Forward Current Derating Curve

Ordering Information (Note 5)

Part Number Case Packaging

®

DFLS1200-7 PowerDI 123 3000/Tape & Reel

Notes: 5. For packaging details, go to our website at http://www.diodes.com/datasheets/ap02007.pdf.

Marking Information

F08 = Product Type Marking Code

YM = Date Code Marking

YM

F08 Y = Year (ex: R = 2004)

M = Month (ex: 9 = September)

Date Code Key

Year 2004 2005 2006 2007 2008 2009 2010 2011 2012

Code R S T U V W X Y Z

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Code 1 2 3 4 5 6 7 8 9 O N D

PowerDI is a registered trademark of Diodes Incorporated.

DFLS1200 2 of 3 October 2008

Document number: DS30628 Rev. 6 - 2 www.diodes.com © Diodes Incorporated

DFLS1200

Package Outline Dimensions

B

®

C E PowerDI 123

Dim Min Max Typ

A 3.50 3.90 3.70

B 2.60 3.00 2.80

C 1.63 1.93 1.78

D 0.93 1.00 0.98

D

E 0.85 1.25 1.00

H

H 0.15 0.25 0.20

L 0.55 0.75 0.65

L L1

L1 1.80 2.20 2.00

L2 0.95 1.25 1.10

All Dimensions in mm

E L2

Suggested Pad Layout

X1 G X2

Dimensions Value (in mm)

G 1.0

X1 2.2

X2 0.9

Y2 Y1 Y1 1.4

Y2 1.4

IMPORTANT NOTICE

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to any product herein. Diodes Incorporated does not assume any liability arising out of the application or use of any product

described herein; neither does it convey any license under its patent rights, nor the rights of others. The user of products in such applications shall

assume all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on our website,

harmless against all damages.

LIFE SUPPORT

Diodes Incorporated products are not authorized for use as critical components in life support devices or systems without the expressed written

approval of the President of Diodes Incorporated.

PowerDI is a registered trademark of Diodes Incorporated.

DFLS1200 3 of 3 October 2008

Document number: DS30628 Rev. 6 - 2 www.diodes.com © Diodes Incorporated

You might also like

- Configuring DDR in U-Boot Using QCVSDocument8 pagesConfiguring DDR in U-Boot Using QCVSm3y54mNo ratings yet

- Porting U-Boot and Linux To T4240Document11 pagesPorting U-Boot and Linux To T4240m3y54mNo ratings yet

- In-Service Monitoring of Lubricating Oil For Auxiliary Power Plant EquipmentDocument20 pagesIn-Service Monitoring of Lubricating Oil For Auxiliary Power Plant Equipmentمحمد نصیریNo ratings yet

- Diode 30 V1 ADocument4 pagesDiode 30 V1 AHjetoNo ratings yet

- SB160 Schottky Diode 60V 1a PDFDocument3 pagesSB160 Schottky Diode 60V 1a PDFdemostenessNo ratings yet

- SR5150 Won TopDocument4 pagesSR5150 Won TopRafael LehmkuhlNo ratings yet

- SBL2030PT, SBL2040PT: Vishay General SemiconductorDocument4 pagesSBL2030PT, SBL2040PT: Vishay General SemiconductortallertecuNo ratings yet

- 1.0A Surface Mount Schottky Barrier Rectifier Mechanical Data FeaturesDocument4 pages1.0A Surface Mount Schottky Barrier Rectifier Mechanical Data FeaturespeternewsNo ratings yet

- Ug2A, Ug2B, Ug2C, Ug2D: Vishay General SemiconductorDocument5 pagesUg2A, Ug2B, Ug2C, Ug2D: Vishay General SemiconductorKhan SahibNo ratings yet

- MBR3045PT Switchmode Power Rectifier: Schottky Barrier Rectifier 30 Amperes, 45 VoltsDocument4 pagesMBR3045PT Switchmode Power Rectifier: Schottky Barrier Rectifier 30 Amperes, 45 VoltsSaikumarNo ratings yet

- PB Features: 1.0A Surface Mount Schottky Barrier DiodeDocument4 pagesPB Features: 1.0A Surface Mount Schottky Barrier DiodeMomo MendozaNo ratings yet

- Ultra Low V 0.43 V at I 5 A: Vishay General SemiconductorDocument6 pagesUltra Low V 0.43 V at I 5 A: Vishay General SemiconductorInés DominguezNo ratings yet

- B230LA, B240A: Vishay General SemiconductorDocument4 pagesB230LA, B240A: Vishay General SemiconductorAli JalilaraziNo ratings yet

- Diods11056 1-2541694Document4 pagesDiods11056 1-2541694gustavo gonzalezNo ratings yet

- Media 3323329Document6 pagesMedia 3323329Daniel MesiNo ratings yet

- SBL3030PT, SBL3040PT: Vishay General SemiconductorDocument4 pagesSBL3030PT, SBL3040PT: Vishay General Semiconductorrammstein4445No ratings yet

- SB570 - SB5100: 5.0A Schottky Barrier RectifierDocument3 pagesSB570 - SB5100: 5.0A Schottky Barrier RectifierWalter FabianNo ratings yet

- SB380 SB3100Document4 pagesSB380 SB3100jrhappy systemsNo ratings yet

- Data Sheet: 200Mw Sod-523 Surface MountDocument4 pagesData Sheet: 200Mw Sod-523 Surface MountStuxnetNo ratings yet

- Datasheet - Semiconductor Diode - Sbr05m60blpDocument4 pagesDatasheet - Semiconductor Diode - Sbr05m60blpalvarito12No ratings yet

- 01 1n5400eDocument3 pages01 1n5400eVictor SantosNo ratings yet

- Vishay General Semiconductor: FeaturesDocument4 pagesVishay General Semiconductor: FeaturesAdah BumboneNo ratings yet

- MBRF20100CTG Switch-Mode Schottky Power RectifierDocument4 pagesMBRF20100CTG Switch-Mode Schottky Power RectifierAlf IanNo ratings yet

- Surface Mount Schottky Barrier RectifierDocument4 pagesSurface Mount Schottky Barrier RectifierDashuai WuNo ratings yet

- SR22 Won TopDocument4 pagesSR22 Won TopIgor Rocha PauloNo ratings yet

- 2N7002DDocument4 pages2N7002DCharles PNo ratings yet

- SM8A27T: High Temperature Stability and High Reliability ConditionsDocument5 pagesSM8A27T: High Temperature Stability and High Reliability ConditionsmohanNo ratings yet

- Datasheet Diode IN4002GDocument3 pagesDatasheet Diode IN4002GPoupée De SoieNo ratings yet

- MBR4035PT, MBR4045PT, MBR4050PT, MBR4060PT: Vishay General SemiconductorDocument4 pagesMBR4035PT, MBR4045PT, MBR4050PT, MBR4060PT: Vishay General SemiconductorRamzanNo ratings yet

- Her 151Document4 pagesHer 151Kenedy MolinaNo ratings yet

- w10g - Passivated Bridge RectifierDocument3 pagesw10g - Passivated Bridge Rectifierrudey18No ratings yet

- KBPC600 - KBPC610: FeaturesDocument3 pagesKBPC600 - KBPC610: FeaturesdanielaNo ratings yet

- SB120 Thru SB160: Vishay General SemiconductorDocument4 pagesSB120 Thru SB160: Vishay General SemiconductorrezaNo ratings yet

- B130L DiodesDocument5 pagesB130L DiodesJuan NunesNo ratings yet

- Ds 30483Document6 pagesDs 30483yoxan25808No ratings yet

- MBRB20200CTG, SBRB20200CTT4G Switchmode Power RectifierDocument4 pagesMBRB20200CTG, SBRB20200CTT4G Switchmode Power RectifierAndrey OliveiraNo ratings yet

- MUR460Document4 pagesMUR460Oussama MessaoudiNo ratings yet

- Ss 29Document5 pagesSs 29Yasmin HasnaNo ratings yet

- Datasheet SFP50N06 PDFDocument7 pagesDatasheet SFP50N06 PDFAdeniltonNo ratings yet

- DatasheetDocument5 pagesDatasheetStuxnetNo ratings yet

- Gs1A - Gs1M: PB FeaturesDocument4 pagesGs1A - Gs1M: PB Featuresمحمد المطريNo ratings yet

- By133 N0551 Rev.bDocument4 pagesBy133 N0551 Rev.bMohamed AmineNo ratings yet

- BAR43Document6 pagesBAR43maurosergiorovettaNo ratings yet

- SB5150 - SB5200: PB FeaturesDocument4 pagesSB5150 - SB5200: PB FeaturesSamerNo ratings yet

- FR301 - FR307: PB FeaturesDocument4 pagesFR301 - FR307: PB FeaturesfedewalshNo ratings yet

- Sdb1080pi KodenshiDocument5 pagesSdb1080pi KodenshighbtechabasNo ratings yet

- 1.0 Amp. at 40ºC 600 V To 1000 V: Current VoltageDocument4 pages1.0 Amp. at 40ºC 600 V To 1000 V: Current Voltagepopescu danielaNo ratings yet

- Us1A - Us1M: 1.0A Surface Mount Ultra-Fast RectifierDocument5 pagesUs1A - Us1M: 1.0A Surface Mount Ultra-Fast RectifierAbel GaunaNo ratings yet

- mbrp20035l TestDocument2 pagesmbrp20035l TestfrufruNo ratings yet

- U1B, U1C, U1D: Vishay General SemiconductorDocument5 pagesU1B, U1C, U1D: Vishay General SemiconductorLu CoeNo ratings yet

- SM8S10A Thru SM8S43A: High Temperature Stability and High Reliability ConditionsDocument5 pagesSM8S10A Thru SM8S43A: High Temperature Stability and High Reliability ConditionsSumitomo ExcavatorNo ratings yet

- Diodesincorporated 2w10g Datasheets 8452Document3 pagesDiodesincorporated 2w10g Datasheets 8452maximiliano gagliardiNo ratings yet

- Features: Lead Free Finish, Rohs Compliant (Note 3)Document3 pagesFeatures: Lead Free Finish, Rohs Compliant (Note 3)Därî Bööm GäńgNo ratings yet

- 1N5817,1N5818,1N5819 1N58:, 20 SeriesDocument4 pages1N5817,1N5818,1N5819 1N58:, 20 Seriespre freedaNo ratings yet

- SSB 43 LDocument5 pagesSSB 43 LRomanoNo ratings yet

- S2A, S2B, S2D, S2G, S2J, S2K, S2M: Vishay General SemiconductorDocument4 pagesS2A, S2B, S2D, S2G, S2J, S2K, S2M: Vishay General SemiconductorRevanNo ratings yet

- SB120, SB130, SB140, SB150, SB160: Vishay General SemiconductorDocument4 pagesSB120, SB130, SB140, SB150, SB160: Vishay General SemiconductorYaraNo ratings yet

- Sbyv26C: Vishay General SemiconductorDocument5 pagesSbyv26C: Vishay General SemiconductorSalomon ChoqueNo ratings yet

- D ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TDocument6 pagesD ft1208dj ft1208mj ft1204mj ft1204dj ft1208bj ft1208nj ft1204bj TMindSet MarcosNo ratings yet

- 1N4933/L - 1N4937/L: 1.0A Fast Recovery RectifierDocument3 pages1N4933/L - 1N4937/L: 1.0A Fast Recovery RectifierPablo AllosiaNo ratings yet

- Diode FastSwitching Ba157Document4 pagesDiode FastSwitching Ba157kumaran RNo ratings yet

- BA157Document4 pagesBA157ban4444No ratings yet

- Mastik: A Micro-Architectural Side-Channel Toolkit: The University of Adelaide and Data61, CSIRO Adelaide, AustraliaDocument6 pagesMastik: A Micro-Architectural Side-Channel Toolkit: The University of Adelaide and Data61, CSIRO Adelaide, Australiam3y54mNo ratings yet

- Buffer Overflow Vulnerability LabDocument12 pagesBuffer Overflow Vulnerability Labm3y54mNo ratings yet

- Ubuntu16 04 VM ManualDocument6 pagesUbuntu16 04 VM Manualm3y54mNo ratings yet

- Mipi I3C Basic Specification v1 1 1Document446 pagesMipi I3C Basic Specification v1 1 1m3y54mNo ratings yet

- TCP/IP Attack LabDocument8 pagesTCP/IP Attack Labm3y54mNo ratings yet

- Overview and Characteristics of Fan: Technical MaterialDocument10 pagesOverview and Characteristics of Fan: Technical Materialm3y54mNo ratings yet

- 5001 PDFDocument1 page5001 PDFm3y54mNo ratings yet

- PCB Material DE104 Laminate and Prepreg Datasheet - iMX6 Rex DBBDocument2 pagesPCB Material DE104 Laminate and Prepreg Datasheet - iMX6 Rex DBBm3y54mNo ratings yet

- Using CodeWarrior TAP With PDFDocument5 pagesUsing CodeWarrior TAP With PDFm3y54mNo ratings yet

- 4N25M, 4N26M, 4N27M, 4N28M, 4N35M, 4N36M, 4N37M 6-Pin General Purpose Phototransistor OptocouplersDocument13 pages4N25M, 4N26M, 4N27M, 4N28M, 4N35M, 4N36M, 4N37M 6-Pin General Purpose Phototransistor Optocouplersm3y54mNo ratings yet

- Series 218: Data Sheet Data SheetDocument2 pagesSeries 218: Data Sheet Data Sheetm3y54mNo ratings yet

- NXP Level-Shifting andDocument4 pagesNXP Level-Shifting andm3y54mNo ratings yet

- Mixed Signal Oscilloscope HMO3002 (HMO3004)Document3 pagesMixed Signal Oscilloscope HMO3002 (HMO3004)m3y54mNo ratings yet

- jszf36c512 - 1gx72pz DDR3 SDRAM RDIMM PDFDocument23 pagesjszf36c512 - 1gx72pz DDR3 SDRAM RDIMM PDFm3y54mNo ratings yet

- Device Tree Made EasyDocument22 pagesDevice Tree Made Easym3y54mNo ratings yet

- ADP1706 ADP1707 ADP1708: 1 A, Low Dropout, CMOS Linear RegulatorDocument20 pagesADP1706 ADP1707 ADP1708: 1 A, Low Dropout, CMOS Linear Regulatorm3y54mNo ratings yet

- Introduction To Device Trees PDFDocument34 pagesIntroduction To Device Trees PDFm3y54mNo ratings yet

- Nano Slo-Blo Fuse 449 SeriesDocument3 pagesNano Slo-Blo Fuse 449 Seriesm3y54mNo ratings yet

- Features and Applications of The P82B715 I2C-bus ExtenderDocument29 pagesFeatures and Applications of The P82B715 I2C-bus Extenderm3y54mNo ratings yet

- IDTQS3VH16233 Bus Switch PDFDocument8 pagesIDTQS3VH16233 Bus Switch PDFm3y54mNo ratings yet

- 8ge Port Switch With Integrated Ge Copper PhyDocument2 pages8ge Port Switch With Integrated Ge Copper Phym3y54mNo ratings yet

- Alibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputDocument2 pagesAlibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputrameshNo ratings yet

- c2Document145 pagesc2sathish kumarNo ratings yet

- Laporan Praktik Mesin ListrikDocument4 pagesLaporan Praktik Mesin ListrikFatimah azzahraNo ratings yet

- Earthing 1Document9 pagesEarthing 1renjithas2005No ratings yet

- Thermal Engineering Lectures1Document120 pagesThermal Engineering Lectures1romasokyNo ratings yet

- Ups DSP ManualsDocument46 pagesUps DSP ManualsPaulo GonçalvesNo ratings yet

- OTS60SX2 UG en-medidorRigidezDielectrica PDFDocument14 pagesOTS60SX2 UG en-medidorRigidezDielectrica PDFblancaNo ratings yet

- Mobile Data Center Solutions: High CubeDocument5 pagesMobile Data Center Solutions: High CuberezaNo ratings yet

- Sirius Timer Relay ManualDocument28 pagesSirius Timer Relay ManualVinoth MahendranNo ratings yet

- Batch 23 AdvtDocument6 pagesBatch 23 AdvtV. Krishna ThejaNo ratings yet

- PRD 104 Archivo Ingeteam Inc Wind Catalogue May 2013 Low ResDocument32 pagesPRD 104 Archivo Ingeteam Inc Wind Catalogue May 2013 Low ResAII2013No ratings yet

- Plug FlowDocument17 pagesPlug FlowNurshahirahSapianNo ratings yet

- Deputy Engineer ElectricalDocument3 pagesDeputy Engineer ElectricalSargi BeepumohanNo ratings yet

- Wave GuidesDocument141 pagesWave GuidesVamshi Krishna100% (1)

- Problem StatementDocument4 pagesProblem StatementShubham Agrawal100% (1)

- Heat ExchangerDocument11 pagesHeat ExchangerMangesh MandgeNo ratings yet

- JEE Main 2019 Detailed Analysis January Attempt Shift - 2 (09th January, 2019)Document8 pagesJEE Main 2019 Detailed Analysis January Attempt Shift - 2 (09th January, 2019)Resonance Eduventures100% (2)

- For ELECTRICAL TESTING LABORATORIES - The NABL (PDFDrive)Document122 pagesFor ELECTRICAL TESTING LABORATORIES - The NABL (PDFDrive)Mani Dhamodharan100% (1)

- Auto Tech Review - April 2018Document76 pagesAuto Tech Review - April 2018JUAN ANTONIO PanzaNo ratings yet

- DANIDA Call For Proposal 2023Document46 pagesDANIDA Call For Proposal 2023Kabera GodfreyNo ratings yet

- Planetophysical Function of Vacuum Domains (Dmitriev, Dyatlov)Document15 pagesPlanetophysical Function of Vacuum Domains (Dmitriev, Dyatlov)THE NIKOLA TESLA INSTITUTE100% (1)

- MCQ For Midsem - Ind - Inst.Document5 pagesMCQ For Midsem - Ind - Inst.Nirav ChauhanNo ratings yet

- Trimmer Ceramic CapDocument46 pagesTrimmer Ceramic CapWickna PratabanNo ratings yet

- TR ProtectionDocument23 pagesTR Protectionhafiz_hazreenNo ratings yet

- Energy Conversion and Transport: George G. Karady & Keith HolbertDocument44 pagesEnergy Conversion and Transport: George G. Karady & Keith HolberttechlabNo ratings yet

- 0705 Oil ReportDocument12 pages0705 Oil ReportAnonymous oUJSCyZNo ratings yet

- Comparison Used in IeltsDocument3 pagesComparison Used in IeltsDuyen HongNo ratings yet

- Service Manual: PKA-M60KA - TH PKA-M71KA - TH PKA-M100KA - TH Pka-M60Kal - TH Pka-M71Kal - TH PKA-M100KAL - THDocument40 pagesService Manual: PKA-M60KA - TH PKA-M71KA - TH PKA-M100KA - TH Pka-M60Kal - TH Pka-M71Kal - TH PKA-M100KAL - THcryogen11No ratings yet

- Indian Minerals Yearbook 2019: 58 EditionDocument32 pagesIndian Minerals Yearbook 2019: 58 EditionmohitNo ratings yet