Professional Documents

Culture Documents

Wcaim2059 en

Wcaim2059 en

Uploaded by

zoogle0 ratings0% found this document useful (0 votes)

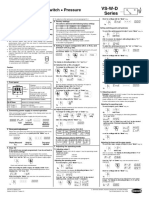

8 views2 pagesThis document provides calibration instructions for a DataFlo C Smart Controller. The instructions include:

1) Allowing the controller to stabilize at a minimum of 15 minutes before calibrating.

2) Setting the thermocouple type, temperature units (F or C), and upper and lower temperature limits.

3) Entering voltage display mode and adjusting the gain potentiometer to display the correct voltage values.

4) Completing calibration by locking in settings and returning to run mode.

Original Description:

Original Title

Wcaim2059 En

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides calibration instructions for a DataFlo C Smart Controller. The instructions include:

1) Allowing the controller to stabilize at a minimum of 15 minutes before calibrating.

2) Setting the thermocouple type, temperature units (F or C), and upper and lower temperature limits.

3) Entering voltage display mode and adjusting the gain potentiometer to display the correct voltage values.

4) Completing calibration by locking in settings and returning to run mode.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesWcaim2059 en

Wcaim2059 en

Uploaded by

zoogleThis document provides calibration instructions for a DataFlo C Smart Controller. The instructions include:

1) Allowing the controller to stabilize at a minimum of 15 minutes before calibrating.

2) Setting the thermocouple type, temperature units (F or C), and upper and lower temperature limits.

3) Entering voltage display mode and adjusting the gain potentiometer to display the correct voltage values.

4) Completing calibration by locking in settings and returning to run mode.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

allowed to temperature stabilize for at least 15 minutes prior

to calibrating. The minimum allowable temperature span is

NOTE: Do not adjust the gain potentiometer in this step. Quick tap

the “SEL” key to lock in the lower limit voltage.

DataFlo C

b.

100°C (212°F).

Simultaneously press and release the “SEL” and “UP” keys

19. Quick tap the “DN” key. Display will flash between “Cyt” and a cycle

time reading.

Smart Controller

to change the thermocouple type. When “SEL” and “UP” are FCD WCAIM2059-00 (Part 08943) Calibration Instructions

20. Simultaneously press and release the “SEL” and “UP” keys. Actua-

pressed, the type will begin flashing. Pressing the “UP” or “DN”

tor will automatically close and will then open to measure cycle

key will change the display to another type. When the correct

time, displaying “PoC” at the clockwise position and “PoCC” at the

value is flashing, quick tap “SEL” to lock in the selection. 1. Remove cover and apply appropriate voltage to terminals 1 (neutral

counterclockwise position.

or negative) and 2 (hot or positive).

c. Simultaneously press and release the “SEL” and “UP” keys

Calibration is now complete. Press and hold “SEL” key for two seconds.

to change the temperature units. When “SEL” and “UP” are 2. Connect setpoint and process input sources to terminal strip per

Controller returns to run mode.

pressed, the units will begin flashing. Pressing the “UP” or appropriate wiring diagram.

“DN” key will change the units between degrees Fahrenheit 3. The dislay should be flashing between “Pr:1” and a number.

and Celsius. When the correct units are flashing, quick tap

4. Simultaneously press and hold the “SEL” and “DN” keys for three

“SEL” to lock in the selection.

seconds. “CAL” will be displayed for two seconds, and the security

d. Simultaneously press and release the “SEL” and “UP” keys to code will be checked. If the required security code is not zero

change the temperature range upper limit. When “SEL” and (“0000”), the display will begin alternating between “CodE” and

“UP” are pressed, the upper limit will begin flashing. Pressing “0000”.

the “UP” or “DN” key will change the upper limit to another

If the required code is zero, it will not need to be entered, i.e., it will

value. When the correct range value is flashing, quick tap

be bypassed and the display will automatically flash “SEtL”. In that

“SEL” to lock in the selection. The upper limit of the range will

case, skip to paragraph 8.

not be able to be set below 100°C (250°F).

5. Enter the security code, if necessary, as follows. (If the code is

e. Simultaneously press and release the “SEL and “UP” keys to

forgotten, the special number 4800 can be used to gain entry.)

enter the voltage display mode. Simulate the upper limit tem-

perature, and adjust the gain potentiometer on the module such 6. Quick tap “SEL” key once. First 0 will flash. Quick tap “UP” key

that the voltage is between 4.200 and 4.700 volts on the display. For more information about FLOWSERVE FLOW CONTROL

until you reach the code number. Quick tap the “DN” key once. The

Quick tap the “SEL” key to lock in the upper limit voltage. Flowserve Corporation, Worcester Actuation Systems second 0 will flash. Quick tap “UP” key until the next code number

visit www.flowserve.com or call 5114 Woodall Road is reached. Continue this procedure as needed for the remaining

f. The value given with this display is the lower temperature USA 1-800-225-6989.

P.O. Box 11318 code numbers. Quick tap “SEL” to accept code.

limit and is shown to remind the technician of the tem- © 2004 Flowserve Corporation, Lynchburg, VA 24506-1318

perature to use for the simulator. This value is fixed and not Irving, Texas, USA. Flowserve is Phone: 434-528-4400 7. Quick tap “DN” key. Display will flash between “SEtL” and a value.

a registered trademark of

programmable. Flowserve Corporation. Fax: 434-845-9736

g. Simultaneously press and release the “SEL” and “UP” keys to

enter the voltage display mode. Enter the lower limit tempera-

ture (either 0°C or 32°F) in the simulator. The resulting voltage

(Part 08943)

reading will be displayed. ��������������������������� FCD WCAIM2059-00 Printed in USA. ���������������������������

5

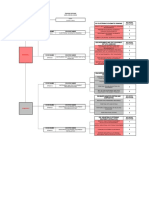

8. Simultaneously press and release “SEL” and “UP” keys; then adjust input signal to upper value of 20 mA. The voltage on the display the above process until the upper and lower voltages are within

setpoint signal to lower input value, e.g., 4 mA. Voltage reading should be greater than 3.000 volts. Quick tap “SEL” to lock in value. the stated limits. When completed, be sure that the simulator

should be less than 1 volt. Quick tap “SEL” to lock in value. is simulating the upper limit temperature. Quick tap the “SEL”

17. Calibrating Single Channel RTD Process Module

key to lock in the upper limit voltage.

9. Quick tap “DN” key. Display will flash “SEtU” and a value.

This procedure is followed only if a single channel RTD process

e. Simultaneously press and release “SEL” and “UP” keys to

10. Simultaneously press and release the “SEL” and “UP” keys; then module is used. This step calibrates both the lower and upper

change the temperature range lower limit. When “SEL” and

adjust setpoint signal to higher input value, e.g., 20 mA. The voltage process limits.

“UP” are pressed, the lower limit will begin flashing. Pressing

reading should be between 3.800 and 5.000 volts. Quick tap “SeL”

Quick tap “DN” to select either the “Pr1L” or “Pr1U” input param- the “UP” or “DN” keys will change the lower limit to another

to lock in value.

eter. Simultaneously press and release “SEL” and “UP” to begin value. When the correct range value is flashing, quick tap

11. Quick tap “DN” key. Display will flash between “PoC” and a number calibrating the parameter. “SEL” to lock in the selection. The lower limit of the range

between 0 and 5 volts. will not be able to be set to a value that is greater than 50°C

a. Attach a calibrated resistance type RTD siumulator to the

12. Simultaneously press and release the “SEL” and “UP” keys. Using process input. (100°F) below the upper limit, i.e., there must be at least 50°C

the “UP” or “DN” key, adjust so shaft is full clockwise. The display (100°F) between limits.

b. Simultaneously press and release “SEL” and “UP” keys to

should read between .200 and .400 volts. If not, rotate feedback f. Simultaneously press and release “SEL” and “UP” keys to

change the temperature units. When “SEL” and “UP” are

potentiometer face gear with your fingers. It is a friction fit. Quick enter the voltage display mode. Enter the lower limit tempera-

pressed, the units will begin flashing. Pressing the “UP” or

tap “SEL” to lock in reading. ture (either 0°C or 32°F) in the simulator. The resulting voltage

“DN” key will change the units between degrees Fahrenheit

13. Quick tap “DN” key. Display will flash between PoCC and the feed- and Celsius. When the correct units are flashing, quick tap reading will be displayed.

back voltage value. “SEL” to lock in the selection. NOTE: Do not adjust either the zero or span potentiometers in

14. Simultaneously press and release the “SEL” and “UP” keys. Using c. Simultaneoulsy press and release “SEL” and “UP” keys to this step.

the “UP” or “DN” key, adjust so shaft is full counterclockwise. The change the temperature range upper limit. When “SEL” and Quick tap the “SEL” key to lock in the lower limit voltage. Note

display should read greater than 3.000 volts. If not, recheck “PoC” “UP” are pressed, the upper limit will begin flashing. Pressing that zero adjustments are made in the procedure for the upper

and if correct, contact factory. Quick tap “SEL” to lock in reading. the “UP” or “DN” keys will change the upper limit to another limit. This step is just used to record the lower limit voltage.

value. When the correct range value is flashing, quick tap

15. Calibrating Analog Process #1 Lower Input Signal 18. Calibrating Thermocouple Process Module

“SEL” to lock in the selection. The upper limit of the range will

This procedure is followed only if an analog process module is used. not be able to be set to a value that is less than 50°C (100°F) This procedure is followed only if a thermocouple process module is

Quick tap “DN” to select the lower input parameter “Pr1L”. Simul- above the lower limit, i.e., there must be at least 50°C (100°F) used. This step calibrates both the lower and upper process limits.

taneously press and release “SEL” and “UP”, then adjust process between limits.

Quick tap “DN” to select either the “Pr1L” or “Pr1U” input param-

input signal to lower value of 4.0 mA. The voltage on the display d. Simultaneously press and release “SEL” and “UP” keys to eter. Simultaneously press and release “SEL” and “UP” to begin

should be less than 1 volt. Quick tap “SEL” to lock in this value. enter the voltage display mode. Simulate the upper limit calibrating the parameter.

16. Calibrating Analog Process #1 Upper Input Signal temperature, and adjust the span potentiometer on the module

a. Attach a calibrated thermocouple simulator to the process input.

such that the voltage is between 4.200 and 4.700 volts on the

This procedure is followed only if an analog process module is used. NOTE: For greatest accuracy, the thermocouple simulator

display. Change the RTD simulator to simulate the lower limit

Quick tap “DN” to select the upper input parameter “Pr1U”. Simul- temperature, and adjust the zero potentiometer on the module should be connected to the controller input module; and the

taneously press and release “SEL” and “UP”, then adjust process such that the voltage is between 0.200 and 0.800 volts. Repeat simulator and the controller board should be turned on and

2 3 4

You might also like

- Secadora Electrolux Manual de ServicioDocument8 pagesSecadora Electrolux Manual de Servicioorkys Tenorio100% (1)

- HY03WE-4 English Manual PDFDocument2 pagesHY03WE-4 English Manual PDFJesus Barriuso AmilloNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document12 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Mahmoud ElbakryNo ratings yet

- Electrical 336el 03Document48 pagesElectrical 336el 03rjan7pe100% (1)

- Elitech®: ETC-974 Operation InstructionsDocument2 pagesElitech®: ETC-974 Operation InstructionsRajko Naprta100% (1)

- Error Due To Diaphragm ConstraintDocument3 pagesError Due To Diaphragm ConstraintChandeshwor ShahNo ratings yet

- Mboard TshootingDocument29 pagesMboard TshootingDrift GeeNo ratings yet

- Eleaf Ikonn 220 User ManualDocument1 pageEleaf Ikonn 220 User ManualrozeNo ratings yet

- Kobastar K1 User ManualDocument10 pagesKobastar K1 User Manualgustian141No ratings yet

- Der-W:N: Panel DisplayDocument6 pagesDer-W:N: Panel DisplayHendra WidaryantoNo ratings yet

- sl70 Op Rev0Document2 pagessl70 Op Rev0danielNo ratings yet

- Eleaf ASTER User ManualDocument1 pageEleaf ASTER User ManualZdenko MahacekNo ratings yet

- Eleaf IStick Pico 25 User ManualDocument1 pageEleaf IStick Pico 25 User ManualAnonymous RF7puwp4XeNo ratings yet

- Tec 3000 Quick Reference GuideDocument57 pagesTec 3000 Quick Reference GuidemhdNo ratings yet

- EWPX 190 (.E) 6.97 IngDocument4 pagesEWPX 190 (.E) 6.97 Ingroby72No ratings yet

- Of The Detected ValueDocument2 pagesOf The Detected ValueCarlos Alberto Garavito DelgadoNo ratings yet

- Eazy v3 ManualDocument2 pagesEazy v3 ManualFernando Zambrano San MartínNo ratings yet

- Instruction Manual For Dso-270dDocument3 pagesInstruction Manual For Dso-270dmicrobiologia pacificNo ratings yet

- CAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToDocument2 pagesCAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToSomkiat K. DonNo ratings yet

- HL2027 (Luna) Only Cooling User Manual (2017.2.16)Document2 pagesHL2027 (Luna) Only Cooling User Manual (2017.2.16)carmen hernandezNo ratings yet

- Eleaf iKonn-220-User-ManualDocument2 pagesEleaf iKonn-220-User-ManualbrNo ratings yet

- STC-1000 Temperature Controller Operating Manual: or or orDocument1 pageSTC-1000 Temperature Controller Operating Manual: or or orziandNo ratings yet

- ManualDocument37 pagesManualJose MorenoNo ratings yet

- Istick Power Nano User ManualDocument1 pageIstick Power Nano User ManualGabriele LazzariNo ratings yet

- h3ct 5uDocument2 pagesh3ct 5uSampath KumarNo ratings yet

- HP11 Manual 4.0Document1 pageHP11 Manual 4.0Mauricio Plaza SalinasNo ratings yet

- Eleaf ASTER RT User ManualDocument1 pageEleaf ASTER RT User ManualTrish CarwellNo ratings yet

- Inst TFC6Document2 pagesInst TFC6Steve WuNo ratings yet

- 9IS44315 - ICPlus 902 - EN-IT-ES-DE-FR - 0716Document124 pages9IS44315 - ICPlus 902 - EN-IT-ES-DE-FR - 0716Nanda KrisbiantoNo ratings yet

- XK3118T4F Technical ManualDocument4 pagesXK3118T4F Technical ManualJosé TimanáNo ratings yet

- Keld KLT11Document1 pageKeld KLT11user userNo ratings yet

- Kenr9501kenr9501-01 - Sis C32 Emcp4.3Document12 pagesKenr9501kenr9501-01 - Sis C32 Emcp4.3Halit YalçınkayaNo ratings yet

- ATC300 Temperature Controller ATC300 Temperature ControllerDocument2 pagesATC300 Temperature Controller ATC300 Temperature ControllerA.ChildsNo ratings yet

- Manual Vacuostato Vs W DDocument3 pagesManual Vacuostato Vs W DHigor MoraesNo ratings yet

- DIGITAL DIMMING THERMOSTAT DAY & NIGHT + TIMER DTC-120 User ManualDocument2 pagesDIGITAL DIMMING THERMOSTAT DAY & NIGHT + TIMER DTC-120 User Manualthommcsi2013No ratings yet

- Digital Dimming Thermostat Day & Night + Timer DTC-120: User ManualDocument2 pagesDigital Dimming Thermostat Day & Night + Timer DTC-120: User Manualthommcsi2013No ratings yet

- HD BE Easy Installation ManualDocument18 pagesHD BE Easy Installation ManualHedefsan TradeNo ratings yet

- Simple Digital Thermostat Programming: Step 1Document3 pagesSimple Digital Thermostat Programming: Step 1Cristian Valencia LondoñoNo ratings yet

- Automatic Tension Controller Usage ManualDocument6 pagesAutomatic Tension Controller Usage Manualsatish09597No ratings yet

- NX1000A Rev M0 Apr 19 MergedDocument2 pagesNX1000A Rev M0 Apr 19 MergedAldi MaryansyahNo ratings yet

- DTA enDocument16 pagesDTA enNaladunNo ratings yet

- Fallas 4mx80hvec (Si12-102)Document5 pagesFallas 4mx80hvec (Si12-102)Daniel SiGlockNo ratings yet

- Carel Pjez Field GuideDocument2 pagesCarel Pjez Field GuideFrio GobalNo ratings yet

- HL2025 Series Touch Pad Thermostat User ManualDocument4 pagesHL2025 Series Touch Pad Thermostat User Manualbnx5dkq786No ratings yet

- 9400 Thermostat Manual - 110-1039Document11 pages9400 Thermostat Manual - 110-1039andrewh3No ratings yet

- Manual Termostato LC AuDocument22 pagesManual Termostato LC AumasterclimaxNo ratings yet

- STC1000 Termostat (WH7016Cdatasheet)Document5 pagesSTC1000 Termostat (WH7016Cdatasheet)Darko FrančeševićNo ratings yet

- HP46 InstDocument2 pagesHP46 InstmahmudNo ratings yet

- 3516C Caterpillar SchematicDocument12 pages3516C Caterpillar SchematicRAMON ARCENo ratings yet

- 20151210201922RC-112E User Manual220v10Document2 pages20151210201922RC-112E User Manual220v10Anonymous ZLmk6mPPnNo ratings yet

- X Series With Advance Micro and Tier 4i Engine Trouble Codes DiagnosisDocument2 pagesX Series With Advance Micro and Tier 4i Engine Trouble Codes DiagnosisRafael Solares100% (1)

- Digital Relay E1200 PDFDocument5 pagesDigital Relay E1200 PDFMisdehRasmanNo ratings yet

- Xwa11v v8 2 01-3110Document8 pagesXwa11v v8 2 01-3110lopez IvánNo ratings yet

- ALC-A Operating ManualDocument6 pagesALC-A Operating ManualThangNo ratings yet

- Ir-Gun-S: Thermometer Operating InstructionsDocument2 pagesIr-Gun-S: Thermometer Operating InstructionsRamadhan FebriNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document8 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768dinny blanco rojasNo ratings yet

- Ekc 102 Rs8dy302Document12 pagesEkc 102 Rs8dy302alphyjayemilianoNo ratings yet

- Temperature CalibrationDocument3 pagesTemperature Calibrationmoh_ichwanuddinNo ratings yet

- Faqe7073ka0 Secadora FrigidaireDocument8 pagesFaqe7073ka0 Secadora FrigidaireVasti Diaz AguilarNo ratings yet

- TR EC Single Stage Temperaure Controller Instructions 6 19Document1 pageTR EC Single Stage Temperaure Controller Instructions 6 19ensipeNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- 01 Class VI Implementation Manual For UIC Program Directors (2018)Document212 pages01 Class VI Implementation Manual For UIC Program Directors (2018)Stephan Lori MabungaNo ratings yet

- Producing Vibrato Naturally: How To Sing VibratoDocument4 pagesProducing Vibrato Naturally: How To Sing VibratoMarilyn MastilleroNo ratings yet

- Training Text: Lx-Mid SpecificationDocument55 pagesTraining Text: Lx-Mid SpecificationЮрий КременскийNo ratings yet

- R. A. Rosenbaum, G. P. Johnson - Calculus - Basic Concepts and Applications-Cambridge University Press (1984)Document439 pagesR. A. Rosenbaum, G. P. Johnson - Calculus - Basic Concepts and Applications-Cambridge University Press (1984)Junk HitmanNo ratings yet

- Module 2 HomeworkDocument4 pagesModule 2 HomeworkCj LinceNo ratings yet

- Customer Relationship Management: Nestle)Document18 pagesCustomer Relationship Management: Nestle)Nitin KherajmalaniNo ratings yet

- Achieving High YieldsDocument34 pagesAchieving High YieldsAciNo ratings yet

- Hibon NX Serisi Blover Katalogu - IngilizceDocument8 pagesHibon NX Serisi Blover Katalogu - IngilizceDocu CenterNo ratings yet

- Fault Tolerant CAN Bus Control SystemImplemented Into FPGADocument5 pagesFault Tolerant CAN Bus Control SystemImplemented Into FPGAOmer TariqNo ratings yet

- CLW - 3-Phase Loco - Jan'2020 To Jun'2020Document86 pagesCLW - 3-Phase Loco - Jan'2020 To Jun'2020sumitshyamal0% (1)

- Biodiversity in MalaysiaDocument36 pagesBiodiversity in MalaysiaJu' NanieNo ratings yet

- MidtermDocument8 pagesMidtermAedrian PuspusNo ratings yet

- 5.TRAINING PATHWAY TAHAP 2&3 BaruDocument2 pages5.TRAINING PATHWAY TAHAP 2&3 Baruainon mismanNo ratings yet

- David Jay Brown, Rebecca McClen Novick - Mavericks of The Mind - Conversations With Terence McKennaDocument107 pagesDavid Jay Brown, Rebecca McClen Novick - Mavericks of The Mind - Conversations With Terence McKennaYaju Dev MisraNo ratings yet

- Compressibility of SoilDocument34 pagesCompressibility of SoilCamille LardizabalNo ratings yet

- MMMDocument6 pagesMMMAbdelkader DraïNo ratings yet

- Indus Valley CivilizationDocument14 pagesIndus Valley CivilizationRiya RoyNo ratings yet

- Plunger and Barrel WebDocument2 pagesPlunger and Barrel WebTanishq ShettyNo ratings yet

- Food and Nutrition PPT TANMAYDocument12 pagesFood and Nutrition PPT TANMAYTanmay SinghalNo ratings yet

- Adsorption at Solid InterfaceDocument4 pagesAdsorption at Solid InterfaceVishu DawarNo ratings yet

- VMware HA Deployment Guide Esri ArcGIS Server 10.1Document28 pagesVMware HA Deployment Guide Esri ArcGIS Server 10.1Willy FilccoNo ratings yet

- Wide Belt Sanding Machines SANDTEQ W 300 700 en PDFDocument48 pagesWide Belt Sanding Machines SANDTEQ W 300 700 en PDFMesara Kod KokijaNo ratings yet

- Size Gen Set 0172610SBYDocument32 pagesSize Gen Set 0172610SBYrabiem100% (1)

- PH VS ChinaDocument5 pagesPH VS ChinaPatricia BautistaNo ratings yet

- Joe Cell ConstructionDocument11 pagesJoe Cell ConstructionNico Neubauer100% (3)

- Bayesian Structural Time Series ModelsDocument100 pagesBayesian Structural Time Series ModelsClaudyaNo ratings yet

- 10 1016@j Compgeo 2012 07 011Document5 pages10 1016@j Compgeo 2012 07 011MohamedNo ratings yet

- Powerrex BulletPro-BP40M-2-post-clear-floor-lift-4-ton-240V-user-manualDocument18 pagesPowerrex BulletPro-BP40M-2-post-clear-floor-lift-4-ton-240V-user-manualCykhong KhongNo ratings yet