Professional Documents

Culture Documents

Modeling and Second Law Based Optimization of Plate Fin and Tube Heatexchanger Using Mopso 2168 9873.1000118

Uploaded by

THE SEZARCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modeling and Second Law Based Optimization of Plate Fin and Tube Heatexchanger Using Mopso 2168 9873.1000118

Uploaded by

THE SEZARCopyright:

Available Formats

Journal of Applied

c

d Me hanica

lie

p Nejad et al., J Appl Mech Eng 2013, 2:2

lE

urnal of Ap

ngin ing

DOI: 10.4172/2168-9873.1000118

Mechanical Engineering

eer

Jo

ISSN: 2168-9873

Research Article Open Access

Modeling and Second Law Based Optimization of Plate Fin and Tube Heat

Exchanger Using MOPSO

Ehsan Khorasani Nejad1, Mohsen Hajabdollahi2 and Hassan Hajabdollahi3*

1

Department of Mechanical Engineering, Behbahan Branch, Islamic Azad University, Behbahan, Iran

2

Department of Computer Engineering, University of Isfahan, Isfahan, Iran

3

Department of Mechanical Engineering, Vali-e-Asr University of Rafsanjan,Rafsanjan, Iran

Abstract

In the present study, a comprehensive thermal modeling and optimal design of plain Fin-and-Tube Heat Ex-

changer (FTHE) is performed. Hence, method is applied to estimate the heat exchanger pressure drop and effec-

tiveness. The design parameters of this scientific study are selected as: longitudinal pitch, transversal pitch, fin pitch,

number of tube pass, tube diameter, cold stream flow length, no-flow length and hot stream flow length. In addition,

Multi Objective Particle Swarm Optimization (MOPSO) is applied to obtain the minimum number of entropy genera-

tion units and total annual cost (sum of investment and operation costs) as two objective functions, simultaneously.

The results of optimal designs are a set of multiple optimum solutions, called ‘Pareto optimal solutions’. It reveals

that any geometrical changes which decrease the number of entropy generation units lead to an increase in the

total annual cost and vice versa. Moreover, for prediction of the optimal design of the FTHE, an equation for number

of entropy generation units versus the total annual cost is derived for the Pareto front. Furthermore, the sensitivity

analysis of change in optimum number of entropy generation units and total annual cost with changes in design

parameters of the fin tube heat exchanger is also performed in detail.

Keywords: Fin and tube heat exchanger; Number of entropy n exponent of nonlinear increase with area increase

generation units; Annual cost; Objective function; MOPSO Nu nusselt number (-)

Nomenclature NP number of tube passes (-)

Aflow minimum free-flow area on the tube outside (m ) 2

Nr number of tube row (-)

Afront frontal area (m ) 2

NS number of entropy generation units

A heat transfer surface area(m ) 2

Nt total number of tube (-)

Pf fin pitch(m) Nl number of plate in L1 direction (-)

Cmax minimum of Ch and Cc (W/K) NTU number of transfer units (-)

Cmax maximum of Ch and Cc (W/K) Pr Prandtl number (-)

C heat capacity rate ratio (Cmax/Cmin)

*

r interest rate (-)

Cinv annual cost of investment ($/year) Re Reynolds number (-)

Cope annual cost of operation ($/year) St Stanton number (-)

Ctot total annual cost($/year) S rate of entropy generation (W/K)

di tube inside diameter (m) U overall heat transfer coefficient (W/M2 k)

do tube outside diameter (m) V heat exchanger volume (m3)

de fin collar outside diameter(m) Vt volumetric flow rate (m3/s)

Dh hydraulic diameter (m) Xl longitudinal pitch(m)

F friction factor (-)

*Corresponding author: Hassan Hajabdollahi, Department of Mechanical

G mass flux (kg/m2s)

Engineering, Vali-e-Asr University of Rafsanjan, Rafsanjan, Iran, E-mail:

h heat transfer coefficient (W/M2k) Hassan.Hajabdollahi@gmail.com

Received December 20, 2012; Accepted January 28, 2013; Published February

j Culburn number (-) 02, 2013

Kel price of electrical energy ($MWh-1) Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second

Law Based Optimization of Plate Fin and Tube Heat Exchanger Using MOPSO. J

L1 cold stream flow length (m) Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

L2 hot stream flow length (m) Copyright: © 2013 Nejad EK, et al. This is an open-access article distributed under

the terms of the Creative Commons Attribution License, which permits unrestricted

L3 no-flow length (m) use, distribution, and reproduction in any medium, provided the original author and

source are credited.

J Appl Mech Eng

ISSN:2168-9873 JAME, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 2 of 9

Xt transversal pitch (m) is widely used in many industrial power generation plants, chemical,

petrochemical, and petroleum industries. Fins or extended surface

y depreciation time (year)

elements are introduced to increase the heat transfer area [1]. Some of

Greek abbreviation commonly used fins are, wavy, offset strip, louver, perforated, and plain

fins [2]. Recently, evolutionary algorithms have received a lot of attention

δ fin thickness (m) as an optimization method particularly in heat exchanger design.

ε thermal effectiveness (-) Sanaye and Hajabdollahi applied NSGA-II and optimized the rotary

regenerator, plate fin and shell and tube heat exchangers [3-5]. Dincer et

λ nondimensional conduction parameter (-) al. obtained optimum cooling water temperature during condensation

τ hours of operation per year of saturated water vapor within a shell and tube condenser [6]. Hilbert

η s overall surface efficiency (-)

et al. also, used a multi objective optimization technique to maximize

the heat transfer rate and to minimize the pressure drop in a tube bank

η f fin efficiency (-) heat exchanger [7]. Xie et al. minimized the total volume as well as the

total annual cost of a compact heat exchanger by considering three

η compressor efficiency (-)

shape parameters as decision variables [8]. Wang et al. applied genetic

µ viscosity (pa.s) algorithm to optimize primary energy saving, annual total cost saving,

and carbon dioxide emission reduction [9]. Guo et al. employed genetic

V specific volume(M3/kg) algorithm to optimize the field synergy number which is defined as the

∆P pressure drop (Pa) indicator of the synergy between the velocity field and the heat flow

[10]. Sahin et al. optimized the design parameters of a heat exchanger

σ ratio between A flow and Afront ( Aflow /A front )

with rectangular fins by Taguchi experimental-design method [11].

Subscripts Doodman et al. minimized the total annual cost of air cooled heat

exchangers using global sensitivity analysis [12]. Foli et al. estimated

f fin the optimum geometric parameters of micro channels in micro heat

c cold exchangers by maximizing the heat transfer rate and minimizing the

pressure drop as two objective functions [13]. Liu and Cheng optimized

i inside a recuperator for the maximum heat transfer effectiveness as well as

In inlet minimum exchanger weight and pressure loss [14]. Gholap and Khan

also studied air cooled heat exchangers by minimizing the energy

o outside consumption of fans and material cost as two objective functions [15].

out outlet In this paper, it is aimed to first conduct a thermal modeling of a

ave average FTHE and later optimize this equipment by minimizing the number of

entropy generation units as well as minimizing the total annual cost,

h hot simultaneously. Particle swarm optimization technique is applied to

provide a set of the Pareto multiple optimum solutions. The sensitivity

tot total

analysis of change in optimum values of number of entropy generation

Introduction units and total annual cost with change in design parameters was

performed and the results are reported. In summary, the following are

Compact heat exchangers are characterized by a large heat transfer

the specific contributions of this paper to the area:

surface area per unit volume of the exchanger. Fin Tube Heat Exchanger

(FTHE) as shown in Figure 1, is a typical compact heat exchanger that Thermal modeling of a plain type fin tube heat exchanger

Applying multi-objective optimization for fin and tube heat

exchanger with number of entropy generation units and total annual

Xl/2 cost as two objectives using particle swarm optimization algorithm.

A

Xt/2 Selecting the longitudinal pitch, transversal pitch, fin pitch, number

C

of tube pass, tube diameter, cold stream flow length, no-flow length and

Xt B hot stream flow length as design parameters (decision variables).

Xl

B L3 Proposing a closed form equation for the total annual cost in term

d0 di of number of entropy generation units at the optimal design point.

Hot stream

Performing sensitivity analysis of change in objective functions

when the optimum design parameters vary and find the degree of each

parameter on objective functions conflicting.

Cold stream

L1

A Thermal modeling

L2

The ε − NTU method is applied here for predicting the heat

Figure 1: Typical plain fin and tube heat exchanger with staggered tube exchanger performance. The effectiveness of cross-flow heat exchanger

arrangement.

with both fluids unmixed is proposed as [16]:

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 3 of 9

ε = 1 − exp[−(1 + C * ) NTU ] × [ I 0 (2 NTU C * ) + c1 = 1.9 − 0.23ln Re dc

(1) c2 = −0.236 + ln Re dc

1 − C* ∞

C * I1 (2 NTU C * ) −

C*

∑ C*n /2 I n (2 NTU C * )]

c3 = −0.361 −

0.042 N r

+ 0.158ln[ N r ( p f / d c )0.41 ]

n=2

ln Re dc

Where is the modified Bessel function. Number of Transfer Units 0.076( X l / Dh )1.42

(11-a-i)

(NTU) and heat capacity ratio (C * ) are defined as follows [1]: c4 = −1.224 −

ln Re dc

0.058 N r

U o Atot , h c5 = −0.083 +

ln Re dc

NTU max = (2)

Cmin Re dc

c6 = −5.735 + 1.21ln

Nr

c7 = −0.764 + 0.739( X t / X l ) + 0.177( p f / dc ) − 0.00758 / N r

C*=Cmax /Cmin (3)

c8 = −15.689 + 64.021 / ln Re dc

Here, U o is the overall heat transfer coefficient based on fin side, c9 = 1.696 − 15.695 / ln Re dc

computed from:

The above equations are valid for 300 < Re < 20000 and for

1 (4) 6.9 ≤ d c ≤ 13.6 mm ,1.3 ≤ Dh ≤ 9.37 mm , 20.4 ≤ X t ≤ 31.8 mm , 12.7 ≤ X l ≤ 32 mm ,

Uo =

1 1 1.0 ≤ p f ≤ 8.7 mm and 1 ≤ N r ≤ 6 . The proposed correlations for Colburn

+

hhη s , h Ai ,c number and fanning friction factor are accurate within ± 15% [18].

(hcη s ,c )

Atot , h The Reynolds number and hydraulic diameter are defined as [18]:

The fouling resistance and wall conduction resistance have been Gd c

Re dc = (12)

assumed to be negligible. Hear the Ai ,c is the total heat transfer area µ

in inside of tube and Atot , h is outside total heat transfer surface area

where

including fins and tubes as follow:

d c = d o + 2δ (13)

Atot , h = A f + Ao,c (5)

and G is mass flux.

where A f and Ao,c are the heat transfer surface area of fins and tube

The heat transfer coefficient is defined as follow [1]:

outside respectively as follow [17]:

h = StGc p (14)

A f = 2 L1 / p f ( L2 × L3 − Nt × π d o2 / 4) (6)

where St is Stanton number defined as:

Ao,c = π d o Nt L1 − Nt × π d oδ ( N1 − 1) (7) j

St = 2/3

(15)

Pr

where Nt and Nl are the total tube number and the number of plate in

Furthermore, the pressure drop was also estimated from [1]:

L1 direction. h is the heat transfer coefficient, δ is the fin thickness and

L1, L2 and L3 are cold stream flow length, hot stream flow length and A v

no-flow length, respectively (Figure 1). ( )

∆P = G 2vin / 2 1 + σ 2 ( vout / vin − 1) + f tot ave

A flow vin

(16)

Also η s in Equation 4 is overall surface efficiency defined as [1]: where A flow minimum free-flow area on the tube outside.

Af The number of entropy generation units is defined as follows [19]:

ηs = 1 − (1 − η f ) (8) .

Atot , h S

NS = (17)

Cmax

and η f is efficiency of a single fin.

.

where S is the rate of entropy generation:

The Fanning factor f and Colburn factor j (respectively

representative of pressure drop and thermal performance) defined in .

S = ∆Sc + ∆Sh (18)

Equations (9) and (10) by Wang et al [18] for plain flat fins on staggered

tube banks as: and:

. T P

0.108Re −dc0.29 ( X t / X l )c1 ( p f / d c ) −1.084 ( p f / Dh ) −0.786 ( p f / X t )c2

for N r = 1 (9) ∆S = m c p ln out − R ln out (19)

j=

c Tin Pin

0.086 Re dc3 .N rc4 ( p f / d c )c5 ( p f / Dh )c6 ( p f / X t ) −0.93 for N r ≥ 2

Influence of longitudinal heat conduction

c

f = 0.0267 Re dc7 ( X t / X l )c8 ( p f / dc )c9 (10)

To evaluate the influence of heat conduction in the flow direction

either in the solid wall or in the fluid, the following approximation

where

for longitudinal conduction analysis has been also performed. Fluids

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 4 of 9

generally have a low thermal conductivity (liquid metal excepted), Velocity and position updating: The movement of the particle

but the wall conductivity may be quite high. Consequently, only wall- towards the optimum solution is governed by updating its position and

conduction effects will be considered in the following treatment. velocity attributes. The velocity and position update equations are given

The influence of longitudinal conduction is to reduce exchanger as [20]:

effectiveness for a given number of transfer units, and this reduction

may be quiet serious in exchangers with short flow lengths design for vki +1 = wvki + c1rand ( pi − xki ) + c2 rand ( pkg − xki ) (25)

high effectiveness values ( ε > 90% ) [1]. Assuming the temperature

difference δ T for the hot fluid, is of the same magnitude for the cold xki +1 = xki + vki +1 (26)

fluid (Cmin/Cmax ≈ 1), and also for the wall then the wall temperature

where i represents the ith particle in the population and k represents

gradient is δ T / L , with L being the flow length and the longitudinal

each iteration.

heat transfer by conduction is of the order [1]. If the wall cross-section

g

area for longitudinal conduction is designated Ak : The term pk specifies the best global solution obtained by the

i

swarm and p is the best position of each particle over time. In

δT

qcond ≈ kw Ak (20) addition w, c1 and c2 are the inertia weight, self confidence factor and

L swarm confidence factor respectively and rand is the random number

where Ak, is the wall cross-section area for longitudinal conduction and generated uniformly in the range [0-1].

kw, is the wall conduction coefficient. i

Best position of each particle ( p ): In MOPSOA the individual

The convection heat transfer rate is also given by energy-balance experience of the particle is captured, that corresponds to the best

considerations as: performance attained so far by it in its flight. Actually the present

solution is compared with the previous solutions, and it replaces the

qconv = Ccδ T = Chδ T (21) latter only if it dominates that solution. If neither of them is dominated

and then: by the other, then one of them is selected randomly [21].

g g

Best global position of swarm ( pk ): The term pk represents the

qcond ( kw / L )Ak ( kw / L ) A fr ( 1 − σ ) (22)

= = =λ best solution obtained by the swarm. Often the conflicting nature of the

qconv C Cmin multiple objectives involved in MOO problems makes the choice of a

single optimum solution difficult. To resolve this problem, the concept

where λ in equation 22, is the nondimensional conduction parameter. of non-dominance is used and an archive of non-dominated solutions is

g

The values of λ are computed for various optimal design points as maintained, from which a solution is picked up as the pk . The selection

g

presented in the case study. of the pk solution is done from the archive on the basis of the diversity

of the solutions. In MOPSOA the diversity measurement has been done

Particle Swarm for multi-objective optimization using a concept similar to the crowding-distance measure in [24].

Multi-objective optimization: A multi-objective problem consists Crowding distance: The standard crowding distance proposed by

of optimizing (i.e. minimizing or maximizing) several objectives Deb [24] is utilized, where the crowding distance of an individual is

simultaneously with a number of inequality or equality constraints. The the perimeter of the rectangle with its nearest neighbors at diagonally

problem can be formally written as follows: opposite corners. So, if two individuals have the same rank, each one

who has a larger crowding distance is better.

Find x = ( xi )∀i = 1, 2,..., N param such as

Historical Archive: The MOPSOA algorithm has been modified

fi ( x) minimized or maximized ∀i = 1, 2,..., N obj

to include an archive of the historically non-dominated individuals.

Subject to: Archive is used to update the data at each iteration.

g j ( x) = 0 ∀j = 1, 2,..., M , (23) Objective Functions, Design Parameters and

Constraints

hk ( x) ≤ 0 ∀k = 1, 2,..., K , (24) In this study, number of entropy generation units (defined in

Equation 17) and total annual cost are considered as two objective

where x is a vector containing Nparam design parameters, ( fi )i =1,...., Nobj functions. Total annual cost is includes investment cost (the annualized

cost of the heat transfer surface area) and operating cost of compressor/

are objective functions and Nobj is the number of objectives. Objective

pump to flow the fluid as follows [8]:

functions ( fi )i =1,...., Nobj return a vector containing the set of Nobj

values associated with the elementary objectives to be optimized Ctot = aCinv + Cope (27)

simultaneously. The concept of Particle Swarm Optimization (PSO) n

is inspired by the flocking behavior of the birds. It was first proposed Cinv = C A × Atot (28)

by Kennedy in 1995 [20]. Like evolutionary algorithms PSO is also

a population based heuristic, where the population of the potential ∆pVt ∆pVt

Cope = kelτ + kelτ (29)

solutions is called a swarm and each individual solution within the η c η h

swarm, is called a particle. There have been several recent attempts

Here CA and Kel are the heat exchanger investment cost per unit

to use PSO for Multi-Objective Optimization (MOO) [21-23]. This

surface area and the electricity unit cost respectively, n is a constant and

algorithm is called Multi-Objective Particle Swarm Optimization

Algorithm (MOPSOA) which is coupled with the objective functions

τ is the operation hours of the exchanger per year. ∆p , Vt and η are

pressure drop, volume flow rate and compressor efficiency, respectively.

developed in this study for optimization.

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 5 of 9

Also a is annual cost coefficient defined as:

x10-3

r 5

a= (30)

1 − (1 + r ) − y

4.5

where r and y are interest rate and depreciation time respectively. In

this study longitudinal pitch (Xl), transversal pitch (Xt), fin pitch (Pf), 4

number of tube pass (NP), outside tube diameter (do), cold stream

flow length (L1), no-flow length (L3) and hot stream flow length 3.5

(L2) were considered as eight design parameters. The constrains λ

are introduced to insure that the dc , Dh , X t , X l , p f and Nr are in the

3

range of 6.9 ≤ dc ≤ 13.6 mm , 1.3 ≤ Dh ≤ 9.37 mm , 20.4 ≤ X t ≤ 31.8 mm ,

12.7 ≤ X l ≤ 32 mm , 1.0 ≤ p f ≤ 8.7 mm , 2 ≤ N r ≤ 6 and 300< Re< 20000.

2.5

Case Study

In this part, our case study has been considered. Outlet gases from 2

0 100 200 300 400 500 600 700 800 900

the compressor with mass flow rate 2.5 kg/s and temperature 425 K Population

enters the fin tube pre-cooler heat exchanger. On the other hand, water

Figure 2: The distribution of numerical values of λ (the non-dimensional

with 3.2 kg/s and temperature 285 K flow in the other side. The FTHE heat conduction parameter) in the whole optimal output domain.

metal is made of stainless steel with thermal conductivity about kw=25

W/m.K. Also, the ratio of inside to outside tube diameter is taken to

be 0.8. Operating conditions and the cost function constant values are Variables Value

listed in Table 1. The thermophysical properties of air such as Prandtl Longitudinal pitch (mm) 22

number, viscosity and specific heat were considered as temperature Transversal pitch (mm) 25.4

dependent. Fin pitch (mm) 3.175

Outside tube diameter (mm) 10.2

Discussion and Results Fin thickness (mm) 0.33

Longitudinal heat conduction Reynolds number 1968

To quantify the effect of longitudinal heat conduction in comparison Table 2: Geometrical characteristic of plain fin and tube heat exchanger from

references [1].

with the convection heat transfer, the numerical values of λ (equation

22) were computed for kw=25 W/m.k for all optimum design cases as

Output variables Ref.[1] Present paper Difference (%)

is shown in Figure 2. It was found that the distribution of λ value in

Dh (mm) 3.632 3.368 -7.26

the whole optimal output domain show the numerical values less than

A flow / A front 0.534 0.495 -7.3

0.005 (0.5%). This shows that assuming the negligible conduction heat

transfer in our analysis in flow direction is acceptable for the studied Atot / V (m 2 / m3 ) 587 587.76 0.13

problem. 0.913 0.915 0.35

Ah / Atot

Verification of modeling and optimization results j 0.008 0.0091 13.75

0.0263 0.0299 13.68

To verify the modeling results, the simulation output were f

compared with the corresponding reported results given in reference

Table 3: The comparison of modeling output and the corresponding results from

[1]. The comparison of our modeling results and the corresponding reference [1].

values from reference [1], for the same input values listed in Table 2, are

given in Table 3. The results show that the difference percentage points Variables From To Change step

of two mentioned modeling output results are acceptable. Longitudinal pitch (mm) 12.7 32 1

Optimization results Transversal pitch (mm) 20.4 31.8 1

Fin pitch (mm) 1 8.7 1

To minimize the number of entropy generation units and the total Number of tube pass (-) 2 6 2

Outside tube diameter (mm) 7 10 1

Mass flow rate of hot flow 2.5

Cold stream flow length (m) 0.2 1 0.001

Mass flow rate of cold flow 3.2

No-flow length (m) 0.2 1 0.001

Inlet hot temperature 425

Hot stream flow length (m) 0.06 0.2 0.001

Inlet cold temperature 285

Table 4: The design parameters, their range of variation and their change step.

Inlet pressure (hot side) 250

Inlet pressure (cold side) 200

annual cost, eight design parameters including longitudinal pitch,

Price per unit area 85

transversal pitch, fin pitch, number of tube pass, tube diameter, cold

Exponent of nonlinear increase with area increase 0.6

stream flow length, no-flow length and hot stream flow length were

Hours of operation per year 5000

selected. Design parameters (decision variables) and the range of their

Price of electrical energy 25

variations are listed in Table 4. The number of iterations for finding the

Compressor or pump efficiency 0.65

global extremum in the whole searching domain was about1025. System

Table 1: The operating conditions of the FTHE (input data for the model). was optimized for depreciation time y = 12 years and interest rate The

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 6 of 9

The selection of a single optimum point from existing points on the

Pareto front needs a process of decision-making. In fact, this process is

500

mostly carried out based on engineering experiences and importance

A of each objective for decision makers. The process of final decision-

450

making in Figure 3 is usually performed with the aid of a hypothetical

point named as equilibrium point, that both objectives have their

Annual cost ($/year)

400

optimal values independent of the other objectives [25]. It is clear

350 B that it is impossible to have both objectives at their optimum point,

simultaneously. The equilibrium point is not a solution located on the

300 Pareto frontier. In this paper, LINMAP method was used to find the

C final optimum solution in Pareto front [25].

250 In the LINMAP method, each objective is non-dimensionalized

Ideal D

E

point using the following relation:

200

Fij

150 Fijn = (32)

1.6 1.8 2 2.2 2.4 2.6 m

NS x 10-3

2

∑ i =1( Fij )2

Figure 3: The distribution of Pareto-optimal points solutions using MOPSO. where i is the index for each point on the Pareto frontier, j is the index

for each objective in the objectives space and m denotes the number

A B C D E of points in the Pareto front. After non-dimensionalization of all

Number of entropy 1694×10-6 1739×10-6 1861×10-6 2064×10-6 2533×10-6 objectives, the distance of each solution on the Pareto frontier from

generated units the ideal point obtained. The closest point of Pareto frontier to the

Total Annual Cost 478.4 346.0 274.0 218.8 193.3 equilibrium point (design point D) might be considered as a desirable

($/year) final solution with the 0.002064 of number of entropy generation units

Table 5: The optimum values of number of entropy generation units and the total and 218.8 $/hour as total annual cost rate.

annual cost for the design points A to E in Pareto optimal front for input values

given in table 1. The distribution of variables for the optimal points on Pareto front

(Figure 3) is shown in Figures 4a to 4h. The lower and upper bounds

particle swarm optimization was performed for 500 iterations, using

of the variables are shown by dotted lines. The following points for the

100 particles, inertia weight of w=0.4, self confidence factor of c1=1.75

optimal variables in Figure 4 could be deduced:

and swarm confidence factor c2=1.8. The results for Pareto-optimal front

are shown in Figure 3, which clearly reveal the conflict between two i. The numerical values of the cold stream flow length and no flow

objectives, the number of entropy generation units and the total annual length have the values relatively distributed in its lower domain.

cost. Any geometrical change that decreases the number of entropy

generation units, leads to an increase in the total annual cost and vice ii. The other design parameters are almost constant for all optimum

versa. This shows the need for multi-objective optimization techniques cases.

in optimal design of a FTHE. It is shown in Figure 3, that the minimum Since the optimum values of two decision variables (cold stream

number of entropy generation units exists at design point A (0.001694), flow length and no flow length) have scattered distribution in their

while the total annual cost is the biggest at this point. On the other hand lower domains, one may predict that these two parameters have

the minimum total annual cost occurs at design point (193.3 $/year), important effects on the conflict between the number of entropy

with a biggest number of entropy generation units value (0.002533) at generation units and total annual cost. The other six design parameters

that point. Design point A is the optimal situation at which, number have no effect on the conflict between the two objective functions and

of entropy generation units is a single objective function while design improve both objective functions at a specific value. The variation of

point E is the optimum condition at which total annual cost is a single optimum value of number of entropy generation units with the total

objective function. annual cost for various values of optimum design parameters in design

The optimum values of two objectives for five typical points from point D (selected as final optimum design in Pareto front) are shown in

Figures 5a to 5h. The effect of design variables on objective functions

A to E (Pareto-optimal fronts) for input values are given in table 1 are

are investigated and explained as follows:

listed in table 5.

Cold stream flow length: Based on the information in Figure 5a,

To provide a useful tool for the optimal design of the FTHE, the

it is found that by increase in the cold stream flow length, number of

following equation for number of entropy generation units versus the

entropy generation units is increased continuously and annual cost

total annual cost was derived for the Pareto curve (Figure 3).

decreases. Therefore, this increment leads to conflicting behavior on

objective functions. The relatively scattering distribution of optimal

0.4425NS 3 − 37.171NS 2 − 1735 NS + 52040

Ctotal ($ / year ) = × 100000 (31) points in Figure 4a confirms this idea.

NS 2 − 181.2 NS + 3924

Hot stream flow length: As it is shown in Figure 5b, increasing the

which is valid in the range of 0.001694<NS<0.002533 for number of hot stream flow length results in increase in the both number of entropy

entropy generation units. The interesting point is that considering generation units as well as total annual cost. Therefore, both objectives

a numerical value for the number of entropy generation units in improve by decreases of hot stream flow length. The numerical value

mentioned range, provides the minimum total annual cost for that of hot stream flow length located at its minimum value in Figure 4b

optimal point along with other optimal design parameters. verified this point.

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 7 of 9

a b

0.2

1

0.18

0.8

0.16

0.14

0.6

L1(m)

L2(m)

0.12

0.4 0.1

0.08

0.2

0.06

0 0.04

0 50 100 150 200 250 300 350 0 50 100 150 200 250 300 350

Population Population

c d

1.1 9

1 8

0.9

7

0.8

6

0.7 pf(mm) 5

L3(m)

0.6

4

0.5

3

0.4

2

0.3

0.2 1

0.1 0

0 50 100 150 200 250 300 350 0 50 100 150 200 250 300 350

Population Population

e f

35

30

30 25

Xt(mm)

XI(mm)

20

25

15

20 10

0 50 100 150 200 250 300 350 0 50 100 150 200 250 300 350

Population Population

g h

8 11

7 10.5

10

6

9.5

5 9

d0(mm)

4 8.5

Np

8

3

7.5

2

7

1 6.5

0 6

0 50 100 150 200 250 300 350 0 50 100 150 200 250 300 350

Population Population

Figure 4: Scattering of variables for the Pareto optimal front a: cold stream flow length, b: hot stream flow length, c: no-flow length, d: fin pitch,e: transversal pitch, f:

longitudinal pitch, g: number of tube pass, h: tube diameter.

No-flow length: Like hot stream flow length, by increase in the no- conflict between two objectives. The relative scattering distribution of

flow length number of entropy generation units and annual cost increase no-flow length in Figure 4c at its minimum values confirms this point.

simultaneously. But there is a small region in Figure 5c that causes

Fin pitch, transversal pitch and longitudinal pitch: As shown

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 8 of 9

a b

900 800

800 700

700

Annual cost ($/year)

Annual cost ($/year)

600

600

500

500

400

400 Increase of L1 Increase of L2

300

300

200 200

100 100

1.6 1.8 2 2.2 2.4 2.6 2.8 3 3.2 1 2 3 4 5 6 7 8

NS x 10-3 NS x 10-3

c d

700 6000

650

5000

600

Annual cost ($/year)

Annual cost ($/year)

550

4000

500

450 3000

400

2000 Increase of pf

350

300 Increase of L3

1000

250

200 0

2 2.5 3 3.5 4 4.5 5 5.5 6 0 0.005 0.01 0.015 0.02

NS x 10-3 NS

e f

800 2500

700

2000

Annual cost ($/year)

Annual cost ($/year)

600

1500

500

1000

400 Increase of Xt Increase of XI

500

300

200 0

2 2.5 3 3.5 4 4.5 5 5.5 6 1 2 3 4 5 6 7

NS x 10-3 NS x 10-3

g h

900 600

800 Increase of NP 550

700 500

Annual cost ($/year)

Annual cost ($/year)

600 450

Increase of d0

500 400

400 350

300 300

200 250

100 200

2 2.5 3 3.5 4 1.9 2 2.1 2.2 2.3 2.4 2.5 2.6

NS x 10-3 NS x 10-3

Figure 5: The variation of number of entropy generation units with annual cost for eight optimum design parameters in design point D. a: cold stream flow length, b:

hot stream flow length, c: no-flow length, d: fin pitch e: transversal pitch, f: Longitudinal pitch, g: number of tube pass, h: tube diameter.

in Figures 5d- 5f, by increasing the fin pitch, transversal pitch and constraints) for multi-objective optimization as shown in Figures 4d-

longitudinal pitch both the number of entropy generation units and 4f.

annual cost improved simultaneously. As a result, the higher values

Number of tube pass: Based on Figure 5g, by increase of the tube

of these three parameters are suitable (until it does not violence the

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

Citation: Nejad EK, Hajabdollahi M, Hajabdollahi H (2013) Modeling and Second Law Based Optimization of Plate Fin and Tube Heat Exchanger

Using MOPSO. J Appl Mech Eng 2: 118 doi:10.4172/2168-9873.1000118

Page 9 of 9

passes, both the number of entropy generation units and annual cost 10. Guo J, Xu M, Cheng L (2009) The application of field synergy number in shell-

and-tube heat exchanger optimization design. Appl Energ 86: 2079-2087.

decrease, simultaneously. Therefore, the higher value of this parameter

is suitable until it does not violence the constraints. Hence, number 3 is 11. Sahin B, Yakut K, Kotcioglu I, Celik C (2005) Optimum design parameters of a

selected for tube passes as shown in Figure 4g. heat exchanger. Appl Energ 82: 90-106.

12. Doodman AR, Fesanghary M, Hosseini R (2009) A robust stochastic approach

Tube diameter: As shown in Figure 5h by increasing the tube for design optimization of air cooled heat exchangers. Appl Energ 86: 1240-

diameter, both annual cost and number of entropy generation units 1245.

decrease (except in a small region for number of entropy generation 13. Foli K, Okabe T, Olhofer M, Jin Y, Sendhoff B (2006) Optimization of micro

units). Selecting the maximum value for the tube diameter in Figure 4h heat exchanger: CFD, analytical approach and multi-objective evolutionary

confirms this point. algorithms. Int J Heat Mass Tran 49: 1090-1099.

Conclusions 14. Liu Z, Cheng H (2008) Multi-objective optimization design analysis of primary

surface recuperator for microturbines. Appl Therm Eng 28: 601-610.

In the present paper, thermal modeling of the plain fin and tube 15. Gholap AK, Khan JA (2007) Design and multi-objective optimization of heat

heat exchanger has been carried out. For this task, a fin tube heat exchangers for refrigerators. Appl Energ 84: 1226-1239.

exchanger is optimally designed using multi objective optimization 16. Franco A, Giannini N (2005) Optimum thermal design of modular compact heat

technique. The design parameters (decision variables) are longitudinal exchangers structure for heat recovery steam generators. Applied Thermal

pitch, transversal pitch, fin pitch, number of tube pass, tube diameter, Engineering 25: 1293-1313.

cold stream flow length, no-flow length and hot stream flow length. In 17. Shah RK, Sekulic PD (203) Fundamental of Heat Exchanger Design. John

the presented optimization problem, the number of entropy generation Wiley & Sons Inc.

units and total annual cost were two objective functions (both of them 18. Wang CC, Chi KU, Chang CJ (2000) Heat transfer and friction characteristics of

were minimized, simultaneously). A set of Pareto optimal front points plain fin-and-tube heat exchangers, part II: Correlation. Int J Heat Mass Trans

were shown. Further, the distribution of each design parameters in 43: 2693-2700.

their allowable range is shown. The results revealed the level of conflict 19. Mishra M, Das PK, Sarangi S (2009) Second law based optimization of cross

between the two objectives. Furthermore the correlation between the flow plate-fin heat exchanger design using genetic algorithm. App Thermal Eng

optimal values of two objective functions is proposed. It is found that 29: 2983-2989.

each point in the Pareto frontier would be a final optimized point which 20. Kennedy J, Eberhart R (1995) Particle swarm optimization. IEEE International

strongly depends on the decision maker. However, a decision making Conference Neural Networks, USA.

method based on LINMAP method was presented to specify the final 21. Coello CAC, Pulido GT, Lechuga MS (2004) Handling multiple objectives with

optimum design. Finally, the cold stream flow length and no flow particle swarm optimization, IEEE Transactions on Evolutionary Computation

8: 256-279.

length are found to be important design parameters which caused a

relative conflict between number of entropy generation units and the 22. Mostaghim S, Teich J (2003) Strategies for Finding Good Local Guides in Multi-

total annual cost. The results show that by decrease of hot stream flow objective Particle Swarm Optimization. IEEE Service Center, Inidanapolis,

Indiana, USA.

length and by increase of fin pitch, transversal pitch, longitudinal pitch,

number of tube pass and tube diameter, both the number of entropy 23. Ratnaweera A, Halgamuge SK, Watson HC (2004) Self-organizing hierarchical

particle swarm optimizer with time-varying acceleration coefficients. IEEE

generation units and annual cost improved, simultaneously. Transactions On Evolutionary Computation 8: 240-255.

References 24. K. Deb, A. Pratap, S. Agarwal, T. Meyarivan, A fast and elitist multi-objective

1. Kays WM, London AL (1984) Compact Heat Exchangers. Mc-Graw Hill, New genetic algorithm: NSGA-II, IEEE Transactions On Evolutionary Computation

York, USA. 6: 182–97.

2. Kim B, Sohn B (2006) An experimental study of flow boiling in a rectangular 25. Yu PL. Multiple-Criteria decision making, concepts, Techniques, and

channel with offset strip fins. Int J Heat Fluid Fl 27: 514-521. Extensions. New York, Plenum Press.

3. Sanaye S, Hajabdollahi H (2009) Multi-objective optimization of rotary

regenerator using genetic algorithm. Int J Therm Sci 48: 1967-1977.

4. Sanaye S, Hajabdollahi H (2010) Thermal-economic multi-objective optimization

of plate fin heat exchanger using genetic algorithm. Appl Energ 87: 1893-1902.

5. Sanaye S, Hajabdollahi H (2010) Multi-objective optimization of shell and tube

heat exchangers. Appl Therm Eng 30: 1937-1945.

6. Haseli Y, Dincer I, Naterer GF (2008) Optimum temperatures in a shell and tube

condenser with respect to exergy. Int J Heat Mass Tran 51: 2462-2470.

7. Hilbert R, Janiga G, Baron R, Thevenin D (2006) Multi-objective shape

optimization of a heat exchanger using parallel genetic algorithms. Int J Heat

Mass Tran 49: 2567-2577.

8. Xie GN, Sunden B, Wang QW (2008) Optimization of compact heat exchangers

by a genetic algorithm. Appl Therm Eng 28: 895-906.

9. Wang JJ, Jing YY, Zhang CF (2010) Optimization of capacity and operation for

CCHP system by genetic algorithm. Appl Energ 87: 1325-1335.

J Appl Mech Eng

ISSN:2168-9873, an open access journal Volume 2 • Issue 2 • 1000118

You might also like

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- Journal Pre-Proofs: Applied Thermal EngineeringDocument40 pagesJournal Pre-Proofs: Applied Thermal EngineeringDedi AfandiNo ratings yet

- Essential Words For The TOEFLDocument28 pagesEssential Words For The TOEFLpritam goleNo ratings yet

- Hassanshojaeefard 2016Document67 pagesHassanshojaeefard 2016Sateesh kumar SNo ratings yet

- Performance Prediction Numerical and ExperimentalDocument23 pagesPerformance Prediction Numerical and ExperimentalJitesh DhimanNo ratings yet

- Article - 2014 - Ghanei Et Al. - Thermal-Economic Multi-Objective Optimization of Shell and TubeDocument10 pagesArticle - 2014 - Ghanei Et Al. - Thermal-Economic Multi-Objective Optimization of Shell and TubeMaryam EL FitiNo ratings yet

- Split Heat PipeDocument12 pagesSplit Heat PiperodijammoulNo ratings yet

- Neeraas2004pd PDFDocument9 pagesNeeraas2004pd PDFYasin Agung NugrohoNo ratings yet

- A Critical Review On Flow and Heat Transfer Charescteristiscs of Synthetic JetDocument32 pagesA Critical Review On Flow and Heat Transfer Charescteristiscs of Synthetic Jetgm822057No ratings yet

- 1 s2.0 S2214157X14000239 MainDocument11 pages1 s2.0 S2214157X14000239 Mainait hssainNo ratings yet

- Accepted Manuscript: Computers and FluidsDocument48 pagesAccepted Manuscript: Computers and FluidsilhemNo ratings yet

- Oriffice Flow Analysis and ParametersDocument12 pagesOriffice Flow Analysis and ParametersBryle Kenneth GonzalesNo ratings yet

- Research PublicationDocument5 pagesResearch PublicationER Mangal Singh LodhiNo ratings yet

- 2016-Exhaust Valve Analysis PDFDocument14 pages2016-Exhaust Valve Analysis PDFAniq Syazwan IINo ratings yet

- Conjugate Heat Transfer Study of Combined ImpingemDocument14 pagesConjugate Heat Transfer Study of Combined Impingemosas danNo ratings yet

- J Ijthermalsci 2016 01 013Document17 pagesJ Ijthermalsci 2016 01 013jayNo ratings yet

- Chaudhari 2010Document13 pagesChaudhari 2010VishnuShantanNo ratings yet

- 756-Article Text-2138-3-10-20210713Document10 pages756-Article Text-2138-3-10-20210713zoom_999No ratings yet

- Anisotropic Porous MediaDocument15 pagesAnisotropic Porous MediaparamopedroNo ratings yet

- Applied Thermal Engineering: Derong Duan, Peiqi Ge, Wenbo Bi, Jiadong JiDocument9 pagesApplied Thermal Engineering: Derong Duan, Peiqi Ge, Wenbo Bi, Jiadong JicesarNo ratings yet

- Tribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoDocument13 pagesTribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoAnonymous gM6RZL5lYdNo ratings yet

- Virtual Gas Turbines A Novel Flow Network Solver Formulation For The Automated Design Analysis of Secondary Air SystemDocument30 pagesVirtual Gas Turbines A Novel Flow Network Solver Formulation For The Automated Design Analysis of Secondary Air SystemPablo De FelipeNo ratings yet

- Entropy Generation in Natural Convection PDFDocument8 pagesEntropy Generation in Natural Convection PDFzermiNo ratings yet

- Numerical Simulation of Turbulent Flow and Heat Transfer ThoughDocument15 pagesNumerical Simulation of Turbulent Flow and Heat Transfer ThoughКирилл МаксимовNo ratings yet

- Artículo CalorDocument12 pagesArtículo CalorVerónica ArévaloNo ratings yet

- 2016 Efectos Termicos de Separadores Termicos en La Reduccion de Grietas Termicas en CalderasDocument10 pages2016 Efectos Termicos de Separadores Termicos en La Reduccion de Grietas Termicas en CalderasJeanPierCajasSocualayaNo ratings yet

- Coupling CFD and RSM To Optimize The Flow and Heat Transfer Performance of A Manifold Microchannel Heat SinkDocument20 pagesCoupling CFD and RSM To Optimize The Flow and Heat Transfer Performance of A Manifold Microchannel Heat SinkSustechlabNo ratings yet

- Mirzaei 2017Document39 pagesMirzaei 2017Mustapha MellalNo ratings yet

- Combination of Nanofluid and Inserts For Heat Transfer EnhancementDocument24 pagesCombination of Nanofluid and Inserts For Heat Transfer EnhancementDbrait MechanicalNo ratings yet

- Multi-Objective Optimization of Plain Fin-and-Tube Heat Exchanger Using Evolutionary AlgorithmDocument8 pagesMulti-Objective Optimization of Plain Fin-and-Tube Heat Exchanger Using Evolutionary AlgorithmoleksandrokhapkinNo ratings yet

- A Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical PipesDocument9 pagesA Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical Pipesmostafa shahrabiNo ratings yet

- Thermodynamic OptimizationDocument51 pagesThermodynamic OptimizationMarko PerčićNo ratings yet

- Applied Thermal Engineering: SciencedirectDocument11 pagesApplied Thermal Engineering: SciencedirectSaiNo ratings yet

- Cost Optimization Using Genetic Algorithm: Steam Surface Condenser Design Based OnDocument6 pagesCost Optimization Using Genetic Algorithm: Steam Surface Condenser Design Based Onaliscribd46No ratings yet

- Solar Energy: ArticleinfoDocument13 pagesSolar Energy: ArticleinfoAkshay ThakurNo ratings yet

- Entropy Generation MinimisationDocument13 pagesEntropy Generation MinimisationKar AbhishekNo ratings yet

- The Effect of Ribs Spacing On Heat Transfer in Rectangular Channels Under The Effect of Different Types of Heat Flux in The Presence of A NanofluidsDocument9 pagesThe Effect of Ribs Spacing On Heat Transfer in Rectangular Channels Under The Effect of Different Types of Heat Flux in The Presence of A Nanofluidsmustafa11dahamNo ratings yet

- Convex SurfaceDocument17 pagesConvex SurfaceAshraf IntesaafNo ratings yet

- 5.4.2019 - Heat TransDocument21 pages5.4.2019 - Heat TransMoutinhoRodriguesNo ratings yet

- Azojete 15 (2) 314-328 PDFDocument15 pagesAzojete 15 (2) 314-328 PDFAZOJETE UNIMAIDNo ratings yet

- Numerical Analysis of Concentric Jet Impingement Heat Transfer To The Concave Surface of The ConeDocument19 pagesNumerical Analysis of Concentric Jet Impingement Heat Transfer To The Concave Surface of The ConeMuhammad ZaidNo ratings yet

- Shape Optimization of Welded Plate Heat Exchangers Based On GreyDocument9 pagesShape Optimization of Welded Plate Heat Exchangers Based On GreySandro Chuqui PorteroNo ratings yet

- Numerical Investigation of Combustion Optimization in A Tangential Firing Boiler Considering Steam Tube OverheatingDocument15 pagesNumerical Investigation of Combustion Optimization in A Tangential Firing Boiler Considering Steam Tube OverheatingYogesh DewangNo ratings yet

- CFD Analysis of Turbulent Convective Heat Transfer in A Hydro-Generator Rotor-Stator SystemDocument12 pagesCFD Analysis of Turbulent Convective Heat Transfer in A Hydro-Generator Rotor-Stator SystemMichel DangNo ratings yet

- Moreau AntoineDocument156 pagesMoreau AntoineVinay KashyapNo ratings yet

- HMT 2017 550 Original V0-2Document31 pagesHMT 2017 550 Original V0-2Saheera HazarikaNo ratings yet

- Design Validation of Shell and Tube Heat Exchanger by HTRI Xchanger SoftwareDocument5 pagesDesign Validation of Shell and Tube Heat Exchanger by HTRI Xchanger SoftwareAhmed HassanNo ratings yet

- International Communications in Heat and Mass Transfer: Vivek Kumar, Jahar SarkarDocument9 pagesInternational Communications in Heat and Mass Transfer: Vivek Kumar, Jahar SarkarrameshsmeNo ratings yet

- Applied Energy: Qian Yin, Wen-Jing Du, Xing-Lin Ji, Lin ChengDocument14 pagesApplied Energy: Qian Yin, Wen-Jing Du, Xing-Lin Ji, Lin ChengMatheus M. DwinantoNo ratings yet

- Mohit Paper 1Document27 pagesMohit Paper 1mohitNo ratings yet

- Sparger Design GuideDocument5 pagesSparger Design GuideShooeibNo ratings yet

- Applied Energy: Babak Lotfi, Bengt Sundén, Qiuwang WangDocument21 pagesApplied Energy: Babak Lotfi, Bengt Sundén, Qiuwang WangAnonymous 7BQxlt8cNo ratings yet

- Constant H1Document19 pagesConstant H1alimontazer87No ratings yet

- Fersadou2019 Article EffectOfMagnetohydrodynamicsOnDocument21 pagesFersadou2019 Article EffectOfMagnetohydrodynamicsOnzermiNo ratings yet

- Sizing of Plate and Fin HXDocument6 pagesSizing of Plate and Fin HXNithishNo ratings yet

- Numerical Study of Heat Transfer and Pressure Drop For Flow Past Inline and Staggered Tube BundlesDocument19 pagesNumerical Study of Heat Transfer and Pressure Drop For Flow Past Inline and Staggered Tube BundlesYasser AlrifaiNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19samip shahNo ratings yet

- International Journal of Heat and Mass Transfer: Prashant W. Deshmukh, Rajendra P. VedulaDocument10 pagesInternational Journal of Heat and Mass Transfer: Prashant W. Deshmukh, Rajendra P. VedulaTejal BanmareNo ratings yet

- Stagnation Pressure Effect On The Supersonic Minimum Length Nozzle DesignDocument19 pagesStagnation Pressure Effect On The Supersonic Minimum Length Nozzle DesignRou MàissàNo ratings yet

- Computational Analysis of Shockwave in Convergent Divergent NozzleDocument9 pagesComputational Analysis of Shockwave in Convergent Divergent NozzleMuhammad Daud AliNo ratings yet

- Session 8Document3 pagesSession 8THE SEZARNo ratings yet

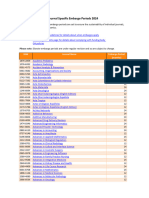

- Embargos Per JournalDocument40 pagesEmbargos Per JournalTHE SEZARNo ratings yet

- PDF 2Document23 pagesPDF 2THE SEZARNo ratings yet

- سيطرة عمليات 1Document105 pagesسيطرة عمليات 1THE SEZARNo ratings yet

- Project 2016Document22 pagesProject 2016THE SEZARNo ratings yet

- Session 6Document6 pagesSession 6THE SEZARNo ratings yet

- ReportDocument25 pagesReportTHE SEZARNo ratings yet

- Professional Architect Book CoverDocument1 pageProfessional Architect Book CoverTHE SEZARNo ratings yet

- CFD Simulation of Heat Enhancement in Internally Helical GroovedDocument102 pagesCFD Simulation of Heat Enhancement in Internally Helical GroovedTHE SEZARNo ratings yet

- Fast and Predictive Heat Pipe Design and Analysis Toolbox H-PatDocument16 pagesFast and Predictive Heat Pipe Design and Analysis Toolbox H-PatTHE SEZARNo ratings yet

- Janun HXDocument8 pagesJanun HXTHE SEZARNo ratings yet

- CFD Analysis and OptimizationDocument6 pagesCFD Analysis and OptimizationTHE SEZARNo ratings yet

- Design 3Document19 pagesDesign 3THE SEZARNo ratings yet

- The Investigation of Grove Geometry Effect For Internally Grooved TubesDocument9 pagesThe Investigation of Grove Geometry Effect For Internally Grooved Tubeszlalkrzybk77No ratings yet

- كاربون الاسودDocument25 pagesكاربون الاسودTHE SEZARNo ratings yet

- Material Balance NotesDocument108 pagesMaterial Balance Notesapi-3709413100% (4)

- Session 1Document20 pagesSession 1THE SEZARNo ratings yet

- Session 6Document6 pagesSession 6THE SEZARNo ratings yet

- تموت البحرDocument96 pagesتموت البحرTHE SEZARNo ratings yet

- Session 8Document3 pagesSession 8THE SEZARNo ratings yet

- Child DevelopmentDocument15 pagesChild Development4AndreeaNo ratings yet

- Test7 PointersDocument16 pagesTest7 PointersPratibha DwivediNo ratings yet

- Gondola CalculationDocument6 pagesGondola CalculationBudi SusantoNo ratings yet

- Metaphysics of LucretiusDocument6 pagesMetaphysics of LucretiusChristopher BennettNo ratings yet

- Comparative Study On Serial and Parallel Manipulators - ReviewDocument23 pagesComparative Study On Serial and Parallel Manipulators - ReviewShaik Himam SahebNo ratings yet

- Islam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamDocument18 pagesIslam and Civilization (Analysis Study On The History of Civilization in Islam) Muhammad Hifdil IslamLoveth KonniaNo ratings yet

- Petersen Coils Basic 20principle and ApplicationDocument3 pagesPetersen Coils Basic 20principle and ApplicationasotozuazuaNo ratings yet

- Principles Involved in Baking 1Document97 pagesPrinciples Involved in Baking 1Milky BoyNo ratings yet

- PH & TemperatureDocument8 pagesPH & TemperatureNanaNo ratings yet

- Ruhangawebare Kalemera Godfrey Thesis PDFDocument116 pagesRuhangawebare Kalemera Godfrey Thesis PDFYoobsan Tamiru TTolaaNo ratings yet

- Sample Appellant BriefDocument6 pagesSample Appellant BriefKaye Pascual89% (9)

- Solar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power GeneratorDocument4 pagesSolar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power Generatorluis fernandoNo ratings yet

- MMW ReviewerDocument3 pagesMMW ReviewerMarcSaloj NeryNo ratings yet

- 3 Curvilinear MotionDocument50 pages3 Curvilinear Motiongarhgelh100% (1)

- Entero SequencesDocument12 pagesEntero SequencesKelvin SueyzyNo ratings yet

- LinkageDocument9 pagesLinkageHarshu JunghareNo ratings yet

- Automatic Train OperationDocument6 pagesAutomatic Train OperationAnupam KhandelwalNo ratings yet

- Pharmalytica Exhibitor List 2023Document3 pagesPharmalytica Exhibitor List 2023Suchita PoojaryNo ratings yet

- ACR39U-U1: (USB Type A) Smart Card ReaderDocument8 pagesACR39U-U1: (USB Type A) Smart Card Readersuraj18in4uNo ratings yet

- Precision CatalogDocument256 pagesPrecision CatalogImad AghilaNo ratings yet

- MA 106: Linear Algebra Tutorial 1: Prof. B.V. Limaye IIT DharwadDocument4 pagesMA 106: Linear Algebra Tutorial 1: Prof. B.V. Limaye IIT Dharwadamar BaroniaNo ratings yet

- Skincare Routine Order Cheat SheetDocument10 pagesSkincare Routine Order Cheat SheetYel Salenga100% (3)

- Colour FastnessDocument37 pagesColour FastnessSivakumar K100% (1)

- Conquest CXAX Air-to-Water Heat PumpDocument6 pagesConquest CXAX Air-to-Water Heat PumpAlexandre LopesNo ratings yet

- Carrefour-SA Shopping Center TurkeyDocument2 pagesCarrefour-SA Shopping Center TurkeyVineet JogalekarNo ratings yet

- Iso 8033 2016Document9 pagesIso 8033 2016Eric ChuNo ratings yet

- Kaged Muscle Magazine Issue 1Document41 pagesKaged Muscle Magazine Issue 1hashimhafiz1100% (1)

- W0L0XCF0866101640 (2006 Opel Corsa) PDFDocument7 pagesW0L0XCF0866101640 (2006 Opel Corsa) PDFgianyNo ratings yet

- Phrasal Verbs Related To HealthDocument2 pagesPhrasal Verbs Related To HealthKnuckles El Naco Narco LechugueroNo ratings yet

- Flusser-The FactoryDocument2 pagesFlusser-The FactoryAlberto SerranoNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyFrom EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansFrom EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansRating: 4 out of 5 stars4/5 (8)

- Advanced Computer-Aided Fixture DesignFrom EverandAdvanced Computer-Aided Fixture DesignRating: 5 out of 5 stars5/5 (1)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (26)