Professional Documents

Culture Documents

Led Vermelho

Uploaded by

caio felipeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Led Vermelho

Uploaded by

caio felipeCopyright:

Available Formats

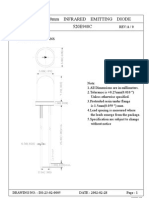

Data Sheet for 5mm Super Bright Red LED

5A3 Series

Angle: 15°

Class: P

Part No: WW05A3SRP4-N

UKAI BILBAO UKAI BARCELONA UKAI MADRID

Ribera Elorrieta 7C Avda. Vallcarca 74-76 Avda Andalucía 2, 2ª planta local 211

48015 Bilbao 08023 Barcelona 28702 San Sebastián de los Reyes

Teléfono: 94 474 5252 Teléfono: 93 284 0898 Teléfono: 91 659 0328

Fax: 94 475 9710 Fax: 93 210 6765 Fax: 91 659 0558

e-mail: ukai@ukai.com e-mail: ukaibcn@ukai.com e-mail: ukaimad@ukai.com

WW05A3SRP4-N Version 1.0 Page 1 of 4

Data Sheet For 5mm Super Bright Red LED – 5A3 Series Angle 15°

Class: P

Features

• Standard T-1 Diameter Type Package.

• General Purpose Leads

• Reliable and Rugged

Absolute Maximum Ratings at Ta=25℃

Parameter MAX. Unit Package Dimensions

Power Dissipation 50 mW

5.0(.197)

Peak Forward Current 5.8(.228)

100 mA

(≦1/10 Duty Cycle, 0.1ms Pulse Wide) 4.98(.196)

Continuous Forward Current 20 mA

8.7(.343)

Derating Linear From 50°C 0.4 mA/°C 0.6

(.024)

1.0(.04)

Reverse Voltage 5 V 25.4(1.0) 0.5(.02)

MIN.

Operating Temperature Range -40°C to +80°C 0.5(.02)

Storage Temperature Range -40°C to +80°C

2.54(.10)

Lead Soldering Temperature

260°C for 3 Seconds NOM. 1.5(.06)MIN

[ 4mm(.157”) From Body]

As the LED chip was in reverse polarity, which is different from normal

LED, please check the polarity of the LED before production.

And please be noted that BIGGER side of the LED is “+ve””

Electrical Optical Characteristics at Ta=25°C

Dominant Wavelength

Luminous Intensity Forward Voltage / Viewing

λd/ nm

Source Iv / mcd V Angle /

Part Number Lens color IF = 20mA

Color IF = 20mA (Note 5) IF = 20mA Deg

(Note8)

(Note 6)

Min. Typ. Max. Min. Typ. Max. Min. Typ. Max.

WW05A3SRP4-N Water Clear Red 620 --- 630 8200 10600 --- --- 2.0 2.4 15°

Reverse Voltage = 5V Reverse Current = 50µA

Notes:

1. All dimensions are in millimeter.

2. Tolerance of measurement is ±0.25mm(.01”) unless others otherwise noted.

3. Protruded resin under flanges is 1.0mm(0.4”) max.

4. Lead spacing is measured where the leads emerge from the package.

5. Luminous intensity is measured with a light sensor and filter combination that approximates the CIE eye-response curve.

Tolerance of measurement of luminous intensity is ±15%

6. θ1/2 is the off-axis angle at which the luminous intensity is half the axial luminous intensity.

It use many parameters that correspond to the CIE 1931 2°

Tolerance of measurement of angle is ±5 degree

7. Caution in ESD: Static Electricity and surge damages the LED. lt is recommended to use a wrist band or anti-electrostatic

glove when handling the LED.All devices, equipment and machinery must be properly grounded.

8. The dominant wavelength λd is derived from the CIE chromaticity diagram and represents the single wavelength which

defines the color of the device.

9. Specifications are subject to change without notice.

WW05A3SRP4-N Version 1.0 Page 2 of 4

Typical Characteristic for Super Bright Red LED

Forward Current vs.

Forward Current vs. Dominant Wavelength

Chromaticity Coordinate (λD)

0.33 633

IFP = 20mA

Dominant Wavelength λD (nm)

631

0.32

629

0.31 -30 C (621nm) 627

y 0 C (624nm)

0.30 25 C (625nm) 625

50 C (627nm)

85 C (629nm) 623

0.29

621

0.28 619

0.68 0.69 0.70 0.71 0.72 0.73 1 5 10 20 50 100

x Forward Current IFP (mA)

Ambient Temperature vs.

Spectrum Dominant Wavelength Directivity (Angle : 15 )

Relative Emission Intensity (a.u.)

Dominant Wavelength λD (nm)

1.2 633

0 10

1 20

1.0 631 Ta = 25 C 30

Relative Luminosity (a.u.)

IF = 20mA 40

0.8 629

50

627

0.6

0.5 60

625

0.4

623

70

0.2

621 80

0 0

450 500 550 600 650 700 750 619

-40 -20 0 20 40 60 80 100 90 60 30 0 0.5 1

90

Wavelength λ(nm)

Ambient Temperature Ta ( C) Radiation Angle

Forward Voltage vs. Ambient Temperature vs. Ambient Temperature vs.

Forward Current Forward Voltage Relative Luminosity

200 2.8

Ta = 25 C 2.0

IFP=20mA

Relative Luminosity (a.u.)

100 2.6 IFP = 20mA

Forward Current IFP (mA)

50

2.4

Forward Voltage V F (V)

1.0

20 2.2

10 2.0 0.5

5 1.8

1.6

1 1.4 0.2

1.6 1.8 2.0 2.2 2.4 2.6 2.8 -40 -20 0 20 40 60 80 100 -40 -20 0 20 40 60 80 100

Forward Voltage ( V )

Ambient Temperature Ta ( C ) Ambient Temperature Ta ( C )

Duty Ratio vs. Forward Current vs. Ambient Temperature vs.

Allowable Forward Current Relative Lumiinosity Allowable Forward Current

200 7.0 40

Allowable Forward Current I FP (mA)

Ta = 25 C Ta = 25 C

Allowable Forward Current I FP (mA)

6.0

Relative Luminosity (a.u.)

100

5.0 30

50 4.0

20

3.0

30

20 2.0

10

1.0

10 0

1 5 10 20 50 100 0 20 40 60 80 100 120 0

0 20 40 60 80 100

Duty Ratio ( % ) Forward Current IFP (mA)

Ambient Temperature ( C )

WW05A3SRP4-N Version 1.0 Page 3 of 4

CAUTIONS- Super Bright LED

(1) Lead Forming

a. At least 3mm from the base of the epoxy bulb should be keep when forming leads.

b. Do not use the base of the leadframe as a fulcrum during lead forming.

Lead forming should be done before soldering.

c. Because the stress to the base may damage the characteristics or it may break the LEDs, do not apply any bending stress to the base of the lead

d. When mounting the LEDs onto a PCB, the holes on the circuit board should be exactly aligned with the leads of the LEDs. Stress at the leads should be avoid when the LEDs are mounted on the PCB,

because it causes damage to the epoxy resin and this will degrade the LEDs.

(2) Storage

a. The LEDs should be stored at stored at 30 C or less and 70%RH or less after being shipped and the storage life limits are 3 months.

b. If the LEDs are stored more then 3 months, they can be stored for a year in a sealed container with a nitrogen atmosphere and moisture absorbent material.

c. Please avoid rapid transitions in ambient temperature, especially, in high humidity environments where condensation can occur.

(3) Static Electricity

a. Static electricity or surge voltage damages the LEDs.

b. It is recommended that a wristband or an anti-electrostatic glove be used when handling the LEDs.

c. All devices, equipment and machinery must be properly grounded.

d. It is recommended that measures be taken against surge voltage to the equipment that mounts the LEDs.

e. Damaged LEDs will show some unusual characteristics such as the leak current remarkably increases, the forward voltage becomes lower, or the LEDs do not light at the low current.

Criteria: (VF>2.0V at IF=0.5mA)

(4) Heat Generation

a. Thermal design of the end product was most importance. Please consider the heat generation of the LED when making the system design.

b. The thermal resistance of the circuit board and density of LED placement on the board, as well as other components was the important factor affecting the coefficient of temperature increase per input

electric power. It must be avoid intense heat generation and operate within the maximum ratings given in the specification.

c. The operating current should be decided after considering the ambient maximum temperature of LEDs.

(5) Cleaning

a. It is recommended that isopropyl alcohol be used as a solvent for cleaning the LEDs. When using other solvents, it should be confirmed beforehand whether the solvents will dissolve the resin or not.

Freon solvents should not be used to clean the LEDs because of worldwide regulations.

b. Do not clean the LEDs by the ultrasonic. When it is absolutely necessary, the influence of ultrasonic cleaning on the LEDs depends on factors such as ultrasonic power and the assembled condition.

Before cleaning, a pre-test should be done to confirm whether any damage to the LEDs would occur.

(6) Safety Guideline for Human Eyes

a. In 1993, the International Electric Committee (IEC) issued a standard concerning laser product safety (IEC 825-1).Since then, this standard has been applied for diffused light sources (LEDs) as well as

lasers.In 1998 IEC 60825-1 Edition 1.1 evaluated the magnitude of the light source.

b. In 2001 IC 60825-1 Amendment 2 converted the laser class into 7 classes for end products.

c. Components are excluded from this system. Products which contain visible LEDs are now classified as class 1. Products containing UV LEDs can be classified as class 2 in cases where viewing angles

are narrow, optical manipulation intensifies the light, and/or the energy emitted is high. For these systems it is recommended to avoid long term exposure. It is also recommended to follow the ICE

regulations regarding safety and labeling of products.

(7) Soldering Condition for LED Lamps

a Careful attention should be paid during soldering.

b. Solder the LED no closer than 3mm from the base of the epoxy bulb. Soldering beyond the base of the tie bar is recommender.

c. Recommender soldering conditions

Dip Soldering Soldering

Pre-Heat 120°C Max Temperature 350°C Max

Pre-Heat Time 60 seconds Max Soldering 3 seconds Max

Solder Bath 260°C Max Time No closer than 3 mm from the

Temperature Position base of the epoxy bulb.

Dipping Time 10 seconds Max

Dipping Position No lower than 3 mm from the base of

the epoxy bulb.

d. Do not apply any stress to the lead particularly when heated.

The LEDs must not be repositioned after soldering.

After soldering the LEDs, the epoxy bulb should be protected from mechanical shock or vibration until the LEDs return to room temperature.

Direct soldering onto a PC board should be avoided. Mechanical stress to the resin may be caused from warping of the PC board or from the clinching and cutting of the leadframes. When it is absolutely necessary, the LEDs may

be mounted in this fashion but the User will assume responsibility for any problems. Direct soldering should only be done after testing has confirmed that no damage, such as wire bond failure or resin deterioration, will occur.

LEDs should not be soldered directly to double sided PC boards because the heat will deteriorate the epoxy resin.

When it is necessary to clamp the LEDs to prevent soldering failure, it is important to minimize the mechanical stress on the LEDs.

Cut the LED leadframes at room temperature. Cutting the leadframes at high temperatures may cause failure of the LEDs.

(8) Others

a. Care must be taken to ensure that the reverse voltage will not exceed the absolute maximum rating when using the LEDs with matrix drive. Keeping the Normal Forward to 20 mA.

b. The LEDs described in this brochure are intended to be used for ordinary electronic equipment (such as office equipment, communications equipment, measurement instruments and household

appliances). Consult manufacturer’s sales staff in advance for information on the applications in which exceptional quality and reliability are required, particularly when the failure or malfunction of

the LEDs may directl y jeopardize life or health (such as for airplanes, aerospace, submersible repeaters, nuclear reactor control systems, automobiles, traffic control equipment, life support

systems and safety devices).

Rx

VF IF = V - VF

Rx

V

c. User shall not reverse engineer by disassembling or analysis of the LEDs without having prior written consent from manufacturer. When defective LEDs are found, the User shall inform

manufacturar directly before disassembling or analysis.

d. The formal specifications must be exchanged and signed by both parties before large volume purchase begins.

e. The appearance and specifications of the product may be modified for improvement without notice.

WW05A3SRP4-N Version 1.0 Page 4 of 4

You might also like

- Cape Comm Studies Study NotesDocument28 pagesCape Comm Studies Study NotesLexi John100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- MouseSensor MCS 12086 DatasheetDocument7 pagesMouseSensor MCS 12086 Datasheetpourya amiriNo ratings yet

- Led AzulDocument4 pagesLed Azulcaio felipeNo ratings yet

- Led VerdeDocument4 pagesLed Verdecaio felipeNo ratings yet

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290StuxnetNo ratings yet

- Data Sheet: para Light Electronics Co., LTDDocument14 pagesData Sheet: para Light Electronics Co., LTDmuaadhNo ratings yet

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetNo ratings yet

- DatasheetDocument6 pagesDatasheetGlaucio GomesNo ratings yet

- 4 Chip Built in RGBW Smd5050Document5 pages4 Chip Built in RGBW Smd5050ZmecleuPeBatzNo ratings yet

- BPW 21 - enDocument13 pagesBPW 21 - enMichael MitchellNo ratings yet

- SMBJ 1Document8 pagesSMBJ 1Omar MelchorNo ratings yet

- Everlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDocument4 pagesEverlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDhuck DhNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysStuxnetNo ratings yet

- LS-SF67(8)1USD24Document7 pagesLS-SF67(8)1USD24Nexor PocztaNo ratings yet

- TLP748J GaAs Photocoupler DatasheetDocument6 pagesTLP748J GaAs Photocoupler DatasheetMigue KuroNo ratings yet

- Of smd2012bDocument4 pagesOf smd2012bIoanaa BadiuNo ratings yet

- LW Q38G - enDocument24 pagesLW Q38G - encorazzaedwardNo ratings yet

- Kw2 Hil532.Tk enDocument25 pagesKw2 Hil532.Tk enPiero PorielliNo ratings yet

- Led - Everlight - 67 21S B3C D5060D5D72936Z6 2T - V1Document10 pagesLed - Everlight - 67 21S B3C D5060D5D72936Z6 2T - V1Carlos H. GojleviciusNo ratings yet

- HP60MUVA, Sterilization LEDDocument8 pagesHP60MUVA, Sterilization LEDbar catalinNo ratings yet

- Datasheet - LED AMARILLODocument2 pagesDatasheet - LED AMARILLOMILLERSALVADOR 11No ratings yet

- DatasheetDocument6 pagesDatasheetTop Techno Lab CompanyNo ratings yet

- Display - ELD-511SURWB-S530-A3Document5 pagesDisplay - ELD-511SURWB-S530-A3guibsgvNo ratings yet

- Datasheet LEDDocument4 pagesDatasheet LEDevhyajahNo ratings yet

- 5mm Round Warm White LED Technical Data SheetDocument9 pages5mm Round Warm White LED Technical Data SheetCris Yo SoyNo ratings yet

- AERD N2xB DS101Document9 pagesAERD N2xB DS101William Medina GómezNo ratings yet

- Luckylight: 0.45mm Height 0402 Package White Chip LED Technical Data SheetDocument11 pagesLuckylight: 0.45mm Height 0402 Package White Chip LED Technical Data SheetVictorburgen Siebenburgen Burgenburg SiebenburgenburgNo ratings yet

- SMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFDocument4 pagesSMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFAntoni MonteroNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysStuxnetNo ratings yet

- Bright Green LED Features 3mm Package ROHS CompliantDocument2 pagesBright Green LED Features 3mm Package ROHS CompliantMario Alberto Saavedra MeridaNo ratings yet

- 5.0Mm Infrared Emitting Diode 520E940CDocument4 pages5.0Mm Infrared Emitting Diode 520E940CRonald TucumanNo ratings yet

- TLP731, TLP732: Office Machine Household Use Equipment Solid State Relay Switching Power SupplyDocument9 pagesTLP731, TLP732: Office Machine Household Use Equipment Solid State Relay Switching Power SupplysNo ratings yet

- Elt512surwa - S53 PDFDocument5 pagesElt512surwa - S53 PDFilian ivanovNo ratings yet

- KW H2l531.te - en 2Document24 pagesKW H2l531.te - en 2fredtranNo ratings yet

- GW CSSRM3.HW - enDocument23 pagesGW CSSRM3.HW - enalutu paluNo ratings yet

- Diode Silicon Mmbd4148 75v 0.2a Sot-23Document5 pagesDiode Silicon Mmbd4148 75v 0.2a Sot-23Udit BalharaNo ratings yet

- 3528 SMD Chip LED - Red: FeaturesDocument5 pages3528 SMD Chip LED - Red: FeaturesdogeballNo ratings yet

- TLP551 Datasheet en 20190624Document7 pagesTLP551 Datasheet en 20190624jose antonio iglesias infantesNo ratings yet

- Display 7 Segmentos 7mm Da03-11srwaDocument4 pagesDisplay 7 Segmentos 7mm Da03-11srwaDJ_CROWNNo ratings yet

- uvled-385-nv3bDocument5 pagesuvled-385-nv3b林益祥No ratings yet

- Tos 23101bmrl BDocument2 pagesTos 23101bmrl BAnonymous Im6zx7xiyNo ratings yet

- Esdlc3v3d5 (Sod 523)Document4 pagesEsdlc3v3d5 (Sod 523)Linux lnxNo ratings yet

- TLP731, TLP732: Office Machine Household Use Equipment Solid State Relay Switching Power SupplyDocument10 pagesTLP731, TLP732: Office Machine Household Use Equipment Solid State Relay Switching Power Supplycarlosjuniors888No ratings yet

- Low Input Current Phototransistor Optically Coupled IsolatorsDocument3 pagesLow Input Current Phototransistor Optically Coupled IsolatorsTaufiku RahmanNo ratings yet

- CS Series Current Sensor Oct2008Document4 pagesCS Series Current Sensor Oct2008NebojsaNo ratings yet

- Datasheet Uvc 3535 PDFDocument10 pagesDatasheet Uvc 3535 PDFValeria MintosuNo ratings yet

- Unijunction Transistor: DescriptionDocument2 pagesUnijunction Transistor: DescriptionRicardo Campos LandaetaNo ratings yet

- LS+T67F_ENDocument22 pagesLS+T67F_ENsajko.ahmetovicNo ratings yet

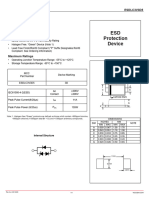

- ESD Protection Diode for SRAM ModulesDocument3 pagesESD Protection Diode for SRAM Modulesshijith. ppNo ratings yet

- UJT2N4870Document2 pagesUJT2N4870JANN ARTHUR CHAVEZ CASTILLONo ratings yet

- LS R976_EN (2)Document21 pagesLS R976_EN (2)maxmoron600No ratings yet

- 0.36-Inch Single Digit Green LED Displays Technical Data SheetDocument5 pages0.36-Inch Single Digit Green LED Displays Technical Data SheetreybimNo ratings yet

- Ly G6SP.02 - enDocument22 pagesLy G6SP.02 - enAndrey PolupanNo ratings yet

- Programmable Controllers DC-Output Module Telecommunication: TOSHIBA Photocoupler IRED & Photo-TransistorDocument8 pagesProgrammable Controllers DC-Output Module Telecommunication: TOSHIBA Photocoupler IRED & Photo-TransistorDraKo BaracunataNo ratings yet

- Subminiature Solid State Lamp: AttentionDocument5 pagesSubminiature Solid State Lamp: Attentionn tanevarNo ratings yet

- Chipled 0603: Produktdatenblatt - Version 1.1Document22 pagesChipled 0603: Produktdatenblatt - Version 1.1Ziyad AkchouchNo ratings yet

- SFH 229 - en PDFDocument15 pagesSFH 229 - en PDFbarisNo ratings yet

- Bav70 (A4w32)Document5 pagesBav70 (A4w32)Emilio QuijanoNo ratings yet

- Tod 5261ame BDocument2 pagesTod 5261ame Bx-wire OfficialsNo ratings yet

- Prompt Engineering Cheat SheetDocument3 pagesPrompt Engineering Cheat SheetJuan Pablo Dell'OroNo ratings yet

- Eskin Seminar ReportDocument18 pagesEskin Seminar ReportKalyan HvNo ratings yet

- IVCAD MT930M1M2A OM HEMT ModelDocument65 pagesIVCAD MT930M1M2A OM HEMT ModellotfiNo ratings yet

- Land Capability Unit of Erosion in Gis Application For Kalikajar District, Wonosobo RegencyDocument6 pagesLand Capability Unit of Erosion in Gis Application For Kalikajar District, Wonosobo Regencyarmeino atanaNo ratings yet

- Kami Export - Exam Booster FCE Speaking Part 3 and 4Document2 pagesKami Export - Exam Booster FCE Speaking Part 3 and 4Valen JacobNo ratings yet

- Why paraphrasing avoids plagiarismDocument3 pagesWhy paraphrasing avoids plagiarismAlAr-JohnTienzoTimeniaNo ratings yet

- Zinc Clad II (85) : Inorganic Zinc Rich CoatingDocument2 pagesZinc Clad II (85) : Inorganic Zinc Rich CoatingKatherine Marimón JiménezNo ratings yet

- Dr. Lê Xuân Đ I: Functions of Several VariablesDocument35 pagesDr. Lê Xuân Đ I: Functions of Several VariablesDuong TranNo ratings yet

- Test Specification: iUBT435 - Anatomy and PhysiologyDocument3 pagesTest Specification: iUBT435 - Anatomy and PhysiologyVicki TseNo ratings yet

- Unit 5.2Document4 pagesUnit 5.2Hanh TranNo ratings yet

- CMC 63rd Batch Class Routine for Thorax CardDocument5 pagesCMC 63rd Batch Class Routine for Thorax CardMath NewNo ratings yet

- A Social Network Analysis of ICTD Conferences (2006-2017) : Information Technology For DevelopmentDocument24 pagesA Social Network Analysis of ICTD Conferences (2006-2017) : Information Technology For DevelopmentRjendra LamsalNo ratings yet

- Grade 5 PPT - Math - Q1 - Lesson 6Document17 pagesGrade 5 PPT - Math - Q1 - Lesson 6Melyn BustamanteNo ratings yet

- J1 - Today 1 - First Test 2022 (KEY)Document3 pagesJ1 - Today 1 - First Test 2022 (KEY)EmanuelBriosoNo ratings yet

- Measures of DispersionDocument16 pagesMeasures of DispersionjbshjcbsdnNo ratings yet

- Leadership+from+the+Inside+Out Cashman EBSDocument13 pagesLeadership+from+the+Inside+Out Cashman EBSRepublik DakasakaNo ratings yet

- Lab 4B Moles of Iron and CopperDocument6 pagesLab 4B Moles of Iron and CopperLaura Sitar0% (1)

- Geology Lesson PlanDocument6 pagesGeology Lesson Planapi-501773574No ratings yet

- Wellington Secondary College: All Orders To Be Completed Online atDocument3 pagesWellington Secondary College: All Orders To Be Completed Online atMathusan LakshmanNo ratings yet

- Overview of Medicine - Its Importance and ImpactDocument9 pagesOverview of Medicine - Its Importance and ImpactDuffosNo ratings yet

- Eth 41276 02 PDFDocument428 pagesEth 41276 02 PDFBiljana PetrusevskaNo ratings yet

- Korea (2017) - Experimental Investigation On Massflow Characteristics of R245fa Through Electronic Expansion ValveDocument7 pagesKorea (2017) - Experimental Investigation On Massflow Characteristics of R245fa Through Electronic Expansion ValveMatias PezoNo ratings yet

- Avian 48 Guide PDFDocument8 pagesAvian 48 Guide PDFEng-Mohamed Zakria ElbadryNo ratings yet

- Percorso Ii: The Led Roadway Lighting..Document2 pagesPercorso Ii: The Led Roadway Lighting..ChangKhenNo ratings yet

- Group 4 (Ap229d 3c)Document11 pagesGroup 4 (Ap229d 3c)aremyulNo ratings yet

- DAY 1 Passage 1Document2 pagesDAY 1 Passage 1wick90715No ratings yet

- Lesson 1: Organs of Speech and Phonemic SymbolsDocument5 pagesLesson 1: Organs of Speech and Phonemic Symbolsnoah granja2No ratings yet

- Stormwater Survey Gauges Rizal Tech University DesignDocument1 pageStormwater Survey Gauges Rizal Tech University DesignAlejandroGonzagaNo ratings yet

- What Is A Gas CompressorDocument5 pagesWhat Is A Gas CompressorI AM NOT CHINESENo ratings yet