Professional Documents

Culture Documents

1485 - EC2169-signed

1485 - EC2169-signed

Uploaded by

Deepak HoleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1485 - EC2169-signed

1485 - EC2169-signed

Uploaded by

Deepak HoleCopyright:

Available Formats

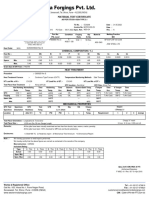

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : TechnipFMC TC No. : EC2169 Date : 18.12.2023

Invoice No.:WIF/EX/23-24/ Date :

P.O. No.: 4500796359 Line Item: 00010 PO Date : 13.12.2023 Spec. Ref.: M25124 Rev. : A

Ver. No : 3

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. PSL Level Ratio Sr.No. Mill

TOP ENTRY BODY FORGING, Forged AISI 4340

1485 P565885 Rev E 11.61 : 1 226 Nos. EAF-LRF-VD-ING

CHECK VALVE, MAX TOP Normalized

ENTRY, 3 15000 CWP AISI 4340 Quenched &

ALLOY STEEL SPEC M25124 Double - SAARLOHA

Tempered,

Heat Code: OTB DU500049322 Rev D Shot Blasted

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Cr Ni Mo Sn As Sb

HN170537 0.42 0.73 0.24 0.002 0.008 0.83 1.75 0.25 0.0070 0.0026 0.0014

Specn. Min. 0.38 0.65 0.15 - - 0.70 1.65 0.20 - - -

Max. 0.43 0.85 0.35 0.015 0.015 0.90 2.00 0.30 - - -

Grain Size (6 OR Finer) : 7 ASTM

HEAT TREATMENT

Procedure :- Q00025 Rev S

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Load No. of N :- CZ-28 HT Load No. of QT :- CZ-52 HT Load No. of DT :- CZ-53-B Qty :- 226 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time Hardening Time Quench Quench Bath Temp. I Temper Time II Temper Time

Ratio Temp. Hrs. Temp. Hrs. Media Start End Temp. Hrs. Temp. Hrs.

7 Hrs 7 Hrs

QTC 11.61 : 1 900⁰C 4 Hrs 40 Min 870⁰C 4 Hrs 40 Min OIL 27°C 58°C 590°C 570°C (Air Cool)

(Air Cool)

7 Hrs 7 Hrs

Forging 11.61 : 1 900⁰C 4 Hrs 40 Min 870⁰C 4 Hrs 40 Min OIL 27°C 58°C 590°C 570°C (Air Cool)

(Air Cool)

Specn. Min. 870⁰C 840⁰C --- --- 580⁰C --

Max. 925⁰C 900⁰C -- 80⁰C 680⁰C --

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C PSI PSI % % Temp. Requirement 1 2 3 Average

Test Piece Orientation:- Longitudinal & Transverse Charpy 'V' notch

Test Piece Size :- 12.50 mm Dia, 50 mm Gauge Length 10 mm X 10 mm X 55 mm LG

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) Mechanical Test Annexure 4) Dimensional Report

Note :- We hereby guarantee that no weld repairs have been performed.

. We hereby certify that the above figures are accurate and are contained in the records of the company.

Method of Forging - Closed Die Forging

Inclusion Rating -

Type A - Thin A - Thick B - Thin B - Thick C - Thin C - Thick D - Thin D - Thick

Actual 1.00 0.50 0.5 - - - 1.0 0.5

Spec. Min - - - - - - - -

Spec. Max 2.00 1.50 2.00 1.00 1.00 1.00 1.50 1.00

Ajay Joshi (GM, MQC & HT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

Works & Registered Office Tel : +91-02137-679819

Gat No. 163, Hissa No.1, Pune-Nagar Road, Fax : +91-02137-679820

Sanaswadi, Tal. Shirur, Pune- 412208 (INDIA) customerservice@westernindiaforgings.com

www.westernindiaforgings.com CIN : U28910PN1981PTC024155

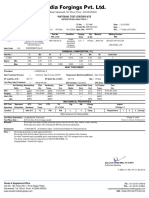

HARDNESS TEST REPORT

Customer:- TechnipFMC TC No: EC2169

P.O. No.:- 4500796359 Line Item: 00010 PO Date : 13.12.2023 Date : 18.12.2023

TOP ENTRY BODY FORGING, CHECK

Item : VALVE, MAX TOP ENTRY, 3 15000 CWP Material : AISI 4340

AISI 4340 ALLOY STEEL SPEC M25124

Part No.: P565885 Rev E Heat No. : HN170537

Drawing No.: DU500049322 Rev D Ambient Temp : 26°C

Die No.: 1485 Hardness Range:- 285-341 HBW

Qty.: 226 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Deep Throat Hardness Tester

HT Load No.: N CZ-28 QT CZ-52 Sr No. 2015/01

Reference Standard: ASTM E10 DT CZ-53-B Machine Make: FSA

Load Applied: 3000 Kgs Calibration Agency: SME Cal. Center

Type of Penetrator: Dia 10 mm Carbide Ball Certificate No.: SME/23/200

Std Block Details: SH-0098/23 (Hardness value - 304.8 HBW) Calibrated On: 13.01.2023

Entity Performing Test: WIF Sanaswadi Calibration Due On: 12.01.2024

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 01 & 02.12.2023

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Sr. No. Hardness in HBW

226 Nos. 285-321 HBW

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Ajay Joshi (GM, MQC & HT)

F-HT-10 / Rev. 00 / 01-Apr-2016

CERTIFICATE OF COMPLIANCE

Customer : TechnipFMC TC No.: EC2169

Date: 18.12.2023

Die No. : 1485 Heat Code : OTB

PO No : 4500796359 Line Item No : 00010

Offer Qty. : 226 Nos.

Part No/ Rev : P565885 Rev E Drg No / Rev : DU500049322 Rev D

Part Name : TOP ENTRY BODY FORGING, Serial No. : -

CHECK VALVE, MAX TOP ENTRY, 3

15000 CWP AISI 4340 ALLOY STEEL

SPEC M25124

I. Material

A. Material Type : AISI 4340

B. Material Spec/ Rev. : As per Spec no : M25124 Rev No. A

C. Material Test Report No : Mill Heat No : HN170537

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 08 Nos

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : CZ-28 Process Spec : Q00025 Rev S

B. Process Name : QT DT

Heat Lot No. : CZ-52 CZ-53-B Process Spec : Q00025 Rev S

IV. NDE

A. Process Name : MPI

Certificate No : NA Process Spec : NA

A. Process Name : UT

Certificate No : NA Process Spec : NA

This certifies that the subjected material is manufactured from the material mentioned above. It has

been verified by us according to the specified sample size and found to conform to the requirements.

Method of Forging - Closed Die Forging

Sign with Stamp

Ajay Joshi (GM, MQC & HT)

Mechanical Test Annexure

Die No.: 1485 Material Grade: AISI 4340

Heat No.: HN170537 HT Lot No. : CZ-52

Heat Code: OTB TC No. : EC2169

TENSILE TEST

UTS YS Elg RA

QTC Test QTC Hardness after

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW

PSI PSI % %

L I-23-433-P 154412 139087 19.64 56.61

0.5" Below HT

331, 321 Ambient 1

Surface

T I-23-434-P 152032 136199 18.80 52.86

285-341 Spec. Min. 130000.00 110000.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

92 94 96 94.00

Single - 32 J Min

L LE - 0.38 mm Min I-23-435-P 1.08 1.10 1.13 1.10

%Shear - Report 65 65 65 65.00

0.5" Below HT

-40°C 1

Surface Avg. - 28 J Min

86 84 84 84.67

Single - 18.7 J Min

T LE - Report I-23-436-P 1.03 1.00 1.01 1.01

%Shear - Report 65 65 65 65.00

Ajay Joshi (GM, MQC & HT)

Authorised Signatory

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1433 Ec0442Document6 pages1433 Ec0442Deepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1447 - Ec0539Document5 pages1447 - Ec0539Deepak HoleNo ratings yet

- 1591 Ec2203 FTDocument1 page1591 Ec2203 FTDeepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- C To DDocument1 pageC To DDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- Western India Forgings Pvt. LTD.: Test CertificateDocument1 pageWestern India Forgings Pvt. LTD.: Test CertificateDeepak HoleNo ratings yet

- Deepak Dattatray HoleDocument2 pagesDeepak Dattatray HoleDeepak HoleNo ratings yet

- Ecn 1Document5 pagesEcn 1Deepak HoleNo ratings yet

- Htytdjhfjgk LJ K JKFTDRGBNDocument45 pagesHtytdjhfjgk LJ K JKFTDRGBNDeepak HoleNo ratings yet

- Bar No 4086Document1 pageBar No 4086Deepak HoleNo ratings yet

- Bar No 4002Document2 pagesBar No 4002Deepak HoleNo ratings yet

- Bar No 4084Document1 pageBar No 4084Deepak HoleNo ratings yet

- 4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDocument3 pages4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDeepak HoleNo ratings yet

- Bar No - 5763: Test CertificateDocument2 pagesBar No - 5763: Test CertificateDeepak HoleNo ratings yet

- Deviation Request - Raltech 10 10 2020Document1 pageDeviation Request - Raltech 10 10 2020Deepak HoleNo ratings yet

- F-HRA-05 On Job Training Record R04Document3 pagesF-HRA-05 On Job Training Record R04Deepak HoleNo ratings yet

- Repayment-Deepak As On Date 07.12.2022Document2 pagesRepayment-Deepak As On Date 07.12.2022Deepak HoleNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanDeepak HoleNo ratings yet

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocument1 pageCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- STK/WIF/20-21/283 Bar No.: QTC With DespatchDocument58 pagesSTK/WIF/20-21/283 Bar No.: QTC With DespatchDeepak HoleNo ratings yet