Professional Documents

Culture Documents

Case 695

Uploaded by

lapan111Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case 695

Uploaded by

lapan111Copyright:

Available Formats

SECTION 21 - TRANSMISSION 95

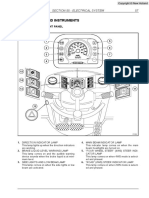

2.2 TRANSMISSION CONTROLS

4X2 POWERSHIFT TRANSMISSION CONTROL

1. TRANSMISSION POWERSHIFT DIRECTION 4X2 POWERSHIFT TRANSMISSION

LEVER: four gears are selectable for the The transmission fitted to this machine is designed

required ground speed in forward and two gears to powershift gear changes supplying drive to the

for reverse travel. machine wheels depending upon the gear and di-

rection selected. The transmission is controlled by a

IMPORTANT: the gear changes and direction of microprocessor in the Powershift lever unit (1).

travel are governed by the micro processor to main- The powershift lever (1) with electronic speed selec-

tain smooth and safe changes, irrespective of gear tion actuates the powershift transmission with four

selected. Therefore upshifting, downshifting or di- forward speeds, two reverse speeds.

rection of travel through the gears will only occur

when the monitored machine speed is safe to do so.

2. DIFFERENTIAL LOCK SELECTION SWITCH:

depressing the spring loaded switch will lock

both rear wheels together giving equal drive and

will disengage when wheel torque equalises or

the foot brakes are applied.

3. LOADER ATTACHMENT CONTROL LEVER

4. TRANSMISSION DISCONNECT BUTTON

5. KICKDOWN SWITCH: if the machine is in 2nd

gear and 1st is required for loader work

engaging kickdown instantly drops the gear from

2nd to 1st. When reverse is selected the

transmission reverts to 2nd gear.

96 SECTION 21 - TRANSMISSION

4X2 POWERSHIFT TRANSMISSION DISPLAY (EGS) - FORWARD SELECTION

SECTION 21 - TRANSMISSION 97

4X2 POWERSHIFT TRANSMISSION DISPLAY (EGS) - REVERSE SELECTION

98 SECTION 21 - TRANSMISSION

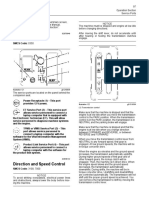

Powershift Lever Display - (LEDs)

LEDs - Numbered 1 through 4:

Indicate the direction of travel by the colour of the

LED

Forward = Green

Neutral = Red

Reverse = Orange

and also indicate the selected shift lever gear.

STEADY ILLUMINATED LED: indicates selected

transmission gear.

FLASHING LED: indicates the actual transmission

gear engaged (if different from that selected).

LEDs - Numbered 1 through 8: used during test

modes

1 2 3 4 5 6 7 8

LED - Number 8: illuminates green when the ma-

chine is at a standstill (in normal mode).

1 2 3 4 5 6 7 8

LED - Letter T = Self-diagnostic Mode: T

Used in self-diagnostic test mode and will illuminate

during self test.

NOTE: in the event of a fault, (the light will flash),

Contact your Authorized Dealer for assistance.

LED - Letter N Indicates Neutral: N

Illuminates when the transmission is shifted to neutral.

Powershift Lever and Microprocessor Functions

The microprocessor controls the transmission and

self checks its own memory continuously to ensure

that gear selection and range changes are always

performed in a safe manner.

Should a fault occur in the transmission or the micro-

processor, the microprocessor will default to the re-

set mode.

SECTION 21 - TRANSMISSION 99

Reset Mode:

When the microprocessor defaults to reset mode

both the T and N LED’s are displayed simultaneously

to indicate that a reset has taken place.

If no critical faults are active the microprocessor se-

lects N2 and goes to the Neutral lock state. See

“Driving with Powershift” chapter.

Limp home:

If a fault is detected at power up the limp home facil-

ity is automatically selected.

IMPORTANT: if limp home is active, only 1st and

2nd gear will be selectable but without modulation.

Limp home active can be identified by the illumina-

tion of the following LEDs.

- Consult your Dealer.

T - LED N - LED CONDITION

Flashing ON Last fault currently shown on display

Flashing Flashes Slower Input error detected

Flashing Flashes in Phase Non critical output error detected

Flashing Flashes Faster Safety critical output error detected

100 SECTION 21 - TRANSMISSION

Selecting Neutral

At power up, “Neutral and 2nd Gear” are automati-

cally selected regardless of the Powershift lever po-

sition (1). The LED-2 and the N-LED are illuminated

RED, (neutral 2nd), the microprocessor is in a neu-

tral lock state.

If after driving, neutral is selected and the shift lever

stays in neutral for more than 3 seconds the micro-

processor automatically defaults to the neutral lock

state for safety. In neutral an automatic shift routine

takes effect to prevent damage to the transmission

due to overspeeding.

Leaving Neutral

A feature of the Powershift lever is the neutral lock

state, which does not allow forward or reverse direc-

tion drive to be selected. This feature prevents the

machine accidentally moving should the lever be

knocked into forward or reverse. To leave the neutral

lock state, you select drive direction followed by an

upshift by rotating the shift lever.

Selecting Forward

To select forward travel push the lever away from

you and the “F” LED will illuminate green.

NOTE: when forward is selected you will not be giv-

en any indication of gear selected, only the maxi-

mum selected gear the transmission will shift to. The

microprocessor is programmed to be an automatic

speed based shift system.

In addition whether forward actually engages at that

time, depends on the status of the machine, for ex-

ample if on the move, road speed and direction will

be considered before any shift changes take place.

Selecting Reverse

To select reverse travel pull the lever towards you

and the reverse “R” LED will illuminate orange.

NOTE: when reverse is selected you will not be giv-

en any indication of gear selected, only the maxi-

mum selected gear the transmission will shift to. The

microprocessor is programmed to be an automatic

speed based shift system.

In addition whether reverse actually engages at that

time, depends on the status of the machine, that is if

on the move road speed and direction will be consid-

ered by the microprocessor.

SECTION 21 - TRANSMISSION 101

Upshifting

Upshifting to a desired gear from neutral is achieved

by twisting the handgrip counter clockwise (+) in sin-

gle movements, If held in this position the processor

will advance the shift selection from 2 through to 4 in

1.8 sec intervals.

NOTE: an upshift request after a downshift is de-

layed for 2 seconds. Should an error occur with the

speed sensor the microprocessor will not allow up-

shifts above 2nd gear and will be indicated by the “T”

LED flashing and the “N” LED flashing slower.

NOTE: if climbing up a steep incline select 2nd and

proceed, if speed and power allow upshift into 3rd

and 4th.

Downshifting

SWARNING

If descending down a steep incline select 2nd and

proceed, upshifting only when safe to do so. You can

not downshift to reduce speed if the machine speed

is above 15 km/h.

Downshifting to the desired gear is achieved by

twisting the handgrip clockwise (-) in single move-

ments. If held in this position the processor will de-

crease the shift from 4, if the shift lever was in this

gear, through to 1 in 1.5 sec intervals.

NOTE: if the gear requested and the shift attainable

are not the same because of torque converter tur-

bine rpm being too high, the gear position LED (e.g.

LED 4) will flash and the shift lever position will illu-

minate, not flashing, (e.g. LED 2), until the requested

gear is reached. When a gear position LED is flash-

ing this indicates that the machine has to reduce

speed to reach the requested gear.

102 SECTION 21 - TRANSMISSION

Direction Changes

Changing driving direction is achieved simply by

shuttling the Powershift lever between forward and

reverse and vice versa which is allowed at any time.

The system response however depends on machine

speed and currently engaged gear. When driving in

1st or 2nd gear direction changes are unrestricted

and are granted immediately.

F1 - R1 F2 - R2

R1 - F1 R2 - F2

When driving forward in 3rd or 4th gear two respons-

es are possible depending on machine speed.

RESPONSE 1: If the machine speed in forward is

above 15 km/h and reverse is selected downshift en-

gages but momentum forward remains, until the

speed lowers sufficiently to allow downshift to take

place when reverse is achieved in 2nd gear.

RESPONSE 2: If the machine speed in forward is

less than 15 km/h reverse takes place immediately

into 2nd gear.

Should a speed sensor fault be detected while in F3

or F4 a downshift sequence to 2nd gear will take

place and is indicated by the LED “T” flashing fast

and the LED “N” flashing slowly.

NOTE: if the transmission is in forward 1st gear due

to kick down the direction change will result in selec-

tion of reverse 2nd gear for efficient pull away. Refer

to Kick down for more information.

SECTION 21 - TRANSMISSION 103

Transmission Powershift

In the previous paragraphs shift changes have been

shown as precise movements and twist actions of

the Powershift lever. However the transmission can

change gear automatically in forward or reverse as

described in the following paragraph:

Select forward and 4th gear on the Powershift lever

and with the handbrake released apply pressure to

the foot accelerator. As the engine revs and machine

speed increase the transmission will start from 2nd

gear and change up through 3rd and 4th gears up to

maximum road speed.

When you require to slow down or stop release the

foot accelerator and apply the foot brake, the trans-

mission will automatically downshift through 4th, 3rd

and 2nd gear as the machine speed decreases.

Once stopped apply the handbrake and neutral will

be selected by the microprocessor.

To select drive again, simply twist the handgrip to se-

lect 4th and with the handbrake released apply pres-

sure to the foot accelerator.

Kick Down

The kick down facility (2nd to 1st gear only) on this

transmission increases torque instantly to the driving

wheels and hence pushing power. For example

when the loader is pushing into a pile and more

torque is required at the wheels.

This is achieved by the instant gear change from 2nd

to 1st by the use of the button (1) without the need to

use the twist grip on the Powershift lever.

NOTE: the kick down facility is only available when

the transmission is in 2nd gear and the kick down

button (1) is depressed. If kick down can not be

achieved (machine speed too high) the LED 1 will be

illuminated and LED 2 will be flashing.

Transmission Disconnect

The disconnect feature is useful when loading, for

example; when pushing the loader into a pile and you

have sufficient dirt in the bucket press the disconnect

switch which disengages the transmission and al-

lows the full power of the engine to be directed to the

hydraulic oil pump.

Disconnect is available in 1st and 2nd gear.

NOTE: transmission disconnect is selectable, when

the machine speed is less than 5 km/h and by de-

pressing the button on the loader lever and remains

active until the pedals or switch are released.

You might also like

- Understanding the TGS Lever SystemDocument18 pagesUnderstanding the TGS Lever Systemalex generalNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Controls and Instruments: 3.1 Front Instrument PanelDocument7 pagesControls and Instruments: 3.1 Front Instrument PanelAdamNo ratings yet

- Cec2 OperationDocument11 pagesCec2 OperationWilson Cendales100% (1)

- Operating Instructions PowertronicDocument16 pagesOperating Instructions PowertronicАлександрNo ratings yet

- Power TronicDocument16 pagesPower TronicSherzad Chem100% (1)

- Maintenance by Garr BhuwaDocument8 pagesMaintenance by Garr BhuwaejazNo ratings yet

- Lippertcomponents, Inc.: Chwintek N AllDocument16 pagesLippertcomponents, Inc.: Chwintek N AllJuan ContrerasNo ratings yet

- Operator Controls: Operation and Maintenance ManualDocument44 pagesOperator Controls: Operation and Maintenance ManualTaufik RizalNo ratings yet

- Transmission Control: Operation and Maintenance ManualDocument4 pagesTransmission Control: Operation and Maintenance ManualAgus DaniNo ratings yet

- Vitara DiagnosticosDocument117 pagesVitara DiagnosticosCoromoto Melendez83% (6)

- Câmbio Automático Vitara - AW03-72LEDocument15 pagesCâmbio Automático Vitara - AW03-72LELeandro Grassmann100% (2)

- 4EAT Phase 1 Diagnosis and Service 4EATPh1Win04Document11 pages4EAT Phase 1 Diagnosis and Service 4EATPh1Win04Bojidar Alexandrov100% (4)

- Calibracion de EmbragguesDocument8 pagesCalibracion de EmbragguesRomeo WilliamsNo ratings yet

- Master Mf6400 WSM 10 enDocument3 pagesMaster Mf6400 WSM 10 enporcha1No ratings yet

- APS II (Automatic Power Shift With Mode Selector) : Información de ServicioDocument3 pagesAPS II (Automatic Power Shift With Mode Selector) : Información de ServicioRay LatinoNo ratings yet

- Automatic Transmission For Range Rover 4.6 HSE P68Document20 pagesAutomatic Transmission For Range Rover 4.6 HSE P68Ben100% (1)

- Transmission Diagnostic Trouble Codes-Limp Home Mode and Inchless Power ShiftDocument2 pagesTransmission Diagnostic Trouble Codes-Limp Home Mode and Inchless Power ShiftLupin GonzalezNo ratings yet

- Dodge Challenger NAG1 5-Speed Automatic Transmission RefresherDocument4 pagesDodge Challenger NAG1 5-Speed Automatic Transmission RefresherEdBunge100% (1)

- Btra 4 Auto Transmission RextonDocument218 pagesBtra 4 Auto Transmission RextonСергей Есипов80% (5)

- Automatic Transmission For Range Rover 4 6 HSE P68Document20 pagesAutomatic Transmission For Range Rover 4 6 HSE P68Louise RogersNo ratings yet

- 4 Case Adt Tran PDFDocument85 pages4 Case Adt Tran PDFRached Douahchua100% (3)

- Check wiring andconnector from selector to TCU11500212LOGICAL ERROR AT DIRECTION SELECTSIGNAL 2ND SHIFT LEVERTCU shifts transmission toneutral if selector activTCU detected a wrong signalDocument38 pagesCheck wiring andconnector from selector to TCU11500212LOGICAL ERROR AT DIRECTION SELECTSIGNAL 2ND SHIFT LEVERTCU shifts transmission toneutral if selector activTCU detected a wrong signalDragan89% (19)

- DYNS 30000 CalibratorDocument4 pagesDYNS 30000 Calibratorgolu201100% (2)

- Actyon B0101004Document1 pageActyon B0101004Sebastian Guzman camachoNo ratings yet

- DC Motor Controller With IR RemoteDocument3 pagesDC Motor Controller With IR RemoteArka DasGuptaNo ratings yet

- CAT-777F-Direction and Speed ControlDocument2 pagesCAT-777F-Direction and Speed ControlCybergoNo ratings yet

- Full Race Unit C-S1R Installation Manual-Feb-2023Document6 pagesFull Race Unit C-S1R Installation Manual-Feb-2023kafayaNo ratings yet

- Engagement Pressure For The Transmission Clutch - CalibrateDocument8 pagesEngagement Pressure For The Transmission Clutch - CalibrateVictor NunezNo ratings yet

- D300 E. Transmission Control - PDFDocument2 pagesD300 E. Transmission Control - PDFRforceIbañezNo ratings yet

- Transmission Diagnostic Trouble Codes-Limp Home Mode and Inchless Power ShiftDocument2 pagesTransmission Diagnostic Trouble Codes-Limp Home Mode and Inchless Power ShiftBer HonzaNo ratings yet

- Caja Automatica Suzuki Sidekick 1995Document15 pagesCaja Automatica Suzuki Sidekick 1995Glenn50% (2)

- Transmission Error Codes - CargadorasDocument36 pagesTransmission Error Codes - CargadorasTeresa Marina Peralta80% (5)

- Electrical Input ComponentsDocument13 pagesElectrical Input ComponentshassanNo ratings yet

- Automatic Transaxle Removal and Installation GuideDocument74 pagesAutomatic Transaxle Removal and Installation GuideMateus FumuassucaNo ratings yet

- APS (Automatic Power Shift) : Service InformationDocument5 pagesAPS (Automatic Power Shift) : Service InformationaliNo ratings yet

- Irtccstd 04Document13 pagesIrtccstd 04Bilal Ahmad100% (3)

- Aw03 PDFDocument15 pagesAw03 PDFamazonagirl19No ratings yet

- Cascade CD101 - Auto-Start Controller - Installation and Operations Manual - 00-02.0594 - Sept 2011 - FW MURPHY PDFDocument26 pagesCascade CD101 - Auto-Start Controller - Installation and Operations Manual - 00-02.0594 - Sept 2011 - FW MURPHY PDFpevareNo ratings yet

- 6 Speed Automatic Transaxle AWF21 PDFDocument66 pages6 Speed Automatic Transaxle AWF21 PDFMihai Mitrea100% (3)

- Luis Info InglesDocument4 pagesLuis Info InglesFrank Mcgyver Yana CarpioNo ratings yet

- Steering System and Main Propulsion ArrangementDocument26 pagesSteering System and Main Propulsion ArrangementveramondNo ratings yet

- New Ad340 All ParametersDocument58 pagesNew Ad340 All Parametersseeni.mathanNo ratings yet

- Operator Controls GuideDocument34 pagesOperator Controls Guideoleg796267% (3)

- Búsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDocument5 pagesBúsqueda Del Medio - RENR6305 - 994F Wheel Loader Power TrainDavidCPNo ratings yet

- Shift on the Fly Drive Line Control System GuideDocument38 pagesShift on the Fly Drive Line Control System GuideMonique SporriNo ratings yet

- Air Filter PressureDocument40 pagesAir Filter PressuressinokrotNo ratings yet

- Auto Trans Diagnosis Mitsubishi MonteroDocument25 pagesAuto Trans Diagnosis Mitsubishi Monteronicamarcos100% (3)

- Cola Yard 3Document11 pagesCola Yard 3pupung182No ratings yet

- 400 Controls and InstrumentsDocument17 pages400 Controls and InstrumentsMrAlbert2009No ratings yet

- Clarke Mechanical Engine Controller Alarm Verification ProcedureDocument4 pagesClarke Mechanical Engine Controller Alarm Verification ProcedureChanat MeonsiNo ratings yet

- Auto Trans Diagnosis - Aw03-72Le Article TextDocument15 pagesAuto Trans Diagnosis - Aw03-72Le Article TextCarlos Andres Campos TorresNo ratings yet

- D6R Track-Type Tractor 2YN00001-UP (MACHINE) POWننERED BY 3306 Engine (SEBP2615 - 58) - Document StructureDocument2 pagesD6R Track-Type Tractor 2YN00001-UP (MACHINE) POWننERED BY 3306 Engine (SEBP2615 - 58) - Document StructureBasem ElhosanyNo ratings yet

- Buhler Versatile Transmission Operation and Overview Manual SectionDocument150 pagesBuhler Versatile Transmission Operation and Overview Manual SectionnunyaNo ratings yet

- C K1 Manual 2020Document6 pagesC K1 Manual 2020Jon PadliNo ratings yet

- 2000 Ford Ranger 4.0l Transfer CaseDocument66 pages2000 Ford Ranger 4.0l Transfer CaseurielferNo ratings yet

- SSP-283 6 Speed Automatic Gearbox Audi A8 03' Part 2 PDFDocument26 pagesSSP-283 6 Speed Automatic Gearbox Audi A8 03' Part 2 PDFRizwan HameedNo ratings yet

- Maintenance Precautions of Transmission, Transaxle (AWR6B45)Document52 pagesMaintenance Precautions of Transmission, Transaxle (AWR6B45)Patricio Valencia100% (7)

- Earthing Calculation: A General Design DataDocument14 pagesEarthing Calculation: A General Design Dataمحمد الأمين سنوساوي100% (1)

- English Language RBI AssistantDocument35 pagesEnglish Language RBI AssistantGeeta Jadhav100% (1)

- Lesson 13 StsDocument11 pagesLesson 13 StsJasmin Lloyd CarlosNo ratings yet

- What is an electrolyser and how does it generate hydrogenDocument1 pageWhat is an electrolyser and how does it generate hydrogenbhaidadaNo ratings yet

- Lab ReportDocument3 pagesLab ReportasdadadNo ratings yet

- Plate Heat ExchangerDocument12 pagesPlate Heat ExchangerEngSafwanQadousNo ratings yet

- Covid 19 ImpactDocument38 pagesCovid 19 ImpactNavneet NandaNo ratings yet

- .Uksitesdefaultfiles2023 10Pages20from20LOCOMOTION20report20part201 PDFDocument109 pages.Uksitesdefaultfiles2023 10Pages20from20LOCOMOTION20report20part201 PDFdfjpennington1No ratings yet

- ME HoneywellVideoSystems PDFDocument157 pagesME HoneywellVideoSystems PDFSteven HungNo ratings yet

- Automatic smoke detector and fire alarm systemDocument7 pagesAutomatic smoke detector and fire alarm systemSwastik JainNo ratings yet

- NURS FPX 6612 Assessment 2 Quality Improvement ProposalDocument6 pagesNURS FPX 6612 Assessment 2 Quality Improvement Proposalzadem5266No ratings yet

- Module 7 Polymorphism and AbstractionDocument55 pagesModule 7 Polymorphism and AbstractionJoshua Miguel NaongNo ratings yet

- Law Made Simple Intellectual Property Law Note 1 0f 7 Notes: Musbri Mohamed Dil Adil (Itm) MBL (Ukm)Document50 pagesLaw Made Simple Intellectual Property Law Note 1 0f 7 Notes: Musbri Mohamed Dil Adil (Itm) MBL (Ukm)musbri mohamedNo ratings yet

- Common Washing Machine Error Codes - Samsung IndiaDocument6 pagesCommon Washing Machine Error Codes - Samsung IndiaRyan KadavilNo ratings yet

- Introduction To Companies - Flipkart and Meesho FlipkartDocument5 pagesIntroduction To Companies - Flipkart and Meesho FlipkartARNAV MISRANo ratings yet

- Webnavigator Wincc Client SiemensDocument156 pagesWebnavigator Wincc Client SiemensEder Rinas0% (1)

- w220 S-Class Encyclopedia Jan 2014Document44 pagesw220 S-Class Encyclopedia Jan 2014Aziz Al-Qadri Wal Chisti100% (2)

- Models - Heat.conical Dielectric ProbeDocument28 pagesModels - Heat.conical Dielectric ProbeDenis JaissonNo ratings yet

- Lecture 10: A Design Example - Traffic Lights: The ProblemDocument6 pagesLecture 10: A Design Example - Traffic Lights: The ProblemrinobiNo ratings yet

- Production of Coated Detergent Enzyme GranulesDocument121 pagesProduction of Coated Detergent Enzyme Granulesdadang71No ratings yet

- Laporan Aplikasi Kalkulator & Intent PDFDocument15 pagesLaporan Aplikasi Kalkulator & Intent PDFchusnun nidhomNo ratings yet

- 050 Vacuum Pump Systems 2021Document190 pages050 Vacuum Pump Systems 2021Balamurugan ArumugamNo ratings yet

- D410 Sleeve Lock Grout Sleeve: Technical Data SheetDocument2 pagesD410 Sleeve Lock Grout Sleeve: Technical Data SheetSofía Córdoba SáenzNo ratings yet

- F2022C00010Document152 pagesF2022C00010CNo ratings yet

- Dell Premium DES-4121 by - VCEplus 60q-DEMO PDFDocument19 pagesDell Premium DES-4121 by - VCEplus 60q-DEMO PDFDinaj AttanayakaNo ratings yet

- Automata Homework SolutionsDocument5 pagesAutomata Homework Solutionsafmsxeghf100% (1)

- Skills-Based Assessment (Version A) : TopologyDocument5 pagesSkills-Based Assessment (Version A) : TopologyYagui100% (1)

- Diseño de Un Sistema Fotovoltaico Universidad de EcuadorDocument17 pagesDiseño de Un Sistema Fotovoltaico Universidad de EcuadorCamila gomez thomasNo ratings yet

- Investor Customer'S Option To Receive Payments Through: No/Ledger Folio NoDocument3 pagesInvestor Customer'S Option To Receive Payments Through: No/Ledger Folio NoAnkur Bharat VermaNo ratings yet

- Resume Rohit JainDocument2 pagesResume Rohit JainJigar JainNo ratings yet