Professional Documents

Culture Documents

DGR 62 en Pi650

Uploaded by

NevenaObrenovićOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DGR 62 en Pi650

Uploaded by

NevenaObrenovićCopyright:

Available Formats

Dangerous Goods Regulations

PACKING INSTRUCTION 650

STATE VARIATIONS: BHG02, CAG05, DQG03, GBG05, GHG02, IDG02, VCG04

OPERATOR VARIATIONS: 4C04, 4M04, 5X01, AM06/10, AS08, BR14, BZ07, CM05, E903, FX04, G302, IP03,

JJ04, KC08, KE06, L704, LA07, LP04, LU04, M304, M704, MS06, OU12, PX08, SV12, TN05, UC04, WR03,

WS03, XL04, XQ05

5 This instruction applies to UN 3373 on passenger and cargo aircraft and Cargo Aircraft Only.

Y645 General Requirements

to The packagings must be of good quality, strong enough to withstand the shocks and loadings normally encountered

during transport, including trans-shipment between transport units and between transport units and warehouses as well as

650 any removal from a pallet or overpack for subsequent manual or mechanical handling. Packagings must be constructed

and closed so as to prevent any loss of contents that might be caused under normal conditions of transport, by vibration,

or by changes in temperature, humidity or pressure.

The packaging must consist of three components:

(a) a primary receptacle(s);

(b) a secondary packaging; and

(c) a rigid outer packaging.

Primary receptacles must be packed in secondary packagings in such a way that, under normal conditions of transport,

they cannot break, be punctured or leak their contents into the secondary packaging. Secondary packagings must be

secured in outer packagings with suitable cushioning material. Any leakage of the contents must not compromise the

integrity of the cushioning material or of the outer packaging.

Packages must be prepared as follows:

(a) For liquid substances:

1. The primary receptacle(s) must be leakproof and must not contain more than 1 L;

2. The secondary packaging must be leakproof;

3. If multiple fragile primary receptacles are placed in a single secondary packaging, they must be either individually

wrapped or separated to prevent contact between them;

4. Absorbent material must be placed between the primary receptacle and the secondary packaging. The absorbent

material, such as cotton wool, must be in sufficient quantity to absorb the entire contents of the primary

receptacle(s) so that any release of the liquid substance will not compromise the integrity of the cushioning

material or of the outer packaging;

5. The primary receptacle or the secondary packaging must be capable of withstanding, without leakage, an internal

pressure of 95 kPa.

6. The outer packaging must not contain more than 4 L. This quantity excludes ice, dry ice or liquid nitrogen when

used to keep specimens cold.

Note:

The capability of a packaging to withstand an internal pressure without leakage that produces the specified

pressure differential should be determined by testing samples of primary receptacles or secondary packagings.

Pressure differential is the difference between the pressure exerted on the inside of the receptacle or packaging

and the pressure on the outside. The appropriate test method should be selected based on receptacle or

packaging type. Acceptable test methods include any method that produces the required pressure differential

between the inside and outside of a primary receptacle or a secondary packaging. The test may be conducted

using internal hydraulic or pneumatic pressure (gauge) or external vacuum test methods. Internal hydraulic or

pneumatic pressure can be applied in most cases as the required pressure differential can be achieved under

568 62nd EDITION, 1 JANUARY 2021

Packing

PACKING INSTRUCTION 650 (continued)

most circumstances. An external vacuum test is not acceptable if the specified pressure differential is not

achieved and maintained. The external vacuum test is a generally acceptable method for rigid receptacles and

packagings but is not normally acceptable for:

– flexible receptacles and flexible packagings;

– receptacles and packagings filled and closed under an absolute atmospheric pressure lower than 95 kPa.

(b) For solid substances:

1. The primary receptacle(s) must be siftproof and must not exceed the outer packaging weight limit;

2. The secondary packaging must be siftproof;

3. If multiple fragile primary receptacles are placed in a single secondary packaging, they must be either individually

wrapped or separated to prevent contact between them;

4. Except for packages containing body parts, organs or whole bodies, the outer packaging must not contain more

than 4 kg. This quantity excludes ice, dry ice or liquid nitrogen when used to keep specimens cold;

5. If there is any doubt as to whether or not residual liquid may be present in the primary receptacle during transport

then a packaging suitable for liquids, including absorbent materials, must be used. 5

An itemized list of contents must be enclosed between the secondary packaging and the outer packaging.

650

At least one surface of the outer packaging must have a minimum dimension of 100 mm × 100 mm.

The completed package must be capable of successfully passing the drop test described in 6.5.4.4 as specified in 6.5.4.2

except that the height of the drop must not be less than 1.2 m. Following the appropriate drop sequence, there must be no

leakage from the primary receptacle(s) which must remain protected by absorbent material, when required, in the

secondary packaging.

For transport, the mark illustrated below must be displayed on the external surface of the outer packaging on a

background of a contrasting colour and must be clearly visible and legible. The mark must be in the form of a square set

at an angle of 45° (diamond-shaped) with each side having a length of at least 50 mm, the width of the line must be at

least 2 mm and the letters and numbers must be at least 6 mm high. The entire mark must appear on one side of the

package. The proper shipping name “Biological Substance, Category B” in letters at least 6 mm high must be marked on

the outer packaging adjacent to the diamond-shaped mark.

Unless all package marks are clearly visible, the following conditions apply when packages are placed in an overpack:

● the overpack must be marked with the word “Overpack” in lettering at least 12 mm high; and

● the package marks must be reproduced on the outside of the overpack.

A Shipper's Declaration for Dangerous Goods is not required.

Alternative packagings for the transport of animal material may be authorized by the competent authority in accordance

with the provisions in 5.0.6.7.

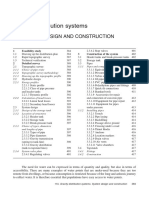

62nd EDITION, 1 JANUARY 2021 569

Dangerous Goods Regulations

PACKING INSTRUCTION 650 (continued)

Specific Requirements

Refrigerated or frozen specimens: Ice, dry ice and liquid nitrogen:

● When dry ice or liquid nitrogen is used to keep specimens cold, all applicable requirements of these Regulations must

be met. When used, ice or dry ice must be placed outside the secondary packagings or in the outer packaging or an

overpack. Interior supports must be provided to secure the secondary packagings in the original position after the ice

or dry ice has dissipated. If ice is used, the outside packaging or overpack must be leakproof. If dry ice is used, the

packaging must be designed and constructed to permit the release of carbon dioxide gas to prevent a build-up of

pressure that could rupture the packagings.

● The primary receptacle and the secondary packaging must maintain their integrity at the temperature of the

refrigerant used as well as the temperatures and the pressures, which could result if refrigeration were to be lost.

Infectious substances assigned to UN 3373 which are packed and marked in accordance with this packing instruction are

not subject to any other requirement of these Regulations except for the following:

(a) the name and address of the shipper and of the consignee must be provided on each package;

5 (b) the name and telephone number of a person responsible must be provided on the air waybill or on the package;

(c) the classification must be in accordance to 3.6.2;

650 (d) the incident reporting requirements in 9.6.1 and 9.6.2 must be met; and

to (e) the inspection for damage or leakage requirements in 9.4.1 and 9.4.2.

651 Note:

When the shipper or consignee is also the ‘person responsible’ as referred to in b) above, the name and address need be

marked only once in order to satisfy the name and address marking provisions in both a) and b), above.

Passengers and crew members are prohibited from transporting infectious substances as or in carry-on baggage, checked

baggage or on their person.

If an Air Waybill is used, the “Nature and Quantity of Goods” box must show “UN 3373”, the text “BIOLOGICAL

SUBSTANCE, CATEGORY B” and the number of packages (unless these are the only packages within the consignment).

Clear instructions on filling and closing such packages must be provided by packaging manufacturers and subsequent

distributors to the shipper or to the person who prepares the package (e.g. patient) to enable the package to be correctly

prepared for transport.

Other dangerous goods must not be packed in the same packaging as Division 6.2 Infectious Substances unless they are

necessary for maintaining the viability, stabilizing or preventing degradation or neutralizing the hazards of the infectious

substances. A quantity of 30 mL or less of dangerous goods included in Classes 3, 8 or 9 permitted as excepted

quantities under 2.6 may be packed in each primary receptacle containing infectious substances. When these small

quantities of dangerous goods are packed with infectious substances in accordance with this packing instruction, no other

requirements in these Regulations need be met.

570 62nd EDITION, 1 JANUARY 2021

You might also like

- DGR51 Pi650 enDocument4 pagesDGR51 Pi650 enDung PhanduyNo ratings yet

- P650 Packaging Instruction P650Document3 pagesP650 Packaging Instruction P650Dung PhanduyNo ratings yet

- Shipping SopDocument8 pagesShipping SopV R Logistics LimitedNo ratings yet

- Almacenamiento Farmacopea InternacionalDocument1 pageAlmacenamiento Farmacopea Internacionallocal5.fsgNo ratings yet

- Conditions For Acceptance of Waste in The Untertagedeponie HeilbronnDocument2 pagesConditions For Acceptance of Waste in The Untertagedeponie HeilbronnAmilton filhoNo ratings yet

- Enp GW57-363-550Document27 pagesEnp GW57-363-550byrsNo ratings yet

- Refrigerated Cargoes PDFDocument6 pagesRefrigerated Cargoes PDFJOYNo ratings yet

- Closed Container GuidanceDocument4 pagesClosed Container GuidanceDeni FahrizaNo ratings yet

- Bulk A Particular Class/type of Dangerous And/or Hazardous Cargoes or GoodsDocument5 pagesBulk A Particular Class/type of Dangerous And/or Hazardous Cargoes or GoodsMarixNo ratings yet

- Packing ProcedureDocument12 pagesPacking Procedureehsan.m100% (2)

- LBC Packaging RulesDocument5 pagesLBC Packaging Ruleszumaduma100% (1)

- Safety Data Dri B ChipsDocument5 pagesSafety Data Dri B ChipsDavid PapelonNo ratings yet

- QC of Packaging MaterialsDocument13 pagesQC of Packaging Materialsvsvsuresh2099No ratings yet

- Resume Refrigerated Cargo: I. Types of Refrigerated CargoesDocument6 pagesResume Refrigerated Cargo: I. Types of Refrigerated CargoesGede SegaraNo ratings yet

- A Basic Packing Guide: Certification of Intermodal ContainersDocument8 pagesA Basic Packing Guide: Certification of Intermodal ContainersgustavoseseNo ratings yet

- Storage and Handling of Drums & Intermediate Bulk Containers:Ppg26Document6 pagesStorage and Handling of Drums & Intermediate Bulk Containers:Ppg26TC Cüneyt ŞanNo ratings yet

- General PackingDocument7 pagesGeneral PackingMuhammad Farukh ManzoorNo ratings yet

- Packaging and Shipping Instructions CoatingDocument15 pagesPackaging and Shipping Instructions CoatingyusefNo ratings yet

- KSPC Packing Marking Shipping InstructionDocument9 pagesKSPC Packing Marking Shipping InstructionMohammed Ahmed NasherNo ratings yet

- Enp GW56-252-300Document20 pagesEnp GW56-252-300byrsNo ratings yet

- CXS - 092e - Codex ShrimpDocument6 pagesCXS - 092e - Codex ShrimpldfdNo ratings yet

- Packaging and StorageDocument3 pagesPackaging and StorageIvana HalingkarNo ratings yet

- Napala, Ronn Andre R. BSMT Ii-A Lo 1.6Document38 pagesNapala, Ronn Andre R. BSMT Ii-A Lo 1.6Andre NapalaNo ratings yet

- DOT Collection Continer RegsDocument1 pageDOT Collection Continer RegsTom SnellingNo ratings yet

- CXS - 190e Standard For Quick Frozen Fish FilletsDocument6 pagesCXS - 190e Standard For Quick Frozen Fish FilletsImanNo ratings yet

- Code of Safe Practice For Solid Bulk CargoesDocument5 pagesCode of Safe Practice For Solid Bulk CargoesRohit KakadeNo ratings yet

- Home AssignmentDocument11 pagesHome Assignmentsuvanshkhanna8No ratings yet

- Clinical Samples, Diagnostic Specimens and Environmental Test SamplesDocument5 pagesClinical Samples, Diagnostic Specimens and Environmental Test Samplesjeka3No ratings yet

- Day 2Document224 pagesDay 2parasytemaxim30100% (1)

- Codex Standard For Quick Frozen Raw Squid: CODEX STAN 191-1995 Page 1 of 6Document6 pagesCodex Standard For Quick Frozen Raw Squid: CODEX STAN 191-1995 Page 1 of 6gustavosantos01No ratings yet

- UCSC Autoclave Procedures 12-2009Document1 pageUCSC Autoclave Procedures 12-2009samarthanNo ratings yet

- Home Assignment - PDF (Cargo Work)Document14 pagesHome Assignment - PDF (Cargo Work)Mitanshu ChadhaNo ratings yet

- Valve Maintenance Packing Replacement 170129023327 PDFDocument36 pagesValve Maintenance Packing Replacement 170129023327 PDFRamalingam PrabhakaranNo ratings yet

- PARBICA 2002 Guide Conservation ENDocument19 pagesPARBICA 2002 Guide Conservation ENJeric Ivan Yee NgoNo ratings yet

- CH 13-Packaged CargoesDocument6 pagesCH 13-Packaged CargoesAntonio AntonioNo ratings yet

- Ports and Maritime Organization Seafarers' Affairs DirectorateDocument6 pagesPorts and Maritime Organization Seafarers' Affairs DirectorateAmir SoleimanyNo ratings yet

- Direct Reduced Iron: DescriptionDocument9 pagesDirect Reduced Iron: DescriptionVivek GillNo ratings yet

- 2 - Pouch - Storage Shelf life-ST79Document2 pages2 - Pouch - Storage Shelf life-ST79Panthita Srisumran100% (1)

- Shipping - Lifting.storage RecommendationsDocument6 pagesShipping - Lifting.storage RecommendationsaslirohmandotcomNo ratings yet

- 0S 2 PacingDocument55 pages0S 2 PacingDoaa HassanNo ratings yet

- Imsbc Code Extract - Ammonium Nitrate Un1942Document3 pagesImsbc Code Extract - Ammonium Nitrate Un1942Harman SandhuNo ratings yet

- Importance of Packing in Marine InsuranceDocument29 pagesImportance of Packing in Marine InsuranceAman DivyaNo ratings yet

- IATA-Live Animal RegulationsDocument23 pagesIATA-Live Animal Regulationsfranky100% (1)

- SOP No. 20.0 Sample Shipping ProceduresDocument6 pagesSOP No. 20.0 Sample Shipping ProceduresMahayudin SaadNo ratings yet

- Packing Procedure PDFDocument12 pagesPacking Procedure PDFpl_arunachalam79100% (1)

- JS04 (Practical) - RGP 3133Document6 pagesJS04 (Practical) - RGP 3133Mohamad Amirul AnisNo ratings yet

- Unpacking ProcedureDocument2 pagesUnpacking Procedurebmanojkumar16100% (1)

- Cargo Separation & segregation-INSPECTION AND PREPARATION OF HOLDSDocument21 pagesCargo Separation & segregation-INSPECTION AND PREPARATION OF HOLDSmoaid013No ratings yet

- Hydaranautics MembraneDocument3 pagesHydaranautics Membraneafraz_xecNo ratings yet

- Sample Handling: 1. FumigationDocument3 pagesSample Handling: 1. FumigationAyoubMuhammadNo ratings yet

- Gen SPC Meq 4010 - Rev.bDocument10 pagesGen SPC Meq 4010 - Rev.bAHMED AMIRANo ratings yet

- Warehouse Standards-6Document4 pagesWarehouse Standards-6Ahmed MostafaNo ratings yet

- Packing and Polybag Requirements and GuidelinesDocument4 pagesPacking and Polybag Requirements and GuidelinesHuongly QuachNo ratings yet

- 7 Dangerous CargoDocument11 pages7 Dangerous CargoMamunNo ratings yet

- Moisture Content of Paper and Paperboard by Oven Drying: Standard Test Method ForDocument2 pagesMoisture Content of Paper and Paperboard by Oven Drying: Standard Test Method ForfrostestNo ratings yet

- Product Manual-En (GW55 72.5-362)Document28 pagesProduct Manual-En (GW55 72.5-362)Hoài Sơn LêNo ratings yet

- I-7.1 Instructions For StorageDocument6 pagesI-7.1 Instructions For StorageborodichNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Soal TPS Bahasa InggrisDocument3 pagesSoal TPS Bahasa InggrisMaya Putri EkasariNo ratings yet

- DTZZIII User's GuideDocument4 pagesDTZZIII User's GuideDiego BaezNo ratings yet

- AaaaaDocument3 pagesAaaaaAnonymous C3BD7OdNo ratings yet

- Simulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine DesignDocument24 pagesSimulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine Designjeevan scplNo ratings yet

- Gravity Distribution Systems: A System Design and ConstructionDocument40 pagesGravity Distribution Systems: A System Design and ConstructionTooma DavidNo ratings yet

- Astm D2777 Determinacion de La Precision y El Sesgo PDFDocument21 pagesAstm D2777 Determinacion de La Precision y El Sesgo PDFAlvaro Pérez PérezNo ratings yet

- Ministry of Health and Family Welfare Pregnancy GuidelinesDocument173 pagesMinistry of Health and Family Welfare Pregnancy GuidelinesKhushi GuptaNo ratings yet

- Humanistic TheoryDocument28 pagesHumanistic TheoryNano KaNo ratings yet

- Reinstatement Management PlanDocument38 pagesReinstatement Management Planvesgacarlos-1No ratings yet

- What Is Emergency Lighting Circuit DiagramDocument14 pagesWhat Is Emergency Lighting Circuit DiagramjackNo ratings yet

- Misel 2Document15 pagesMisel 2Undarma 1405No ratings yet

- SM52 PDFDocument28 pagesSM52 PDFtaqigata75% (4)

- DLL-All Subjects - Week 7 Day 1Document5 pagesDLL-All Subjects - Week 7 Day 1Windel Beth Quimat ZafraNo ratings yet

- Philippine College of Science and Technology: Assignment For Module 1 Nge6 (Art Appreciation)Document1 pagePhilippine College of Science and Technology: Assignment For Module 1 Nge6 (Art Appreciation)Mark Brendon Jess VargasNo ratings yet

- Word Formation - Open Cloze Exercises Unit 1Document2 pagesWord Formation - Open Cloze Exercises Unit 1Fatima Luz RuizNo ratings yet

- SM2 Polygon of ForcesDocument11 pagesSM2 Polygon of ForcesMel DNo ratings yet

- h1 Styleclearboth Idcontentsection0the Only Guide To Commercial Fisheries Reviewh1jbfch PDFDocument14 pagesh1 Styleclearboth Idcontentsection0the Only Guide To Commercial Fisheries Reviewh1jbfch PDFgalleymark22No ratings yet

- Session Nos. 26 - 31: Cities of Mandaluyong and PasigDocument25 pagesSession Nos. 26 - 31: Cities of Mandaluyong and PasigLego AlbertNo ratings yet

- DSS+ SH Risk Management HandbookDocument20 pagesDSS+ SH Risk Management HandbookAlan PicazzoNo ratings yet

- Contact Inform 2002 OldDocument22 pagesContact Inform 2002 OldBelajar PurboNo ratings yet

- Unit 5Document3 pagesUnit 5api-665951284No ratings yet

- IHS Markit Seed Market Analysis and Data InfographicDocument1 pageIHS Markit Seed Market Analysis and Data Infographictripurari pandeyNo ratings yet

- CSC-160 Series Numerical Line Protection EquipmentDocument112 pagesCSC-160 Series Numerical Line Protection EquipmentMarkusKunNo ratings yet

- Accion Didactica 1st Grade NovemberDocument3 pagesAccion Didactica 1st Grade NovemberAntonio Abad GutiérrezNo ratings yet

- Đề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Document8 pagesĐề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Chi Vũ LinhNo ratings yet

- 2347-Article Text-7179-1-10-20220922Document12 pages2347-Article Text-7179-1-10-20220922george weafriNo ratings yet

- Rd6appspecDocument2 pagesRd6appspecravi00098No ratings yet

- Seasons and WeatherDocument2 pagesSeasons and WeatherОлінька СтецюкNo ratings yet

- VERITAS Cluster Server For UNIX, Fundamentals: Lesson 6 VCS Configuration MethodsDocument50 pagesVERITAS Cluster Server For UNIX, Fundamentals: Lesson 6 VCS Configuration MethodsNirmal AsaithambiNo ratings yet

- Final Exam For EappDocument2 pagesFinal Exam For EappReychel NecorNo ratings yet