Professional Documents

Culture Documents

Kekavuzasegamumajot

Kekavuzasegamumajot

Uploaded by

BASEM NOMAN ALI MOHAMMEDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kekavuzasegamumajot

Kekavuzasegamumajot

Uploaded by

BASEM NOMAN ALI MOHAMMEDCopyright:

Available Formats

Krones labeler troubleshooting guide version 2017

Krones training manuals pdf. Krones machine pdf. Krones labeler troubleshooting. Krones manual of labelling technology pdf. Krones labeler troubleshooting guide.

Krones Checkmat label inspectors By Alex Lubyansky Updated January 09, 2018 Krones labelers do not represent your typical hand-held labeling devices.

Rather, these massive devices help major companies label large quantities of products. For example, a beer company would use a Krones labeler to place a label on the thousands of bottles they produce on a daily basis. Because of this, you cannot simply troubleshoot a Krones labeler. You need to obtain certification through a training course in order

to do so.

Visit the Krones website (see Resources). Go to the “Academy” section.Find a course of your liking. Krones’s courses last two days and teach a plethora of operational procedures for their high-tech labelers. All of the courses deal with basic troubleshooting. A course can cost anywhere from $950 to $1,190 as of March 2011. You can find courses in

both English and Spanish. Contact Krones to sign up for the course. They will give you concrete instructions. Arrive for the course. Take careful notes and retain all information you possibly can.

You will now have the ability to troubleshoot your Krones labeler. Lifecycle Service Support Requirements: Basic knowledge of operation and mechanical components of the Contiroll Topics: Poor label quality (seat too high or too low, overlapping, etc.) Cutting mark control and incorrect label lengths Gluing (too much, too little, uneven) Label

crooked on the container Problem with cutting unit and cutting position Fault during automatic splicing Problems the container runthrough can cause Handling “Gripper monitoring 2 & 3” fault messages Change parameters or adjust mechanically – find the right way Course objective: Learn how to solve problems quickly, prevent malfunctions and

avoid downtimes: This compact seminar contains tested analysis routines for the most frequent problems on the Contiroll labeller.

You will learn in a mechanical way directly on the training machine how they can be troubleshot.

You might also like

- Paint and Coatings Industry June 2010Document76 pagesPaint and Coatings Industry June 2010sami_sakr100% (1)

- Landrover Discovery RepuestosDocument101 pagesLandrover Discovery RepuestosAntonioJFunezLuna100% (1)

- Loctite HandbookDocument213 pagesLoctite Handbookvp989No ratings yet

- Ib867e Code On Alert IndicatorDocument2 pagesIb867e Code On Alert Indicatoredtatel73No ratings yet

- Catalogue: Fixing SystemsDocument602 pagesCatalogue: Fixing SystemsOmar AL-jazairiNo ratings yet

- Catalogue AMF Hand ToolsDocument72 pagesCatalogue AMF Hand ToolskitofanecoNo ratings yet

- (European Coatings TECH FILES) Winkelaar, Adrie - Coatings Basics-Vincentz Network (2014)Document149 pages(European Coatings TECH FILES) Winkelaar, Adrie - Coatings Basics-Vincentz Network (2014)Arthur Thiesen100% (1)

- Global Davit GMBHDocument8 pagesGlobal Davit GMBHTimothy JacksonNo ratings yet

- Running a Good Business - Book 7: Designing Your Space: Running a Good Business, #7From EverandRunning a Good Business - Book 7: Designing Your Space: Running a Good Business, #7No ratings yet

- صيانة المولدات والمحركات الكهربائية PDFDocument15 pagesصيانة المولدات والمحركات الكهربائية PDFBASEM NOMAN ALI MOHAMMEDNo ratings yet

- Engineering Documentation Control / Configuration Management Standards ManualFrom EverandEngineering Documentation Control / Configuration Management Standards ManualNo ratings yet

- Car Washing 1Document44 pagesCar Washing 1zivkovic brankoNo ratings yet

- Loctite Adhesive SourcebookDocument212 pagesLoctite Adhesive Sourcebookechobravo1No ratings yet

- Pushing The Limits.: Your Global SpecialistDocument24 pagesPushing The Limits.: Your Global SpecialistAashish JainNo ratings yet

- Tips For Using The Maryland Metrics Fastener Catalog: Supply All Products With Surface Treatment Per Your RequestDocument3 pagesTips For Using The Maryland Metrics Fastener Catalog: Supply All Products With Surface Treatment Per Your RequestAlejandroNo ratings yet

- Offshore CV Examples UkDocument8 pagesOffshore CV Examples Ukafjwfugcueaonf100% (2)

- Carl Ostermann Erben (COE) Is Announced As German Trade Shop For Bellissima DMSDocument4 pagesCarl Ostermann Erben (COE) Is Announced As German Trade Shop For Bellissima DMSPR.comNo ratings yet

- Short Case Handles and Hinges LTDDocument4 pagesShort Case Handles and Hinges LTDYasir ShafiqNo ratings yet

- HannDocument80 pagesHannEdwin RodriguezNo ratings yet

- Workplace Resources: Visual Systems Supplies That Help Deliver Results Fast!Document6 pagesWorkplace Resources: Visual Systems Supplies That Help Deliver Results Fast!pallavan.kNo ratings yet

- Automotive en 20082Document165 pagesAutomotive en 20082Nishant ShahNo ratings yet

- Automobil Brancheninfo enDocument8 pagesAutomobil Brancheninfo enclcspfcNo ratings yet

- Full Download Solution Manual For Operations and Supply Management The Core Jacobs Chase 3rd Edition PDF Full ChapterDocument36 pagesFull Download Solution Manual For Operations and Supply Management The Core Jacobs Chase 3rd Edition PDF Full Chapterdewdrop.threat.7ia4yn100% (17)

- Company Description, Schedule and Risk AllocationDocument3 pagesCompany Description, Schedule and Risk AllocationDiane Angel OmnosNo ratings yet

- Chapter I Company ProfileDocument16 pagesChapter I Company ProfilelooserNo ratings yet

- Coatings Word February 2013Document52 pagesCoatings Word February 2013sami_sakrNo ratings yet

- Catalog Of: Standard Clamping ToolsDocument80 pagesCatalog Of: Standard Clamping ToolsJosip ZrilićNo ratings yet

- Corporate GEA KestnerDocument8 pagesCorporate GEA KestnerlaurentpalierneNo ratings yet

- 2017 ASC Exhibit GuideDocument36 pages2017 ASC Exhibit GuideAlvaro Nerviani AltieriNo ratings yet

- Monitor Sharp LL-T15V1Document124 pagesMonitor Sharp LL-T15V1Anonymous RCPxaonfvNo ratings yet

- Trridev Labels BrochureDocument6 pagesTrridev Labels Brochurevasanti vasanti100% (1)

- Asian PaintsDocument155 pagesAsian Paintsrahulcute_ipsNo ratings yet

- Quality Assurance Steps For Preventing Label Printing ProblemsDocument12 pagesQuality Assurance Steps For Preventing Label Printing ProblemsDaniel MerlosNo ratings yet

- Shrinktech KatalogusDocument76 pagesShrinktech KataloguspuzsooNo ratings yet

- Emissions Control BrochureDocument12 pagesEmissions Control BrochureAlliance Transport Technologies LtdNo ratings yet

- Lancia Thesis Owners Manual EnglishDocument8 pagesLancia Thesis Owners Manual Englishgxirgjwff100% (2)

- Competition and Technology How To Make Money F Rom HardwareDocument9 pagesCompetition and Technology How To Make Money F Rom HardwarepostscriptNo ratings yet

- 6404 LtsiDocument4 pages6404 LtsiYashvanth ShettyNo ratings yet

- Helios - Preisser - Katalog 2012 ENDocument274 pagesHelios - Preisser - Katalog 2012 END.T.No ratings yet

- LT5798 Industrial Adhesives CatalogDocument28 pagesLT5798 Industrial Adhesives CatalogJOSEANTONIO2001No ratings yet

- Avery Thermal Transfer Ribbons - WWW - TrridevlabelssDocument4 pagesAvery Thermal Transfer Ribbons - WWW - TrridevlabelssTrridev Labelss Mfg CoNo ratings yet

- Curriculum Vitae English ClubDocument8 pagesCurriculum Vitae English Clube76qy0tk100% (1)

- Enterprise Resource Planning Case Studies 123Document9 pagesEnterprise Resource Planning Case Studies 123Shah ParthivNo ratings yet

- MAGMA - Cryostar Magazine6Document12 pagesMAGMA - Cryostar Magazine6Narayan MarndiNo ratings yet

- Regal MarineDocument3 pagesRegal MarineUmer FarooqNo ratings yet

- Manual de Marca Innospec CM 1197909112 Brand GuidelinesDocument16 pagesManual de Marca Innospec CM 1197909112 Brand GuidelinespazymatiNo ratings yet

- Company ProfileDocument3 pagesCompany Profileamoghitis18No ratings yet

- A Local Partner With A Global Reach: The Premier Tech Chronos WorldDocument8 pagesA Local Partner With A Global Reach: The Premier Tech Chronos WorldNaeemSiddiquiNo ratings yet

- Curriculum Vitae English DateDocument5 pagesCurriculum Vitae English Datezpxjybifg100% (2)

- ReflexesDocument7 pagesReflexesZsolt HorváthNo ratings yet

- Blow Room 2015Document100 pagesBlow Room 2015Bernardus SianturiNo ratings yet

- Lechler Brochure Shipbuilding Industry enDocument16 pagesLechler Brochure Shipbuilding Industry enAlbert AbessonNo ratings yet

- Paint Inspection LTD: WelcomeDocument3 pagesPaint Inspection LTD: WelcomeAndrew PattersonNo ratings yet

- Rexam Beverage Can Americas S Profile Sheet 2016 (Premio Shingo, Santiago de Queretaro, Queretaro, Mexico)Document4 pagesRexam Beverage Can Americas S Profile Sheet 2016 (Premio Shingo, Santiago de Queretaro, Queretaro, Mexico)Salvador Sierra GasparianoNo ratings yet

- CH 01Document12 pagesCH 01FaisalsasaNo ratings yet

- Vulcam Mechanical SealsDocument122 pagesVulcam Mechanical SealsRicardoDoPradoNo ratings yet

- Reference OnlyDocument6 pagesReference Onlyafazakemb100% (2)

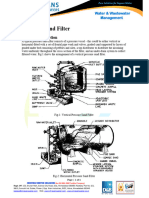

- Sand FilterDocument4 pagesSand FilterBASEM NOMAN ALI MOHAMMEDNo ratings yet

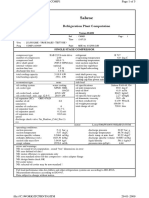

- C029 PAHBvi 1500 20230630Document20 pagesC029 PAHBvi 1500 20230630BASEM NOMAN ALI MOHAMMEDNo ratings yet

- Hpet 4 Hpet 6 Hpet 7.5 Hpet 10Document16 pagesHpet 4 Hpet 6 Hpet 7.5 Hpet 10BASEM NOMAN ALI MOHAMMEDNo ratings yet

- أكسجين نيتروجينDocument3 pagesأكسجين نيتروجينBASEM NOMAN ALI MOHAMMEDNo ratings yet

- SABROE Heat Pump Programme SB-4106r GB120dpiDocument2 pagesSABROE Heat Pump Programme SB-4106r GB120dpiBASEM NOMAN ALI MOHAMMEDNo ratings yet

- NHsoft VPDocument5 pagesNHsoft VPBASEM NOMAN ALI MOHAMMEDNo ratings yet