Professional Documents

Culture Documents

TableSaw - Test1 .1

Uploaded by

kinderinhococOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TableSaw - Test1 .1

Uploaded by

kinderinhococCopyright:

Available Formats

Table Saw Test # 1 Checking Arbor Run-out and Bearing Play

For your saw to operate properly, the “business end” of the

saw must be in good mechanical condition. This means

that the arbor shaft should be straight, and the arbor shaft

bearings must be in good condition.

One thing that should be emphasized is that this is a very

preliminary test, and can be done with either of the A-

Line-It kits.

I also want to emphasize that if your readings aren’t

perfect on this test, don’t panic and set your saw out near

the street with a “For Sale” sign on it...we have more

detailed tests that will explain how we can determine what

is happening near the saw blade teeth due to the condition

of the arbor.

Thoroughly clean the arbor shaft to insure there are no burrs or contamination that can cause improper readings as

you make the following tests.

The following procedure will allow you to determine the straightness of the arbor shaft. The reading is taken on

the smooth surface (behind the threads) where the bore of the saw blade is positioned.

Step 1. With the A-LINE-IT positioned on the guide slot as shown in the photo above, the dial indicator

should be pivoted (and locked) in a position that places the tip of the indicator over the smooth area on the

arbor that is between the threads for the blade nut and the arbor flange.

Step 2. Elevate the arbor shaft to make the pointer on the dial indicator to move at least 1 revolution

(clockwise).

Step 3. Slide the A-LINE-IT back and forth to position the tip of the indicator at “top-dead-center” on the

arbor shaft. (This is the point at which the pointer on the indicator goes “”clockwise” to a high reading, and

then starts to go “counter-clockwise”.

Step 4. Either clamp (or hold) the A-LINE-IT at this position, and “zero” the pointer on the indicator by

either rotating the face of the dial or changing the elevation on the arbor.

Step 5. Slowly rotate the arbor by turning the belt(s) on the saw. You will see any run-out in the arbor shaft.

If you see more than .001” - .002” (one to two thousandths of an inch), there is either some dirt or

contamination on the shaft, or you may need to do more detailed tests (Table Saw Test 2) to determine if

there is a problem with the arbor shaft. I’d recommend you re-inspect the shaft to make sure there is no

contamination, and re-test the arbor.

The following procedure will allow you to determine the condition of the arbor bearings. The reading is taken on

the smooth surface (behind the threads) on the arbor shaft where the sw blade is positioned.

Step 1. Position and secure the A-LINE-IT as explained in Step 1 through Step 4 above.

Step 2. Hold the threads of your arbor, and lightly try to move it (back-and-forth and up-and-down)

while watching the pointer on the dial indicator. You should see no movement of the pointer (but you

more than likely will, because we normally apply more pressure than necessary).

NOTE: Table Saw Test 2 will illustrate how you can determine the condition of the arbor, and show the effect

it has at the teeth of the blade.

You might also like

- AR 15 Lower Receiver Step by Step - MachiningDocument81 pagesAR 15 Lower Receiver Step by Step - Machiningshakeval90% (40)

- Ve Rega Arc StevensonDocument2 pagesVe Rega Arc Stevensonsofragiu petru0% (1)

- Ve Rega Arc BaerwaldDocument2 pagesVe Rega Arc Baerwaldunapaems100% (1)

- Complete Grand Regulation PDFDocument53 pagesComplete Grand Regulation PDFCharles D ArmbrusterNo ratings yet

- Acoustic Professional Service Manual PDFDocument34 pagesAcoustic Professional Service Manual PDFaeroseb1100% (1)

- O'Bannon Well Servicing Tools-1Document28 pagesO'Bannon Well Servicing Tools-1Praveen ChoudharyNo ratings yet

- 5R110W Low QualityDocument66 pages5R110W Low QualityScott NoelNo ratings yet

- Belt Tension Checker Instruction Sheet PDFDocument2 pagesBelt Tension Checker Instruction Sheet PDFhectorNo ratings yet

- VibrAlign Shaft System ManualDocument92 pagesVibrAlign Shaft System ManualMahmoud Hanafy100% (1)

- Remington 700 Rebuild: .243 Dec 2007 - Jan 2008Document23 pagesRemington 700 Rebuild: .243 Dec 2007 - Jan 2008john smith100% (2)

- Manual Orion EQ2Document8 pagesManual Orion EQ2cicerosaNo ratings yet

- Dial Indicator Alignment Procedure PDFDocument4 pagesDial Indicator Alignment Procedure PDFMohamed ShehataNo ratings yet

- CraftyCNC Probe Manual Rev 4Document9 pagesCraftyCNC Probe Manual Rev 4lynnwardleNo ratings yet

- Trouble Shooting Guide ShavingDocument4 pagesTrouble Shooting Guide ShavingShashindra DhopeshwarNo ratings yet

- BCS-S-003 - HA-360 Sampling Lift Motor AbnormalDocument9 pagesBCS-S-003 - HA-360 Sampling Lift Motor AbnormalGaurav JhaNo ratings yet

- Mounting Adjusting Pump UnitDocument2 pagesMounting Adjusting Pump UnitRalf JonesNo ratings yet

- 5.SMP Drag Chain Feeder (DCF)Document5 pages5.SMP Drag Chain Feeder (DCF)Abdullatif umatiyaNo ratings yet

- Ridgid Precision Flaring Tools ManualDocument1 pageRidgid Precision Flaring Tools ManualmaftmutoNo ratings yet

- PDF Manual290Document9 pagesPDF Manual290torbenNo ratings yet

- Using Adjustable Snap Gages: Section M 1Document14 pagesUsing Adjustable Snap Gages: Section M 1Bhaskar KrishnacharNo ratings yet

- Relay Base Wiring Guide Relay Base Wiring Guide: Fig 1 Locking The Relay Base Fig 1 Locking The Relay BaseDocument2 pagesRelay Base Wiring Guide Relay Base Wiring Guide: Fig 1 Locking The Relay Base Fig 1 Locking The Relay BaseAnonymous YWmB9HDgNo ratings yet

- Syncro Trak Service ManualDocument26 pagesSyncro Trak Service ManualMelina SbhNo ratings yet

- Tubing Casing Thread Training PR - PDFDocument60 pagesTubing Casing Thread Training PR - PDFSad RachidNo ratings yet

- TSR-009 - EngDocument7 pagesTSR-009 - EngA2139No ratings yet

- Ilide - Info Wire Rope Inspection PRDocument15 pagesIlide - Info Wire Rope Inspection PRHendri AdiNo ratings yet

- Elflow Inspection Procedure.2018Document28 pagesElflow Inspection Procedure.2018Yayan RuslanNo ratings yet

- Directions For The New T-REX ROTARY TABLE AND CHAINSAW GUIDEDocument1 pageDirections For The New T-REX ROTARY TABLE AND CHAINSAW GUIDEDanny DanNo ratings yet

- Specifications: 2010 Steering Steering Wheel and Column - Equinox & TerrainDocument117 pagesSpecifications: 2010 Steering Steering Wheel and Column - Equinox & Terrainvictorinox dlcbNo ratings yet

- Instruction Sheet Instruction Sheet Instruction SheetDocument1 pageInstruction Sheet Instruction Sheet Instruction SheetullwnNo ratings yet

- CRAFT Installation-Guide For Split Bearings PDFDocument7 pagesCRAFT Installation-Guide For Split Bearings PDFAdrian CantaragiuNo ratings yet

- BCS S 027 - HA 360 Lyse EmptyDocument4 pagesBCS S 027 - HA 360 Lyse EmptyGaurav JhaNo ratings yet

- Button Not Functioning ReportDocument14 pagesButton Not Functioning ReportninjaNo ratings yet

- Technical Guide Archery Sights Bow Sights ANTSDocument8 pagesTechnical Guide Archery Sights Bow Sights ANTSCarlos Fernández SNo ratings yet

- Periodic Preventive Maintenance Safety Check: Manual For Eleganza 1 (1GT) BedDocument5 pagesPeriodic Preventive Maintenance Safety Check: Manual For Eleganza 1 (1GT) BedJorge LagosNo ratings yet

- Axial Flow FanDocument2 pagesAxial Flow FancraponzelNo ratings yet

- Maintenance: & Troubleshooting GuideDocument28 pagesMaintenance: & Troubleshooting GuideALBERTO CUEVASNo ratings yet

- PrealignmentDocument38 pagesPrealignmentpsk.pranesh5520100% (1)

- RASNE-3 CommentsDocument2 pagesRASNE-3 CommentsPrashant KumarNo ratings yet

- Method Statement For Installation and Dismantling of Scaffolding at ACCDocument8 pagesMethod Statement For Installation and Dismantling of Scaffolding at ACCJethin SurendranNo ratings yet

- Projctile Launcher ManalDocument8 pagesProjctile Launcher Manalnanio_7No ratings yet

- World-Wide Technical Reference Guide: Upright RegulationDocument25 pagesWorld-Wide Technical Reference Guide: Upright Regulationcjarcher1677No ratings yet

- Ohaus 310 311 ManualDocument8 pagesOhaus 310 311 ManualRick LinseNo ratings yet

- Caliper CalibrationDocument3 pagesCaliper CalibrationBalamurugan BalahaisninNo ratings yet

- 2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuideDocument2 pages2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuidemajoNo ratings yet

- CupTester Type F - Maintenance PackyardDocument2 pagesCupTester Type F - Maintenance Packyardandrei20041No ratings yet

- Are You Supposed To Slot T.O.M. Bridge Saddles?Document2 pagesAre You Supposed To Slot T.O.M. Bridge Saddles?Samuel Aires LourencoNo ratings yet

- Id 183228Document12 pagesId 183228Christian VarelaNo ratings yet

- API RP 687-2001 (2015) Ut BabbitpdfDocument1 pageAPI RP 687-2001 (2015) Ut BabbitpdfudomNo ratings yet

- 6.SMP Cooling Tower Fan (CTF)Document5 pages6.SMP Cooling Tower Fan (CTF)Abdullatif umatiyaNo ratings yet

- Stock Inletting With A Ball End Mill: by James A. BoatrightDocument3 pagesStock Inletting With A Ball End Mill: by James A. Boatrightrick.mccort2766No ratings yet

- Barett RC 150 Compound Crossbow ManualDocument16 pagesBarett RC 150 Compound Crossbow ManualRichard Braun100% (1)

- Part#: 30B5TT, 30B1TT: Please Note Adapter Is Needed For The #30B5TT & #30B1TTDocument3 pagesPart#: 30B5TT, 30B1TT: Please Note Adapter Is Needed For The #30B5TT & #30B1TTWimper SpeedNo ratings yet

- Spur Gear Installation and AlignmentDocument2 pagesSpur Gear Installation and AlignmentAmbika Prasad NayakNo ratings yet

- Instruction Manual: Spring BalancerDocument7 pagesInstruction Manual: Spring Balancerjaskaran singhNo ratings yet

- Sima Demonstration Plan For RPL ExamDocument3 pagesSima Demonstration Plan For RPL ExamSUBARNAMAYEE BARIKNo ratings yet

- Falk Installation Manuel, Ring Gear, Pages 17 24Document8 pagesFalk Installation Manuel, Ring Gear, Pages 17 24Yerko NavarroNo ratings yet

- RASNE-3 - Comments RepliedDocument2 pagesRASNE-3 - Comments RepliedPrashant KumarNo ratings yet

- Series 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsDocument3 pagesSeries 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsluchitocapoNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- AAI Approved Make List 2017Document6 pagesAAI Approved Make List 2017NitinNo ratings yet

- Shaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and ApplicationDocument13 pagesShaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and ApplicationDr Chhabi Ram MatawaleNo ratings yet

- (Inch) (MM) (Per Inch) (Per CM) (Kcmil) (MM ) ( /KM) ( /KFTDocument6 pages(Inch) (MM) (Per Inch) (Per CM) (Kcmil) (MM ) ( /KM) ( /KFTMuhammad Reihan IskandarNo ratings yet

- CAD BIM Typicals ASSET DOC LOC 8373945 PDFDocument8 pagesCAD BIM Typicals ASSET DOC LOC 8373945 PDFMin KhantNo ratings yet

- XG Rack-Mount Install Guide M370078-05Document11 pagesXG Rack-Mount Install Guide M370078-05Dumi BogdanNo ratings yet

- Lantana Smart Sharp - Knife Sharpener - Instructions (22-11-19)Document5 pagesLantana Smart Sharp - Knife Sharpener - Instructions (22-11-19)Fabian DeeNo ratings yet

- 3.8 L Mk2 Electrical ServiceDocument79 pages3.8 L Mk2 Electrical ServiceAnonymous fDmkXcIqNo ratings yet

- Stranded Solid Copperweld Wire ChartDocument1 pageStranded Solid Copperweld Wire ChartKhan KakarNo ratings yet

- Din 6311Document1 pageDin 6311Dule JovanovicNo ratings yet

- LG DVD User ManualDocument14 pagesLG DVD User ManualAlanNo ratings yet

- Wire Identification AirbusDocument66 pagesWire Identification AirbusMamadouNo ratings yet

- Catalogo de Peças R954C - HD - 1128 - 29253 - en - EsDocument781 pagesCatalogo de Peças R954C - HD - 1128 - 29253 - en - EsDaniel F BarrosNo ratings yet

- LG lmh2016 Microwave Installation Instructions PDFDocument20 pagesLG lmh2016 Microwave Installation Instructions PDFelvisandmick100% (1)

- Duraflex Wires PriceDocument1 pageDuraflex Wires PriceJay TabagoNo ratings yet

- Local Media4705897986145793381Document1 pageLocal Media4705897986145793381Roiz Eman BartolataNo ratings yet

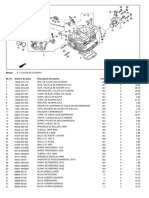

- Despiece Motor XR 200Document45 pagesDespiece Motor XR 200Cristian AlfonsoNo ratings yet

- Chain SawsDocument2 pagesChain Sawsابو محمد عليNo ratings yet

- ProForm 750 CSDocument26 pagesProForm 750 CSNathan CatesNo ratings yet

- Catálogo Resistencia Calefactora HOTSTARTDocument56 pagesCatálogo Resistencia Calefactora HOTSTARTJorge CalcaneoNo ratings yet

- Final Doccument File Allocation GGS12Document12 pagesFinal Doccument File Allocation GGS12Raj KiranNo ratings yet

- Mounting Instruction - SNL30, SNL31 and SNL32 With Labyrinth Seals (TS) - EN 2008Document2 pagesMounting Instruction - SNL30, SNL31 and SNL32 With Labyrinth Seals (TS) - EN 2008Jose ChambiNo ratings yet

- Explosion Diagram: Xz6350Za Milling/Drilling MachineDocument52 pagesExplosion Diagram: Xz6350Za Milling/Drilling MachineLuiz felipe NakagawaNo ratings yet

- Thrust PDFDocument26 pagesThrust PDFRock hard100% (1)

- Turning Fixtures 1Document40 pagesTurning Fixtures 1Appu MukundanNo ratings yet

- KFB40 Spare Part BreakdownDocument2 pagesKFB40 Spare Part BreakdownrodrigomessiasNo ratings yet

- HSK DIN 69893 enDocument29 pagesHSK DIN 69893 enalphatoolsNo ratings yet

- Johnsoncontrol t2000hhc 0c0 PDFDocument5 pagesJohnsoncontrol t2000hhc 0c0 PDFVictor AANo ratings yet

- Diagram Cat Starter and Selenoid 4n241 - InfoDocument11 pagesDiagram Cat Starter and Selenoid 4n241 - InfoMatz D2No ratings yet

- Stainless Steel Pipe Dimension As Per Astm & Weight-Kg. Per Mtr. (Ansi B36.19)Document2 pagesStainless Steel Pipe Dimension As Per Astm & Weight-Kg. Per Mtr. (Ansi B36.19)Mohammad SaleemNo ratings yet

- Manual Transaxle: Service Data and Specifications (SDS) Have Been ChangedDocument136 pagesManual Transaxle: Service Data and Specifications (SDS) Have Been Changedeurotaller Calderon calderonNo ratings yet