Professional Documents

Culture Documents

XSL 27 April 2021

XSL 27 April 2021

Uploaded by

Alessandro LòpezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XSL 27 April 2021

XSL 27 April 2021

Uploaded by

Alessandro LòpezCopyright:

Available Formats

XSL Series: 12 and 19 lb (5.4 and 8.

6 kg) capacity

XSL Series Loader

The XSL Series Loader is standard with brushed

motor, pendant control and pivot access.

XSL Series loaders provide self-contained, vacuum transfer of

plastic pellets and regrind over short distances using powerful

single-phase vacuum motors.

› Double Pivot Access › MicroBurst Keeps Filters Clean

Loader operates in upright position High intensity MicroBurst blowback

then pivots and locks in place for air blasts the whole filter area to

easy access. remove dust and fines, ensuring

that the dump throat is clear for

› Full-Featured, Standard proper sealing.

Plug-In Pendant Control

Full-featured control is mounted › SureSeal Flapper Valve Avoids

on the loader. A 12-foot cable Loading Failures

(standard) puts control at your Reliable SureSeal seal surfaces

fingertips, so changing loader stay aligned and resist wear, while

parameters is easy. a MicroBurst air blast removes

residual dust for a tight seal.

XSL-12

›› Plus

›› 115V/1ph/50-60 Hz operation

›› 15-foot (4.6 meters) length of

flex hose, lance and hose clamps

›› Dual reinforced polyester disc

filter media

›› All material contact points are

non-ferrous

›› Dump valve with integrated

demand level switch on

standard models

›› Conveying rate up to

500 lb/hr

›› Five-year warranty

Application

Full-featured Pendant Control

Puts Loader Parameter Changes,

Alarms, and Acknowledgments

at the Operator’s Fingertips

XSL loader

Control pendant can be

15-foot flex hose loader or remote mounted.

with clamps (12-foot pendant included)

Magnetic backed control

pendant mounts on hopper and

other metal surfaces convenient

to the operator.

Pick-up

wand

Full-featured control includes load time, no-load

alarm, alarm light and silencer, as well as

proportioning and purging.

Upright Operating Position

Isolated exhaust air protects

motor from plastic fines. Brushed vacuum motor

for proven reliable

performance.

Adjustable inlet position for

Removable control pendant convenient installation.

for remote operation.

Modular construction for

easy installation.

Discharge shroud protects dump throat.

Pivot Position Clean Out is Quick and Easy

Easy pivot access for clean out.

Loader pivots forward from operating position and a captive detent pin locks loader

in place during operation. Lid pivots back and locks in place for easy access.

Tool-less, Lockable Pivot Position Access

MicroBurst blowback

Hinge design holds

lid open for cleaning,

Loader pivots forward

from operating position

and captive detent

pin locks the loader in

place during operation.

Lid pivots back and

locks in place for Stainless steel body

easy access.

Locking base

Cast aluminum cone/pivot stop

SPECIFICATIONS

XSL-19

XSL-12

C

C

A

A

3.25 in. 3.25 in. 3.25 in. 3.25 in.

B D B D

Model Capacity* Inlet O.D. Discharge Diameter A B C D

XSL-12 12 lb 1.5 in. 3 in. 23.78 in. 14.83 in. 30.05 in. 17.52 in.

XSL-19 19 lb 1.5 in. 3 in. 27.78 in. 14.60 in. 33.46 in. 19.49 in.

*Based on PC pellets @ 38 lb/ft3

Pivoting and opening top requires 6 in. (15.2 cm) for clearance on XSL-19.

Recommended throughput: XSL-19 = up to 500 lb/hr (227 kg/hr) XSL-12 = up to 400 lb/hr (181 kg/hr) based on free flowing virgin pellets through 15 feet of flex hose.

Exceeding recommended throughputs may result in shortened motor and filter life; however, increased throughputs are possible depending on resin and equivalent feet calculation.

Generally, a brushless GSL or central conveying system should be used for higher throughputs.

Maximum conveying distance in addition to 15 feet of hose, can include 30 feet of horizontal tubing and one elbow. Additional vertical travel, bends or flex hose will reduce

recommended throughput.

Mounting Flexibility

Standard mounting hole pattern plus adapter ring allows XSL

to replace any Novatec loader as well as competitive models.

Machine Mount Glass for GSLs/XSLs

0.39-in. holes, 4 places, equally

0.39-in. holes, 4 places, equally spaced on a 9.00-in./229 mm

spaced on a 6.38-in./175 mm diameter bolt circle

diameter bolt circle

6.00 in. 2.00 OD

A

6.13

in.

Machine mount

6.25 in. flange dimensions

10.38 in. 8.00 in. cutout

OD cutout 6 inch x 6 inch 13 in.

7.00 in. 3.44 OD

Config Machine Mount Assy P/N* A (in.)

8 lb GMM-GSL-8 14.47

7.00

12 lb GMM-GSL-12 18.47

in.

16 lb GMM-GSL-16 22.47

Mounting Patterns * Order separately. Must be assembled in field.

OPTIONS ACCESSORIES

› 2-inch Inlet › Replacement Plug-N-Play Control Pendant with 12 ft Cable

In lieu of the standard 1.5-inch inlet. One included with each XSL.

› Extended Wear Package

› Replacement 12 ft Cable

Recommended when loading abrasive materials - contact factory.

› Alternate Glass Size › External Proportioning Valve

12 lb glass (adds 4 in to height) or 16 lb glass (adds 7 in. to height). Includes coupler, wand, hose and clamps. 1.5 in. and 2.0 in. O.D.

› Retrofit Kit to Convert XSLs Into Machine-Mount Models › Level Switch, Capacitance, 30 mm dia., 2 m Cable

Kit includes glass, twist-lock plug and photo-eye alternate mounting › Capacitance Level Switch in Lieu of Photo-Eye Sensor

flange (7 in. x 7 in. with 3.5 in. opening) removes 1.5 in. from height. For XSL-MM models.

Baltimore, MD 21225 USA 410-789-4811 | Fax: 410-789-4638 | 1-800-BESTDRY (800-237-8379) | sales@novatec.com | www.novatec.com

© 2021 NOVATEC, Inc. All rights reserved All information in this bulletin is subject to change without notice.

Form

Form #

# XSL

GSL 27

11 APRIL

02 2021

JUNE2018

FEB 2019

You might also like

- 85ton Open Loop Power SwivelDocument27 pages85ton Open Loop Power SwivelGasim MohNo ratings yet

- DS Cameron Control Chokes CatalogDocument16 pagesDS Cameron Control Chokes CatalogAbdelkader Draï100% (1)

- 120 Ton Power Swivels PISDocument17 pages120 Ton Power Swivels PISgheorgheNo ratings yet

- ValtekDocument20 pagesValtekhugolm9-1100% (1)

- Cleaning Method Statement SiteDocument10 pagesCleaning Method Statement SiteKeemeNo ratings yet

- Bray Controls - Manual OperatorsDocument2 pagesBray Controls - Manual OperatorsChandravadanNo ratings yet

- No. 17 Ports 34 Sub-PortsDocument5 pagesNo. 17 Ports 34 Sub-PortsCeline Ajero100% (1)

- Wheel Loader 9020 - Full (2012)Document12 pagesWheel Loader 9020 - Full (2012)Plr. Baswapur100% (1)

- Ship's Organizational StructureDocument8 pagesShip's Organizational StructureAmos BagaipoNo ratings yet

- Food Materials Science Principles and PracticeDocument608 pagesFood Materials Science Principles and PracticeMario de los SantosNo ratings yet

- General Valve Four-Way Diverter BrochureDocument16 pagesGeneral Valve Four-Way Diverter BrochureOndRechTacLetMovNo ratings yet

- 1450 01 Air Hoists and Trolleys Atlas CopcoDocument12 pages1450 01 Air Hoists and Trolleys Atlas Copcomohammed shammiNo ratings yet

- Kubota Zero-Tail Swing Mini-ExcavatorDocument6 pagesKubota Zero-Tail Swing Mini-ExcavatorwhsjNo ratings yet

- Diamond Power IR-3Z: Furnace Wall SootblowerDocument4 pagesDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcNo ratings yet

- E101 3236 IR 3Z SootblowerDocument4 pagesE101 3236 IR 3Z SootblowerKartika SuryawanNo ratings yet

- Catálogo DK - InglêsDocument20 pagesCatálogo DK - InglêsRobson MonteiroNo ratings yet

- Brochure Limit Switch AxiomAXDocument16 pagesBrochure Limit Switch AxiomAXSANDRA TORRESNo ratings yet

- 8290 SERIES: Angle Body Piston ValvesDocument12 pages8290 SERIES: Angle Body Piston ValvesCarlos Giovanni Camperos GaitanNo ratings yet

- Serie T-Super T-Boletin-Av-05005-05Document2 pagesSerie T-Super T-Boletin-Av-05005-05Karen VásconezNo ratings yet

- PC200 - 200LC 8mo - Zessp208m0ep 01 12 13Document2 pagesPC200 - 200LC 8mo - Zessp208m0ep 01 12 13Windi TriyonoNo ratings yet

- CM Electric Chain Hoists Specs and DrawingsDocument105 pagesCM Electric Chain Hoists Specs and DrawingsBaris YeltekinNo ratings yet

- SV3-16 SellSht UPDATED-52821Document1 pageSV3-16 SellSht UPDATED-52821igorNo ratings yet

- ZG ZH Telescopic Loading Bellows E1016Document6 pagesZG ZH Telescopic Loading Bellows E1016Triết Lãm NgôNo ratings yet

- Flowserve Mark OneDocument20 pagesFlowserve Mark OnetinozasableNo ratings yet

- Asco Series 290 Angle Body Full CatalogDocument12 pagesAsco Series 290 Angle Body Full CatalogJuan Sebastián BustosNo ratings yet

- SF6 Circuit Breakers For Out D 040126.HTML AvsDocument4 pagesSF6 Circuit Breakers For Out D 040126.HTML AvsLinh VănNo ratings yet

- Electra Quarter Turn ActuatorsDocument20 pagesElectra Quarter Turn ActuatorsHarry HonchoNo ratings yet

- BSF - CT 4281-8 in - 36-5 PDFDocument6 pagesBSF - CT 4281-8 in - 36-5 PDFHugh O'Brien GwazeNo ratings yet

- Atuador Elétrico Série 70Document8 pagesAtuador Elétrico Série 70Lucas RodriguesNo ratings yet

- 9851 2962 01b - Robbins 34RH C - Technical Specification - EnglishDocument8 pages9851 2962 01b - Robbins 34RH C - Technical Specification - EnglishJulio Acevedo MartinezNo ratings yet

- (Eng) Zx17u 5a Ks En282uDocument9 pages(Eng) Zx17u 5a Ks En282uMC TAK LEENo ratings yet

- KS En282Document9 pagesKS En282Nguyen The PhatNo ratings yet

- CT ORBit VALVE 01 PDFDocument28 pagesCT ORBit VALVE 01 PDFHieuNo ratings yet

- Vlentb0001-02-Aq (LR)Document20 pagesVlentb0001-02-Aq (LR)Milos BajicNo ratings yet

- Schwing TSR 30.14 Mark II May 2022Document11 pagesSchwing TSR 30.14 Mark II May 2022NITHISH KUMAR S SECNo ratings yet

- Double Seat Valves Complete Sudmo Brochure v2113 enDocument16 pagesDouble Seat Valves Complete Sudmo Brochure v2113 enJOSE MANUEL PEREZ PRIETONo ratings yet

- Lodestar CatalogDocument8 pagesLodestar CatalogBaris YeltekinNo ratings yet

- Loading SpoutsDocument6 pagesLoading SpoutsDouglas GonzagaNo ratings yet

- Ancaster High Performance Production Chokes Drilling Chokes Retrofit Kits Heater Chokes Control Chokes Actuators Back-Up Power SuppliesDocument6 pagesAncaster High Performance Production Chokes Drilling Chokes Retrofit Kits Heater Chokes Control Chokes Actuators Back-Up Power SuppliesleonardomaoNo ratings yet

- CAM 20 MT Choke BrochureDocument4 pagesCAM 20 MT Choke BrochureWilliams Smailliw100% (1)

- Moviroll&movicart WireDocument18 pagesMoviroll&movicart WireMohamed ElagibNo ratings yet

- Waterblast Catalog Web Spreads 25Document1 pageWaterblast Catalog Web Spreads 25Luiz PauloNo ratings yet

- AX AXIOM CatalogDocument16 pagesAX AXIOM CatalogGeorge Eapen ChethimattamNo ratings yet

- Valtek Mark One Control Valves Valtek Mark One Control ValvesDocument21 pagesValtek Mark One Control Valves Valtek Mark One Control ValvesMgc ElektronikNo ratings yet

- Telescopic Loading Bellows For High CapacitiesDocument4 pagesTelescopic Loading Bellows For High CapacitiesRestuNo ratings yet

- Series BDV ValvesDocument20 pagesSeries BDV ValvesMuhammad NaeemNo ratings yet

- FT036 LIMITADOR DE CAIDAS PERSONAL-Workman Twin Leg Personal Fall Limiter BulletinDocument4 pagesFT036 LIMITADOR DE CAIDAS PERSONAL-Workman Twin Leg Personal Fall Limiter BulletinSarubNo ratings yet

- 12 - Cast Iron Tapping MachinesDocument14 pages12 - Cast Iron Tapping MachinesaurabloodNo ratings yet

- SKG - ValvulasDocument8 pagesSKG - ValvulasfrmalthusNo ratings yet

- 2012 RF Insamcor LW Catalogue - EnglishDocument7 pages2012 RF Insamcor LW Catalogue - EnglishNay Win MaungNo ratings yet

- LSH 167 - Fte20 Fc11ab11Document12 pagesLSH 167 - Fte20 Fc11ab11Álvaro HernándezNo ratings yet

- New Removal of Bore Pump SWIDocument11 pagesNew Removal of Bore Pump SWIchrisNo ratings yet

- Technical Appendix: Selecting The Proper DESTACO ClampDocument8 pagesTechnical Appendix: Selecting The Proper DESTACO ClampGurneet SinghNo ratings yet

- Technical Information Soliswitch FTE20: Point Level Switch For Granular SolidsDocument12 pagesTechnical Information Soliswitch FTE20: Point Level Switch For Granular SolidsHữu MạnhNo ratings yet

- Brochure Orbit Valvula Vástago AscendenteDocument28 pagesBrochure Orbit Valvula Vástago AscendenteMiguel SoteloNo ratings yet

- Kubota Tracked Dumper: 45.5 PS 2700 KGDocument8 pagesKubota Tracked Dumper: 45.5 PS 2700 KGKeron TrotzNo ratings yet

- Hyster n35 45zdrsDocument16 pagesHyster n35 45zdrsjqn de los santosNo ratings yet

- Rov Dredge Pump Excavation Jetting Tritech MerlinDocument2 pagesRov Dredge Pump Excavation Jetting Tritech MerlinCleoNo ratings yet

- Caged Control Plug Valves: Dependability in Critical ApplicationsDocument2 pagesCaged Control Plug Valves: Dependability in Critical ApplicationsAhmed KhairiNo ratings yet

- Fdocuments - in - 239813017 Catalogo Varco BJDocument56 pagesFdocuments - in - 239813017 Catalogo Varco BJAbelardo CortezNo ratings yet

- GENERAL VALVE Four Way Diverter ValveDocument16 pagesGENERAL VALVE Four Way Diverter ValveLuis Miguel EstradaNo ratings yet

- 06 - 24kV Pole Mount Solid Dielectric Load Break SwitchDocument8 pages06 - 24kV Pole Mount Solid Dielectric Load Break SwitchMauricio VilledaNo ratings yet

- The Manitou Power PackDocument8 pagesThe Manitou Power Packdaniel03_181975No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Wienold MFC Brochure 2018Document4 pagesWienold MFC Brochure 2018sebastianavinaNo ratings yet

- Finalizes Synopsis Topic 1 SharmiliDocument8 pagesFinalizes Synopsis Topic 1 SharmiliSanchana ViswanathanNo ratings yet

- Yates Washington 0250O 16760Document103 pagesYates Washington 0250O 16760Abeer NåśįmNo ratings yet

- GSS - Final ReportDocument22 pagesGSS - Final ReportSzeshein Gan100% (1)

- Chapter 11 Organizational Design Structur, Culture and ControlDocument38 pagesChapter 11 Organizational Design Structur, Culture and ControlOfelia BordadoraNo ratings yet

- (Dekningsbidrag) : (Inntekter) (Variable Kostnader) (Faste Betalbare Kostnader) (Avskrivninger)Document5 pages(Dekningsbidrag) : (Inntekter) (Variable Kostnader) (Faste Betalbare Kostnader) (Avskrivninger)umarbutt99No ratings yet

- Ionic EqDocument53 pagesIonic EqNurul FarhanaNo ratings yet

- Exploring Hierarchy Situation of 4A Marketing Mix OnDocument11 pagesExploring Hierarchy Situation of 4A Marketing Mix OnHAYNo ratings yet

- IV Tier Business PlanDocument69 pagesIV Tier Business PlanAlauddin AliNo ratings yet

- Capitol SteelDocument13 pagesCapitol SteelJIMMY CARREONNo ratings yet

- Software Development ProcessDocument16 pagesSoftware Development ProcessSri WulanNo ratings yet

- 1 2 Performing Mensuration and CalculationDocument4 pages1 2 Performing Mensuration and CalculationRonaldo CruzNo ratings yet

- Molecular Immunology: Claire L. Harris, Richard B. Pouw, David Kavanagh, Ruyue Sun, Daniel RicklinDocument31 pagesMolecular Immunology: Claire L. Harris, Richard B. Pouw, David Kavanagh, Ruyue Sun, Daniel Ricklinguugle gogleNo ratings yet

- Nox RedoxEqn PDFDocument2 pagesNox RedoxEqn PDFeysNo ratings yet

- DPP KinematicsDocument4 pagesDPP KinematicsMy Moto G2No ratings yet

- Bimco Milk - 1Document20 pagesBimco Milk - 1Mustapha AbdullahiNo ratings yet

- GMAT Ratio and Proportions Formula (PDF)Document12 pagesGMAT Ratio and Proportions Formula (PDF)vishal bommineniNo ratings yet

- Lean and Green Combine To Impact Environmental and Operational PerformanceDocument18 pagesLean and Green Combine To Impact Environmental and Operational PerformancesapientesgladioNo ratings yet

- LPJ MR AreaDocument11 pagesLPJ MR AreaBagas AudiNo ratings yet

- Lista Verbelor NeregulateDocument77 pagesLista Verbelor NeregulateHilda ClevelandNo ratings yet

- Slawomir Mrozek Lolo FactsheetDocument3 pagesSlawomir Mrozek Lolo Factsheetolaprz24No ratings yet

- JHS LCP English Grade 7 10Document25 pagesJHS LCP English Grade 7 10Daryl RiveraNo ratings yet

- HR Staffing RatioDocument3 pagesHR Staffing RatioJan Ryan F. DimaanoNo ratings yet

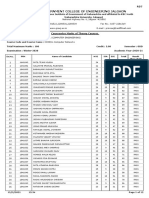

- Government College of Engineering Jalgaon: Coursewise Marks of Theory CoursesDocument12 pagesGovernment College of Engineering Jalgaon: Coursewise Marks of Theory CoursesShyam SulbhewarNo ratings yet

- English SummaryDocument9 pagesEnglish Summaryyaminshehadeh14No ratings yet

- Full Download Financial Management Theory and Practice An Asia 1st Edition Brigham Test BankDocument35 pagesFull Download Financial Management Theory and Practice An Asia 1st Edition Brigham Test Bankjosephkvqhperez100% (39)