Professional Documents

Culture Documents

Schneider Electric - Altivar-212 - ATV212HD75N4

Uploaded by

Mohamed Fahhad CoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schneider Electric - Altivar-212 - ATV212HD75N4

Uploaded by

Mohamed Fahhad CoCopyright:

Available Formats

Product datasheet

Specifications

variable speed drive, Altivar 212,

75kW, 100hp, 480V, 3 phases,

with EMC, IP21

ATV212HD75N4

Main

Device Short Name ATV212

Product Destination Asynchronous motors

Disclaimer: This documentation is not intended as a substitute for and is not to be used for determining suitability or reliability of these products for specific user applications

Network Number Of Phases 3 phases

Motor Power Kw 75 kW

Motor Power Hp 100 hp

Supply Voltage Limits 323…528 V

Supply Frequency 50...60 Hz - 5...5 %

Line Current 141.8 A at 380 V

111.3 A at 480 V

Range Of Product Altivar 212

Product Or Component Type Variable speed drive

Product Specific Application Pumps and fans in HVAC

Communication Port Protocol METASYS N2

Modbus

APOGEE FLN

BACnet

LonWorks

[Us] Rated Supply Voltage 380...480 V - 15...10 %

Emc Filter Class C2 EMC filter integrated

Ip Degree Of Protection IP21

Complementary

Apparent Power 105.3 kVA at 380 V

Continuous Output Current 160 A at 380 V

160 A at 460 V

Maximum Transient Current 176 A for 60 s

Speed Drive Output Frequency 0.5…200 Hz

Speed Range 1…10

Speed Accuracy +/- 10 % of nominal slip 0.2 Tn to Tn

Local Signalling 1 LED (red) for DC bus energized

Output Voltage <= power supply voltage

Isolation Electrical between power and control

Type Of Cable Without mounting kit: 1 wire(s)IEC cable at 45 °C, copper 90 °C / XLPE/EPR

Without mounting kit: 1 wire(s)IEC cable at 45 °C, copper 70 °C / PVC

With UL Type 1 kit: 3 wire(s)UL 508 cable at 40 °C, copper 75 °C / PVC

Dec 13, 2023 1

AD

Electrical Connection VIA, VIB, FM, FLA, FLB, FLC, RY, RC, F, R, RES: terminal 2.5 mm² / AWG 14

L1/R, L2/S, L3/T: terminal 150 mm² (300 kcmil)

Tightening Torque 0.6 N.m (VIA, VIB, FM, FLA, FLB, FLC, RY, RC, F, R, RES)

41 N.m, 360 lb.in (L1/R, L2/S, L3/T)

Supply Internal supply for reference potentiometer (1 to 10 kOhm): 10.5 V DC +/- 5 %, <10

A, protection type: overload and short-circuit protection

Internal supply: 24 V DC (21…27 V), <200 A, protection type: overload and short-

circuit protection

Sampling Duration 2 ms +/- 0.5 ms F discrete

2 ms +/- 0.5 ms R discrete

2 ms +/- 0.5 ms RES discrete

3.5 ms +/- 0.5 ms VIA analog

22 ms +/- 0.5 ms VIB analog

Response Time FM 2 ms, tolerance +/- 0.5 ms for analog output(s)

FLA, FLC 7 ms, tolerance +/- 0.5 ms for discrete output(s)

FLB, FLC 7 ms, tolerance +/- 0.5 ms for discrete output(s)

RY, RC 7 ms, tolerance +/- 0.5 ms for discrete output(s)

Accuracy +/- 0.6 % (VIA) for a temperature variation 60 °C

+/- 0.6 % (VIB) for a temperature variation 60 °C

+/- 1 % (FM) for a temperature variation 60 °C

Linearity Error VIA: +/- 0.15 % of maximum value for input

VIB: +/- 0.15 % of maximum value for input

FM: +/- 0.2 % for output

Analogue Output Type FM switch-configurable voltage 0...10 V DC, impedance: 7620 Ohm, resolution 10

bits

FM switch-configurable current 0...20 mA, impedance: 970 Ohm, resolution 10 bits

Discrete Output Type Configurable relay logic: (FLA, FLC) NO - 100000 cycles

Configurable relay logic: (FLB, FLC) NC - 100000 cycles

Configurable relay logic: (RY, RC) NO - 100000 cycles

Minimum Switching Current 3 mA at 24 V DC for configurable relay logic

Maximum Switching Current 5 A at 250 V AC on resistive load - cos phi = 1 - L/R = 0 ms (FL, R)

5 A at 30 V DC on resistive load - cos phi = 1 - L/R = 0 ms (FL, R)

2 A at 250 V AC on inductive load - cos phi = 0.4 - L/R = 7 ms (FL, R)

2 A at 30 V DC on inductive load - cos phi = 0.4 - L/R = 7 ms (FL, R)

Discrete Input Type F programmable 24 V DC, with level 1 PLC, impedance: 4700 Ohm

R programmable 24 V DC, with level 1 PLC, impedance: 4700 Ohm

RES programmable 24 V DC, with level 1 PLC, impedance: 4700 Ohm

Discrete Input Logic Positive logic (source) (F, R, RES), <= 5 V (state 0), >= 11 V (state 1)

Negative logic (sink) (F, R, RES), >= 16 V (state 0), <= 10 V (state 1)

Dielectric Strength 3535 V DC between earth and power terminals

5092 V DC between control and power terminals

Insulation Resistance >= 1 mOhm 500 V DC for 1 minute

Frequency Resolution Display unit: 0.1 Hz

Analog input: 0.024/50 Hz

Communication Service Read device identification (43)

Write single register (06)

Time out setting from 0.1 to 100 s

Monitoring inhibitable

Read holding registers (03) 2 words maximum

Write multiple registers (16) 2 words maximum

Option Card Communication card for LonWorks

Power Dissipation In W 1945 W

Air Flow 666 m3/h

Functionality Mid

Specific Application HVAC

Variable Speed Drive Application Building - HVAC compressor for scroll

Selection Building - HVAC fan

Building - HVAC pump

2 Dec 13, 2023

AD

Motor Power Range Ac-3 55…100 kW at 380…440 V 3 phases

55…100 kW at 480…500 V 3 phases

Motor Starter Type Variable speed drive

Discrete Output Number 2

Analogue Input Number 2

Analogue Input Type VIA switch-configurable voltage: 0...10 V DC 24 V max, impedance: 30000 Ohm,

resolution 10 bits

VIB configurable voltage: 0...10 V DC 24 V max, impedance: 30000 Ohm, resolution

10 bits

VIB configurable PTC probe: 0...6 probes, impedance: 1500 Ohm

VIA switch-configurable current: 0...20 mA, impedance: 250 Ohm, resolution 10 bits

Analogue Output Number 1

Physical Interface 2-wire RS 485

Connector Type 1 open style

1 RJ45

Transmission Rate 9600 bps or 19200 bps

Transmission Frame RTU

Number Of Addresses 1…247

Data Format 8 bits, 1 stop, odd even or no configurable parity

Type Of Polarization No impedance

Asynchronous Motor Control Voltage/frequency ratio, 5 points

Profile Voltage/frequency ratio - Energy Saving, quadratic U/f

Voltage/frequency ratio, automatic IR compensation (U/f + automatic Uo)

Voltage/frequency ratio, 2 points

Flux vector control without sensor, standard

Torque Accuracy +/- 15 %

Transient Overtorque 120 % of nominal motor torque +/- 10 % for 60 s

Acceleration And Deceleration Automatic based on the load

Ramps Linear adjustable separately from 0.01 to 3200 s

Motor Slip Compensation Not available in voltage/frequency ratio motor control

Automatic whatever the load

Adjustable

Switching Frequency 6...16 kHz adjustable

8...16 kHz with derating factor

Nominal Switching Frequency 8 kHz

Braking To Standstill By DC injection

Network Frequency 47.5...63 Hz

Prospective Line Isc 22 kA

Protection Type Overheating protection: drive

Thermal power stage: drive

Short-circuit between motor phases: drive

Input phase breaks: drive

Overcurrent between output phases and earth: drive

Overvoltages on the DC bus: drive

Break on the control circuit: drive

Against exceeding limit speed: drive

Line supply overvoltage and undervoltage: drive

Line supply undervoltage: drive

Against input phase loss: drive

Thermal protection: motor

Motor phase break: motor

With PTC probes: motor

Width 320 mm

Height 630 mm

Dec 13, 2023 3

AD

Depth 290 mm

Environment

Pollution Degree 3 conforming to IEC 61800-5-1

Ip Degree Of Protection IP20 on upper part without blanking plate on cover conforming to IEC 61800-5-1

IP20 on upper part without blanking plate on cover conforming to IEC 60529

IP21 conforming to IEC 61800-5-1

IP21 conforming to IEC 60529

IP41 on upper part conforming to IEC 61800-5-1

IP41 on upper part conforming to IEC 60529

Vibration Resistance 1.5 mm (f= 3…13 Hz) conforming to IEC 60068-2-6

1 gn (f= 13…200 Hz) conforming to EN/IEC 60068-2-8

Shock Resistance 15 gn for 11 ms conforming to IEC 60068-2-27

Environmental Characteristic Classes 3C1 conforming to IEC 60721-3-3

Classes 3S2 conforming to IEC 60721-3-3

Noise Level 63.7 dB conforming to 86/188/EEC

Operating Altitude 1000...3000 m limited to 2000 m for the Corner Grounded distribution network with

current derating 1 % per 100 m

<= 1000 m without derating

Relative Humidity 5…95 % without condensation conforming to IEC 60068-2-3

5…95 % without dripping water conforming to IEC 60068-2-3

Ambient Air Temperature For -10…40 °C (without derating)

Operation 40…50 °C (with derating factor)

Operating Position Vertical +/- 10 degree

Product Certifications UL

NOM 117

C-Tick

CSA

Marking CE

Standards IEC 61800-3 category C3

IEC 61800-3 category C2

IEC 61800-3 environments 1 category C3

IEC 61800-3

UL Type 1

IEC 61800-3 environments 2 category C3

IEC 61800-3 category C2

IEC 61800-3 environments 2 category C2

IEC 61800-3 environments 1 category C1

IEC 61800-5-1

IEC 61800-3 environments 2 category C1

IEC 61800-3 environments 1 category C2

EN 61800-3 category C3

IEC 61800-3 environments 2 category C2

IEC 61800-3 environments 1 category C3

IEC 61800-3 environments 2 category C3

IEC 61800-5-1

IEC 61800-3

IEC 61800-3 environments 1 category C1

IEC 61800-3 environments 1 category C2

EN 55011 class A group 1

IEC 61800-3 environments 2 category C1

Assembly Style With heat sink

Electromagnetic Compatibility Electrostatic discharge immunity test level 3 conforming to IEC 61000-4-2

Radiated radio-frequency electromagnetic field immunity test level 3 conforming to

IEC 61000-4-3

Electrical fast transient/burst immunity test level 4 conforming to IEC 61000-4-4

1.2/50 µs - 8/20 µs surge immunity test level 3 conforming to IEC 61000-4-5

Conducted radio-frequency immunity test level 3 conforming to IEC 61000-4-6

Voltage dips and interruptions immunity test conforming to IEC 61000-4-11

Regulation Loop Adjustable PI regulator

Ambient Air Temperature For -25…70 °C

Storage

4 Dec 13, 2023

AD

Packing Units

Unit Type Of Package 1 PCE

Number Of Units In Package 1 1

Package 1 Height 47 cm

Package 1 Width 50 cm

Package 1 Length 77 cm

Package 1 Weight 43.5 kg

Contractual warranty

Warranty 18 months

Dec 13, 2023 5

AD

Sustainability

Green PremiumTM label is Schneider Electric’s commitment to delivering products with best-in-

class environmental performance. Green Premium promises compliance with the latest regulations,

transparency on environmental impacts, as well as circular and low-CO2 products.

Guide to assessing product sustainability is a white paper that clarifies global eco-label

standards and how to interpret environmental declarations.

Transparency RoHS/REACh

Well-being performance

Mercury Free

Rohs Exemption Information Yes

Certifications & Standards

Reach Regulation REACh Declaration

Eu Rohs Directive Pro-active compliance (Product out of EU RoHS legal scope)

EU RoHS Declaration

China Rohs Regulation China RoHS declaration

Environmental Disclosure Product Environmental Profile

Weee The product must be disposed on European Union markets following specific waste

collection and never end up in rubbish bins

Circularity Profile End of Life Information

6 Dec 13, 2023

AD

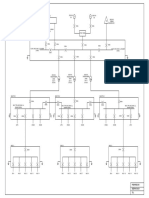

Product datasheet ATV212HD75N4

Dimensions Drawings

Dimensions

EMC mounting plate (supplied with drive)

Dec 13, 2023 7

AD

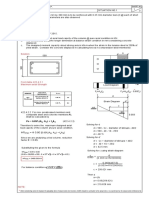

Product datasheet ATV212HD75N4

Mounting and Clearance

Mounting Recommendations

Clearance

Depending on the conditions in which the drive is to be used, its installation will require certain precautions and the use

of appropriate accessories.

Install the unit vertically:

• Do not place it close to heating elements.

• Leave sufficient free space to ensure that the air required for cooling purposes can circulate from bottom to the

top of the unit.

Mounting Types

Type A mounting

Type B mounting

Type C mounting

By removing the protective blanking cover from the top of the drive, the degree of protection for the drive becomes

IP21. The protective blanking cover may vary according to the drive model, see opposite.

8 Dec 13, 2023

AD

Product datasheet ATV212HD75N4

Specific Recommendations for Mounting in an Enclosure

To help ensure proper air circulation in the drive:

• Fit ventilation grilles.

Check that there is sufficient ventilation. If there is not, install a forced ventilation unit with a filter. The

• openings and/or fans must provide a flow rate at least equal to that of the drive fans (refer to the product

characteristics).

• Use special filters with UL Type 12/IP54 protection.

• Remove the blanking cover from the top of the drive.

Sealed Metal Enclosure (IP54 Degree of Protection)

The drive must be mounted in a dust and damp proof enclosure in certain environmental conditions, such as dust,

corrosive gases, high humidity with risk of condensation and dripping water, splashing liquid, etc.This enables the drive

to be used in an enclosure where the maximum internal temperature reaches 50°C.

Dec 13, 2023 9

AD

Product datasheet ATV212HD75N4

Connections and Schema

Recommended Wiring Diagram

3-Phase Power Supply

A1: ATV 212 drive

KM1: Contactor

Q1: Circuit breaker

Q2: GV2 L rated at twice the nominal primary current of T1

Q3: GB2CB05

S1, S2: XB4 B or XB5 A pushbuttons

T1: 100 VA transformer 220 V secondary

(1) Fault relay contacts for remote signalling of the drive status

(2) Connection of the common for the logic inputs depends on the positioning of the switch (Source, PLC, Sink)

(3) Reference potentiometer SZ1RV1202

NOTE: All terminals are located at the bottom of the drive. Install

interference suppressors on all inductive circuits near the drive or

connected on the same circuit, such as relays, contactors, solenoid

valves, fluorescent lighting, etc.

Switches (Factory Settings)

Voltage/current selection for analog I/O (VIA and VIB)

Voltage/current selection for analog I/O (FM)

10 Dec 13, 2023

AD

Product datasheet ATV212HD75N4

Selection of logic type

(1) negative logic

(2) positive logic

Dec 13, 2023 11

AD

Product datasheet ATV212HD75N4

Other Possible Wiring Diagrams

Logic Inputs According to the Position of the Logic Type Switch

“Source” position

“Sink” position

“PLC” position with PLC transistor outputs

(1) PLC (1) PLC

2-wire control

F: Forward

R: Preset speed

(2) ATV 212 control terminals

3-wire control

F: Forward

R: Stop

RES: Reverse

(2) ATV 212 control terminals

PTC probe

12 Dec 13, 2023

AD

Product datasheet ATV212HD75N4

(2) ATV 212 control terminals

(3) Motor

Analog Inputs

Voltage analog inputs

External +10 V

(2) ATV 212 control terminals

(2) ATV 212 control terminals

(4) Speed reference potentiometer 2.2 to 10 kΩ

Analog input configured for current: 0-20 mA, 4-20 mA, X-Y mA

(2) ATV 212 control terminals

(5) Source 0-20 mA, 4-20 mA, X-Y mA

Analog input VIA configured as positive logic input (“Source” position)

(2) ATV 212 control terminals

Analog input VIA configured as negative logic input (“Sink” position)

(2) ATV 212 control terminals

Dec 13, 2023 13

AD

Product datasheet ATV212HD75N4

Performance Curves

Derating Curves

The derating curves for the drive nominal current (In) depend on the temperature, the switching frequency and the

mounting type (A, B or C).

For intermediate temperatures (45°C for example), interpolate between 2 curves.

X Switching frequency

14 Dec 13, 2023

AD

You might also like

- Altivar 212 - ATV212HD45N4Document12 pagesAltivar 212 - ATV212HD45N4Raul Bautista SuclupeNo ratings yet

- Altivar 212 - ATV212HD30N4Document12 pagesAltivar 212 - ATV212HD30N4Mohammad TahaNo ratings yet

- Schneider Electric - Altivar-212 - ATV212HD22N4Document15 pagesSchneider Electric - Altivar-212 - ATV212HD22N4sofianigniteNo ratings yet

- Variable speed drive ATV212 technical specificationsDocument12 pagesVariable speed drive ATV212 technical specificationsjokoNo ratings yet

- Altivar 212 Variable Frequency Drive VFD_ATV212HD75N4 (1)Document12 pagesAltivar 212 Variable Frequency Drive VFD_ATV212HD75N4 (1)Jossuet MaldonadoNo ratings yet

- Schneider Electric - Altivar-212-Variable-Frequency-Drive-VFD - ATV212HD55N4Document14 pagesSchneider Electric - Altivar-212-Variable-Frequency-Drive-VFD - ATV212HD55N4sofianigniteNo ratings yet

- Atv212hu30n4 Datasheet WW En-GbDocument12 pagesAtv212hu30n4 Datasheet WW En-GbksNo ratings yet

- Variable speed drive product data sheetDocument4 pagesVariable speed drive product data sheetRafik MeksenNo ratings yet

- Variable Speed Drives - ATV212HD75N4Document13 pagesVariable Speed Drives - ATV212HD75N4wafiikNo ratings yet

- Product datasheet for ATV21 variable speed driveDocument4 pagesProduct datasheet for ATV21 variable speed driveArgenis UlloaNo ratings yet

- ATV212HD55N4 Product Data SheetDocument5 pagesATV212HD55N4 Product Data SheetYousif MohammedNo ratings yet

- Altivar 212 - ATV212HD37N4Document5 pagesAltivar 212 - ATV212HD37N4Pasindu PriyankaraNo ratings yet

- 11kW 480V Variable Speed Drive for HVAC Pumps and FansDocument11 pages11kW 480V Variable Speed Drive for HVAC Pumps and FansDelaurieNo ratings yet

- Product data sheet for 11kW ATV212 variable speed driveDocument4 pagesProduct data sheet for 11kW ATV212 variable speed driveTomasz KownackiNo ratings yet

- Variable speed drive product data sheetDocument4 pagesVariable speed drive product data sheetGabriel Paulo Lazaro de OliveiraNo ratings yet

- Altivar 212 - ATV212HD15N4Document5 pagesAltivar 212 - ATV212HD15N4Cinta KasihNo ratings yet

- Product data sheet for ATV212 variable speed driveDocument13 pagesProduct data sheet for ATV212 variable speed drivembgprsmsNo ratings yet

- ATV212HU55N4 variable speed drive product data sheetDocument12 pagesATV212HU55N4 variable speed drive product data sheetjulio cesar cardenas ocampoNo ratings yet

- Altivar 212 - ATV212HU75N4Document12 pagesAltivar 212 - ATV212HU75N4Nano SalamNo ratings yet

- Altivar 212 - ATV212HU40N4Document12 pagesAltivar 212 - ATV212HU40N4Saravana Kumar JNo ratings yet

- Altivar 212 - ATV212H075N4Document12 pagesAltivar 212 - ATV212H075N4OnurCinarNo ratings yet

- Altivar 312 Variable Frequency Drives VFD - ATV312HU15S6 PDFDocument4 pagesAltivar 312 Variable Frequency Drives VFD - ATV312HU15S6 PDFAbdelhak HaouchineNo ratings yet

- Altivar 312 Solar - ATV312HU11M2412Document4 pagesAltivar 312 Solar - ATV312HU11M2412tongaiNo ratings yet

- Altivar 21 Variable Speed Drives - Legacy Product - ATV21HU22N4Document5 pagesAltivar 21 Variable Speed Drives - Legacy Product - ATV21HU22N4xavier morenoNo ratings yet

- Schneider Electric - Easy-Altivar-310 - ATV310HU75N4EDocument8 pagesSchneider Electric - Easy-Altivar-310 - ATV310HU75N4EMrtav 'LadanNo ratings yet

- Altivar 31 - ATV31HU40M3XDocument4 pagesAltivar 31 - ATV31HU40M3Xdan-claudiu filipanNo ratings yet

- Easy Altivar 310 - ATV310HU22N4EDocument6 pagesEasy Altivar 310 - ATV310HU22N4EPhaniNo ratings yet

- Product datasheet specifications for variable speed drive ATV312Document4 pagesProduct datasheet specifications for variable speed drive ATV312Jeje worldعالم چيچيNo ratings yet

- ATV303HU22N4E: Product DatasheetDocument3 pagesATV303HU22N4E: Product Datasheetsweet boy play boyNo ratings yet

- Easy Altivar 310 - ATV310HD18N4EFDocument7 pagesEasy Altivar 310 - ATV310HD18N4EFTengku MunzirNo ratings yet

- Easy Altivar 310 - ATV310HU15N4EDocument6 pagesEasy Altivar 310 - ATV310HU15N4EPhaniNo ratings yet

- Altivar 61 Plus - ATV61ES5C16N4Document7 pagesAltivar 61 Plus - ATV61ES5C16N4Zarko MikicNo ratings yet

- Altivar 31C - ATV31C075N4Document4 pagesAltivar 31C - ATV31C075N4anm bNo ratings yet

- Easy Altivar 310 - ATV310HD22N4EDocument7 pagesEasy Altivar 310 - ATV310HD22N4EDeepakKumarNo ratings yet

- Altivar 312 - ATV312HU15N4Document4 pagesAltivar 312 - ATV312HU15N4Ferdiansyah KCNo ratings yet

- Altivar 12 - ATV12HU22M3Document4 pagesAltivar 12 - ATV12HU22M3MantenimientoNo ratings yet

- Altivar 61 - ATV61HC13N4Document5 pagesAltivar 61 - ATV61HC13N4muhammad sholeh0% (1)

- Easy Altivar 310 - ATV310HD22N4EDocument6 pagesEasy Altivar 310 - ATV310HD22N4EPhaniNo ratings yet

- Altivar 71 - ATV71HD75N4Document13 pagesAltivar 71 - ATV71HD75N4Bayu Arga NugrahaNo ratings yet

- Altivar 61 - ATV61HC40N4DDocument5 pagesAltivar 61 - ATV61HC40N4DDanny AndriandaruNo ratings yet

- Altivar 312 - ATV312H037N4Document4 pagesAltivar 312 - ATV312H037N4yao nestorNo ratings yet

- Schneider Electric - Easy-Altivar-310 - ATV310HU55N4EDocument8 pagesSchneider Electric - Easy-Altivar-310 - ATV310HU55N4Esrg powerNo ratings yet

- Altivar 312 - ATV312H075N4Document4 pagesAltivar 312 - ATV312H075N4phong dauNo ratings yet

- Altivar 312 - ATV312H075N4Document4 pagesAltivar 312 - ATV312H075N4Jose Norton Doria100% (1)

- Altivar Easy 310 - ATV310H075N4E PDFDocument6 pagesAltivar Easy 310 - ATV310H075N4E PDFsumarsonoNo ratings yet

- Altivar Easy 310 - ATV310HU30N4EDocument6 pagesAltivar Easy 310 - ATV310HU30N4EtrunghieutcNo ratings yet

- Altivar 61 - ATV61HD90N4Document4 pagesAltivar 61 - ATV61HD90N4Anonymous PUmoImIfONo ratings yet

- ATV212HD45N4: Product Data SheetDocument11 pagesATV212HD45N4: Product Data SheetArren KhanNo ratings yet

- Variable speed drive ATV12 - 1.5kW - 2hp - 200..240V - 3ph - with heat sinkDocument11 pagesVariable speed drive ATV12 - 1.5kW - 2hp - 200..240V - 3ph - with heat sinkLeví StrataNo ratings yet

- Product data sheet ATV310HU75N4EDocument6 pagesProduct data sheet ATV310HU75N4Ekirtiraj gehlotNo ratings yet

- Atv310hu15n4e Datasheet Id In-IdDocument3 pagesAtv310hu15n4e Datasheet Id In-IdAhmed Khodja KarimNo ratings yet

- ATV310H075N4E Variable Speed Drive SpecsDocument6 pagesATV310H075N4E Variable Speed Drive SpecsSiswanto SiswantoNo ratings yet

- ATV310HD11N4E Variable Speed DriveDocument6 pagesATV310HD11N4E Variable Speed DriveAdi kurniantoNo ratings yet

- Altivar 71 - ATV71HU22N4ZDocument5 pagesAltivar 71 - ATV71HU22N4ZmessayNo ratings yet

- Product Data Sheet: Variable Speed Drive ATV312 - 15kW - 28.5kVA - 628W - 200..240 V-3 - Phase SupplyDocument4 pagesProduct Data Sheet: Variable Speed Drive ATV312 - 15kW - 28.5kVA - 628W - 200..240 V-3 - Phase SupplyAlex StrasserNo ratings yet

- Variable Speed Drive ATV310 0.37 kW Product DatasheetDocument3 pagesVariable Speed Drive ATV310 0.37 kW Product DatasheetAdnan Naeem MalikNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Industrial-Automation-using-Schneider-PLCDocument7 pagesIndustrial-Automation-using-Schneider-PLCMohamed Fahhad CoNo ratings yet

- Geo SCADA Brochure TBULM01028 V5 LetterDocument8 pagesGeo SCADA Brochure TBULM01028 V5 LetterMohamed SaidNo ratings yet

- AMTED398032 EN - Web PDFDocument84 pagesAMTED398032 EN - Web PDFPrasad ShahNo ratings yet

- 1VDD006144 GB SafeRing - Plus - Air - April 2016Document74 pages1VDD006144 GB SafeRing - Plus - Air - April 2016Gary FortuinNo ratings yet

- List-of-projectsDocument7 pagesList-of-projectsMohamed Fahhad CoNo ratings yet

- 8800 CT 1801Document64 pages8800 CT 1801Mohamed Fahhad CoNo ratings yet

- 20211027101924_45141Document24 pages20211027101924_45141Mohamed Fahhad CoNo ratings yet

- Scada_Compatible_3_wayDocument41 pagesScada_Compatible_3_wayMohamed Fahhad CoNo ratings yet

- By Teacher: Omar MohamedDocument17 pagesBy Teacher: Omar MohamedMohamed Fahhad CoNo ratings yet

- ABB Catalogue SafeRing 36Document68 pagesABB Catalogue SafeRing 36JOGmzNo ratings yet

- 2-Position Control Signal PDM (Pulse-Duration Modulation) : Building TechnologiesDocument6 pages2-Position Control Signal PDM (Pulse-Duration Modulation) : Building TechnologiesMohamed Fahhad CoNo ratings yet

- 621 MX SagDocument469 pages621 MX SagSpirt AlexNo ratings yet

- Eaton Variable Frequency Drive Storage Requirements: Application NoteDocument2 pagesEaton Variable Frequency Drive Storage Requirements: Application NoteCoba BisnisNo ratings yet

- Sustainable Hvac For Healthcare: SolutionsDocument7 pagesSustainable Hvac For Healthcare: SolutionsMohamed Fahhad CoNo ratings yet

- Ao Smith Motors PDFDocument59 pagesAo Smith Motors PDFmarvin17100% (1)

- DSE60xx MKII Operators ManualDocument100 pagesDSE60xx MKII Operators ManualJan AhmedNo ratings yet

- PART1Document52 pagesPART1sardarmkhan100% (3)

- ACS 800 CraneDrive Control Firmware Manual 7.2 2006-06-20Document238 pagesACS 800 CraneDrive Control Firmware Manual 7.2 2006-06-20woronofNo ratings yet

- PART1Document52 pagesPART1sardarmkhan100% (3)

- LIST of Tools-BartenderDocument5 pagesLIST of Tools-BartenderLegal DepartmentNo ratings yet

- MandrakeDocument6 pagesMandrakeEmry Kamahi Tahatai KereruNo ratings yet

- SP HousekeepingDocument4 pagesSP HousekeepingLomunyak SaruniNo ratings yet

- HeavyMetalLimits For Leachability PROP 65 PB and CDDocument3 pagesHeavyMetalLimits For Leachability PROP 65 PB and CDspades24kNo ratings yet

- Dolphin Facts For Kids Ilovepdf CompressedDocument1 pageDolphin Facts For Kids Ilovepdf CompressedtechboostmrktgNo ratings yet

- Cascade Control: 25.1 Master and Slave LoopsDocument10 pagesCascade Control: 25.1 Master and Slave Loopsdeepak pandeyNo ratings yet

- Read Online Here: Bronto Skylift F32Document3 pagesRead Online Here: Bronto Skylift F32Randu WatangNo ratings yet

- Datasheet GenDocument2 pagesDatasheet GenEdgar Bonilla MuñozNo ratings yet

- Easytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFDocument10 pagesEasytronic Micro II 28 05 2010 08 35 20 Revision 05 Controller 1 PDFСергей Заика100% (1)

- MANAURITE XM Material PDFDocument8 pagesMANAURITE XM Material PDFkbc404No ratings yet

- Material Cost - EOQDocument16 pagesMaterial Cost - EOQSimranNo ratings yet

- Astm C1396 C1396M-17Document8 pagesAstm C1396 C1396M-17Stefano CamillucciNo ratings yet

- Unit 1 Purva Swadhyaya QuestionsDocument4 pagesUnit 1 Purva Swadhyaya QuestionsSurrender to Krishna AlwaysNo ratings yet

- TELchart ECS Manual en Rev 1 - 24Document233 pagesTELchart ECS Manual en Rev 1 - 24Old Yeller100% (1)

- CIA Patho 1Document23 pagesCIA Patho 1Suhas H GNo ratings yet

- Al KynesDocument12 pagesAl KynesjolanpascualNo ratings yet

- Conceptual SLDDocument1 pageConceptual SLDakhilNo ratings yet

- Joe Rozencwajg InterviewDocument17 pagesJoe Rozencwajg InterviewGold SunriseNo ratings yet

- Compounding Pharmacy Information SheetDocument2 pagesCompounding Pharmacy Information SheetSatish HiremathNo ratings yet

- Chapter2 AligningSelectionProjectsDocument36 pagesChapter2 AligningSelectionProjectsZeynep SenerNo ratings yet

- Ball Pen Canvas Painting Exhibition MumbaiDocument19 pagesBall Pen Canvas Painting Exhibition Mumbaiapi-25885725No ratings yet

- 1 PB PDFDocument11 pages1 PB PDFaldo surya pratamaNo ratings yet

- Storm Water Drainage GuidelinesDocument16 pagesStorm Water Drainage GuidelinesSeeni GovindNo ratings yet

- Sample Final OutputDocument3 pagesSample Final OutputRey Dominique VillarNo ratings yet

- Namma Kalvi 12th Maths Book Back and Creative Questions em 219383Document185 pagesNamma Kalvi 12th Maths Book Back and Creative Questions em 219383TharaneshNo ratings yet

- Assessment AreasDocument27 pagesAssessment AreasbumblebabybiNo ratings yet

- BINALAY VS ManaloDocument3 pagesBINALAY VS ManaloAnonymous 7BpT9OWPNo ratings yet

- EA PSC Substation Earthing Course Leaflet PSC006CL MAR15Document2 pagesEA PSC Substation Earthing Course Leaflet PSC006CL MAR15David RothwellNo ratings yet

- Angles of Elevation and Depression, Bearings NotesDocument4 pagesAngles of Elevation and Depression, Bearings Notesroddyeal100% (2)

- Ashok M.tech CompleteDocument65 pagesAshok M.tech CompleteAshok BhatiaNo ratings yet