Professional Documents

Culture Documents

Calculation / Installation Proposal: Bearing Analysis

Calculation / Installation Proposal: Bearing Analysis

Uploaded by

Daniel Andrés ReigOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation / Installation Proposal: Bearing Analysis

Calculation / Installation Proposal: Bearing Analysis

Uploaded by

Daniel Andrés ReigCopyright:

Available Formats

Bearing analysis

Calculation / Installation proposal

Date: 2023-03-01 11:49:04

Attention

Please see list of warnings at the end of print out.

All rights are reserved with regard to this document, even in the event that a patent should be granted or a utility model registered. The document must be treated

confidentially. Without our written consent, neither the document itself, nor copies thereof or any other renderings of the complete contents or of extracts therefrom

may be made available to third parties or put to improper use by the recipient in any other way. The document has been prepared on the basis of your requirements

as set forth above and our own assumptions. Our details take into account those risks which were apparent to us on the basis of your requirements as made

available to us. The document has been prepared solely in connection with the purchase of our products. The results shown in the document have been worked out

carefully and in accordance with the state of the art, but do not constitute an express or implied guaranty as to quality or durability in the legal sense. You are not

dispensed thereby from checking the suitability of the products. We shall be liable for the details provided in the document only in the event of willful intent or

negligence. If the document is part of a supply agreement, the liability provisions agreed there shall apply.

Table of contents

1 Input

2 Results

3 Warnings

1 Input

Bearing

Designation 22220-E1-XL-K

Inside diameter d 100,000 mm

Outside diameter D 180,000 mm

Width B 46,000 mm

Basic dynamic load rating C 430000 N

Basic static load rating C0 475000 N

Fatigue limit load Cu 53000 N

Reference speed n_ref 3150,0 1/min

Limiting speed n_lim 4550,0 1/min

Limiting speed, oil n_lim_o 4550,0 1/min

Limiting speed, grease n_lim_g 3400,0 1/min

Basic frequency factors related to 1/s

Overrolling frequency factor on outer ring BPFFO 7,6149

Overrolling frequency factor on inner ring BPFFI 10,3851

Overrolling frequency factor on rolling element BSFF 3,1329

Ring pass frequency factor on rolling element RPFFB 6,2658

Speed factor of rolling element set for rotating inner ring FTFF_i 0,4231

Speed factor of rolling element set for rotating outer ring FTFF_o 0,5769

Lubrication data

Permitted lubricants Oil or grease

Type of lubrication grease

Type of grease user defined

ISO VG class ISO VG 320

Contamination normal cleanliness

External heat flow dQ/dt 0,0 kW

Other conditions

Ambient temperature t 20,0 °C

Requisite reliability 90 %

Condition of rotation rotating inner ring

Load Load case 1

Time portion q 100,000 %

Speed n_i 4,50 1/min

Type of movement rotating

Radial load Fr 110000,0 N

Axial load Fa 10000,0 N

Mean operating temperature T 70 °C

2 Results

Overrolling frequencies Load case 1

Overrolling frequency on outer ring BPFO 0,5711 1/s

Overrolling frequency on inner ring BPFI 0,7789 1/s

Overrolling frequency on rolling element BSF 0,2350 1/s

Ring pass frequency on rolling element RPFB 0,4699 1/s

Speed of rolling element set FTF 0,0317 1/s

Load factors and equivalent loads Load case 1

Equivalent static load P0 137800,00 N

Equivalent dynamic load P_i 138400,00 N

Friction and thermally permissible speed Load case 1

Speed-dependent frictional torque M0 118,5 N mm

Load-dependent frictional torque M1 5285,3 N mm

Total frictional torque MR 5403,8 N mm

Total frictional power loss NR 0,00 kW

Thermally safe operating speed n_theta 950 1/min

Lubrication Load case 1

Operating viscosity ny 69,4 mm²/s

Reference viscosity ny1 > 1000,0 mm²/s

Viscosity ratio kappa 0,06

Bearing behavior 22220-E1-XL-K

Static safety S0_min 3,447

Total rating life in hours (nominal) Lh10 162079 h

Maximum equivalent static load P0_max 137800,00 N

Equivalent speed n 4,5 1/min

Equivalent dynamic load P 138400,00 N

3 Warnings

Please note the miscibility of greases in the chapter on grease lubrication.

· 22220-E1-XL-K: Type of grease = user defined

The reference viscosity determined is greater than 1000 mm2/s. In case of such a high viscosity a sufficient lubricant flow must be ensured.

· Load case 1

For the following load cases the operating viscosity is less than the nominal viscosity:

· Load case 1

The viscosity ratio is less than 0.1. The actual rating life can be considerably less than calculated.

· Load case 1

Do not overspecify the bearing - A rating life (to ISO 281) greater than 60000 hours usually leads to overspecified bearing arrangements.

The relubrication interval cannot be calculated for the grease used.

www.schaeffler.com

2023-03-01 11:49:04 (12.0)

You might also like

- Auto Care FormulationsDocument42 pagesAuto Care Formulationsmansuraquel80% (15)

- UntitledDocument37 pagesUntitledAmartugs BatbayarNo ratings yet

- Goodrich Proprietary - This Document Is Subject To The Controls and Restrictions On The Title Page. U.S. Export Classification: EAR 9E991Document108 pagesGoodrich Proprietary - This Document Is Subject To The Controls and Restrictions On The Title Page. U.S. Export Classification: EAR 9E991duythienddtNo ratings yet

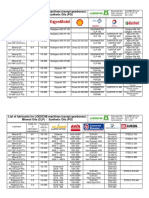

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Document8 pagesList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaNo ratings yet

- Three Phase Induction Motor - Squirrel Cage: Data SheetDocument6 pagesThree Phase Induction Motor - Squirrel Cage: Data Sheetjulio100% (1)

- Caterpillar MachinesDocument514 pagesCaterpillar Machinesjosmel2100% (1)

- Production of GreaseDocument7 pagesProduction of GreasevisharlanNo ratings yet

- Vespa LX 50 (EN)Document160 pagesVespa LX 50 (EN)ManuallesNo ratings yet

- Citroen CX Manual Series 2 PDFDocument646 pagesCitroen CX Manual Series 2 PDFFilipe Alberto Magalhaes0% (1)

- The Castrol Range of Industrial Lubricants High - 1Document40 pagesThe Castrol Range of Industrial Lubricants High - 1Shan Rana100% (1)

- MAM6070Document45 pagesMAM6070Vitor FreitasNo ratings yet

- Bearing Analysis Calculation / Installation Proposal: AttentionDocument3 pagesBearing Analysis Calculation / Installation Proposal: AttentionNestor VelazNo ratings yet

- Bearing Analysis Calculation / Installation Proposal: AttentionDocument3 pagesBearing Analysis Calculation / Installation Proposal: AttentionNestor VelazNo ratings yet

- Bearing Analysis Calculation / Installation Proposal: AttentionDocument4 pagesBearing Analysis Calculation / Installation Proposal: AttentionsabriNo ratings yet

- Lezaj Izlazno VratiloDocument2 pagesLezaj Izlazno VratiloThe bossNo ratings yet

- Bearing Component GeneratorDocument2 pagesBearing Component GeneratorAos GidionNo ratings yet

- Lezaj Ulazno VartiloDocument2 pagesLezaj Ulazno VartiloThe bossNo ratings yet

- Spur Gears Component GeneratorDocument4 pagesSpur Gears Component GeneratorRodrigo NavarreteNo ratings yet

- Zupcasti Par B-F B 35Document4 pagesZupcasti Par B-F B 35Stefan MilojevicNo ratings yet

- Attachment 4 - 630kW 380V 4pole 50Hz Electric Motor Data SheetDocument2 pagesAttachment 4 - 630kW 380V 4pole 50Hz Electric Motor Data Sheetachmadj1405100% (1)

- Zupcasti Par A-G B 16Document4 pagesZupcasti Par A-G B 16Stefan MilojevicNo ratings yet

- 1FG1101-1RC26-2AW1-Z D03+K06 Datasheet enDocument2 pages1FG1101-1RC26-2AW1-Z D03+K06 Datasheet endlquirogaNo ratings yet

- DS14051985Document1 pageDS14051985appuNo ratings yet

- 1FG1106-1PD23-1AS1-Z D01+G23+G53+G99+K08 Datasheet enDocument3 pages1FG1106-1PD23-1AS1-Z D01+G23+G53+G99+K08 Datasheet enAung Naing OoNo ratings yet

- Bea XL K MB1Document2 pagesBea XL K MB1Teguh TirtayasaNo ratings yet

- Maxon EC60 400wattDocument1 pageMaxon EC60 400wattElectromateNo ratings yet

- SheetDocument6 pagesSheetAlejandro MartinezNo ratings yet

- Ds 12438117Document1 pageDs 12438117Angel GrandeNo ratings yet

- Data Sheet: Single Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Single Phase Induction Motor - Squirrel CageAlberto ToalomboNo ratings yet

- Bea XL K MB1Document2 pagesBea XL K MB1Johnatas GamaNo ratings yet

- 23252-BEA-XL-K-MB1-C3: Spherical Roller BearingDocument2 pages23252-BEA-XL-K-MB1-C3: Spherical Roller BearingPhan Tuan AnhNo ratings yet

- Three Phase Induction Motor - Squirrel Cage: Data SheetDocument3 pagesThree Phase Induction Motor - Squirrel Cage: Data SheetJesus PerezNo ratings yet

- Spur Gears Component Generator (Version: 2019 (Build 230136000, 136) )Document4 pagesSpur Gears Component Generator (Version: 2019 (Build 230136000, 136) )The bossNo ratings yet

- 3 Phase Induction Motor - LRVPDocument3 pages3 Phase Induction Motor - LRVPLance AyoubNo ratings yet

- Melservo Jet Series Rotary Servo MotorDocument8 pagesMelservo Jet Series Rotary Servo MotorvermadelipNo ratings yet

- Weg Motor 400VDocument1 pageWeg Motor 400VJ. Abel C. S.No ratings yet

- DC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525Document1 pageDC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525NewsUPdateNo ratings yet

- 2KJ3514-3KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet enDocument2 pages2KJ3514-3KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet encaukhoeoNo ratings yet

- Data Sheet Three Phase Induction Motor Customer Type Brand Client Reference Date G3-355LY4Document1 pageData Sheet Three Phase Induction Motor Customer Type Brand Client Reference Date G3-355LY4Đức NguyễnNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument2 pagesData Sheet: Three Phase Induction Motor - Squirrel CageVratNo ratings yet

- Watermist SystemDocument21 pagesWatermist SysteminnovativekarthiNo ratings yet

- Ficha Motor 0.75hp BTPDocument6 pagesFicha Motor 0.75hp BTPYenni BarretoNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument5 pagesData Sheet: Three Phase Induction Motor - Squirrel CageBalady HayatyNo ratings yet

- Motor Data Sheet 18. KW 4 PoleDocument1 pageMotor Data Sheet 18. KW 4 Poledeepak kumarNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument7 pagesData Sheet: Three Phase Induction Motor - Squirrel Cagegego2No ratings yet

- 02 - 2technical Data of The GeneratorDocument16 pages02 - 2technical Data of The GeneratorJŐn PardédéNo ratings yet

- Motor 3F 0.5HP BridaDocument2 pagesMotor 3F 0.5HP BridaJuan PiñerosNo ratings yet

- Data Sheet: Induction Motor Champion Series Motor Type: 1SE0 083-6NA70 SDocument3 pagesData Sheet: Induction Motor Champion Series Motor Type: 1SE0 083-6NA70 SK. RAJA SEKARNo ratings yet

- Bea XL MB1Document1 pageBea XL MB1CAT CYLINDERNo ratings yet

- Dry / Empty Case: Section ADocument6 pagesDry / Empty Case: Section Aevrim77100% (1)

- Specification For Induction Motor: by Mark Haire at 8:48 Am, Nov 10, 2014Document16 pagesSpecification For Induction Motor: by Mark Haire at 8:48 Am, Nov 10, 2014aqweqeqweNo ratings yet

- Spur Gears Component GeneratorDocument4 pagesSpur Gears Component GeneratorEngineering ProductionNo ratings yet

- WEG 55kW 4P B3 IE3 WIMES Data SheetDocument7 pagesWEG 55kW 4P B3 IE3 WIMES Data SheetJoey seoNo ratings yet

- Pre Planet CPM2671 - Static LoadDocument2 pagesPre Planet CPM2671 - Static Loadrafael rodarteNo ratings yet

- WEG Datasheet DS13095026Document2 pagesWEG Datasheet DS13095026stefancuandreiNo ratings yet

- Timken 22219EJW33-SphericalRollerBearings-SteelCageDocument4 pagesTimken 22219EJW33-SphericalRollerBearings-SteelCageArief sitompulNo ratings yet

- 37kW, 4P, IMB3, Brake Motor DatasheetDocument1 page37kW, 4P, IMB3, Brake Motor DatasheetsyamprasadNo ratings yet

- 23132-E1A-XL-M: Spherical Roller BearingDocument2 pages23132-E1A-XL-M: Spherical Roller BearingvivianaNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument10 pagesData Sheet: Three Phase Induction Motor - Squirrel CageSergeiNo ratings yet

- NU2218 CylindricalRollerBearing Separable PlainInnerRing OuterRingwTwoRibs NUTypeDocument3 pagesNU2218 CylindricalRollerBearing Separable PlainInnerRing OuterRingwTwoRibs NUTypeEmmanuel Quequesana VílchezNo ratings yet

- 4T-HM813844/HM813810: Technical DataDocument3 pages4T-HM813844/HM813810: Technical DataVipul RathodNo ratings yet

- Caterpillar Generator Data Production DE550 GCDocument8 pagesCaterpillar Generator Data Production DE550 GCDedi MaryadiNo ratings yet

- SKF Bearing SelectDocument7 pagesSKF Bearing SelectJaimeNo ratings yet

- 2000 KVA LS Alternator Specs (11.04.2019)Document4 pages2000 KVA LS Alternator Specs (11.04.2019)ali ahmadNo ratings yet

- Data Sheet: Induction Motor Champion Series Motor Type: 1SE0 090-2NB70 SDocument3 pagesData Sheet: Induction Motor Champion Series Motor Type: 1SE0 090-2NB70 SK. RAJA SEKARNo ratings yet

- WEG 15kW 2P B3 IE3 WIMES Data SheetDocument7 pagesWEG 15kW 2P B3 IE3 WIMES Data Sheetabel manuel chico oleceNo ratings yet

- Truck Mixter Liebherr Operatinal ManualDocument40 pagesTruck Mixter Liebherr Operatinal ManualGovind JadhavNo ratings yet

- Unibeam Chain ConveyorsDocument48 pagesUnibeam Chain ConveyorsLeonardo Figueroa100% (1)

- Especificação de GraxasDocument1 pageEspecificação de GraxasDouglas TondelloNo ratings yet

- Savsol Oil Internship ReportDocument14 pagesSavsol Oil Internship ReportRohit Choudhary 2No ratings yet

- Multi Lin Eskf LubricationDocument68 pagesMulti Lin Eskf LubricationNakul RNo ratings yet

- Arcanol MULTITOP: FAG Rolling Bearing GreaseDocument1 pageArcanol MULTITOP: FAG Rolling Bearing GreasejuniorNo ratings yet

- Dichta CatalogueDocument62 pagesDichta CataloguemaxatadesignNo ratings yet

- 2005 FZ6-S Service ManualDocument20 pages2005 FZ6-S Service ManualBratkó BenceNo ratings yet

- Catalogues SKF 5Document38 pagesCatalogues SKF 5Common Rail Cân BécNo ratings yet

- HXI Maintenance ManualDocument118 pagesHXI Maintenance ManualFrancisco Wilton bezerraNo ratings yet

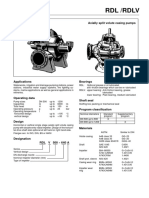

- Bomba KSB Data SheetDocument4 pagesBomba KSB Data SheetLuis Christian Davila CangalayaNo ratings yet

- Diagram of Lubricating Points DWR Front StandDocument7 pagesDiagram of Lubricating Points DWR Front StandPoposki PetreNo ratings yet

- Aurora Pump MaintenanceDocument35 pagesAurora Pump MaintenancemetropumpsNo ratings yet

- Service and Replacement Parts Manual: WarningDocument136 pagesService and Replacement Parts Manual: WarningRodney RichardsonNo ratings yet

- Front Susp ADocument83 pagesFront Susp AAnimemanuel MuñozNo ratings yet

- D6 User Manual REV ADocument47 pagesD6 User Manual REV ASenthilkumar SubbiahNo ratings yet

- CX225SR Crawler Excavator: Consult The Engine Service ManualDocument23 pagesCX225SR Crawler Excavator: Consult The Engine Service Manualjose manuel barroso pantojaNo ratings yet

- MANUAL - Power Tong Model 01F05C - March 29, 2019Document43 pagesMANUAL - Power Tong Model 01F05C - March 29, 2019Son DDarrellNo ratings yet

- File Shell Alvania r3 Grease Msds PDFDocument3 pagesFile Shell Alvania r3 Grease Msds PDFDina MaulidaNo ratings yet

- Cop Grease: Keep Your Rock Drill in Peak ConditionDocument4 pagesCop Grease: Keep Your Rock Drill in Peak ConditionMarcelo L ZamoraNo ratings yet