Professional Documents

Culture Documents

Kinco GL070&GL070E Usermanual

Uploaded by

octavioamezquita0 ratings0% found this document useful (0 votes)

39 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views1 pageKinco GL070&GL070E Usermanual

Uploaded by

octavioamezquitaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

line to the ’FG’ terminal.

GL070 /GL070E HMI 3.External Interface

Installation Instruction

Kinco Electric (Shenzhen) Ltd.

Add:Building 1, No. 6 Langshan 1st Rd, Hi-tech Park North, Nanshan, Shenzhen, China.

Tel:0755-26585555 Fax:0755-26616372http://www.kinco.cn Email:sales@kinco.cn

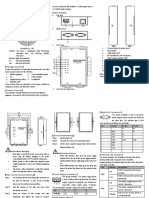

1. Installation Note

1.1 Environmental Requirement

Operating temperature: GL070/GL070E HMI can work stably in most industrial environments that the

temperature between 32°F to122°F (0~50°C).

NEMA rating: This Series HMI frontpanel is NEMA 1 rated.

Please do not use in the following places: Please take shielding

Places direct in sunlight measures in the following 3.1 POWER

Surrounding temperature and humidity beyond the places:

Pin# Signal

specifications Places that exist electrostatic

Places of temperature changes sharply and easily or other kinds of noise 1 DC24V

cause condensation Places of strong

2 GND

Places that exist corrosive gas and combustible gas electromagnetic

Places of much dust, dirt, salt and iron powder Places that may be exposed 3 FG

Places that will be splashed water, oil and drugs to rays

Places that bring direct vibration and shock to host Places near the power 3.2 COM0/COM2

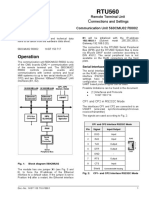

Pin assignment of the 9-pin male, D-SUB, COM0/COM2.Note:

1.2 Power Requirement RS232/485/422 communication functions are supported by COM0.COM2

Input voltage:DC10 V~DC28V. supports RS232 communication function.

Particularly note that there must be enough distance between this product and converters or switch

PC/PLC

mode power supply. Make sure that the input and output cables of that kind equipment are shield PLC (COM0) PLC(COM0) PLC (COM0)

cable and the shielding network is connected with the ground. Pin Signal (COM2)

[RS-422] [RS-485] [RS-232]

Make sure that the DC power and AC power is isolated. [RS-232]

Do not use common power with perceptual load or input circuit of the controller. 1 Rx-(B) RS422 R- RS485 B

Note: An Internal fuse will prevent damage for over voltage condition, however it isn’t guaranteed the 2 RxD_PLC RS232 RxD

internal electronic components are not damaged. 3 TxD_PLC RS232 TxD

4 Tx- RS422 T-

2.Installation Description

5 GND Signal ground

2.1Dimensional Drawing

6 Rx+(A) RS422 R+ RS485 A

7 RxD_PC RS232 RxD

8 TxD_PC RS232 TxD

9 Tx+ RS422 T+

3.3 USB HOST

Connection Connect with USB interface devices or U disks

This interface can be connected with USB keyboard, mouse and printers, and the

Port

U disk can be used for user’s configuration uploading/ downloading as well as

Function

data storage.

3.4 USB SLAVE

The interface type is MicroUSB

2.2 Fixed Screw Installation Instructions Connection USB Slave port can be connected with a PC

The product is put into the well mounted hole of the machine control box’s panel, and the mounting Port The port is only used to download user configuration program to the HMI and to

screws are inserted into the fixing holes around the HMI shell from the back of the control box’s panel. Function set HMI system parameters.

Recommended lock torque: 0.5N.m (to waterproof effect and avoid shell deformation)

3.5 Ethernet(Only GL070E support)

10M/100M adaptive Ethernet RJ45 port.

Connection With CAT5 UTP cable connected to the Ethernet device.

The port can be used for upload/download of HMI configuration, setting of

system parameters and online simulations of configurations. It can connect

Port

multiple HMIs via the Ethernet to form an HMI network. Furthermore, it can

Function

implement communications between HMI and PLC via the Ethernet, as well

as communications with a PC via the Ethernet port.

2.3 Power Connection

Before connecting the power, please make sure all local and national electrical standards are met.For 4.After-sales Service

power cables,please select cables with their dielectric strength values and current values in compliance

For < Service Terms and Conditions for HMI >, please check:http://www.kinco.cn

with the safety specifications.

First find the power terminal at the back of the product and loosen the screw according to

counterclockwise, then insert the power cables and tighten the screw up.

Connect positive DC line to the ‘DC24V’ terminal, the DC ground to the ‘GND’ terminal and the ground

You might also like

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- IC200ACC415 DS RS232 RS485 Interface Adapter VersaMaxMicroNano GFK1834 2002Document1 pageIC200ACC415 DS RS232 RS485 Interface Adapter VersaMaxMicroNano GFK1834 2002jav_08No ratings yet

- RS-232 To RS-485: User ManualDocument6 pagesRS-232 To RS-485: User ManualEdward MainaNo ratings yet

- STM422 RS232 To RS485-RS422 Interface Converter User GuideDocument2 pagesSTM422 RS232 To RS485-RS422 Interface Converter User GuideMojixNo ratings yet

- Dtech dt-9003Document3 pagesDtech dt-9003ViệnVuiVẻNo ratings yet

- 1-20120809-164459Document5 pages1-20120809-164459anon_238578985No ratings yet

- Isolated, Single-Channel RS-232 Line Driver/Receiver: ADM3251EDocument16 pagesIsolated, Single-Channel RS-232 Line Driver/Receiver: ADM3251ENda SmuNo ratings yet

- RS-485 to RS-232 Converter InstructionDocument1 pageRS-485 to RS-232 Converter InstructionSeka Vilar SorucoNo ratings yet

- RS-232/RS-485/422: UT-203 Interface Converter InstructionDocument1 pageRS-232/RS-485/422: UT-203 Interface Converter InstructionMahran MastouriNo ratings yet

- Sci Module: Rs232 / Rs485 ConvertorDocument4 pagesSci Module: Rs232 / Rs485 ConvertorWomz FLNo ratings yet

- Installation Manual - RS232-485-OPTO-A ConverterDocument4 pagesInstallation Manual - RS232-485-OPTO-A ConverterrobertmithieryNo ratings yet

- EZ035 ES-U-3001-M - USB-COMi-M - Manual-1Document9 pagesEZ035 ES-U-3001-M - USB-COMi-M - Manual-1shazziiiNo ratings yet

- I/O Port Pinouts and Cabling Diagrams for EasyConnection ModulesDocument5 pagesI/O Port Pinouts and Cabling Diagrams for EasyConnection ModulesDanang KartikaNo ratings yet

- Isolate RS-232, RS-422 and RS-485 SignalsDocument2 pagesIsolate RS-232, RS-422 and RS-485 SignalsMaitry ShahNo ratings yet

- CON-422-PE25Document2 pagesCON-422-PE25yanghao1976No ratings yet

- Abb Ag: OperationDocument4 pagesAbb Ag: OperationCosmic Garash 2No ratings yet

- Gavc 1200 Uniwire To RS232Document8 pagesGavc 1200 Uniwire To RS232Ahsan SiddiquiNo ratings yet

- Pinout Convertidor 232-422 PDFDocument2 pagesPinout Convertidor 232-422 PDFjaballesterosvNo ratings yet

- Idm-6830 and Idm-7842dag (C)Document22 pagesIdm-6830 and Idm-7842dag (C)BOsy Ying LoNo ratings yet

- Rexeoth Control Panel BF-1Document4 pagesRexeoth Control Panel BF-1Hrvoje ŠkaricaNo ratings yet

- ATC-105 User's Manual PDFDocument2 pagesATC-105 User's Manual PDFVishwas MaritronicsNo ratings yet

- E560 Cmu02 CSDocument4 pagesE560 Cmu02 CSAlikNo ratings yet

- RF Data Transceiver Module InstructionDocument3 pagesRF Data Transceiver Module Instructionkurocans100% (2)

- EX9520/A/R/AR Quick Manual: Jumper Setting (For EX9520A/AR) JP1: PIN 2,3 For RS485 PIN 1,2 For RS422Document4 pagesEX9520/A/R/AR Quick Manual: Jumper Setting (For EX9520A/AR) JP1: PIN 2,3 For RS485 PIN 1,2 For RS422Carolina SanchezNo ratings yet

- General Specifications CO-920-01: GS48D20Z01-00E-NDocument4 pagesGeneral Specifications CO-920-01: GS48D20Z01-00E-N赵先生No ratings yet

- RS232 Smartcard Reader CircuitDocument6 pagesRS232 Smartcard Reader Circuitmrshare2010No ratings yet

- EX9520ARAR Quick ManualDocument4 pagesEX9520ARAR Quick ManualSi ClaNo ratings yet

- ATC-108 User's ManualDocument0 pagesATC-108 User's ManualMaitry ShahNo ratings yet

- Interfaces For Dedicated Lines: FW-50 Series5eDocument3 pagesInterfaces For Dedicated Lines: FW-50 Series5emuhammad syaefudinNo ratings yet

- I/O Controller 2 Manual - Ethernet - RS-232/485 + Inputs and OutputsDocument44 pagesI/O Controller 2 Manual - Ethernet - RS-232/485 + Inputs and OutputsMarvel PerlaNo ratings yet

- JZ862 User ManualDocument6 pagesJZ862 User ManualEhab IsmailNo ratings yet

- 520CMD01 CS enDocument4 pages520CMD01 CS enDJ ThangNo ratings yet

- 15 KV ESD-Protected, 3.3 V, 12 MBPS, EIA RS-485/RS-422 Transceiver ADM3485EDocument17 pages15 KV ESD-Protected, 3.3 V, 12 MBPS, EIA RS-485/RS-422 Transceiver ADM3485EJose BenitezNo ratings yet

- SV-iP5A or IV5 User ManualDocument25 pagesSV-iP5A or IV5 User ManualTechnology HelperNo ratings yet

- Rdc232hub Um11Document2 pagesRdc232hub Um11hennrynsNo ratings yet

- 8522A RS232 To RS485-Rs422 Converter User GuideDocument2 pages8522A RS232 To RS485-Rs422 Converter User Guidetegar sulistiantoNo ratings yet

- Description Features: LTC485 Low Power RS485 Interface TransceiverDocument14 pagesDescription Features: LTC485 Low Power RS485 Interface Transceivergreemax100% (1)

- TCC-80 80I SeriesDocument3 pagesTCC-80 80I SeriesHengki ANo ratings yet

- Usb Rs485-232 Converter V - 1.1 enDocument8 pagesUsb Rs485-232 Converter V - 1.1 enErman GÖGENNo ratings yet

- Usb To 8 Port Rs232 ConverterDocument2 pagesUsb To 8 Port Rs232 Convertermanekantta bondadaeNo ratings yet

- Serial Communication Between STM32F103C8 and Arduino UNO Using RS-485Document1 pageSerial Communication Between STM32F103C8 and Arduino UNO Using RS-485Katia KisswaniNo ratings yet

- B202v103 ModemDocument2 pagesB202v103 ModemObey O MadzivireNo ratings yet

- USB To RS232 - RS232 To RS485 - Interface Converters ManufacturersDocument2 pagesUSB To RS232 - RS232 To RS485 - Interface Converters ManufacturersPrasadPurohitNo ratings yet

- USB To RS232 ConverterDocument2 pagesUSB To RS232 ConverterPrasadPurohitNo ratings yet

- Dokumen - Tips - Protocol Description Iec 60870 5 101Document18 pagesDokumen - Tips - Protocol Description Iec 60870 5 101alextivanNo ratings yet

- Gw1102-2di (3in1) QigDocument3 pagesGw1102-2di (3in1) QigTam DuongNo ratings yet

- Intech Isolated Auto Detecting Converter 2400 Is Installation GuideDocument12 pagesIntech Isolated Auto Detecting Converter 2400 Is Installation GuideSUMYPORT SASNo ratings yet

- RS485 To TTL Converter DatasheetDocument3 pagesRS485 To TTL Converter DatasheetPrasanna. KotikalaNo ratings yet

- Esr 2 K 1Document3 pagesEsr 2 K 1Procurement PardisanNo ratings yet

- TCSolutions HWG PortBox2 MAN enDocument34 pagesTCSolutions HWG PortBox2 MAN enRoberto Amaral FurlaniNo ratings yet

- Moxa TCC 80 80i Series Qig v4.1Document7 pagesMoxa TCC 80 80i Series Qig v4.1samgariyen2_84181027No ratings yet

- ATC-105 User's ManualDocument0 pagesATC-105 User's ManualMaitry Shah100% (1)

- Operation: Connections and Settings Communication Unit 560CMU02 R0001Document4 pagesOperation: Connections and Settings Communication Unit 560CMU02 R0001Cosmic Garash 2No ratings yet

- UTS-1458B Product ManualDocument4 pagesUTS-1458B Product ManualZForeNo ratings yet

- MGate MB3170/MB3270 Quick Install GuideDocument6 pagesMGate MB3170/MB3270 Quick Install GuideheikelNo ratings yet

- Dataradio Dl-3400 Application NoteDocument15 pagesDataradio Dl-3400 Application NotehectorNo ratings yet

- Module DI ModbusDocument8 pagesModule DI ModbusfakhriNo ratings yet

- Bro Iso485 e PDFDocument3 pagesBro Iso485 e PDFJa AkNo ratings yet

- CSNB123 - tutorial on computer organization fundamentalsDocument7 pagesCSNB123 - tutorial on computer organization fundamentalsMuhd Izzuddin Abd RazakNo ratings yet

- SJ-20140312095717-002-ZXA10 C300&C320 (V2.0.1) Optical Access Convergence Equipment Product DescriptionDocument94 pagesSJ-20140312095717-002-ZXA10 C300&C320 (V2.0.1) Optical Access Convergence Equipment Product Descriptionccbs2010100% (1)

- PDF CapacitorquestionnaireDocument2 pagesPDF Capacitorquestionnairesukhvinder singhNo ratings yet

- Chapter 3. CMOS Processing Technology - VLSI - CAD LaboratoryDocument45 pagesChapter 3. CMOS Processing Technology - VLSI - CAD LaboratoryYidnekachwe MekuriaNo ratings yet

- MinimizeDocument10 pagesMinimizefikaduNo ratings yet

- RHOMBIC ANTENNAS WITH SLOPING VEE KITDocument4 pagesRHOMBIC ANTENNAS WITH SLOPING VEE KITAngie Gaid TayrosNo ratings yet

- Lecture 09 and 10 (02-02-24)Document26 pagesLecture 09 and 10 (02-02-24)postgeeaccNo ratings yet

- Safemine Manual 2019Document28 pagesSafemine Manual 2019DEEPAK GOYALNo ratings yet

- 555 Timer Examination Questions - 2: Click Here For Printable Version of Exercise Seen BelowDocument8 pages555 Timer Examination Questions - 2: Click Here For Printable Version of Exercise Seen BelowPic MicroNo ratings yet

- Eton Scorpion ManualDocument9 pagesEton Scorpion ManualFirefly666No ratings yet

- Audio and Power ConnectorsDocument3 pagesAudio and Power ConnectorsAndrea CalissyNo ratings yet

- Z80 Instruction Set - ClrHomeDocument5 pagesZ80 Instruction Set - ClrHomesatriomochammadNo ratings yet

- Apg 66Document18 pagesApg 66arseniusone100% (3)

- Features Description: Lt3992 Monolithic Dual Tracking 3A Step-Down Switching RegulatorDocument37 pagesFeatures Description: Lt3992 Monolithic Dual Tracking 3A Step-Down Switching RegulatorMaicol AlmadaNo ratings yet

- Three-phase capacitors BO/R Series technical specificationsDocument2 pagesThree-phase capacitors BO/R Series technical specificationsBenhar ImadNo ratings yet

- Rjp63f3a PDFDocument7 pagesRjp63f3a PDFElizabeth GonzálezNo ratings yet

- 7300 ASAM Detail GuideDocument160 pages7300 ASAM Detail GuidemuhammadrustamNo ratings yet

- Baq Ils Z Rwy 05 PDFDocument1 pageBaq Ils Z Rwy 05 PDFAlexandra DiazNo ratings yet

- Experiment No. 1 Multisim Live Familiarization Course: Section: Group No.:8 Date Performed: Group Members: Jose Enrique R. Gonzaga Date SubmittedDocument6 pagesExperiment No. 1 Multisim Live Familiarization Course: Section: Group No.:8 Date Performed: Group Members: Jose Enrique R. Gonzaga Date SubmittedJose Enrique GonzagaNo ratings yet

- Quick-PWM Master Controllers For Voltage-Positioned CPU Core Power Supplies (IMVP-IV)Document43 pagesQuick-PWM Master Controllers For Voltage-Positioned CPU Core Power Supplies (IMVP-IV)joe wiillsonNo ratings yet

- I V I 1/R I V/R V Ir: Department of Mechanical Engineering Djj20053: Electrical TechnologyDocument5 pagesI V I 1/R I V/R V Ir: Department of Mechanical Engineering Djj20053: Electrical TechnologyMohd ZahiruddinNo ratings yet

- LBS College BTech S6 July 2021 Exam ResultsDocument17 pagesLBS College BTech S6 July 2021 Exam Resultsrakumar500No ratings yet

- DPScope Build Your Own USBPC Based OscilloscopeDocument28 pagesDPScope Build Your Own USBPC Based Oscilloscopealidurrani50% (2)

- New Rich Text DocumentDocument12 pagesNew Rich Text DocumentAnonymous crTLRKqbNo ratings yet

- What Is Optoisolator (Optical Coupler or Optocoupler) - Definition From WhatIsDocument5 pagesWhat Is Optoisolator (Optical Coupler or Optocoupler) - Definition From WhatIsProcurement PardisanNo ratings yet

- Integrated Power MOSFET Off-Line PRC ControllersDocument26 pagesIntegrated Power MOSFET Off-Line PRC ControllersAngel CallejebrioNo ratings yet

- RED LION - Módulo IO - E2 MIX24880 D - Data Sheet PDFDocument2 pagesRED LION - Módulo IO - E2 MIX24880 D - Data Sheet PDFAnonymous LcXtuKuSmNo ratings yet

- Dell Color Laser Printer 2155CN Parts Service Manual PDFDocument1,048 pagesDell Color Laser Printer 2155CN Parts Service Manual PDFlmsserviceNo ratings yet

- Terminating Resistor: RS-422 Communication Instruction ManualDocument1 pageTerminating Resistor: RS-422 Communication Instruction ManualasdNo ratings yet

- Circuit Theorems: Chapter Objectives: ChapterDocument6 pagesCircuit Theorems: Chapter Objectives: ChapterAsseel FleihanNo ratings yet