Professional Documents

Culture Documents

Equotip 550 Sales Flyer English - High

Equotip 550 Sales Flyer English - High

Uploaded by

Abimanyu LearingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equotip 550 Sales Flyer English - High

Equotip 550 Sales Flyer English - High

Uploaded by

Abimanyu LearingCopyright:

Available Formats

Solutions since 1954

Portable Hardness Testing

Leeb – Rockwell – UCI

atent pe

g·P nd

din in

en g

tp

en

nt

Pat

Pate ing

pend

Pat

en

tp

en

ing din

g· nd

Patent pe

ASTM DIN EN ISO GB/T JB/T Interactive

Measuring Performance

• High accuracy

• Custom conversions

• Combined methods

Powerful Hardware Ease of Use

• Rugged housing • Large touchscreen

• High capacity battery • Personalized views

• Versatile connectivity • Custom reports

The All-In-One Portable Hardness Testing Solution

Portable

Leeb UCI

Rockwell

Find out more Find out more Find out more

(Page 5) (Page 7) (Page 9)

2 Swiss Precision since 1954

Covering Broad Application Range

Portable

Leeb UCI

Rockwell

Ultrasonic Contact

Dynamic Rebound Static Rockwell

Impedance Method

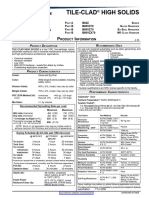

Av. Roughness Ra (µm / µinch) 7 / 275 2 / 80 12.5 / 500

Min. Mass (kg / lbs) 0.02 / 0.045 No requirement 0.3 / 0.66

Min. Thickness (mm / inch) 1 / 0.04 10 x ind. depth 5 / 0.2

Oil & Gas

Weld, Base Material & HAZ

Pressure Vessels

Flanges

Pipes

Wellhead Equipment

Automotive

Engine Blocks

Shafts

Panels

Gears

Brake Systems

Aerospace

Turbine Blades

Casings / Housings

Panels

Cast Objects

Landing Gears

Manufacturing and Machinery

Rolls

Coils

Bars / Pipes

Heat Treatment / Casting

Wires

Combining methods

Extends the application range to confined spaces, non-ideal Leeb & UCI &

samples and for correlating one method with another. Portable Rockwell Portable Rockwell

3 Swiss Precision since 1954

Equotip® 550 Touchscreen Unit

Built for Demanding Environments

Scratch-resistant solid touchscreen

with Gorilla® Glass technology

Shock-absorbing, dust and water proof

(IP 54) rugged housing

Functional at a wide temperature range

from -10 °C to +50 °C

Connectors and circuits are protected

against dust and voltage spikes

4 Swiss Precision since 1954

Standards Equotip® 550 Leeb

ASTM A956 / A370

ISO EN 16859

DIN 50156

GB/T 17394

JB/T 9378

Conversion Standards

ASTM E140

Guidelines

ASME CRTD-91

DGZfP Guideline MC 1

The global

VDI / VDE Guideline 2616 Paper 1 industry standard

Nordtest Technical Reports

99.12, 99.13, 99.36

Highly accurate ±4 HL

Wide Measurement Range Impact Devices & Accessories

Leeb impact devices are Proceq offers a wide variety

best suited for on-site testing of impact devices along with

of heavy, large or already support rings to serve most

installed parts. hardness testing requirements.

Broad Hardness Scales Test Blocks Portfolio

HB Coverage

HRA Extensive range of precise

HS The measurements are hardness test blocks available

automatically converted to for each impact device with

HRC all common hardness scales

(HV, HB, HRC, HRB, HRA,

different hardness levels for

regular verification.

HRB HV HS) as required.

The Leeb Measuring Principle – Invented by Proceq

Leeb hardness principle is based on the dynamic (rebound)

method. An impact body with a hard metal test tip is propelled

v

by spring force against the surface of the test piece. Surface HL = B * 1000 = r * 1000

deformation takes place when the impact body hits the test A vi

~vi

surface, which results in loss of kinetic energy. This energy loss is

detected by a comparison of velocities vi and vr when the impact

body is at a precise distance from the surface for both the impact Time

and rebound phase of the test, respectively. ~vr

Velocities are measured using a permanent magnet in the impact

body that generates an induction voltage in the coil which is

precisely positioned in the impact device. The detected voltage is Impact phase Rebound phase

proportional to the velocity of the impact body. Signal processing

is then providing the hardness reading.

5 Swiss Precision since 1954

Equotip® Leeb Impact Devices

D/DC DL S E G C

Impact energy 11 Nmm 11 Nmm 11 Nmm 11 Nmm 90 Nmm 3 Nmm

Indenter Tungsten Tungsten Ceramics Polycrystalline Tungsten Tungsten

carbide carbide 3 mm diamond carbide carbide

3 mm 2.8 mm 3 mm 5 mm 3 mm

Scope Most com- Narrow indent- For mea- For mea- Large and For surface

monly used er (probe) tip surements in surements in heavy com- hardened

probe. For the for measure- extreme hard- extreme hard- ponents, e.g. components,

majority of ment on hard ness ranges. ness ranges. casts and coatings, thin

applications. reach areas or Tool steels with Tool steels with forged parts. or impact-sen-

spaces with a high carbide high carbide sitive parts.

limited access. content. content.

Test blocks <500 HLD <710 HLDL <815 HLS ~740 HLE ~450 HLG ~565 HLC

~600 HLD ~780 HLDL ~875 HLS ~810 HLE ~570 HLG ~665 HLC

~775 HLD ~890 HLDL ~835 HLC

Steel and cast Vickers HV 81-955 80-950 101-964 84-1211 81-1012

steel Brinell HB 81-654 81-646 101-640 83-686 90-646 81-694

Rockwell HRB 38-100 37-100 48-100

HRC 20-68 21-68 22-70 20-72 20-70

HRA 61-88 61-88

Shore HS 30-99 31-97 28-104 29-103 30-102

Rm N/mm² σ1 275-2194 275-2297 340-2194 283-2195 305-2194 275-2194

σ2 616-1480 614-1485 615-1480 616-1479 618-1478 615-1479

σ3 449-847 449-849 450-846 448-849 450-847 450-846

Cold work tool steel Vickers HV 80-900 80-905 104-924 82-1009 * 98-942

Rockwell HRC 21-67 21-67 22-68 23-70 20-67

Measuring Range

Stainless steel Vickers HV 85-802 * 119-934 88-668 * *

Brinell HB 85-655 105-656 87-661

Rockwell HRB 46-102 70-104 49-102

HRC 20-62 21-64 20-64

Cast iron lamellar Brinell HB 90-664 * * * 92-326 *

graphite GG Vickers HV 90-698

Rockwell HRC 21-59

Cast iron, nodular Brinell HB 95-686 * * * 127-364 *

graphite GGG Vickers HV 96-724

Rockwell HRC 21-60 19-37

Cast aluminium Brinell HB 19-164 20-187 20-184 23-176 19-168 21-167

alloys Vickers HV 22-193 21-191 22-196 22-198

Rockwell HRB 24-85 24-86 23-85

Copper/zinc alloys Brinell HB 40-173 * * * * *

(brass) Rockwell HRB 14-95

CuAI/CuSn-alloys Brinell HB 60-290 * * * * *

(bronze)

Wrought copper Brinell HB 45-315 * * * * *

alloys, low alloyed

Surface Roughness grade class ISO 1302 N7 N9 N5

preparation Max. roughness depth Rt (μm / μinch) 10 / 400 30 / 1200 2.5 / 100

Test Piece Requirements

Average roughness Ra (μm / μinch) 2 / 80 7 / 275 0.4 / 16

Minimum sample Of compact shape (kg / lbs) 5 / 11 15 / 33 1.5 / 3.3

mass On solid support (kg / lbs) 2 / 4.5 5 / 11 0.5 / 1.1

Coupled on plate (kg / lbs) 0.05 / 0.2 0.5 / 1.1 0.02 / 0.045

Minimum sample Uncoupled (mm / inch) 25 / 0.98 70 / 2.73 15 / 0.59

thickness Coupled (mm / inch) 3 / 0.12 10 / 0.4 1 / 0.04

Surface layer thickness (mm / inch) 0.8 / 0.03 0.2 / 0.008

Indentation size on With 300 HV, Diameter (mm / inch) 0.54 / 0.021 1.03 / 0.04 0.38 / 0.015

test surface 30 HRC Depth (μm / μinch) 24 / 960 53 / 2120 12 / 480

With 600 HV, Diameter (mm / inch) 0.45 / 0.017 0.9 / 0.035 0.32 / 0.012

55 HRC Depth (μm / μinch) 17 / 680 41 / 1640 8 / 2560

With 800 HV, Diameter (mm / inch) 0.35 / 0.013 0.30 / 0.011

63 HRC Depth (μm / μinch) 10 / 400 7 / 280

*Custom conversion curve / correlation

6 Swiss Precision since 1954

Equotip® 550 Portable Rockwell

Standards

DIN 50157

Conversion Standards

ASTM E140

ISO EN 18265

Guidelines World-Class

DGZfP Guideline MC 1 Portable Static

VDI / VDE Guideline 2616 Paper 1

Hardness Testing

Advanced algorithm option Probe can be connected

for faster measurement directly to PC

Specially For Thin Parts Suits Various Sample

Particularly suited for scratch- Geometries

sensitive and polished parts or on Unique measuring clamp and

thin parts, profiles and pipes. The support feet are available

required minimum thickness for for the probe allowing tests

a reliable hardness reading is ten to be carried out on various

times the indentation depth. For geometries.

the mass there is no minimum

requirement.

Broad Hardness Scales For Any Environment

Coverage

HB The Equotip 550 Portable

HRA Measurements in HRC and Rockwell can be utilized

µm HV with automatic integrated for on-site, factory and lab

HRC conversions to HB, HRA, HRB

and many more common scales

environment with almost no

limitation.

in compliance to ASTM E140

HRB HV and ISO 18265.

The Rockwell Measuring Principle

The test principle of the Equotip Portable Rockwell follows the

traditional Rockwell static test method. During measurements

with the Equotip Portable Rockwell Probe, a diamond indenter

is forced into the test piece using a precisely controlled

force. The indentation depth of the diamond is continuously

measured while a load is applied and released. From the

indentation depths d1 and d2 recorded at two defined loads,

the difference is calculated: Δ = d2 – d1. This is traditionally

referred to as plastic deformation.

7 Swiss Precision since 1954

Equotip® Portable Rockwell

Probe and Accessories

Measuring range 0-100 µm; 19-70 HRC; 35-1‘000 HV

Resolution 0.1 µm; 0.1 HRC; 1 HV

Measuring accuracy ± 0.8 µm; ~ ± 1.0 HRC over entire range

Test loads Preload 10 N / Total Load 50 N

Diamond indenter Angle 100.0° ± 0.5°, diameter of flat area of 60 µm ± 0.5 µm

Dimensions Ø 40 mm, Length 115 mm

Round standard foot (magnetic) Tripod foot Special feet RZ 18-70 and 70-∞

Ideal for flat parts, and test locations Designed for tests that require accurate Designed for curved test pieces such as cylindrical

more than 10 mm from an edge. positioning (welds, heat-affected zones). parts, tubes, pipes.

The Portable Rockwell Measuring Clamp

Clamp Adapters

Support Z1 Support Z2

for flat parts max. 40 mm for thin cylindical parts, wires,

thickness bolts min. Ø 3 mm

Support Z4 Support Z4+28

for tubes and pipes up to for tubes and pipes over

Ø 28 mm Ø 28 mm

8 Swiss Precision since 1954

Equotip® 550 UCI

Standards

ASTM A1038

DIN 50159

Conversion Standards

ASTM E140

ISO 18265

Most Flexible

Guidelines

DGZfP Guideline MC 1

and Convenient

VDI / VDE Guideline 2616 Paper 1 Ultrasonic Hardness Tester

ASME CRTD-91

One-Step Calibration

atent pe

g·P nd

din in

en g

tp

en

nt

Pat

Pate ing

pend

Pat

en

Adjustable test load from Quick & Reliable

tp

en

ing din

g· nd

Patent pe

HV 1

HV1 to HV10 Measurements

HV 2

With this unique and patented User guidance enables

feature a wide range of reliable and accurate hardness

HV 3

applications can be covered readings to be obtained

HV 4 with out HV1-HV10 probe. quickly and easily.

HV 5

Unique Software Features Broad Hardness Scales

Coverage

HAZ feature is specially HB

designed for one of the HRA Measurements in HV

most often applications with with automatic integrated

UCI, the evaluation of heat

affected zones of welds. This HRC conversions to HB, HRA, HRB,

HRC and many more common

feature makes it even easier scales in compliance to ASTM

to evaluate and document the HRB HV E140 and ISO 18265.

results.

The UCI Measuring Principle

The UCI (Ultrasonic Contact Impedance) method uses the

same pyramid-shaped diamond as a conventional Vickers

hardness tester. Unlike Vickers testing, no optical evaluation

of the indentation is required, enabling fast and portable

measurements. The UCI method excites a rod into an ultrasonic

oscillation. The test load is applied by a spring and typically

ranges from 1 to 10 kg of force (HV1 – HV10). As the diamond

is forced into the material, the frequency of the rod oscillation

changes in response to the contact area between the diamond

and the material under test. The instrument detects the shift in

frequency, converts it to a hardness value which is immediately

displayed on the screen.

9 Swiss Precision since 1954

Equotip® UCI Probe and Accessory

Measuring range 20 – 2000 HV

Resolution 1 HV (UCI), 0.1 HRC

Measuring accuracy ± 2 % (150 – 950 HV)

Test loads (in 10 N steps) Selectable: HV1, HV2, HV3, HV4, HV5, HV10

Diamond indenter Vickers diamond according to ISO 6507-2

Dimensions 155 x ø 40 mm (6.1 x ø 1.57 inches) without foot

Adjustable test load for the HV1-HV10 probe

The required test load can be selected by the user in the settings

menu. For each measurement series, the force can be chosen

from six levels between HV1 and HV10 (~10 N and ~100 N), to

fit a wide range of applications. The minimum required mass for

reliable UCI measurements is 0.3 kg (0.66 lbs), and a thickness

of at least 5 mm (0.2 inch).

Examples:

HV1 Precision parts, thin coatings, hardened layers World e

ier

HV5 hardened or carburized material, weld inspection, HAZ prem

HV10 forgings, cast material, weld inspection

Special Foot

40mm

The optionally available special foot increases the measurement

repeatability. It can be used for flat or curved surfaces.

For curved surfaces there are two different apertures, one for

diameters from 5 to 25 mm and one for larger diameters from

20 to 70 mm.

10 Swiss Precision since 1954

Equotip® 550 Touchscreen Unit

Unique Features

Equotip 550 takes advantage of a new generation full color, dual processor Touchscreen Unit with enhanced software capabilities.

The instrument offers a unique range of functions which ultimately help speed up on-site and laboratory inspections and analysis.

Best-in-class reliability arising Equotip solutions are recognised worldwide for providing best-in-class

from 40 years of experience durability, high long-term accuracy and premium service.

Increased accuracy through Select from preloaded established conversions. Create, edit and verify

conversion curve options material conversion curves directly on the instrument (one-point, two-

point shift or polynomial). PC software allows to share conversions with

customers, suppliers and associated companies.

Reduce incorrect measurements Intelligent on-screen notifications to obtain the most relevant settings for

with interactive guides any application and to recognize and prevent faulty usage.

Time saving through The Equotip 550 allows to easily create pdf

customized reports reports on-site directly on the instrument

and export to a USB stick.

The reports can be fully configured and

enhanced with customer specific information

and company logo.

11 Swiss Precision since 1954

Equotip® 550 Touchscreen Unit

Unique Features

Traceable precision by Step by step verification wizard in line with applicable standards helps to

verification management regularly check the proper functioning of the instrument over time.

Optimized production process Comprehensive software tools and libraries

with automation package help to easily include the Equotip 550

into existing production chains. Feed the

measurement results directly into data

management systems.

Reduced costs due to a The high versatile Equotip 550 gives the possibility to apply three

future proof all-in-one solution measuring principles and to connect nine different probes to only one

device. There is no need to buy several instruments from now on.

Enlarged application range The step by step combined method wizard allows automatic on-site

by combining methods correlation of two different measuring principles to reduce dependencies

on material and geometries.

12 Swiss Precision since 1954

Equotip® 550 Touchscreen Unit

Unmatched User Experience

Touchscreen Features

For simplified and improved usability on

high resolution display

Personalized Screens

Arrange the view

according to your needs

Elaborated User Interface

Designed by industry experts

for smooth operation

Display 7” color display 800x480 pixels Battery 3.6 V, 14.0 Ah

Memory Internal 8 GB flash memory Battery Lifetime > 8 h (in standard operating mode)

Regional Settings Metric and Imperial units, multi-lan- Humidity < 95 % RH, non condensing

guage and timezone supported Operating -10 °C to +50 °C

Power Input 12 V +/-25 % / 1.5 A Temperature

Connectors Probe, USB host / device and Ethernet IP 54

Dimensions 250 x 162 x 62 mm Certification CE

Weight 1525 g (incl. Battery)

13 Swiss Precision since 1954

Proceq – A Story of Success

over more than 60 Years

Market Leader

Proceq SA, founded 1954 in Switzerland, is the global leader in

portable measurement solutions for the non-destructive testing of

material properties of metal, concrete, rock, paper and composites.

Find out more on the Proceq history

INVENTOR OF LEEB

Worldwide Local Support

Our team of dedicated experts are available to advise you on

INDUSTRY STANDARD our instruments and their applications. In addition you may

take further benefits from our instructional videos, evaluation

tools, online webinars and of course our live seminars globally.

NON-DESTRUCTIVE

Swiss Made

INVENTED IN 1975 Proceq instruments are developed, designed and

manufactured in Switzerland, that guarantees the

highest product and service quality. Since 1994, the

PORTABLE management system of Proceq SA is also certified

according to ISO 9001.

LEEB

ROCKWELL

UCI Experience

Proceq has been a proud innovator in the field of portable non-

destructive testing, developing solutions that have conquered

the inspection industry for decades. Most famous brands are

Equotip®, Schmidt®, Pundit®, Profometer ® and Carboteq®.

14 Swiss Precision since 1954

Solutions since 1954

Overcome the limitations of stationary

hardness testing

• 100% portable and extremely flexible

• No interruptions in production due to 24h availability

• Equally reliable, accurate and standardized

Ordering Information

Contact us for an on-site demo

Prepacked Units

All units include: Equotip Touchscreen incl. Battery, Power Supply, USB Cable, Surface Roughness Comparator Plate, DVD with Software,

Documentation, Carrying Strap and Carrying Case

Equotip® 550 Equotip® 550 Equotip® 550 Equotip® 550 Portable Equotip® 550

Leeb D Leeb G Rockwell UCI HV1 - HV10

356 10 001 356 10 002 356 10 003 356 10 004 356 10 007

For flexible probe Additionally includes Additionally includes Additionally includes Additionally includes

configuration and for Equotip Leeb Impact Equotip Leeb Impact Equotip Portable Equotip UCI Probe HV1-

existing owners of Device D, Impact Device Device G, Impact Device Rockwell Probe 50 N, HV10, UCI Probe Cable,

Equotip and Equostat 3 Cable, Test Block Cable, Test Block Protective Rubber Sleeve, UCI Test Block ~850 HV

probes ~775 HLD / ~56 HRC, ~570 HLG / ~340 HB, Probe Cable, Test Block

Coupling Paste, Cleaning Coupling Paste, Cleaning ~62 HRC

Brush Brush

2-in-1 Kits 356 10 023: Equotip 550 Portable Rockwell & UCI Kit

Special Offers 356 10 021: Equotip 550 Portable Rockwell & Leeb D Kit

356 10 024: Equotip 550 Leeb D & UCI Kit

Impact Devices & Probes Accessories

Equotip Leeb Impact Devices Equotip Leeb Accessories

356 00 500 Equotip Leeb Impact Device C 353 03 000 Set of Support Rings

356 00 100 Equotip Leeb Impact Device D 356 00 080 Equotip Impact Device Cable 1.5 m (5 ft)

356 00 110 Equotip Leeb Impact Device DC 353 00 086 Equotip Impact Device Cable 5 m (15 ft)

356 00 120 Equotip Leeb Impact Device DL

356 00 400 Equotip Leeb Impact Device E Equotip Portable Rockwell Accessories

356 00 300 Equotip Leeb Impact Device G 354 01 200 Equotip Portable Rockwell Measuring Clamp

356 00 200 Equotip Leeb Impact Device S 354 01 130 Equotip Portable Rockwell Tripod

Equotip Portable Rockwell Special Foot

354 01 250

Equotip Portable Rockwell Probe RZ 18 - 70

Equotip Portable Rockwell Special Foot

Equotip Portable Rockwell Probe 50N 354 01 253

356 00 600 RZ 70 - ∞

(for Equotip 550 or PC)

Equotip Portable Rockwell support Z2 for

354 01 243 measuring clamp

Equotip UCI Probe Equotip Portable Rockwell Support Z4+28 for

356 00 800 Equotip UCI Probe HV1-HV10 354 01 229 measuring clamp (for tubes and pipes over

Ø 28 mm)

Equotip Portable Rockwell support Z4

354 01 228 for measuring clamp (for tubes and pipes

up to Ø 28 mm)

Equotip UCI Accessories

356 00 720 Equotip UCI Special Foot

16 Swiss Precision since 1954

Ordering Information

Test Blocks Additional Test Block Calibrations

Equotip Leeb Test Blocks Calibrated by Proceq Factory Calibrations by Proceq

357 11 500 Equotip Test Block C, ~565 HLC / <220 HB Equotip Leeb Test Block Additional

357 10 109

357 12 500 Equotip Test Block C, ~665 HLC / ~325 HB Calibration HLD / HLDC

357 13 500 Equotip Test Block C, ~835 HLC / ~56 HRC Equotip Leeb Test Block Additional

357 10 129 Calibration HLDL

357 11 100 Equotip Test Block D/DC, <500 HLD / <220 HB

Equotip Leeb Test Block Additional

357 12 100 Equotip Test Block D/DC, ~600 HLD / ~325 HB 357 10 209 Calibration HLS

357 13 100 Equotip Test Block D/DC, ~775 HLD / ~56 HRC Equotip Leeb Test Block Additional

357 10 409

357 13 105 Equotip Test Block D/DC, ~775 HLD, one side Calibration HLE

357 11 120 Equotip Test Block DL, <710 HLDL / <220 HB Equotip Leeb Test Block Additional

357 10 509 Calibration HLC

357 12 120 Equotip Test Block DL, ~780 HLDL /~325 HB

357 13 120 Equotip Test Block DL, ~890 HLDL / ~56 HRC Equotip Leeb Test Block Additional

357 30 309 Calibration HLG

357 13 400 Equotip Test Block E, ~740 HLE / ~56 HRC

357 14 400 Equotip Test Block E, ~810 HLE / ~63 HRC

357 31 300 Equotip Test Block G, <450 HLG / <200 HB By Accredited Institutes

357 32 300 Equotip Test Block G, ~570 HLG / ~340 HB Equotip Leeb Test Block Additional

357 90 909 Calibration HL (DIN 50156-3)

357 13 200 Equotip Test Block S, ~815 HLS / ~56 HRC

Equotip Leeb Test Block Additional

357 14 200 Equotip Test Block S, ~875 HLS / ~63 HRC 357 90 919 Calibration HB (ISO 6506-3)

Equotip Leeb Test Block Additional

357 90 929 Calibration HV (ISO 6507-3)

Equotip Leeb Test Block Additional

357 90 939 Calibration HR (ISO 6508-3)

Equotip Portable Rockwell Test Blocks By Accredited Institutes

357 41 100 Equotip Portable Rockwell Test Block Equotip Portable Rockwell Test Block

357 90 918

~20 HRC, ISO 6508-3 HRC Calibration Additional Calibration HB (ISO 6506-3)

357 42 100 Equotip Portable Rockwell Test Block Equotip Portable Rockwell Test Block

357 90 928

~45 HRC, ISO 6508-3 HRC Calibration Additional Calibration HV (ISO 6507-3)

357 44 100 Equotip Portable Rockwell Test Block

~62 HRC, ISO 6508-3 HRC Calibration

Equotip UCI Test Blocks By Accredited Institutes

357 51 200 Equotip UCI Test Block ~300HV, ISO 6507-3 Equotip UCI Test Block Additional

357 90 940

HV10 Calibration Calibration HB, ISO 6506-3, one side

357 52 200 Equotip UCI Test Block ~550HV, ISO 6507-3 Equotip UCI Test Block Additional

357 90 941

HV10 Calibration Calibration HR, ISO 6508-3, one side

357 54 200 Equotip UCI Test Block ~850HV, ISO 6507-3 Equotip UCI Test Block ~550HV, ISO 6507-3

357 52 100

HV10 Calibration HV5 Calibration

Service and Support Warranty Information

Proceq is committed to providing the best support and service Each instrument is backed by the standard Proceq warranty

available in the industry through the Proceq certified service and extended warranty options.

centers worldwide. This results in a complete support for Equotip »» Electronic portion of the instrument: 24 months

by means of our global service and support facilities. »» Mechanical portion of the instrument: 6 months

Subject to change without notice. All information contained in this documentation is presented in good faith and believed to be correct. Proceq SA makes no warranties and ex-

cludes all liability as to the completeness and/or accuracy of the information. For the use and application of any product manufactured and/or sold by Proceq SA explicit reference

is made to the particular applicable operating instructions.

17 Swiss Precision since 1954

You might also like

- Marketing Plan - The Playstation NetworkDocument19 pagesMarketing Plan - The Playstation NetworkBharath KarthikeyanNo ratings yet

- Ivy Sports Symposium PlaybookDocument16 pagesIvy Sports Symposium PlaybookSports Symposium Inc.No ratings yet

- Ashrae Filtration Disinfection c19 GuidanceDocument38 pagesAshrae Filtration Disinfection c19 GuidanceVishal JainNo ratings yet

- DS 1 CatDocument38 pagesDS 1 CatMuhammad Bilal Khattak100% (1)

- Application Layer - Networks Questions and AnswersDocument31 pagesApplication Layer - Networks Questions and AnswersSojol Kumar100% (1)

- ANALYSISTABS MOM Template 1Document10 pagesANALYSISTABS MOM Template 1FSArifNo ratings yet

- PE Design OnDocument13 pagesPE Design OnMASITAH MUHAMMADNo ratings yet

- Partex CatalogDocument199 pagesPartex CatalogjamilNo ratings yet

- Sales Presentation PDFDocument16 pagesSales Presentation PDFQuang Thanh100% (1)

- Module 1 - Technical TrainingDocument85 pagesModule 1 - Technical TrainingSSP1234fulNo ratings yet

- Shinkawa Presentation PDFDocument66 pagesShinkawa Presentation PDFAhmed KhairiNo ratings yet

- Chapter 5-ADocument23 pagesChapter 5-AMahrouz MadoNo ratings yet

- BarillaDocument7 pagesBarillasahil.ssc838No ratings yet

- Fraser Hardie Rev. 2 Sbpaut For Kint Issue 2Document28 pagesFraser Hardie Rev. 2 Sbpaut For Kint Issue 2Tony TheFatoneNo ratings yet

- WellIntegrity RBL+combinedDocument4 pagesWellIntegrity RBL+combinedJulio BaratçabalNo ratings yet

- Rovins Nano - DatasheetDocument2 pagesRovins Nano - Datasheetpaolo attanasioNo ratings yet

- Liquidtight Fittings: Cooper Crouse-HindsDocument8 pagesLiquidtight Fittings: Cooper Crouse-HindsAlex RamirezNo ratings yet

- TDS 8007F-04 English UnitsDocument3 pagesTDS 8007F-04 English UnitsSanthosh V RaajendiranNo ratings yet

- CTSDG 06515 XDMDocument4 pagesCTSDG 06515 XDMCAMILO SEBASTIAN DAROCH PAQUIENNo ratings yet

- Quadzero TDS 312ipDocument2 pagesQuadzero TDS 312ipTheAnh TranNo ratings yet

- 5kV 6mm Xlpe Cts PVC Cable: Application StandardsDocument1 page5kV 6mm Xlpe Cts PVC Cable: Application StandardsAHMED YOUSEFNo ratings yet

- Product Specifications Product Specifications: HWXX HWXX - 6516DS - VTM VTM 6515DS 6515DSDocument2 pagesProduct Specifications Product Specifications: HWXX HWXX - 6516DS - VTM VTM 6515DS 6515DSИван КадигробNo ratings yet

- 9.5in OntrakDocument2 pages9.5in OntrakPaul Ticona SNo ratings yet

- ALPU Fit Lite SpecsDocument8 pagesALPU Fit Lite SpecsAlejandro AlbornozNo ratings yet

- Firetec Bs 7846 LPCB Basec Approved Power CableDocument5 pagesFiretec Bs 7846 LPCB Basec Approved Power CableSanjay MNo ratings yet

- Product Specifications Product Specifications: HWXX HWXX - 6516DS 6516DS - VTM VTMDocument2 pagesProduct Specifications Product Specifications: HWXX HWXX - 6516DS 6516DS - VTM VTMЕвгений ГрязевNo ratings yet

- QBXLH-6565A-VTM Product SpecificationDocument5 pagesQBXLH-6565A-VTM Product Specificationmegamaster0987654321No ratings yet

- Rotary Positioning SensoresDocument19 pagesRotary Positioning SensoresJesse JoabeNo ratings yet

- 1430 - Golden Altos Nepp 2017 JuneDocument19 pages1430 - Golden Altos Nepp 2017 JuneAylia RizviNo ratings yet

- Victaulic Style 75Document4 pagesVictaulic Style 75Mancasi RazvanNo ratings yet

- Datasheet MomentiveDocument5 pagesDatasheet Momentivehuynh thi y viNo ratings yet

- Neugroschl 2017Document31 pagesNeugroschl 2017Ujjwal SinghNo ratings yet

- Rotary Substitutes (Subs & X-Overs) - InformationDocument2 pagesRotary Substitutes (Subs & X-Overs) - Informationinternet.casa149No ratings yet

- Series: Vickers Hardness TesterDocument6 pagesSeries: Vickers Hardness TesterAdien DienNo ratings yet

- 5 Model TuningDocument37 pages5 Model TuningTameem JeelaniNo ratings yet

- HEADER MOLEX - KK 7395 - 5-Pin - 0022057058 - PCB - HEADERS PDFDocument2 pagesHEADER MOLEX - KK 7395 - 5-Pin - 0022057058 - PCB - HEADERS PDFLodewyk KleynhansNo ratings yet

- Aec VS MilspecDocument28 pagesAec VS MilspecJeremy ChiangNo ratings yet

- Hidraulica 6.125Document19 pagesHidraulica 6.125Mario MedinaNo ratings yet

- 1-2620 Low Voc Conformal CoatingDocument4 pages1-2620 Low Voc Conformal CoatingGreat StuffNo ratings yet

- Mounting AccessoriesDocument10 pagesMounting AccessoriesNg Wei LihNo ratings yet

- 006ksf t4130d20 CorningDocument4 pages006ksf t4130d20 CorningRenzo Romero ArenasNo ratings yet

- 101.1 IntroductiontoALDocument29 pages101.1 IntroductiontoALBassemNo ratings yet

- EagleBurgmann BT-AR ENDocument6 pagesEagleBurgmann BT-AR ENswosthi sambitNo ratings yet

- SBS-30 SBS30Document8 pagesSBS-30 SBS30damarNo ratings yet

- Feed-Through Terminal Block - UT 2,5 - 3044076: Your AdvantagesDocument32 pagesFeed-Through Terminal Block - UT 2,5 - 3044076: Your AdvantagesKushal DixitNo ratings yet

- Zaragoza Factory - Our Product - enDocument34 pagesZaragoza Factory - Our Product - enEngr Fahimuddin QureshiNo ratings yet

- Product SpecificationsDocument2 pagesProduct Specificationsjorge garzaNo ratings yet

- RV K CableDocument5 pagesRV K Cablejesusgarcia279No ratings yet

- Technical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Document5 pagesTechnical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Sami LAHMIDINo ratings yet

- TECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorDocument2 pagesTECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorjxvichoNo ratings yet

- Dual Hi-Lo Pressure SwitchesDocument16 pagesDual Hi-Lo Pressure SwitchesfreddyheavymetalNo ratings yet

- Chemistry For Engineers: (Use The Table in The PPT As Your Guide in Accomplishing Table 1.)Document8 pagesChemistry For Engineers: (Use The Table in The PPT As Your Guide in Accomplishing Table 1.)Aivan Lloyd CapuleNo ratings yet

- WAGO 773-104enDocument4 pagesWAGO 773-104enDavid MuniveNo ratings yet

- 932qlg65vteb PDFDocument4 pages932qlg65vteb PDFMariaNo ratings yet

- Profometer Sales Flyer English HighDocument15 pagesProfometer Sales Flyer English Highfranklin91No ratings yet

- EISO Deck 2023 en V5-GeneralDocument22 pagesEISO Deck 2023 en V5-Generaljewel610620No ratings yet

- Niton Family BrochureDocument6 pagesNiton Family Brochurecelestino biasottoNo ratings yet

- 1.5KE Series 1N6267 A 1N6303A - Vishay (TransZorb Transiente Voltage Suppressors)Document7 pages1.5KE Series 1N6267 A 1N6303A - Vishay (TransZorb Transiente Voltage Suppressors)Rubio Marra da SilvaNo ratings yet

- LK Rockwell Machines Brochure PDFDocument2 pagesLK Rockwell Machines Brochure PDFArun SasiNo ratings yet

- Motwane - Oil BDVDocument34 pagesMotwane - Oil BDVvikash kumarNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- NDT Catalogue AJ - 2017 PDFDocument32 pagesNDT Catalogue AJ - 2017 PDFzokytoNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- How To Calculate P90 (Or Other PXX) PV Energy Yield Estimates - SolargisDocument8 pagesHow To Calculate P90 (Or Other PXX) PV Energy Yield Estimates - SolargisgoyalmanojNo ratings yet

- Upload MD1 - Lecture 8 - Keys, Couplings 2021Document16 pagesUpload MD1 - Lecture 8 - Keys, Couplings 2021PotatoFryNo ratings yet

- LN-WDA EngDocument50 pagesLN-WDA EngMorgen GumpNo ratings yet

- Data Sheet - LSA-PLUS Series 2 FamilyDocument24 pagesData Sheet - LSA-PLUS Series 2 FamilyvyevtnhmarxynmmuNo ratings yet

- Pspice Orcad TutorialDocument22 pagesPspice Orcad Tutorialอาร์มซ่า ทีนซ๋าNo ratings yet

- MMTC Franchisee ApplnDocument3 pagesMMTC Franchisee ApplnrajatmaheshwariNo ratings yet

- Introduction of Nita AmbaniDocument35 pagesIntroduction of Nita Ambanipriyanka_gandhi28No ratings yet

- Mec Show RunDocument5 pagesMec Show Runsheraz salimNo ratings yet

- FB4410Z IorDocument11 pagesFB4410Z IorDavi FienniNo ratings yet

- Pawan 09 Graph AlgorithmsDocument26 pagesPawan 09 Graph Algorithmsgorot1No ratings yet

- Base-Lab-8 5 1Document9 pagesBase-Lab-8 5 1Steve JonesNo ratings yet

- Pedagogy Mcqs For SST PDF and For All Competitive ExamsDocument39 pagesPedagogy Mcqs For SST PDF and For All Competitive Examsfarooqmkl123No ratings yet

- Backfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersDocument1 pageBackfill Materials GW, GP, SW: 600 (Min) WELL HAND Packed BouldersRVNLPKG6B VBL-GTLMNo ratings yet

- Transforming Literacy Instruction With TechnologyDocument146 pagesTransforming Literacy Instruction With TechnologyskibtechNo ratings yet

- DC Molded Case BreakersDocument6 pagesDC Molded Case BreakersMrNo ratings yet

- Hibridni Oblak Una - Modul 7Document5 pagesHibridni Oblak Una - Modul 7Una DrakulićNo ratings yet

- State of North Carolina: CountyDocument2 pagesState of North Carolina: CountyWilliam JamesNo ratings yet

- Stratix 2000 SwitchesDocument2 pagesStratix 2000 SwitchesMarisurNo ratings yet

- Diabetes DietDocument27 pagesDiabetes DietLeomark RespondeNo ratings yet

- DOH Oral Maxillofacial ASC OMS LTO AT1262015rev2Document13 pagesDOH Oral Maxillofacial ASC OMS LTO AT1262015rev2al gulNo ratings yet

- Cebu Shipyard V William GDocument4 pagesCebu Shipyard V William GDhevee MLNo ratings yet

- AF201 Assignment 2Document8 pagesAF201 Assignment 2Navinesh NandNo ratings yet

- Precision Power Analyzer Communication Interface: WT3000 Manual, Vol 2/3Document151 pagesPrecision Power Analyzer Communication Interface: WT3000 Manual, Vol 2/3Hữu DuyệtNo ratings yet

- J&K Recog. Act Final by Randhir SirDocument3 pagesJ&K Recog. Act Final by Randhir SirUNIQUE YOUTUBERNo ratings yet