Professional Documents

Culture Documents

Welding Dissimilar Metals

Uploaded by

manishkapriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Dissimilar Metals

Uploaded by

manishkapriCopyright:

Available Formats

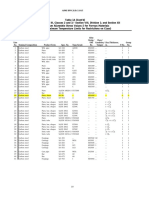

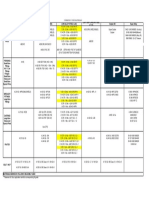

JOINING OF DISSIMILAR METALS AND ALLOYS

FERROUS MATERIALS NICKEL BASE ALLOYS

12Cr

316 304 12Cr 2-1/4Cr 1-1/4Cr P. (2)

TYPE P. No 310 347 321 3-1/2 Ni 405, 9Cr 5Cr C-Mo CS Type Nickel Monel Inconel Incoloy

316L 304L 410 (2,3) (2,3) No.

410S

Carbon Steel P-1 12A 12A 12A 12A 1C 1B 1F 1G 1E 1E 1D 1B 1A(4) Carbon &

P-1 13 14 13 13

Carbon Moly P-3 12B 12B 12B 12B 2C 2B 2F 2G 2E 2E 2D 2B(4) Alloy Steels

1-1/4 Cr-1/2 Mo P-4 12D 12D 12D 12D 3D 3D 3F 3G 3E 3E 3D(4) Stainless Steel P-8 13 13 13 13

2-1/4 Cr-1 Mo P-5 12E 12E 12E 12E 4E 4E 4F 4G 4E 4E(4) Incoloy P-45 13 13 13 13

5 Cr-1/2 Mo P-5 12E 12E 12E 12E 5E 5E 5F 5G 5E(4) Inconel P-43 13 13 13

9 Cr-1 Mo P-5 12G 12G 12G 12G 6G 6G 6G 6G(4) Monel P-42 15 14 Min preheat is 50°F.

12 Cr Type 410 P-6 12F 12F 12F 12F 7F 7F 7F(4) Nickel P-41 15 No PWHT for above combinations

12 Cr Type 405, 410S P-7 12H 12H 12H 12H 7C 12H THERMAL TREATMENT

Treatment

3-1/2 Nickel P-9B 12C 12C 12C 12C 8C, 13A,C Preheat PWHT

Symbols

18 Cr-8 Ni SS

P-8 9H 9H 9H 9H A 50°F Min Over 1" 175°F Min Per Code

Type 304, 304L

18 Cr-8 Ni Stabilised SS

P-8 10H 10H 10H B 50°F Min Over 1/2" 175°F Min Per Code

Type 347, 321

18 Cr-10 Ni Moly SS

P-8 11H 11H C 300°F Min. Per Code

Type 316, 316L

25 Cr-20 Ni Type-310 P-8 16H D 300°F Min Per Code

Sl. COATED ELECTRODES BARE WIRE E 350°F Min. 1300-1375°F(2)

MATERIALS

No ASME CLASSIFICATION ASME CLASSIFICATION F 400°F Min Per Code

1 Carbon Steel SFA-5.1 E 6010, E 7018 SFA-5.18 ER 70S-2 G 400°F Min. plus (See Note 9) Per Code

2 Carbon-1/2 Moly SFA-5.5 E 7010-A1, E 7018-A1 SFA-5.28 ER 70S-A1 / ER 80S-D2 Note : H 50°F Min. None

3 1-1/4 Chrome Moly (10) SFA-5.5 E 7018-B2L, E 8018-B2 SFA-5.28 ER 80S-B2 / ER 70S-B2L 1. Material listings by P-number groups are given in ASME Section IX. Table QW-422, and in ANSI B31.3, Appendix A

4 2-1/4 Chrome moly (10) SFA-5.5 E 8018-B3L, E 9018-B3 SFA-5.28 ER 90S-B3 / ER 80S-B3L 2. Sealwelds of threaded joints and sockets or fillets welds in piping welded with electrode number 13 or 12

5 5 Chrome Moly SFA-5.5 E 8018 B6/B6L SFA-5.28 ER 80S-B6 need no post weld heat treatment. Preheat requirements must be observed (ANSI B31.3 Table 331.2.1)

6 9 Chrome Moly SFA-5.5 E 8018 B8/B8L SFA-5.28 ER 80S-B8 3. Butt welds in pipe and tubes of these materials need no post weld heat treatment of the maximum

7 12 Chrome SFA-5.4 E 410-16 or 15 SFA-5.9 ER 410 nominal OD is 4 inches, a maximum thickness is 1/2 inch, a maximum carbon content is 0.15%, and a

8 3-1/2 Nickel SFA-5.5 E 308-16

E 8016-C2,

or E8018-C2

15 E SFA-5.9 ER 80S-Ni-3 4. These welds are subject to a hardness test.

9 18 Chrome-8Nickel(308, 308L) (5) SFA-5.4 308L-16 or 15 SFA-5.9 ER 308, ER 308L 5. Where L-grade materials (extra low carbon) are being joined, the corresponding L-grade of weld filler must be used.

10 18 Cr-10Ni-Cb (347) SFA-5.4 E 347-16 or 15 SFA-5.9 ER 347 6. Type 309 filler metal shall not be used if the operating temperature exceeds 600°F.

11 18 Cr-10Ni-Mo (316, 316L) (5) SFA-5.4 E316-16/15, E316L-16/15 SFA-5.9 ER 316, ER 316L 7. Any substitution of these materials must be approved.

12 25Cr-12Ni (309) (6) SFA-5.4 E 309-16 or 15 SFA-5.9 ER 309 8. Weld must be cooled down to atleast 400°F before welding and post weld heat treatment to allow any

13 Inconel (7) SFA-5.11 E Ni Cr Fe-3 (Incoweld-A) SFA-5.14 ER Ni Cr-3 (Inconel-82) retained austenite to transform.

14 Monel SFA-5.11 E Ni Cu-7 (Monel -400) SFA-5.14 ER Ni Cu-7 (Monel-60) 9. ERNi-1 (Nickel 61) is the preferred filler wire for gas tungsten arc welding monel to CS.

15 Nickel SFA-5.11 E Ni-1 (Nickel-141) SFA-5.14 ER Ni-1 (Nickel-61) 10. Low carbon grade electrodes are also acceptable.

16 25 Cr-20 Ni (310) SFA-5.4 E 310-16 or 15 SFA-5.9 ER 310 11 Impregnated oil, other volatile matter can be eliminated by heating the casting or weld groove to approximately 900°F

17 Avesta 254 SMO - Avesta P-12 - Avesta P-12 (480ºC) for about 15 minutes and then wire brushing, grinding or rotary filing to remove the residue

Low Temperature Carbon Steel 12. This table is compiled for petroleum refinery applications based on the prevailing practices. For joining of dissimilar metals,

18 SFA-5.1 E 7018-1 SFA-5.28 ER 80S-Ni1

(Below -20°F up to -50°F) alternative welding electrodes / filler wires may be selected as per API 582 guidelines.

COMMON WELDING ELECTRODES / FILLER WIRES

Cast Iron ( Note 11) E Ni-CI / E NiFe-CI Tp 2205 / 2304 E-2209 Al Bronze ER CuAl-A2/A3 904L E 385-15/16 AISI 4130 / 4140 E 7018-A1 or ER 70S-6 (D)

CS-CuNi (70/30) E Ni Cu-7 Tp 2507(Sup. Dup) E-2594 P Bronze ER CuSn-A/C Brazing wire B Cu P-4

Aluminium ER 4043 ER NiCrMo-3 / Cu-Ni ER Cu Ni Alloy 20 ER 320

Alloy 625

Stellite E CoCr-A E NiCRMo-3 Brass ER Cu Zn-A 17-4 PH E/ER 630 + PWHT

15/07/2014 Rev. 0 SVR / PBK

You might also like

- Schneider Documentation - Hook-Ups-6Document1 pageSchneider Documentation - Hook-Ups-6genih44348No ratings yet

- ST 41 SteelDocument1 pageST 41 Steelagus fitriyadiNo ratings yet

- 09 - Replication&Met Evaluation PDFDocument61 pages09 - Replication&Met Evaluation PDFSACHIN PETKARNo ratings yet

- JC Catalogue Globe Valves BBDocument24 pagesJC Catalogue Globe Valves BBarnettoNo ratings yet

- Qualifikasi Material ASME IX LTCS A333, A350, A420Document3 pagesQualifikasi Material ASME IX LTCS A333, A350, A420Solikhul Haris0% (1)

- Electrical Properties of Lead Solder AlloyDocument9 pagesElectrical Properties of Lead Solder AlloyVedant PrustyNo ratings yet

- Gate Valve Chart Trim Ra 2006 11 29Document1 pageGate Valve Chart Trim Ra 2006 11 29lfbenahmedNo ratings yet

- Piping Study - HomeDocument5 pagesPiping Study - HomeshantilalNo ratings yet

- Material Comparison For Piping MaterialsDocument1 pageMaterial Comparison For Piping Materialskrishna_pipingNo ratings yet

- 04 - Sundaramoorthy - LAB - RLADocument56 pages04 - Sundaramoorthy - LAB - RLADSGNo ratings yet

- Tablamateriales enDocument1 pageTablamateriales enLeandro Ribeiro Do PradoNo ratings yet

- VR300BC-Rev 3Document4 pagesVR300BC-Rev 3Nourdine EL-HASANYNo ratings yet

- Valvula Mariposa FlowsealDocument12 pagesValvula Mariposa Flowsealsakura_jNo ratings yet

- FlowBiz Forged Steel Gate Valve Flanged End 150 ClassDocument2 pagesFlowBiz Forged Steel Gate Valve Flanged End 150 ClassSHAKIR ANSARINo ratings yet

- Katalog-KTS en 2018 15Document1 pageKatalog-KTS en 2018 15Alomaki KismaNo ratings yet

- SS41Document1 pageSS41Srhosseini30% (1)

- Assambly SheetDocument1 pageAssambly Sheet3ME59 Vasava JayeshNo ratings yet

- Issuer & Norm Modality / Abbreviation Metal Coat Thickness in MDocument10 pagesIssuer & Norm Modality / Abbreviation Metal Coat Thickness in MBartek HajaNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Gate Valve VC1500BBDocument4 pagesGate Valve VC1500BBDanielle JohnsonNo ratings yet

- Bill of Material - Globe Valve - Model 3000Document1 pageBill of Material - Globe Valve - Model 3000RAVIKIRAN BARDENo ratings yet

- A-36 - Pages From Section II Part D (Customary)Document3 pagesA-36 - Pages From Section II Part D (Customary)siswantoNo ratings yet

- Materail Spec For PumpDocument1 pageMaterail Spec For PumpkapsarcNo ratings yet

- Asme Sec Ix-2013 165Document1 pageAsme Sec Ix-2013 165Durgarao VasaNo ratings yet

- Tabla de Referencia de Materiales: Material Reference ChartDocument2 pagesTabla de Referencia de Materiales: Material Reference Chartsateesh chandNo ratings yet

- MIL-STD-871 REV. D - Part6Document2 pagesMIL-STD-871 REV. D - Part6David WongNo ratings yet

- DSM-0274.0 Bronze AlloysDocument5 pagesDSM-0274.0 Bronze AlloyskerbaubiruNo ratings yet

- JC Catalogue Gate Valves BB PDFDocument24 pagesJC Catalogue Gate Valves BB PDFMahdi DalyNo ratings yet

- Valve MaterialsDocument1 pageValve MaterialsMarcel BolovedeaNo ratings yet

- Pamela Anderson'S Smaw & Gtaw Filler Metal Selection GuideDocument10 pagesPamela Anderson'S Smaw & Gtaw Filler Metal Selection GuideJames RodriguezNo ratings yet

- Katalog-KTS en 2018 14Document1 pageKatalog-KTS en 2018 14Alomaki KismaNo ratings yet

- Material Comparison For ASTM JISDocument2 pagesMaterial Comparison For ASTM JISAnonymous Q4YUvRNo ratings yet

- Consumables For SSDocument14 pagesConsumables For SSELongLeeNo ratings yet

- Equivalent MaterialDocument1 pageEquivalent Materialmuhammadf SardarNo ratings yet

- Equivalent MaterialDocument1 pageEquivalent Materialmuhammadf SardarNo ratings yet

- Materials Comparison DIN / EN / ASTM: Finished PartsDocument6 pagesMaterials Comparison DIN / EN / ASTM: Finished PartsBittuNo ratings yet

- Threaded End Connection: Series S Ductile IronDocument1 pageThreaded End Connection: Series S Ductile IronptnusadharmafNo ratings yet

- Bonded Seal Size ChartDocument6 pagesBonded Seal Size Charts bNo ratings yet

- Filler Metal Selection GuideDocument2 pagesFiller Metal Selection GuideMehta Mehul100% (1)

- FlowBiz Forged Steel Globe Valve Full BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Full BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- FilesDocument14 pagesFilescuchufliNo ratings yet

- Equivalent Grade ChartDocument1 pageEquivalent Grade ChartDipesh Patel100% (1)

- rpp2022 Rev Elements Electronic StructDocument2 pagesrpp2022 Rev Elements Electronic StructFrancisco José MoralejoNo ratings yet

- 7 Eaf BofDocument36 pages7 Eaf BofRijalNo ratings yet

- VẬT LIỆU THEO TIÊU CHUẨN - JIS - ASTMDocument3 pagesVẬT LIỆU THEO TIÊU CHUẨN - JIS - ASTMThanh BuiNo ratings yet

- Steel St3sp - St3Document3 pagesSteel St3sp - St3jmartinezmoNo ratings yet

- NAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsDocument2 pagesNAF-Navalsteam Ball Valves FK 25.76 (2) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- Series 64 Screwed End Ball ValvesDocument2 pagesSeries 64 Screwed End Ball ValvesProcess Controls & ServicesNo ratings yet

- Valve Material Equivalents PDFDocument3 pagesValve Material Equivalents PDFmahdi.guidara100% (1)

- Commonly Used MaterialDocument1 pageCommonly Used MaterialJitendra PrasadNo ratings yet

- Equivalent Cross Valve CastDocument1 pageEquivalent Cross Valve Castg_casalinuovo19812344No ratings yet

- Itb - PPT Final Matl Idf Workshop PT - Ip 21-23 Agst 2019Document113 pagesItb - PPT Final Matl Idf Workshop PT - Ip 21-23 Agst 2019Rizqi PriatnaNo ratings yet

- Seamless Fiux Fored Wire - Megafil250Document1 pageSeamless Fiux Fored Wire - Megafil250SungJun ParkNo ratings yet

- Comparison of Astm Specifications and SIMILAR Standards PDFDocument1 pageComparison of Astm Specifications and SIMILAR Standards PDFRoberto_PrrNo ratings yet

- File 1557373151Document17 pagesFile 1557373151JOWAN PERKASANo ratings yet

- PNP - Iss H - Channel NutsDocument1 pagePNP - Iss H - Channel Nutsselva nayagamNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- EEMUA 159 183 Tank-Foundation PDFDocument91 pagesEEMUA 159 183 Tank-Foundation PDFTuğrulhan Özdemir80% (5)

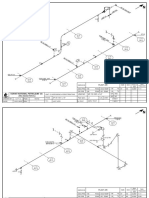

- Ap 15 1001Document5 pagesAp 15 1001manishkapriNo ratings yet

- Ap 15 1002Document1 pageAp 15 1002manishkapriNo ratings yet

- Ai 15 1002Document1 pageAi 15 1002manishkapriNo ratings yet

- Ap 15 1003Document1 pageAp 15 1003manishkapriNo ratings yet

- Ap 15 1004Document1 pageAp 15 1004manishkapriNo ratings yet

- BD 15 1002Document2 pagesBD 15 1002manishkapriNo ratings yet

- BD 15 1001Document2 pagesBD 15 1001manishkapriNo ratings yet

- Ap 15 1004Document1 pageAp 15 1004manishkapriNo ratings yet

- Business EthicsDocument61 pagesBusiness EthicsJinesh GadaNo ratings yet

- Qualities of A Good PresenterDocument2 pagesQualities of A Good PresenterMuhammad Umair KhanNo ratings yet

- Rockmass Strength PropertiesDocument32 pagesRockmass Strength PropertieskannonzkNo ratings yet

- jOB aNALYSIS POWERPOINTDocument34 pagesjOB aNALYSIS POWERPOINTdushyant12288No ratings yet

- Industrial Mechanical Vapour Recompression 1Document2 pagesIndustrial Mechanical Vapour Recompression 1Gaurav UpaNo ratings yet

- CBSE Class 11 History Syllabus 2021-22Document12 pagesCBSE Class 11 History Syllabus 2021-22Muskan TiwariNo ratings yet

- Kidstone Mines Start UpDocument5 pagesKidstone Mines Start UpCraftychemistNo ratings yet

- Remote Sensing GeologyDocument438 pagesRemote Sensing GeologyStalin Bryan100% (2)

- Long Quiz For Week 12345Document26 pagesLong Quiz For Week 12345Jerwyn Marie CayasNo ratings yet

- Module 5 Utilitarianism Part IDocument30 pagesModule 5 Utilitarianism Part IDenver Acenas100% (1)

- Nursing ResumeDocument2 pagesNursing Resumeapi-655558844No ratings yet

- Introduction To PFADocument7 pagesIntroduction To PFACHRISTINE KYLE CIPRIANONo ratings yet

- Thesis Correction RanjitDocument3 pagesThesis Correction Ranjitranjit makajuNo ratings yet

- Answers Association Rules We KaDocument7 pagesAnswers Association Rules We KaBảo BrunoNo ratings yet

- Momentum Equation in Cylindrical Coordinate: Appendix BDocument8 pagesMomentum Equation in Cylindrical Coordinate: Appendix BAbdul Rauf AttariNo ratings yet

- Business Partner and Master DataDocument5 pagesBusiness Partner and Master DataPamela PerezNo ratings yet

- Program - 1:: Lab - Data Structure Using CDocument50 pagesProgram - 1:: Lab - Data Structure Using Ceshmnash9298No ratings yet

- Ppt-Nav1 - PrelimDocument174 pagesPpt-Nav1 - PrelimKayle Christian TaroyNo ratings yet

- Filipino ThinkingDocument2 pagesFilipino ThinkingRheyven JuanNo ratings yet

- PGDBA From MIT PuneDocument2 pagesPGDBA From MIT PuneMIT,PuneNo ratings yet

- AccountingDocument45 pagesAccountingAfia ZaheenNo ratings yet

- FC9170 02Document14 pagesFC9170 02ВладимирNo ratings yet

- Tunnel Thru The Air Correct Starting PointDocument2 pagesTunnel Thru The Air Correct Starting Pointkhit wong54% (13)

- SMPS FundamentalsDocument53 pagesSMPS FundamentalsRahul Gupta100% (2)

- FIS-Finishes Schedule - R1Document4 pagesFIS-Finishes Schedule - R1meghadurganNo ratings yet

- Heat Transfer EquipmentDocument28 pagesHeat Transfer Equipmentdeepak.dce.meNo ratings yet

- RT Series Manual v005Document44 pagesRT Series Manual v005Muhammed Abo-FandoodNo ratings yet

- Denso Mitsubishi L200 Common Rail PDFDocument53 pagesDenso Mitsubishi L200 Common Rail PDFAlex Renne Chambi100% (8)

- Manual Hydraulic Power UnitsDocument20 pagesManual Hydraulic Power UnitsabdiNo ratings yet

- Impact On OrganizationsDocument14 pagesImpact On OrganizationsogakhanNo ratings yet

- Apex CheatsheetDocument4 pagesApex CheatsheetAmit GangwarNo ratings yet