0% found this document useful (0 votes)

284 views47 pagesPCB Design and Manufacturing Guide

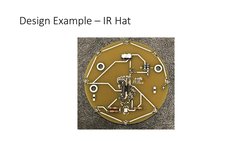

This document provides an overview of printed circuit board (PCB) design. It discusses what a PCB is, the design process, and important considerations. The 10-step design process includes specifying requirements, selecting components, schematic design, simulation, layout, manufacturing, assembly, testing, and use. Key topics covered are trace width, pours, thermals, grounding, decoupling, high-frequency effects, and common mistakes. An example infrared hat design is presented to illustrate the process.

Uploaded by

dlc352-sc1Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

284 views47 pagesPCB Design and Manufacturing Guide

This document provides an overview of printed circuit board (PCB) design. It discusses what a PCB is, the design process, and important considerations. The 10-step design process includes specifying requirements, selecting components, schematic design, simulation, layout, manufacturing, assembly, testing, and use. Key topics covered are trace width, pours, thermals, grounding, decoupling, high-frequency effects, and common mistakes. An example infrared hat design is presented to illustrate the process.

Uploaded by

dlc352-sc1Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction and Overview: Overview of the course and topics including PCB basics and purpose.

- Agenda: Overview of the topics such as design process, layout considerations, and a PCB demo.

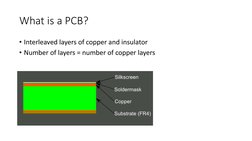

- Introduction to PCBs: Explains the basic structure of a PCB and its layers.

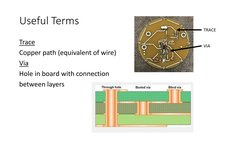

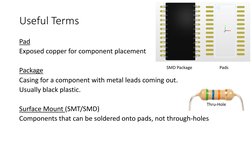

- Useful Terms: Defines key terms such as trace, via, pad, package, and surface mount related to PCB design.

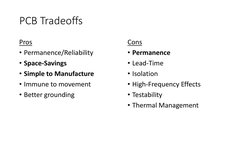

- PCB Tradeoffs: Lists pros and cons of PCB usage including permanence, space-saving, and lead-time issues.

- PCB Manufacturing: Details the methods involved in PCB manufacturing such as etching, milling, and direct plating.

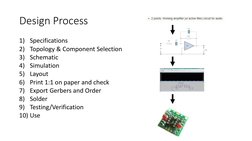

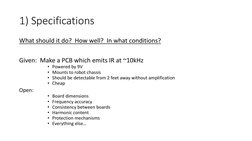

- Design Process: Outlines the steps in PCB design from specifications to use, including component selection and layout.

- Layout Considerations: Delves into technical considerations for PCB layout like trace width, grounding, and thermal management.

- Miscellaneous: Addresses more diverse and advanced PCB options like flexible boards and many-layer designs.

- Applications: Explores various applications for PCB use in projects, emphasizing adaptability.

- References: Provides references and resources for further reading and in-depth study on PCB design and manufacturing.