Professional Documents

Culture Documents

1988 - Template For Positioning and Angulation of Intraosseous Implants

Uploaded by

VõHoàngThủyTiênOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1988 - Template For Positioning and Angulation of Intraosseous Implants

Uploaded by

VõHoàngThủyTiênCopyright:

Available Formats

Template for positioning and angulation of

intraosseous implants

David R. Bums, D.M.D.,* Donald G. Crabtree, D.D.S.,* and Dewey H. Bell, D.D.S.**

Virginia Commonwealth University, School of Dentistry, Richmond, Va.

S ubmerged implants opposing an existing or planned

occlusion require accurate intraosseousimplant place-

the edentulousridge to the opposing occlusal surface is

measuredto make certain that adequate spaceis avail-

ment to satisfy prosthodontic considerations.The posi- able for fabrication of the prosthesisabove the implant at

tion and angulation of the submergedimplant needto be the vertical dimension of occlusion. Artificial teeth of a

planned before the time of surgical implant placement size similar to the opposing or adjacent dentition are

for proper occlusal alignment with the opposing denti- selected.They are arranged in the edentulous spaceon

tion or prosthesis. the cast over the ridge, as determined by the clinical

The surgeon usesdifferent criteria for implant place- examination, to provide an appropriate occlusal rela-

ment than that usedby the prosthodontist.’ The surgeon tionship with the opposing arch. The artificial teeth are

must place the implant in a region where the quantity held in position with a small amount of utility wax

and quality of bone is adequate to provide functional directly under each tooth (Fig. 2). An outline is drawn

support2 The prosthodontist should not rely on the with a pencil on the cast around each artificial tooth

surgeon’s skills alone to provide appropriate implant (Fig. 3). The cast with the artificial teeth is removed

placement, but should provide the surgeon with a from the articulator and placedon a surveyor (J.M. Ney

template for the correct placement of the intraosseous Co., Hartford, Conn.). The analyzing rod is aligned

implant. with the long axis of the artificial teeth (Fig. 4). If a

This article describesa technique for fabrication of a natural tooth is to be prepared for useasan abutment for

surgical guide that gives the surgeon the appropriate the planned prosthesisin combination with an implant,

location and angulation of the submergedimplant rela- the surveyor alignment can be made parallel to the long

tive to the opposing dentition. axis of the natural tooth.’

In conjunction with the surgeon, the prosthodontist After the surveyor is properly aligned, the artificial

initially should evaluate the patient for potential implant teeth are removedfrom the cast.The center of the outline

treatment including an adequate history, oral examina- around the artificial teeth that will represent locations

tion, radiographic examination, and mounted diagnostic for implant placementis then marked, and the analyzing

casts.3The surgeon should carefully palpate the regions rod is removed from the surveyor mandrel.

of potential implant placement for bone undercuts and A 10 mm length of 0.045 inch round tubing (Unitek

bone thickness and morphology. In addition, it may be Corp., Monrovia, Calif.) is prepared. The outer surface

desirable to ‘%ound” the bone through the soft tissue of the tubing is serrated with a separatingdisk to provide

from the buccal and lingual aspect of the alveolar ridge. multiple serrationsalong the entire tube length (Fig. 5).

This can be done by locally anesthetizing the region and This procedure provides mechanical retention for the

then inserting, perpendicular to the tissue surface, a tube within acrylic resin on processingof the template

25-gauge needle through the soft tissue until it hits the and holds the tube in place during investment and

underlying bone. The distanceof insertion into the soft processing.Care must be taken not to cut through the

tissueis measuredon the buccal and lingual aspectof the inner surface of the tube. The open ends of the tubing

alveolar ridge at varying vestibular depths. From this lumen are closedwith a temporary plug material such as

information, regions of potentially adequate bone, Dentkote (Dentsply International, Inc., York, Pa.). As

implant size, number, and location can be tentatively much material as possible should be forced into the

determined. The surgeon and prosthodontist should lumen. All excessmaterial is removed from around the

carefully review and discusstheir findings and develop a lumen. The tubing is placed and tightened into the

mutual understanding regarding implant location and surveyor mandrel. The tube should be supported within

angulation. the mandrel with the metal sheath provided with the

surveyor to support the carbon marker (Fig. 6). The

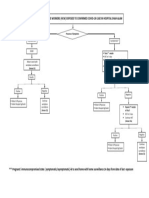

TECHNICAL PROCEDURES tubing is then centered over the outline of one of the

Diagnostic castsare mounted in an articulator using a artificial teeth representing the location for implant

centric jaw relation record (Fig. 1). The distance from placement.At this angulation, the round tubing is made

to lightly contact the cast and is luted into place with a

*Assistant Professor, Department of Removable Prosthodontics. small amount of sticky wax (Fig. 7). It is then carefully

**Professor Emeritus, Department of Removable Prosthodontics. releasedfrom the surveyor. Additional identically pre-

THE JOURNAL OF PRO!STHETIC DENTISTRY 479

BURNS, CRABTREE, AND BELL

See opposite page for legends.

480 OCTOBER 1988 VOLUME 60 NUMBER 4

TEMPLATE FOR POSITIONING AND ANGULATION

pared pieces of tubing are luted into position in the same bone. The surgeon and prosthodontist study these

fashion, as determined by the number of submerged radiographs in conjunction with the mounted diagnostic

implants planned in the treatment. One length of tubing castsand findings from the clinical evaluation to deter-

is placed for each anticipated location (Fig. 8). mine implant size, position, and potential complications

After all of the round tubing is positioned on the that may arise from the selectedsite. The tubing, as seen

edentulousridge, the acrylic resin portion of the surgical in the radiograph, can help identify the location and

template is outlined on the cast, incorporating the tubes angulation of the implant within the underlying bone

and covering all denture-bearing surfaces, similar to a and aid in providing a more predictable outcome for the

record base(Fig. 9). This template is built up with three entire treatment. If problems are anticipated with the

thicknessesof baseplate wax (Fig. 10). The cast is surgical site, reevaluation of the implant location on the

carefully invested and the template is processedin the diagnostic cast and redesign and fabrication of a new

conventional manner with clear heat-processedacrylic template must be done before surgery.

resin. The surgical template is carefully recovered from When the presurgical evaluation is completed, the

the cast after processingto avoid damageor alteration to portion of tubing extending out of the polished surface of

the tubes. Acrylic resin flash around the tubesis removed the template is removed with a separatingdisk (Fig. 12).

with an acrylic resin bur and the temporary plug within The remaining tubing, embeddedinto the acrylic resin,

the tube lumen is pushed out with an anesthetic needle. should be approximately 3 mm in length as measured

The acrylic resin surgical template is smoothed and with a Boley gauge around the template. Metal flash

polished, ultrasonically cleaned, and sterilized by using around the tubing lumen should be removed with an

cold sterilization (Fig. 11). explorer and smoothedwith a rubber wheel. The entire

surgical template is then smoothed and polished and

CLINICAL PROCEDURE again ultrasonically cleanedand sterilized by using cold

Before surgery, the potential implant placementsite is sterilization.

again studied if the desired implant location is still The surgical template is transferred to the surgeon.

questionablefrom a surgical point of view. Each length After anesthesia,the template is positioned intraorally

of tubing on the template is measured with a Boley and held firmly onto the tissue. The tubes are usedas a

gauge and shortened to an accurate 5 mm length. The guide for drilling a channel hole through the mucosaand

template is fitted to the tissue by using a pressure- into the bone. The round-tube lumen diameter is select-

indicating pasteon the tissuesurface sideof the template ed to provide a closetolerance fit around the model No.

and adjustments are made as required with an acrylic 203-102 latch-type spiral twist drill (Brassler USA, Inc.,

resin finishing bur. The template is then positioned Savannah, Ga.) or any other bur with a 1.2 mm

firmly over the tissues.The patient may need to hold the diameter in the slow-speedhandpiece (Fig. 13). The

template in position by closing the mouth against cotton pilot bur allows fitting of instrumentation for placement

rolls positioned between the template and the opposing orientation of the Core-Vent implant system(Core-Vent

residual ridge or dentition. While the template is in Corp., Encino, Calif.) and the Integral implant system

position, a radiograph is madeof the region showing the (Calcitek, Inc., San Diego, Calif.). It can also be

potential implant site and tubing. This can be accom- successfullyused in the placement orientation of other

plished by using a panoramic, pcriapical, lateral cepha- implant systems.The hole shouldbe madeapproximate-

lometric, or occlusal view radiograph or a combination of ly 4 mm into the bone.

views. For the panoramic and other nonocclusal views, On drilling, the bur is lowered into the tube, which

the 5 mm length of tubing is used as a standard reference guidesit into the bone while the surgical template is held

length to dimensionally correct any measurements taken in placeover the tissue(Fig. 14). The hole is then usedas

from the radiograph in determining the availability of a guide for the location and angulation of the guide pins,

Fig. 1. Diagnostic casts are mounted in articulator.

Fig. 2. Prosthetic denture teeth are set in edentulous space and held in position with

small amount of utility wax.

Fig. 3. Pencil outline is drawn on cast around each of prosthetic denture teeth.

Fig. 4. Appropriate cast is placed on surveyor and analyzing rod is aligned with long

axis of prosthetic denture teeth. Teeth are then removed.

Fig. 5. Round tubing is prepared and cut in 10 mm lengths.

Fig. 6. Prepared tubing is tightened into surveyor mandrel.

Fig. 7. Tubing is aligned with center of outline on cast of prosthetic denture tooth. It is

luted to cast with sticky wax. Surveyor positions tubing at same angulation as long axis

of prosthetic denture teeth.

Fig. 8. One length of tubing is placed for each anticipated implant location.

THE JOURNAL OF PROSTHETIC DENTISTRY 481

Bums, ~R.~~REE,AND BELL

Fig. 9. Acrylic resin portion of surgical template is outlined on cast.

Fig. 10. Acrylic resin outline is built up with three thicknesses of baseplate wax.

Fig. 11. Surgical template is processed in clear acrylic resin.

Fig. 12. Tubing length is reduced to 3 mm and enclosed within thickness of acrylic

resin.

Fig. 13. Round tube lumen diameter provides close tolerance fit around twist-drill pilot

bur used for implant orientation.

Fig. 14. When surgical template is in place intraorally it is used to guide location and

angulation of implant placement as pilot bur is lowered into tube and drilled into bone

below.

instruments, and burs supplied with the desired implant determined by hone morphology and character. When

system in preparing the hone for reception of the this occurs, the prosthodontist and surgeon should have

implant.. an understanding that the altered implant location will

Occasionally the surgeon will reflect the soft tissue he as closely parallel to the presurgical site as is

and find that the use of the template is inappropriate as possible.

482 OCTOBER1988 VOLUME60 NUMBER4

TEMPLATE FOR POSCMONING AND ANGULATION

The template can be used to determine the location of REFERENCES

the implants when the time comes to uncover and expose 1. Burns DR, Crabtree DG, Bell DH. Transfer impression for

them for restorative purposes. The template is again accurate adjustment of a metal coping insert for the submerged

positioned intraorally, similar to the position at the time implant. J PROSTHET DENT 1987;57:484-7.

2. Lekholm V. Clinical procedures for treatment with osseointe-

of surgery. After anesthesia, a bur or needle is placed

grated dental implants. J PR~SIXET DENT 1983;50:116-20.

through the tubes and into the soft tissue. This mark is 3. Laney WR. Selecting edentulous patients for tissue-integrated

then used as a guide for uncovering the implant located prostheses. Int J Oral Maxillofac Implants 1986;1:129-38.

beneath the soft tissue in the underlying bone.

Reprint requests to:

DR. DAVID R. BURNS

SUMMARY

VIRGINL4COMMONWWLTHUNM3RSITY

Presurgical planning for submerged implant location SCHOOL OF DENTISTRY

and angulation within bone relative to the opposing P.O. Box 566

RICHMOND, VA 23298

occlusion is important for the prosthodontist. This

information is accurately communicated to the surgeon

by using a surgical template. A technique for fabrication

of the template is described.

Inverted anatomic tracing: A guide to establishing

orbital tissue contours for the oculofacial prosthesis

Norman S. Nusinov, M.A.,” John W. McCartney, D.D.S.,** and

Donald L. Mitchell, D.D.S., M.S.***

Walter Reed Army Medical Center, Washington, D.C., and Naval Dental School, Naval Dental Clinic, Naval

Medical Command National Capital Region; Bethesda, Md.

A stonecast duplicate of facial contours is usedin the

fabrication of an oculofacial prosthesis. The cast is

obtained from a facial moulage in which the remaining

eye is closed and often distorted by the weight of the

impression. In addition, the patient must be present

when the ocular prosthesisis tentatively located.‘4 When

orbital anatomy is sculpted, another appointment is

needed to verify the contours of the lids, brow, and

adjacent tissueswhen the eye is open and oriented in its

“conversational gaze.”

This article describesthe technique for making an

inverted anatomic tracing that enablesthe maxillofacial

prosthetic technician to closely approximate individual-

ized contours of the orbital tissues in the laboratory

without requiring the presenceof the patient.

The opinions or assertions contained herein are those of the authors

and are not to be construed as official or as reflecting the views of the

Department of the Navy or the Department of the Army.

*Maxillofacial Prosthetist, Hospital Dental Clinic, Walter Reed Army

Medical Center.

**Lieutenant Colonel, U.S. Army, DC; Resident, Maxillofacial Pros-

thetics Division, Prosthodontia Department, Naval Dental

School.

***Captain U.S. Navy, DC; Chief, Maxillofacial Prosthetics Divi- Fig. 1. Orientation lines are placed with indelil ble

sion, Pdthodonticv Department, Naval Dental School. marker with aid of rigid ruler.

THE JOURNAL OF PROSTI-IEl-IC DENTISTRY 183

You might also like

- Short ImplantsFrom EverandShort ImplantsBoyd J. TomasettiNo ratings yet

- A Dual-Purpose Guide For Optimum Placement of Dental ImplantsDocument4 pagesA Dual-Purpose Guide For Optimum Placement of Dental ImplantskadrologyNo ratings yet

- Imp 1Document5 pagesImp 1pradeepgade1No ratings yet

- An Easy Way of Chair-Side Stent Fabrication For Accurate Placement of Miniscrew ImplantDocument3 pagesAn Easy Way of Chair-Side Stent Fabrication For Accurate Placement of Miniscrew ImplantJORGE CARLOS MELGAR GUTIERREZNo ratings yet

- Immediateimplantplacementbeckeretalperio2k2008 PDFDocument11 pagesImmediateimplantplacementbeckeretalperio2k2008 PDFNiaz AhammedNo ratings yet

- Content ServerDocument7 pagesContent ServerEidy A HerasNo ratings yet

- Use of Diagnostic and Surgical Stent A SimplifiedDocument7 pagesUse of Diagnostic and Surgical Stent A Simplifiedwaf51No ratings yet

- 2 - 2023 - Novel Technique For Placement of Immediate Implant in Mandibular RegionDocument5 pages2 - 2023 - Novel Technique For Placement of Immediate Implant in Mandibular RegionVõHoàngThủyTiênNo ratings yet

- Development of Implant Soft Tissue Emergence ProfileDocument5 pagesDevelopment of Implant Soft Tissue Emergence ProfilemishNo ratings yet

- RSGDocument5 pagesRSGHugoMoralesTecnicoDentalNo ratings yet

- Bone Ring 1Document6 pagesBone Ring 1Pradusha RevuruNo ratings yet

- Dabreo 1990Document3 pagesDabreo 1990SaptarshiMondalNo ratings yet

- Ijss Feb Ra01Document5 pagesIjss Feb Ra01Ruxandra FitaNo ratings yet

- AJDSM Volume 22 Issue 3 Pages 247-251Document5 pagesAJDSM Volume 22 Issue 3 Pages 247-251MarisbebelaNo ratings yet

- Implant-Retained Cantilever Fixed Prosthesis: Where and WhenDocument4 pagesImplant-Retained Cantilever Fixed Prosthesis: Where and WhenSitiKhadijahNo ratings yet

- Current Methods For Soft Tissue Enhancement of The Esthetic ZoneDocument11 pagesCurrent Methods For Soft Tissue Enhancement of The Esthetic Zonecmfvaldesr7No ratings yet

- AsdfaDocument4 pagesAsdfaFree PizzaNo ratings yet

- Bodily Distalization of Molars With Absolute AnchorageDocument12 pagesBodily Distalization of Molars With Absolute AnchorageAnamika AttrishiNo ratings yet

- Immediate Implant Placement PDFDocument11 pagesImmediate Implant Placement PDFFerdinan PasaribuNo ratings yet

- Pneumocephalus As A Fatal But Very RareDocument27 pagesPneumocephalus As A Fatal But Very RareHossam ThabetNo ratings yet

- 1 s2.0 S0377529115300626 MainDocument6 pages1 s2.0 S0377529115300626 MainNémethBálintNo ratings yet

- Biomed 2Document5 pagesBiomed 2Olesea CutitaruNo ratings yet

- Double Jaw Immediate Load Hybrids: Case Abstract: Scott E. Keith, DDS, MsDocument3 pagesDouble Jaw Immediate Load Hybrids: Case Abstract: Scott E. Keith, DDS, MsShyam BhatNo ratings yet

- Complications With Osseointegrated Implants PDFDocument5 pagesComplications With Osseointegrated Implants PDFDental Del NorteNo ratings yet

- Loss of Anterior TissuesDocument5 pagesLoss of Anterior Tissuesjinny1_0No ratings yet

- Diastema Closure With Direct Composite: Architectural Gingival ContouringDocument6 pagesDiastema Closure With Direct Composite: Architectural Gingival ContouringDiego SarunNo ratings yet

- Ferula 1Document6 pagesFerula 1AlexNo ratings yet

- 1 s2.0 S0022391312001205 MainDocument5 pages1 s2.0 S0022391312001205 MainErwin SutonoNo ratings yet

- CCR3 4 831 PDFDocument7 pagesCCR3 4 831 PDFArmareality ArmarealityNo ratings yet

- Variations in Bracket Placement in The Preadjusted Orthodontic ApplianceDocument6 pagesVariations in Bracket Placement in The Preadjusted Orthodontic ApplianceAna Maria Clara HernándezNo ratings yet

- Accuracy of Miniscrew ImplantDocument8 pagesAccuracy of Miniscrew ImplantShaivi ShrivastavaNo ratings yet

- Rosa 2014Document6 pagesRosa 2014Michal PerkowskiNo ratings yet

- 7 - 2020 - A Digital Intraoral Implant Scan Technique Using A Combined Healing Abutment and Scan Body SystemDocument4 pages7 - 2020 - A Digital Intraoral Implant Scan Technique Using A Combined Healing Abutment and Scan Body SystemVõHoàngThủyTiênNo ratings yet

- Bone ReactionDocument9 pagesBone ReactionFourthMolar.comNo ratings yet

- CCD 4 509Document3 pagesCCD 4 509gbaez.88No ratings yet

- The Biotransfer Approach: The Use of An Alveolar Cast Die For The Fabrication of The Emergence Profile On Implant-Supported Interim RestorationsDocument4 pagesThe Biotransfer Approach: The Use of An Alveolar Cast Die For The Fabrication of The Emergence Profile On Implant-Supported Interim RestorationsClaudioNo ratings yet

- Horizontal Ridge Augmentation Using Particulate BoneDocument12 pagesHorizontal Ridge Augmentation Using Particulate Bonecmfvaldesr7No ratings yet

- Ac 72Document5 pagesAc 72Giovani TardiniNo ratings yet

- Prosthetic Rehabilitation Using Extra Coronal Attachments: Case ReportDocument4 pagesProsthetic Rehabilitation Using Extra Coronal Attachments: Case ReportLakshmi Sarvani ValluriNo ratings yet

- Evaluation of Interarch Space For ImplanDocument4 pagesEvaluation of Interarch Space For Implanwaf51No ratings yet

- I S M B M o L A: CDocument7 pagesI S M B M o L A: CAshraf KamalNo ratings yet

- TMP 371 BDocument4 pagesTMP 371 BFrontiersNo ratings yet

- An 2/2 Implant Overdenture: Case ReportDocument3 pagesAn 2/2 Implant Overdenture: Case ReportasclepiuspdfsNo ratings yet

- Document PDFDocument4 pagesDocument PDFBagis Emre GulNo ratings yet

- Analysis of Influence of Lip Line and Lip Support in Esthetics and SelectionDocument3 pagesAnalysis of Influence of Lip Line and Lip Support in Esthetics and SelectionDaniel AtiehNo ratings yet

- Botticelli 2004Document9 pagesBotticelli 2004medNo ratings yet

- A Tooth-Stabilized Surgical Template For AlveolectomyDocument3 pagesA Tooth-Stabilized Surgical Template For Alveolectomyheri asriyadiNo ratings yet

- A New Design For A Hybrid PDocument16 pagesA New Design For A Hybrid PDavid CLNo ratings yet

- Articol Pentru Teme 14-18Document9 pagesArticol Pentru Teme 14-18Diamanta Yalomit CirsteaNo ratings yet

- The Hybrid Denture1Document9 pagesThe Hybrid Denture1SitiKhadijah100% (1)

- Survey and DesignDocument4 pagesSurvey and DesignPadmini ReddyNo ratings yet

- Asds 06 1448Document7 pagesAsds 06 1448Joao Carlos JuniorNo ratings yet

- 2007 JomiDocument7 pages2007 JomiCássio BernardNo ratings yet

- The Team ApproachDocument2 pagesThe Team ApproachThe SmileNo ratings yet

- Use of Titanium Mesh For Staged Localized Aeveolar Ridge AugmentationDocument12 pagesUse of Titanium Mesh For Staged Localized Aeveolar Ridge AugmentationAnonymous bOhsjs1Y7mNo ratings yet

- Australian Dental Journal - 2008 - Blum - A Quick and Simple Method To Obtain A Radiographic Evaluation of RemainingDocument3 pagesAustralian Dental Journal - 2008 - Blum - A Quick and Simple Method To Obtain A Radiographic Evaluation of RemainingPatricia CauanNo ratings yet

- Ultrasonic Versus Drills Implant Site Preparation: A Histologic Analysis in Bovine RibsDocument4 pagesUltrasonic Versus Drills Implant Site Preparation: A Histologic Analysis in Bovine RibsAnusha BorraNo ratings yet

- Clinical Application of Various Surgical Guides For Optimal Implant PlacementDocument9 pagesClinical Application of Various Surgical Guides For Optimal Implant PlacementMrinmayee ThakurNo ratings yet

- Provisional RestorationsDocument4 pagesProvisional RestorationsMyri Gebert SchererNo ratings yet

- 2022 - Effect of Guiding Sleeve Design On Intraosseous Heat Generation During Implant Site PreparationDocument8 pages2022 - Effect of Guiding Sleeve Design On Intraosseous Heat Generation During Implant Site PreparationVõHoàngThủyTiênNo ratings yet

- 1 s2.0 S0022391323003761 MainDocument3 pages1 s2.0 S0022391323003761 MainVõHoàngThủyTiênNo ratings yet

- The Impact of Surgical Guide Fixation and Implant Location On Accuracy of Static ComputerDocument10 pagesThe Impact of Surgical Guide Fixation and Implant Location On Accuracy of Static ComputerGustavo IsmaelNo ratings yet

- 2019 - in Vitro Comparison Between Metal Sleeve-Free and Metal SleeveDocument10 pages2019 - in Vitro Comparison Between Metal Sleeve-Free and Metal SleeveVõHoàngThủyTiênNo ratings yet

- 2018 - The Influence of Guided Sleeve Height, Drilling Distance and Drilling Key Length On The Accuracy of Static ComputerAssisted Implant SurgeryDocument7 pages2018 - The Influence of Guided Sleeve Height, Drilling Distance and Drilling Key Length On The Accuracy of Static ComputerAssisted Implant SurgeryVõHoàngThủyTiênNo ratings yet

- S - 2022 - Open-Sleeve Templates For Computer-Assisted Implant Surgery at Healed or Extraction SocketsDocument11 pagesS - 2022 - Open-Sleeve Templates For Computer-Assisted Implant Surgery at Healed or Extraction SocketsVõHoàngThủyTiênNo ratings yet

- Chenetal 2009aJOMIDocument33 pagesChenetal 2009aJOMI63127No ratings yet

- 2 - 2023 - Novel Technique For Placement of Immediate Implant in Mandibular RegionDocument5 pages2 - 2023 - Novel Technique For Placement of Immediate Implant in Mandibular RegionVõHoàngThủyTiênNo ratings yet

- A Systematic Review of The Accuracy of Digital Surgical Guides For Dental ImplantationDocument23 pagesA Systematic Review of The Accuracy of Digital Surgical Guides For Dental ImplantationehabidentNo ratings yet

- 2020 - Stereolithographic Surgical Guide With A Combination of Tooth and Bone SupportDocument13 pages2020 - Stereolithographic Surgical Guide With A Combination of Tooth and Bone SupportVõHoàngThủyTiênNo ratings yet

- 2019 - in Vitro Comparison Between Metal Sleeve-Free and Metal SleeveDocument10 pages2019 - in Vitro Comparison Between Metal Sleeve-Free and Metal SleeveVõHoàngThủyTiênNo ratings yet

- 2011 - Key Principles That Enhance Success When Restoring Endodontically Treated TeethDocument7 pages2011 - Key Principles That Enhance Success When Restoring Endodontically Treated TeethVõHoàngThủyTiênNo ratings yet

- S - 2022 - Open-Sleeve Templates For Computer-Assisted Implant Surgery at Healed or Extraction SocketsDocument11 pagesS - 2022 - Open-Sleeve Templates For Computer-Assisted Implant Surgery at Healed or Extraction SocketsVõHoàngThủyTiênNo ratings yet

- S - 2019 - Influence of Implant Macrodesign and Insertion Connection Technology On The Accuracy of Static Computer-Assisted Implant SurgeryDocument7 pagesS - 2019 - Influence of Implant Macrodesign and Insertion Connection Technology On The Accuracy of Static Computer-Assisted Implant SurgeryVõHoàngThủyTiênNo ratings yet

- 2018 - The Influence of Guided Sleeve Height, Drilling Distance and Drilling Key Length On The Accuracy of Static ComputerAssisted Implant SurgeryDocument7 pages2018 - The Influence of Guided Sleeve Height, Drilling Distance and Drilling Key Length On The Accuracy of Static ComputerAssisted Implant SurgeryVõHoàngThủyTiênNo ratings yet

- Protecting All Children's Teeth: CariesDocument45 pagesProtecting All Children's Teeth: CariesTUTOR ENAM CD TIGANo ratings yet

- APolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part2Document7 pagesAPolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part2Ayu RafaniaNo ratings yet

- APolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part2Document7 pagesAPolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part2Ayu RafaniaNo ratings yet

- Carcinosarcoma of Parotid Gland Malignant Mixed TuDocument4 pagesCarcinosarcoma of Parotid Gland Malignant Mixed TuVõHoàngThủyTiênNo ratings yet

- Case ReportDocument52 pagesCase ReportVõHoàngThủyTiênNo ratings yet

- Clinical Tips & Tricks Anterior Restorations. FiltekTM. Supreme Plus. Universal RestorativeDocument40 pagesClinical Tips & Tricks Anterior Restorations. FiltekTM. Supreme Plus. Universal RestorativeVõHoàngThủyTiênNo ratings yet

- Dietschi 2016 PDFDocument7 pagesDietschi 2016 PDFPanchyRojasNo ratings yet

- APolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part1Document7 pagesAPolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part1VõHoàngThủyTiênNo ratings yet

- Design: Dung d ịch bù nước qua đường uốngDocument2 pagesDesign: Dung d ịch bù nước qua đường uốngVõHoàngThủyTiênNo ratings yet

- Necrotising Ulcerative Gingivitis: A Literature Review: James Dufty / Nikolaos Gkranias / Nikos DonosDocument10 pagesNecrotising Ulcerative Gingivitis: A Literature Review: James Dufty / Nikolaos Gkranias / Nikos DonosmayaNo ratings yet

- Phrma Seniority List 01Document38 pagesPhrma Seniority List 01vasan980100% (1)

- BOSIET With EBS Course Descriptor & Joinning InstructionDocument5 pagesBOSIET With EBS Course Descriptor & Joinning InstructionNisamudheenNo ratings yet

- Mental Hygiene Reaction PaperDocument2 pagesMental Hygiene Reaction PaperMary Louise Vapor UyvicoNo ratings yet

- PRE OP ChecklistDocument1 pagePRE OP ChecklistDR.No ratings yet

- Management of Healthcare Workers (HCW) Exposed To Confirmed Covid-19 Case in Hospital Shah AlamDocument1 pageManagement of Healthcare Workers (HCW) Exposed To Confirmed Covid-19 Case in Hospital Shah AlamNurhafizah IbrahimNo ratings yet

- 1st Quarter 2022 CBDRP-Reporting-Forms - IfugaoDocument53 pages1st Quarter 2022 CBDRP-Reporting-Forms - IfugaoJeda MonayaoNo ratings yet

- Drug Delivery SystemDocument14 pagesDrug Delivery SystemAmit PrasadNo ratings yet

- Psychia Ncp-MetchelDocument9 pagesPsychia Ncp-MetchelCarmelita SaltNo ratings yet

- TFN 3F Concept of HealthDocument2 pagesTFN 3F Concept of HealthkushiroNo ratings yet

- Australasian Health Facility Guidelines 2013Document49 pagesAustralasian Health Facility Guidelines 2013aegysabetterwayNo ratings yet

- ReportDocument7 pagesReportapi-482961632No ratings yet

- Addiction World Conference AWC 2024Document2 pagesAddiction World Conference AWC 2024addictionNo ratings yet

- Discharge Planning TBDocument2 pagesDischarge Planning TBNurida LatipahNo ratings yet

- Applying To The AmcDocument72 pagesApplying To The AmcgracieMD100% (1)

- Burning Mouth Syndrome and Treatment With ParoxetinDocument2 pagesBurning Mouth Syndrome and Treatment With ParoxetinFitri AngginiNo ratings yet

- JobsDocument8 pagesJobsPalani Samy TNo ratings yet

- Prescription - Apollo 2471659105066202Document2 pagesPrescription - Apollo 2471659105066202JEENEET CHEMISTRYNo ratings yet

- Code of SanitationDocument8 pagesCode of SanitationNikki Nina Arabe BarcinasNo ratings yet

- Baidyanath Ayurvedic LTD: Presented By: Group 7 Pragati Punith Ritesh Shwethakumari Uma YashawanthDocument25 pagesBaidyanath Ayurvedic LTD: Presented By: Group 7 Pragati Punith Ritesh Shwethakumari Uma YashawanthPragati A SubbannavarNo ratings yet

- Explanation Essay Example and ActivityDocument6 pagesExplanation Essay Example and ActivityAlesther Vhon D. PedronNo ratings yet

- Institutional Review Board/Independent Ethics Committee (Irb/Iec)Document40 pagesInstitutional Review Board/Independent Ethics Committee (Irb/Iec)Swati chauhanNo ratings yet

- Sarver Mission PossibleDocument13 pagesSarver Mission PossibleAndrea Cárdenas Sandoval100% (1)

- E-Learning, Telemadicin, Tele Nursing AssignmentDocument22 pagesE-Learning, Telemadicin, Tele Nursing AssignmentBhawna Joshi100% (2)

- List of HospitalsDocument13 pagesList of HospitalsRajeev VenegallaNo ratings yet

- Talay Behavioral Center Outreach ProgramDocument1 pageTalay Behavioral Center Outreach ProgramiMaibelle BelleNo ratings yet

- PDF Introduction To Surveillance RA 11332Document35 pagesPDF Introduction To Surveillance RA 11332Dan Joseph AguilarNo ratings yet

- TOP Dialysis Centres in MumbaiDocument2 pagesTOP Dialysis Centres in MumbaiTerminal VelocityNo ratings yet

- Bridging The Gap Between Medical Literacy and Language BarrierDocument6 pagesBridging The Gap Between Medical Literacy and Language BarrierstanleyNo ratings yet

- Oet Speakingr PDFDocument133 pagesOet Speakingr PDFAlphonsa Thomas100% (1)

- LIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionFrom EverandLIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionRating: 4 out of 5 stars4/5 (403)

- Raising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsFrom EverandRaising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsRating: 5 out of 5 stars5/5 (1)

- Think This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeFrom EverandThink This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeNo ratings yet

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedRating: 5 out of 5 stars5/5 (78)

- The Age of Magical Overthinking: Notes on Modern IrrationalityFrom EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityRating: 4 out of 5 stars4/5 (20)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisFrom EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisRating: 4.5 out of 5 stars4.5/5 (42)

- By the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsFrom EverandBy the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsNo ratings yet

- Gut: the new and revised Sunday Times bestsellerFrom EverandGut: the new and revised Sunday Times bestsellerRating: 4 out of 5 stars4/5 (392)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 4 out of 5 stars4/5 (5)

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaFrom EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaRating: 4.5 out of 5 stars4.5/5 (266)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 4 out of 5 stars4/5 (3)

- Dark Psychology & Manipulation: Discover How To Analyze People and Master Human Behaviour Using Emotional Influence Techniques, Body Language Secrets, Covert NLP, Speed Reading, and Hypnosis.From EverandDark Psychology & Manipulation: Discover How To Analyze People and Master Human Behaviour Using Emotional Influence Techniques, Body Language Secrets, Covert NLP, Speed Reading, and Hypnosis.Rating: 4.5 out of 5 stars4.5/5 (110)

- 12 Rules for Life by Jordan B. Peterson - Book Summary: An Antidote to ChaosFrom Everand12 Rules for Life by Jordan B. Peterson - Book Summary: An Antidote to ChaosRating: 4.5 out of 5 stars4.5/5 (207)

- The Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeFrom EverandThe Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeRating: 4.5 out of 5 stars4.5/5 (253)

- Raising Good Humans: A Mindful Guide to Breaking the Cycle of Reactive Parenting and Raising Kind, Confident KidsFrom EverandRaising Good Humans: A Mindful Guide to Breaking the Cycle of Reactive Parenting and Raising Kind, Confident KidsRating: 4.5 out of 5 stars4.5/5 (169)

- The Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsFrom EverandThe Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsRating: 3.5 out of 5 stars3.5/5 (3)

- Outlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisFrom EverandOutlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (1)

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- Sleep Stories for Adults: Overcome Insomnia and Find a Peaceful AwakeningFrom EverandSleep Stories for Adults: Overcome Insomnia and Find a Peaceful AwakeningRating: 4 out of 5 stars4/5 (3)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- ADHD is Awesome: A Guide to (Mostly) Thriving with ADHDFrom EverandADHD is Awesome: A Guide to (Mostly) Thriving with ADHDRating: 5 out of 5 stars5/5 (1)

- The Garden Within: Where the War with Your Emotions Ends and Your Most Powerful Life BeginsFrom EverandThe Garden Within: Where the War with Your Emotions Ends and Your Most Powerful Life BeginsNo ratings yet

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessFrom EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessRating: 4.5 out of 5 stars4.5/5 (328)