Professional Documents

Culture Documents

Laugier Elastic Plastic Indentation of Ceramics (1985)

Laugier Elastic Plastic Indentation of Ceramics (1985)

Uploaded by

michaellaugierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laugier Elastic Plastic Indentation of Ceramics (1985)

Laugier Elastic Plastic Indentation of Ceramics (1985)

Uploaded by

michaellaugierCopyright:

Available Formats

JOURNAL OF MATERIALS SCIENCE LETTERS 4 (1985) 1539-1541

The elastic/plastic indentation of ceramics

M. T. L A U G I E R

Materials Testing Laboratories, 9 Nova Croft, Coventry CV5 7FJ, War., UK

Indentation fracture mechanics has undergone expression of Hill [3] is

considerable development following the work of

E 9[(1 - v)[33 - 2(1 - 2v)]

Evans and Charles [1] who found a "universal"

relation linking the length of surface traces of H 2(1 + In [33)

cracks in brittle materials resulting from where v is Poisson's ratio. Equating the inden-

"sharp" indentation to conventional fracture tation volume with the cavity volume gives for a

toughness. However, it was found necessary to pyramidal indentation

introduce the empirical correction factor

[3 = b/r = (b/a)(21/2rc/cot ~)1/3

( E / H ) 2/5, where E is Young's modulus and H is

hardness, to calibrate their universal plot. The Chiang et al. [5], in an extensive indentation

significance of the correction factor was clearly analysis, have compared the predictions of the

brought out in the detailed elastic/plastic inden- Hill formula above, those of the Johnson [6]

tation analysis of Lawn et al. [2] where it was analysis and those of their own analysis with

shown to be related to the "plastic" driving force available experimental results on a wide range of

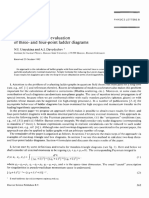

for crack growth, from consideration of the Hill materials (see Fig. 1). The experimental results

expanding cavity model [3]. are closely described by the extension of the Hill

The important plastic or residual crack driv- analysis by Chiang et al. [5] which allows for

ing force Pr was shown by means of a careful surface effects. The slope of their line is 0.38,

physical argument to be of the form which may be compared with the value of 0.41

for the slope of the Hill line and 0.33 for the

P~ ~ P ( a / b ) ( E / H ) cot ~k

slope of the simple analytical approximation,

where P is the indenter load, a is the indentation [3 = (E/H) ~/3, to the Hill result (see Fig. 1). Lawn

half-diagonal, b is the radius of the plastic zone et al. [2] chose to represent the experimental

and ~ is the indenter semi-angle. In the limit of data by the form [3 ~ ( E / H ) ~/2 also shown in

well-developed cracks c >> b, where c is the Fig. 1; this is neither an analytical approxi-

crack length, the residual force Pr may be mation nor is it the best empirical description of

regarded as being concentrated at a point. the experimental data. It may be mentioned that

Assuming half-penny crack geometry, the stress the original Evans and Charles relation which

intensity factor K~ may be written [2] contains ( E / H ) 2/5 would correspond to the form

[3 ~ ( E / H ) 3/5 and so would differ even more

Pr P

Kr ~ f(4~) ~ = f(4~)(a/b)(E/H) cot ¢ - ~ sensibly than the form of Lawn et al. [2] from

observation (see Fig. 1).

where f(~b) is an angular function introduced to The form [3 ,-~ ( E / H ) l/2 used by Lawn et al. [2]

take account of the free surface and, by analogy leads to b/a ,,~ (E/H)l/2(cot ~9)1/3, enabling the

with the uniformly loaded case [4], is considered residual crack driving force to be written

to be slowly varying with value near unity [2] (q~ Pr ~ P(E/H)I/2( c°t ~)2/3

is measured from the downward normal to the

surface). The ratio a/b may be closely linked to so that the expression for toughness is

the relative plastic zone [3 = b/r of the Hill

Kr ~ f(q~)(cot ~)2/3(E/H)'/Zp/c3/Z

expanding plastic/elastic cavity in which [3 is

linked to E/H, where r is the cavity radius, when Using the analytical approximation to the Hill

it is assumed that the plastic zone volume is result and applying the same reasoning as above

determined by the indentation volume. The gives

0261 8028/85 $03.00 + .12 © 1985 Chapman and Hall Ltd. 1 539

1°,, , , , I i l/..j~, , ~b.. ~ i _

o t /

7_ _ / / . - t / / _ I"

> - ~ - /

./

/

/

~ ~ Ill I I I I I I I II I

5 I0 I00 500

Figure 1 Relative plastic zone size fl as a function of E / H following Chiang et al. [5]: 1. fl = (E/H) 3/5 (Evans and Charles

[I]); 2. fl = (E/H) 1/2 (Lawn et al. [2]); 3. from Hill's analysis [3]; 4. Chiang et al. [5]; 5. fl = (E/H)I/3; 6. Johnson [6]. O,

soda-lime glass, ZX, A1203 + 42vol % ZrO2; I~, KCt (single crystal); ~ , ZnS; v , cold-rolled steel; O., hot-rolled brass.

b/a ~ (E/H)Z/3(cot ~O)2/3 kSe = Ave {Kc/[(E/H)2/3(p/c3/2)]}

and = 0.0098 _+ 0.0025

P~ ,.~ P(EIH)2/3(cot ~9)2/3 (0.0025 = 1 s.D.) with a coefficient o f variation

v = 25.5%. Table I shows the data used for the

so that the expression for toughness Kr becomes calibrations taken from [7] together with the

calculated indentation toughness. It is also o f

K r ~ f(q~)(cot O ) ~ / 3 ( E / H ) 2 / 3 p / c 3/2

interest to use this data to provide a calibration

which differs f r o m the expression o f L a w n et al. o f the original relation o f Evans and Charles [1].

[2] only in that the exponent o f E / H is 2/3 and The calibration constant is

not 1/2.

/?EC = Ave {Ko/[(E/H)2/5(p/c3/2)]}

Anstis et al. [7] carried out a critical evalu-

ation o f the indentation fracture technique = 0.021 ___ 0.006

based on the results o f L a w n et al. [2] and using

(0.006 = 1 S.D.) with a coefficient o f variation

a wide range o f brittle materials for which

v = 26%. This differs significantly f r o m the

toughness values were available. They f o u n d

original value o f 0.031 o f Evans and Charles [1]

that for well-behaved materials the convention-

obtained when the constraint factor is given the

ally determined toughness Ko correlated well

value 3.

with the result o f L a w n et al. [2] when crack

A l t h o u g h the Laugier modification has the

growth is dominated by the residual plastic

merit o f an analytical derivation o f the exponent

forces. A calibration constant

2/3 in the term (E/H), the formulae provide

k7A = Ave {Ko/[(E/H)'/2(p/c3/2)]} essentially equivalent descriptions o f the data

(v ~ 25 to 26%) when W C - C o is included.

= 0.016 + 0.004

W C - C o materials are a special case the point

(0.004 = 1 S.D.) with a coefficient o f variation loading requirement is not met (c/b ~ 1 to 2)

v = 25% was obtained by averaging over the - and must be treated separately. W h e n W C - C o

data in braces. is excluded, the Laugier modification provides

The data o f Anstis et al. [7] m a y be used to the best description o f the data (see Table I) with

calibrate the modified expression for Kr, leading /~L, = 0.010, v = 19%; this m a y be c o m p a r e d

to a new calibration constant with kSA' = 0.017, v = 21% and /~EC" = 0.022,

1 540

T A B L E I Indentation toughness data used for calibration taken from [7]

Material P/c 3/2 E/H kA kL k Ec KcA K~c K~c K~c+

(MPa m t/2) (MPa m I/2) (MPa m I/2)

WC Co 210 43.6 0.00865 0.00456 0.0126 22 26 20 12

Si3N4 (NC132) 60 16.2 0.0166 0.0103 0.0219 3.9 4.1" 3.8 3.9* 3.8 4.0* 4.0

SiC 50 18.2 0.0188 0.0114 0.0251 3.4 3.6* 3.4 3.5* 3.4 3.5* 4.0

A1203 (AD999) 36 20.2 0.0241 0.0145 0.0326 2.6 2.8* 2.6 2.7* 2.5 2.6* 3.9

A1203 (AD90) 31 29.8 0.0171 0.0096 0.0241 2.7 2.9* 3.0 3,0" 2.5 2.6* 2.9

Glass ceramic 43 12.8 0.0162 0.0105 0.0210 2.5 2.6* 2.3 2,4* 2.5 2.6* 2.5

Si3N4 (NC350) 33 17.7 0.0144 0.0088 0.0192 2.2 2.4* 2.2 2,3" 2.2 2.3* 2.0

Sapphire 22 19.5 0.0216 0.0130 0.0291 1.6 1.6" 1.6 1,6" 1.5 1.6" 2.1

Glass (AS) 19 13.5 0.0130 0.0084 0.0169 1.1 1.2" 1.1 1.I* 1.1 1.2" 0.91

Glass (SL1, II) 14 12.7, 13.0 0.0148 0.0096 0.0192 0.80 0.85* 0.76 0.77* 0.82 0.86* 0.74, 0.75

Glass LA 14 13.3 0.0133 0.0086 0.0172 0.82 0.87* 0.78 0.79* 0.83 0.87* 0.68

Si 13 15.8 0.0135 0.0085 0.0178 0.83 0.88* 0.81 0.83* 0.82 0.86* 0.7

F¢a = 0.016, S.D. = 0.004; v = 25%; /~A' = 0.017, S.D. = 0.004, V = 21%

EL = 0.0098, S.D. = 0.025, V = 25%; E L" = 0.010, S.D. = 0.002, V = 19%

~rEC = 0.021, S.D. = 0.006; V = 26%; EEC' = 0.022, S.D. = 0.005, V = 23%

*Predicted toughness when WC Co is excluded (' prime indicates WC Co has been excluded).

+Experimental results.

v = 23% for the corresponding forms of Anstis 2. B. R. LAWN, A . G . EVANS and D.B.

et al. [7] and Evans and Charles [1]. MARSHALL, ibM. 63 (1980) 574.

3. R. HILL, "The Mathematical Theory of Plasticity",

The modified formula applicable to ceramics

Ch. 5 (Oxford University Press, 1950).

and glasses is 4. F. W. SMITH, A. S. KOBAYASHI and A . F .

KLc = O.OlO(E/H)2/3p/c3/2; EMERY, J. AppL Mech. 34 (1967) 953.

5. S. S. C H I A N G , D. B. MARSHALL and A . G .

E L' = 0.010, v = 19% EVANS, J. Appl. Phys. 53 (1982) 298.

6. K. L. JOHNSON, J. Mech. Phys. Solids 18 (1970)

115.

Acknowledgement 7. G. R. ANSTIS, P. C H A N T I K U L , B. R. LAWN

The author thanks Sandvik Ltd for permission and D. B. MARSHALL, J. Am. Ceram. Soc. 64

to publish this work. (1981) 533.

References

1. A. G. EVANS and E. A. CHARLES, J. Am. Ceram. Received 3 April

Soc. 59 (1976) 371. and accepted 28 May 1985

1 541

You might also like

- Deflection of Curved BeamsDocument14 pagesDeflection of Curved BeamsStephen Mirdo82% (28)

- Fundamentals of CT PDFDocument415 pagesFundamentals of CT PDFAl Marchese100% (1)

- Nester A NEW GRAVITATIONAL ENERGY EXPRESSION WITH A SIMPLE POSITIVITY PROOFDocument2 pagesNester A NEW GRAVITATIONAL ENERGY EXPRESSION WITH A SIMPLE POSITIVITY PROOFJason PayneNo ratings yet

- Mongo Shell Cheat SheetDocument1 pageMongo Shell Cheat SheetJamie Smith100% (1)

- An Agent-Based Model To Simulate Motorcycle BehaviourDocument227 pagesAn Agent-Based Model To Simulate Motorcycle Behaviourhasib100% (6)

- Zheng Liang1992Document11 pagesZheng Liang1992Hasanain AlmusawiNo ratings yet

- The Thermochemistry of A Reacting Mixture of Elastic Materials With DiffusionDocument31 pagesThe Thermochemistry of A Reacting Mixture of Elastic Materials With DiffusionSantiago Peña ClavijoNo ratings yet

- Tedbelytschko 1992Document15 pagesTedbelytschko 1992Sudhanwa KulkarniNo ratings yet

- On The Nature of The Phase Transition ..... Physica CDocument2 pagesOn The Nature of The Phase Transition ..... Physica CkjborkenNo ratings yet

- Physica: Self-Organization and Fractal Dynamics in TurbulenceDocument23 pagesPhysica: Self-Organization and Fractal Dynamics in TurbulenceligNo ratings yet

- Journal of Wind Engineering and Industrial Aerodynamics,: Uniform Flow Upwind OFDocument6 pagesJournal of Wind Engineering and Industrial Aerodynamics,: Uniform Flow Upwind OFvidallopez1No ratings yet

- 1993-An Improved Technique For The Prediction of Axial Fatique Life From Tensile DataDocument7 pages1993-An Improved Technique For The Prediction of Axial Fatique Life From Tensile DataJaime Andres CastañedaNo ratings yet

- Effect of Shear Friction On Solid Flow Through An Orifice (1991)Document5 pagesEffect of Shear Friction On Solid Flow Through An Orifice (1991)池定憲No ratings yet

- EII Lots EmpiricalFormula PDFDocument7 pagesEII Lots EmpiricalFormula PDFMohammadNo ratings yet

- P. Sollero and M. H. Aliabadi. 1993. Fracture Mechanics Analysis of Anisotropic Plates by The Boundary Element Method.Document16 pagesP. Sollero and M. H. Aliabadi. 1993. Fracture Mechanics Analysis of Anisotropic Plates by The Boundary Element Method.Leonardo BernardoNo ratings yet

- Investigation of Air Film Conveyor PressurisedDocument9 pagesInvestigation of Air Film Conveyor Pressurisedluong van toiNo ratings yet

- Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, CroatiaDocument10 pagesFaculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, CroatiachoopoNo ratings yet

- Icorr Ba BC - Bandy1980Document12 pagesIcorr Ba BC - Bandy1980chau_riberNo ratings yet

- Orris 1973Document20 pagesOrris 1973Supantho ChaudhuriNo ratings yet

- Articulo Di Fusion Currie 2Document7 pagesArticulo Di Fusion Currie 2jose.25No ratings yet

- Cam Clay PlasticityDocument24 pagesCam Clay PlasticityKarena QuirozNo ratings yet

- Iterated Crossed Box Diagram in The Complex Angular Momentum Plane and Bethe-Salpeter EquationDocument15 pagesIterated Crossed Box Diagram in The Complex Angular Momentum Plane and Bethe-Salpeter EquationAnonymous FigYuONxuuNo ratings yet

- Application of Fractal Theory To Unsaturated Soil Mechanics - Xu Yongfu & Tong LixinDocument11 pagesApplication of Fractal Theory To Unsaturated Soil Mechanics - Xu Yongfu & Tong LixinMAXO44No ratings yet

- Calculation Constant: Theoretical of The Dielectric of A Bilayer MembraneDocument18 pagesCalculation Constant: Theoretical of The Dielectric of A Bilayer MembraneKirill TsiberkinNo ratings yet

- Structural Mechanics of Buried PipesDocument6 pagesStructural Mechanics of Buried PipesobricenoNo ratings yet

- XCIV The Large Deflection of Simply Supported BeamsDocument8 pagesXCIV The Large Deflection of Simply Supported BeamsFacheng ZhaoNo ratings yet

- A Curved Finite Element For Thin ElasticDocument38 pagesA Curved Finite Element For Thin ElasticJosé Cléber Rodrigues da SilvaNo ratings yet

- Ruscheweyh 1990Document8 pagesRuscheweyh 1990diocazzoNo ratings yet

- Poynting EffectDocument13 pagesPoynting EffectFernandocf90No ratings yet

- Chen, W. F.Document19 pagesChen, W. F.Caliche YumboNo ratings yet

- Design Charts For Random Vibrations of Elasto-Plastic Oscillators Subjected To Kanai-Tajimi SpectraDocument18 pagesDesign Charts For Random Vibrations of Elasto-Plastic Oscillators Subjected To Kanai-Tajimi SpectraSimpson LukeNo ratings yet

- Bulletin of The Seismological Society of America. Vol. No. 6, Pp. 1811-1841. December, 1964Document31 pagesBulletin of The Seismological Society of America. Vol. No. 6, Pp. 1811-1841. December, 1964LavJoshiNo ratings yet

- Demonstrating Rubber Elasticity: (I) Gives A Fascinating HisDocument3 pagesDemonstrating Rubber Elasticity: (I) Gives A Fascinating HisRicky EstepaNo ratings yet

- Snoek Effect PDFDocument5 pagesSnoek Effect PDFhamed soleymaniNo ratings yet

- Ussyukina and Davydychev - An Approach To The Evaluation of 3 - and 4-Point Ladder DiagramsDocument8 pagesUssyukina and Davydychev - An Approach To The Evaluation of 3 - and 4-Point Ladder DiagramsJulienBarratNo ratings yet

- Demengel1989 Article CompactnessTheoremsForSpacesOf PDFDocument39 pagesDemengel1989 Article CompactnessTheoremsForSpacesOf PDFMathSpaceNo ratings yet

- NigamJennings CalResponseSpectra1969 PDFDocument14 pagesNigamJennings CalResponseSpectra1969 PDFCristianMolinaOreNo ratings yet

- The Fast: Energy Loss A ParticleDocument10 pagesThe Fast: Energy Loss A ParticleEric ConradNo ratings yet

- Diamètre de HeywoodDocument4 pagesDiamètre de Heywooddavidal13No ratings yet

- Yield Line Analysis of A Web Connection in Direct TensionDocument4 pagesYield Line Analysis of A Web Connection in Direct Tensionkartik raj100% (1)

- Walsh Effective PermeabilityDocument7 pagesWalsh Effective PermeabilityGlusmNo ratings yet

- Talzat Zacharia PDFDocument16 pagesTalzat Zacharia PDFArun KumarNo ratings yet

- Semiclassical Variational Calculation of Liquid-Drop Model Coefficients For Metal ClustersDocument3 pagesSemiclassical Variational Calculation of Liquid-Drop Model Coefficients For Metal Clustersnaymin998No ratings yet

- Double Tapered FRP Beam For Automotive Suspension: Leaf SprungDocument22 pagesDouble Tapered FRP Beam For Automotive Suspension: Leaf SprungYogesh ShindeNo ratings yet

- Damaskin 1985Document12 pagesDamaskin 1985pescaofritoNo ratings yet

- Tensor Calculus, Part 2Document14 pagesTensor Calculus, Part 2hammoudeh13No ratings yet

- "I Iii I: On Stresses in A Plate With A Circular Hole.Document12 pages"I Iii I: On Stresses in A Plate With A Circular Hole.Kris SmaczekNo ratings yet

- DW) Ifw - .F (4 : Wear, 28 (1974) 217-234 7' Elsevier Sequoia S.A., Lausanne - Printed in The NetherlandsDocument18 pagesDW) Ifw - .F (4 : Wear, 28 (1974) 217-234 7' Elsevier Sequoia S.A., Lausanne - Printed in The Netherlandssurajit1987No ratings yet

- Cam Clay Plasticity Part II Implicit Integration of Constitutive Equation Based On A Nonlinear Elastic Stress Predictor PDFDocument16 pagesCam Clay Plasticity Part II Implicit Integration of Constitutive Equation Based On A Nonlinear Elastic Stress Predictor PDFrwilliams9001No ratings yet

- (1990) (Kataoka) (Interfacial Area Concentration in Bubbly Flow)Document18 pages(1990) (Kataoka) (Interfacial Area Concentration in Bubbly Flow)Erol BicerNo ratings yet

- Physics: Abstract. Determinants of Laplacians On Tensors and Spinors of ArbitraryDocument10 pagesPhysics: Abstract. Determinants of Laplacians On Tensors and Spinors of ArbitraryAntareep MandalNo ratings yet

- J. Electroanal. Chem., 101 (1979) 19 - 28Document10 pagesJ. Electroanal. Chem., 101 (1979) 19 - 28Bruno LuccaNo ratings yet

- Numerical Study On The Effect of Mooring Line Stiffness On Hydrodynamic Performance of Pontoon-Type Floating BreakwaterDocument6 pagesNumerical Study On The Effect of Mooring Line Stiffness On Hydrodynamic Performance of Pontoon-Type Floating Breakwatermostafa shahrabiNo ratings yet

- Measurement The of Sheet Resistivities Four-Point Probe WithDocument8 pagesMeasurement The of Sheet Resistivities Four-Point Probe WithAna Maria Muñoz GonzalezNo ratings yet

- Boundary Element Analysis For Axisymmetric Heat Conduction and Thermal Stress in Steady StateDocument11 pagesBoundary Element Analysis For Axisymmetric Heat Conduction and Thermal Stress in Steady StateFemi Richard FakoyaNo ratings yet

- Inelastic Buckling of Beam-Columns With Unequal End Moments: J. Construct. Steel Research 5 (1985) 195-212Document18 pagesInelastic Buckling of Beam-Columns With Unequal End Moments: J. Construct. Steel Research 5 (1985) 195-212juan carlosNo ratings yet

- A Short Introduction To Quantum Symmetry: PhysicsDocument6 pagesA Short Introduction To Quantum Symmetry: PhysicsSamuel SoaresNo ratings yet

- 4-Chinese Paper - Ren - Peng2000Document7 pages4-Chinese Paper - Ren - Peng2000thamiradNo ratings yet

- Review JurnalDocument13 pagesReview JurnalLuluk AKNo ratings yet

- Rensselaer Polytechnic Institute, Troy, New York (U.S.A.)Document6 pagesRensselaer Polytechnic Institute, Troy, New York (U.S.A.)Kartik DuttNo ratings yet

- Tables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiFrom EverandTables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiNo ratings yet

- Brochure - Valves For Chemical and Petrochemical Processes (EN) .Document58 pagesBrochure - Valves For Chemical and Petrochemical Processes (EN) .Valmet Flow WANo ratings yet

- Odabir Motorne Zaštite - Allen Bradley - Za Motore - Za - TransformatoreDocument500 pagesOdabir Motorne Zaštite - Allen Bradley - Za Motore - Za - TransformatoreKristian MevželjNo ratings yet

- Spares-40 Mva, 66-33 KV TransformerDocument1 pageSpares-40 Mva, 66-33 KV TransformerislamNo ratings yet

- Lab - 04 - Handout - Behavioral ModelingDocument12 pagesLab - 04 - Handout - Behavioral ModelingMuhammad SaudNo ratings yet

- 6453 05 Hw11solDocument8 pages6453 05 Hw11soll7aniNo ratings yet

- Surge Current Protection Using SuperconductorDocument21 pagesSurge Current Protection Using SuperconductorpraneethNo ratings yet

- E6000 Complete Operating ManualDocument154 pagesE6000 Complete Operating ManualsudeshbhagganNo ratings yet

- Class 8 Exemplar 7 PDFDocument32 pagesClass 8 Exemplar 7 PDFSarvesh Kumar Rai0% (1)

- 6931033765-DW-H-DiagramWinch ElectricDocument11 pages6931033765-DW-H-DiagramWinch ElectriciinsukniaNo ratings yet

- Fan Inverter Installation, Service - 335654Document58 pagesFan Inverter Installation, Service - 335654Ryan Savi0% (1)

- Lab 2Document9 pagesLab 2Asad IqbalNo ratings yet

- Sticker Instructions PDFDocument3 pagesSticker Instructions PDFVy LeNo ratings yet

- Ts 13810103v160400pDocument493 pagesTs 13810103v160400pla;lsd;No ratings yet

- Model CS3551 DC Set 2Document2 pagesModel CS3551 DC Set 2NambiRajaNo ratings yet

- CS4 Engl 122016Document2 pagesCS4 Engl 122016Support Next EngineeringNo ratings yet

- Engineering AnalysisDocument12 pagesEngineering AnalysisJack ButlerNo ratings yet

- Kalol Institute O Technology & Research Center, KalolDocument3 pagesKalol Institute O Technology & Research Center, KalolJay ThakarNo ratings yet

- BX Data PDFDocument6 pagesBX Data PDFJulio TovarNo ratings yet

- Microchip RTG4 Radiation Mitigated Clock and Reset Network Usage Application Note AC463 V2Document34 pagesMicrochip RTG4 Radiation Mitigated Clock and Reset Network Usage Application Note AC463 V2FalsoNo ratings yet

- 658-Article Text-1763-1-10-20200729Document9 pages658-Article Text-1763-1-10-20200729UMT JournalsNo ratings yet

- 3 DControllerDocument178 pages3 DControllerRoberto Felipe UrbinaNo ratings yet

- Chemistry Form 4 Mid-Term ExamDocument7 pagesChemistry Form 4 Mid-Term ExamsanusiNo ratings yet

- Transfix Dga 500: GE Grid SolutionsDocument2 pagesTransfix Dga 500: GE Grid Solutionslxd.hepNo ratings yet

- Booster SetsDocument16 pagesBooster SetsIshan RanganathNo ratings yet

- SQL Scripting & AMDPDocument11 pagesSQL Scripting & AMDPgvrahul100% (1)

- Code Coupling For Simulation of Flow-Induced Vibrations: Elisabeth LONGATTE Fabien HUVELIN Mhamed SOULIDocument28 pagesCode Coupling For Simulation of Flow-Induced Vibrations: Elisabeth LONGATTE Fabien HUVELIN Mhamed SOULIAshraf S. HusseinNo ratings yet

- Torsion ShaftDocument6 pagesTorsion ShaftmichaelNo ratings yet