Professional Documents

Culture Documents

Most Efficient Thermoelectric Harvester-Ali Hassan

Uploaded by

muhammadfawadnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Most Efficient Thermoelectric Harvester-Ali Hassan

Uploaded by

muhammadfawadnCopyright:

Available Formats

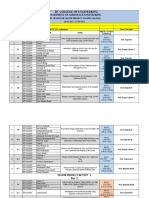

Mechanical Facts

Subject:

Most efficient thermoelectric harvester

Researchers innovated a stretchable thermoelectric generator with a skin-attachable gasket, enhancing

energy production through "mechanical metamaterials."

From :

Ali Hassan

Reg. No.:

2021-ME-521

Society:

American Society of Mechanical Engineers (ASME) Chapter Narowal University:

University of Engineering and Technology, Lahore (NWL)

Study abstract:

Wearable thermoelectric generators (WTEGs) have relied on soft encapsulation materials

typically used for the structural support of thermoelectric legs. Heat loss through the filler and

low heat transfer via the mismatched contact with the skin causes a small temperature gradient

between the human body (hot side) and the natural environment (cold side). Instead of using

soft encapsulation materials, a partially air-filled deformable gasket is purposed for leg support,

achieving the thermal isolation of thermoelectric legs by preventing parasitic heat transfer. The

WTEG comprising the deformable gasket exhibits a 30% larger temperature gradient than that

with conventional encapsulant structures filled with soft materials. Additionally, the deformable

gasket shows an auxetic metastructure owing to its negative Poisson's ratio, reversibly

responding to changes in their environment, which is suitable for skin-like stretchable wearable

devices. The band type of WTEG with the optimized leg geometry and fill factor shows a power

output of 2 uW cm−2 for eight pairs of thermocouples, a record-high value among the

stretchable TEGs obtained indoors at room temperature (23 °C) without wind. This approach

paves the way for the efficient conversion of thermal energy into electrical energy and broadens

potential applications for self-powered wearable electronics.

University of Engineering and Technology, Lahore (NWL)

Most efficient thermoelectric harvester

Engineers have developed cutting-edge technology that may considerably increase the

flexibility and efficiency of thermoelectric generators to unprecedented levels. This

breakthrough has the potential to revolutionize the area of energy generation by leveraging

the power of "mechanical metamaterials." These materials belong to a distinct category and

thus are not present in nature. They are manufactured by carefully organizing their internal

structures.

Researchers from the Korea Electrotechnology Research Institute (KERI) have developed a

flexible, skin-attachable gasket for stretchable thermoelectric generators.

As per the official release, this development could possibly increase the efficiency of a

thermoelectric generator to the “world's highest level.”

Stretchable, highly efficient thermoelectric generator gasket

A thermoelectric generator is a device that converts heat energy into electrical power using the

Seebeck effect. The Seebeck effect is a voltage differential caused by a temperature variation

between two dissimilar electrical conductors or semiconductors. In a thermoelectric generator,

this voltage difference is used to generate an electric current, thus producing electrical power.

The team's major goal was to develop a thermoelectric generator with better efficiency and

stretchability, ideal for use on curved surfaces such as skin or hot water pipes. Conventional

thermoelectric generators rely heavily on stiff ceramic printed circuit boards, which makes

adaption to curved surfaces difficult.

Interestingly, the scientists increased the stretchability of thermoelectric generators by a

remarkable 35 percent by adding a deformable gasket with a metastructure.The use of a

metastructure improves the thermoelectric generator's structural stability, allowing it to easily

adapt to diverse geometries and demonstrate exceptional stretchability.

Furthermore, the efficient insulation provided by the gasket's partial air gap reduces heat loss,

increasing the thermoelectric generator's efficiency. When compared to currently existing

flexible thermoelectric generators, this results in a staggering 30 percent increase in

temperature differential.

Dr Hyekyoung Choi of KERI stated: "Researchers in the team not only have the know-how to

develop high-performance thermoelectric materials but also have modularization technology

dedicated to energy harvesting and technology related to stable self-powered devices."

University of Engineering and Technology, Lahore (NWL)

Choi added: "With such convergence research, we were able to create synergy and consider

everything from core technology development, and testing to real-life applications."

Mechanical metamaterials

Mechanical metamaterials are a class of materials engineered to exhibit unique mechanical

properties that are not found in nature. These materials derive their properties from their

geometric design rather than their composition, and they often consist of repeating unit cells

arranged in specific patterns. The goal is to create materials with extraordinary mechanical

characteristics, such as negative Poisson's ratio (auxetic behavior), tunable elasticity, or high

strength-to-weight ratios.

Key characteristics and concepts related to mechanical metamaterials include:

Auxetic Behavior: Some mechanical metamaterials exhibit auxetic behavior, meaning they have

a negative Poisson's ratio. Unlike most materials that contract in one direction when stretched,

auxetic materials expand in the transverse direction. This can be useful in applications such as

impact protection and energy absorption.

Tunable Mechanical Properties: Mechanical metamaterials can be designed to have tunable

mechanical properties. By adjusting the geometry of the unit cells or the arrangement of the

material, it's possible to control properties like stiffness, elasticity, and damping.

Negative Stiffness Materials: These materials have a negative effective stiffness, which means

they can oscillate or deform in response to an applied force without experiencing an opposing

force. This property can be exploited for shock absorption or vibration isolation.

Lattice Structures: Many mechanical metamaterials rely on lattice structures, where the

arrangement of beams or struts in a specific pattern determines the overall mechanical

behavior of the material. Common lattice structures include hexagonal, square, or triangular

configurations.

Applications of mechanical metamaterials span various fields, including aerospace engineering,

robotics, medical devices, and infrastructure. They offer the potential for creating lightweight

yet strong structures, adaptive materials, and innovative solutions to engineering challenges.

Researchers continue to explore and develop new designs to unlock the full potential of

mechanical metamaterials in diverse applications.

University of Engineering and Technology, Lahore (NWL)

Figure 1: Mechanical Metamaterial

Reference:

For more information: https://techxplore.com/news/2023-11-stretchable-efficient-

wearable-thermoelectric-energy.html

University of Engineering and Technology, Lahore (NWL)

You might also like

- Energies 14 02339 v2Document13 pagesEnergies 14 02339 v2Khalid YahyaNo ratings yet

- Batería HumanaDocument9 pagesBatería HumanaFrancisco Ciaffaroni MNo ratings yet

- Polymer Artificial MusclesDocument10 pagesPolymer Artificial MusclesChemistry Q OfficialNo ratings yet

- Wearable Thermoelectric Materials and Devices For Self Powered Electronic SystemsDocument46 pagesWearable Thermoelectric Materials and Devices For Self Powered Electronic Systemsanmol sharmaNo ratings yet

- Energy Scavenging With Shoe-Mounted Piezoelectrics: Piezoelectric Shoe Power: Two ApproachesDocument9 pagesEnergy Scavenging With Shoe-Mounted Piezoelectrics: Piezoelectric Shoe Power: Two Approachesvrgvin002No ratings yet

- Triboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsDocument25 pagesTriboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsAnonymous AEicha08AF100% (1)

- A Review of Energy Harvesting From Piezoelectric Materials: S. M.Taware, S.P. DeshmukhDocument8 pagesA Review of Energy Harvesting From Piezoelectric Materials: S. M.Taware, S.P. DeshmukhxesNo ratings yet

- Wearable Thermoelectric Generator For Harvesting Heat On The Curved Human WristDocument11 pagesWearable Thermoelectric Generator For Harvesting Heat On The Curved Human WristNuttakrit somdockNo ratings yet

- Design and Evaluation of 3D Printed Polymeric Cellular Materials For Dynamic Energy AbsorptionDocument15 pagesDesign and Evaluation of 3D Printed Polymeric Cellular Materials For Dynamic Energy AbsorptionHimprakash DasNo ratings yet

- TRP C52Document5 pagesTRP C52Roshan KhadaseNo ratings yet

- Journal of Power Sources: Anja Lund, Yuan Tian, Sozan Darabi, Christian MüllerDocument11 pagesJournal of Power Sources: Anja Lund, Yuan Tian, Sozan Darabi, Christian Müllerlion walrusNo ratings yet

- 2017 ARTICLE, Integration of Energy Harvesting and Electrochemical Storage DevicesDocument14 pages2017 ARTICLE, Integration of Energy Harvesting and Electrochemical Storage DeviceslcordobaNo ratings yet

- Fabrication of Electromagnetic DamperDocument9 pagesFabrication of Electromagnetic DamperIJRASETPublicationsNo ratings yet

- Modern Piezoelectric Harvesting PDFDocument165 pagesModern Piezoelectric Harvesting PDFrit686100% (2)

- Fabrication of Multi-Purpose Solar UmbrellaDocument13 pagesFabrication of Multi-Purpose Solar UmbrellaIJRASETPublicationsNo ratings yet

- Selfcharging Batteries 09 00371Document17 pagesSelfcharging Batteries 09 00371therm000No ratings yet

- Final Revision 3Document151 pagesFinal Revision 3KairosNo ratings yet

- Li2014 3Document6 pagesLi2014 3Hry EngineNo ratings yet

- Journal Pre-Proofs: EngineeringDocument33 pagesJournal Pre-Proofs: EngineeringWahyu Dwilestari100% (1)

- Review of Nanocomposite Dielectric Materials With High Thermal ConductivityDocument34 pagesReview of Nanocomposite Dielectric Materials With High Thermal Conductivityshameem siddiqueNo ratings yet

- SYNOPSIS of RanjitDocument9 pagesSYNOPSIS of RanjitVishal OjhaNo ratings yet

- Thermoelectric Generator Literature ReviewDocument4 pagesThermoelectric Generator Literature Reviewaflsigfek100% (1)

- Safaei, Sodano and Anton, 2019Document9 pagesSafaei, Sodano and Anton, 2019Muhammad Saad AbdullahNo ratings yet

- ThermalDocument37 pagesThermalAbdulganiyu IsmaeelNo ratings yet

- Wang Just HBM-2017 Journal-PreprintDocument11 pagesWang Just HBM-2017 Journal-PreprintTheDreamMNo ratings yet

- Transient Model and Parameters Matching of A Segmented Solar Thermoelectric SystemDocument15 pagesTransient Model and Parameters Matching of A Segmented Solar Thermoelectric SystemsmuftahNo ratings yet

- Future For INDIA !!!!!!!!: Ajmer Institute of Technology, AjmerDocument12 pagesFuture For INDIA !!!!!!!!: Ajmer Institute of Technology, Ajmerkjuneja212No ratings yet

- PNAS 1999 Cao 8330 1Document2 pagesPNAS 1999 Cao 8330 1dushyantNo ratings yet

- Smart MatrlsDocument13 pagesSmart MatrlsaeroacademicNo ratings yet

- STRDocument22 pagesSTRJustin Brian MariñasNo ratings yet

- Atomic Layer Deposition For Thin Film Solid State Battery and CapacitorDocument23 pagesAtomic Layer Deposition For Thin Film Solid State Battery and Capacitorpriyono slametNo ratings yet

- Ijesrt: VIDYUT Generation Via W VIDYUT Generation Via Walking: AnalysisDocument3 pagesIjesrt: VIDYUT Generation Via W VIDYUT Generation Via Walking: AnalysisShashi ShekharNo ratings yet

- Designing Thermoelectric Generators For Self-Powered Wearable ElectronicsDocument15 pagesDesigning Thermoelectric Generators For Self-Powered Wearable ElectronicsPablo MazariegosNo ratings yet

- Reference 8 - Piezoelectric MaterialsDocument6 pagesReference 8 - Piezoelectric MaterialsRohan G RaikarNo ratings yet

- An Analytical Model For The Design of peano-HASEL Actuators With Drastically Improved Performance PDFDocument10 pagesAn Analytical Model For The Design of peano-HASEL Actuators With Drastically Improved Performance PDFEdward ValderramaNo ratings yet

- Experimental and Numerical Studies of A Soft Impact Piezoelectric Energy Harvesting Using An MR FluidDocument10 pagesExperimental and Numerical Studies of A Soft Impact Piezoelectric Energy Harvesting Using An MR FluidOleksii BalitskyiNo ratings yet

- 6 Mechanical Engineering Innovations That Could Change The Industrial GameDocument8 pages6 Mechanical Engineering Innovations That Could Change The Industrial GameAnonymous rtDlncdNo ratings yet

- Designing, Fabrication and Performance Review of Triboelectric Nanogenerated (TENG) Tile For Sustainable Energy HarvestingDocument3 pagesDesigning, Fabrication and Performance Review of Triboelectric Nanogenerated (TENG) Tile For Sustainable Energy HarvestingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 基于静电纺丝纳米纤维的可穿戴电子和自供电传感材料Document23 pages基于静电纺丝纳米纤维的可穿戴电子和自供电传感材料Gymnast PeakNo ratings yet

- Energy & Environmental Science: PerspectiveDocument24 pagesEnergy & Environmental Science: PerspectiveFamiloni LayoNo ratings yet

- Impact 2Document15 pagesImpact 2Shoaib MalikNo ratings yet

- IRJMETS31200003556Document8 pagesIRJMETS31200003556but chocNo ratings yet

- Safaei 2019 Smart Mater. Struct. 28 113001Document63 pagesSafaei 2019 Smart Mater. Struct. 28 113001Angelo RosNo ratings yet

- Hadas 2019Document16 pagesHadas 2019bsjsjsjNo ratings yet

- 1 s2.0 S0264127522001903 MainDocument7 pages1 s2.0 S0264127522001903 MainHooper ChheangNo ratings yet

- 1 s2.0 S2352484723011861 MainDocument13 pages1 s2.0 S2352484723011861 MainRohith k rNo ratings yet

- Chapter 7: (A) Energy Generation and Its EnhancementsDocument3 pagesChapter 7: (A) Energy Generation and Its EnhancementsamolNo ratings yet

- Polymer Artificial MusclesDocument9 pagesPolymer Artificial MusclesnamyefNo ratings yet

- Piezo Literature ReviewDocument7 pagesPiezo Literature ReviewEngineering ProjectNo ratings yet

- Three-Dimensional Ultra Exible Triboelectric Nanogenerator Made by 3D PrintingDocument11 pagesThree-Dimensional Ultra Exible Triboelectric Nanogenerator Made by 3D PrintingAduNo ratings yet

- New Microsoft Office Word DocumentDocument6 pagesNew Microsoft Office Word DocumentAnuj SachdevNo ratings yet

- 1 s2.0 S0167844218302234 MainDocument8 pages1 s2.0 S0167844218302234 MainSudeep SAHOONo ratings yet

- Smart MaterialDocument25 pagesSmart MaterialPT shamhoonNo ratings yet

- International Journal of Solids and Structures: R. Jayendiran, A. ArockiarajanDocument12 pagesInternational Journal of Solids and Structures: R. Jayendiran, A. ArockiarajanMani PrakashNo ratings yet

- Bending VibrationsDocument11 pagesBending Vibrationshyld3nNo ratings yet

- Design Optimization of A Large-Scale Thermoelectric GeneratorDocument6 pagesDesign Optimization of A Large-Scale Thermoelectric GeneratorMARSHALNo ratings yet

- Mechanical Design of Piezoelectric Energy Harvesters: Generating Electricity from Human WalkingFrom EverandMechanical Design of Piezoelectric Energy Harvesters: Generating Electricity from Human WalkingNo ratings yet

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationFrom EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNo ratings yet

- Integration of Distributed Energy Resources in Power Systems: Implementation, Operation and ControlFrom EverandIntegration of Distributed Energy Resources in Power Systems: Implementation, Operation and ControlToshihisa FunabashiRating: 4.5 out of 5 stars4.5/5 (3)

- Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingDocument9 pagesStress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingRory Cristian Cordero RojoNo ratings yet

- MGMT Audit Report WritingDocument28 pagesMGMT Audit Report WritingAndrei IulianNo ratings yet

- Digital MetersDocument47 pagesDigital MetersherovhungNo ratings yet

- AntibioticsDocument36 pagesAntibioticsBen Paolo Cecilia RabaraNo ratings yet

- Review1 ScheduleDocument3 pagesReview1 Schedulejayasuryam.ae18No ratings yet

- Golf Croquet Refereeing Manual - Croquet AustraliaDocument78 pagesGolf Croquet Refereeing Manual - Croquet AustraliaSenorSushi100% (1)

- Chapter 3 - Organization Structure & CultureDocument63 pagesChapter 3 - Organization Structure & CultureDr. Shuva GhoshNo ratings yet

- g6 - AFA - Q1 - Module 6 - Week 6 FOR TEACHERDocument23 pagesg6 - AFA - Q1 - Module 6 - Week 6 FOR TEACHERPrincess Nicole LugtuNo ratings yet

- Classifications of AssessmentsDocument11 pagesClassifications of AssessmentsClaire CatapangNo ratings yet

- A Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDocument110 pagesA Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDeepak SinghalNo ratings yet

- Methods of Recording Retruded Contact Position in Dentate PatientsDocument15 pagesMethods of Recording Retruded Contact Position in Dentate PatientsYossr MokhtarNo ratings yet

- From Philo To Plotinus AftermanDocument21 pagesFrom Philo To Plotinus AftermanRaphael888No ratings yet

- II 2022 06 Baena-Rojas CanoDocument11 pagesII 2022 06 Baena-Rojas CanoSebastian GaonaNo ratings yet

- Salads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDocument1,092 pagesSalads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDebora PanzarellaNo ratings yet

- SMC 2D CADLibrary English 1Document590 pagesSMC 2D CADLibrary English 1Design IPGENo ratings yet

- Tribal Banditry in Ottoman Ayntab (1690-1730)Document191 pagesTribal Banditry in Ottoman Ayntab (1690-1730)Mahir DemirNo ratings yet

- RSA - Brand - Guidelines - 2019 2Document79 pagesRSA - Brand - Guidelines - 2019 2Gigi's DelightNo ratings yet

- Marketing FinalDocument15 pagesMarketing FinalveronicaNo ratings yet

- PM CH 14Document24 pagesPM CH 14phani chowdaryNo ratings yet

- Rockaway Times 11818Document40 pagesRockaway Times 11818Peter J. MahonNo ratings yet

- The Homework Song FunnyDocument5 pagesThe Homework Song Funnyers57e8s100% (1)

- All You Need To Know About Egg YolkDocument7 pagesAll You Need To Know About Egg YolkGolden Era BookwormNo ratings yet

- Rule 113 114Document7 pagesRule 113 114Shaila GonzalesNo ratings yet

- Sindi and Wahab in 18th CenturyDocument9 pagesSindi and Wahab in 18th CenturyMujahid Asaadullah AbdullahNo ratings yet

- Theory GraphDocument23 pagesTheory GraphArthur CarabioNo ratings yet

- GPS Spoofing (2002-2003)Document8 pagesGPS Spoofing (2002-2003)Roger JohnstonNo ratings yet

- Business Analytics Emphasis Course GuideDocument3 pagesBusiness Analytics Emphasis Course Guidea30000496No ratings yet

- CX Programmer Operation ManualDocument536 pagesCX Programmer Operation ManualVefik KaraegeNo ratings yet

- Howard R700X - SPL - INTDocument44 pagesHoward R700X - SPL - INTJozsefNo ratings yet

- Working With Difficult People Online WorksheetDocument4 pagesWorking With Difficult People Online WorksheetHugh Fox IIINo ratings yet