Professional Documents

Culture Documents

Designing, Fabrication and Performance Review of Triboelectric Nanogenerated (TENG) Tile For Sustainable Energy Harvesting

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing, Fabrication and Performance Review of Triboelectric Nanogenerated (TENG) Tile For Sustainable Energy Harvesting

Copyright:

Available Formats

Volume 8, Issue 7, July – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Designing, Fabrication and Performance Review of

Triboelectric Nanogenerated (TENG) Tile for

Sustainable Energy Harvesting

Yash Shah

Department of Mechanical Engineering

Dwarkadas J. Sanghvi College of Engineering

Mumbai – 400056, India

Juhi Kothari Nihar Parmar

Department of Mechanical Engineering Department of Mechanical Engineering

Dwarkadas J. Sanghvi College of Engineering Dwarkadas J. Sanghvi College of Engineering

Mumbai – 400056, India Mumbai – 400056, India

Abstract:- There is an increase in the need of sustainable sources like the solar, wind, hydro, geothermal, etc. do not

energy harvesting sources as the world is on the verge of deplete over time and produce minimal harmful effects on the

exhausting all the non-renewable sources of energy. ecosystem. This will also reduce the carbon footprint to a

Hence, there is developed focus on development of new greater extent by harnessing the abundant inexhaustible

harvesting devices with the view of decreasing the sources. With the rise in sustainable energy sources,

dependency of energy on non-renewable sources. One of innovative technologies have also been on a rise which

the methods is the development of energy using harness energy from different sources. There are over 200

triboelectric nanogenerator. It has gained significant billion sensor projects in use till date and the number is on a

attention due to the high energy output, low cost, and eco- rise. One of the sensors use to harness energy is the

friendliness. Development and use of triboelectric triboelectric nanogenerator. This technology has emerged as a

nanogenerator is in different forms, one of which is use of promising solution of generating electricity and energy from

it in tile form. The tile will harvest the waste mechanical waste mechanical energy, the best part it offers is that it does

energy from various mechanical forces, vibrations or not require any recharging and replacement is required only

pressure and convert it to electrical energy. In this paper when there is any damage to sensor.

an attempt is made to develop and review the

performance of a low-cost [1], small scale triboelectric Now the question arises is what is triboelectric

nanogenerator tile which will harvest energy from the nanogenerator and how does it work? The TENG can be

pressure applied on it via different mechanical forces, for compared to a normal piezoelectric crystal that converts

example, walking, vibrating machines or rain drops. mechanical stress to electricity. But unlike piezoelectric

There is also an attempt to integrate the tile with solar property which is exhibited by a handful of known

panels to increase the efficiency of the device when there components TENG capabilities can be found in materials

is no mechanical force applicable on it. Materials using which have tendency to gain and loose electrons. There is

are Kapton (C22H10N2O5), Aluminum (Al) for exchange of electrons between two electrodes of a TENG

electrodes and copper wires for the electrical when there is mechanical stress applied [2]. They can be used

conductivity. in different modes to exchange electrons like the contact

separation tap mode, sliding mode or single electrode tap

Keywords:- Triboelectric Nanogenerator, Sustainable mode (refer fig. 1) [3].

Energy, TENG, Mechanical Energy Conversion.

I. INTRODUCTION

As the world faces interrelated challenges of climate

change, energy security and environmental degradation there

is a pressing need for renewable energy. There is a finite

source of fossil fuels which have been more or less the

dominant source for energy. Different problems have arisen

due to the extensive use of the non-renewable sources like

rising sea levels, extreme weather events, loss of biodiversity,

etc. Renewable energy is a great alternative and sustainable

energy available which can replace the fossil fuels. Energy Fig 1. Tap mode separation mode

IJISRT23JUL248 www.ijisrt.com 361

Volume 8, Issue 7, July – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The basic principle is that when the electrode is tapped Polydimethylsiloxane (PDMS) – This is the most abudent

onto one another there is exchange of electrons this used material for TENG as it can gain and loose electrons

phenomenon is called as contact electrification [4], this causes easily

a flow of electrons and hence an electrical flow is generated. Polyimide (PI) – This material posses excellent

By repeated cycle of contact making a and breaking there is mechanical and thermal properties hence it is used as

more and more electron loos and gain and hence electrical dielectric layer in TENG

flow is maintained. Coming to manufacturing the TENG in Teflon (PTFE) – It is a non conductive polymer having

small scale working form it can be used in the form of a tile low fritional properties, it has comparable capabilities

which has an electrode at the base and second electrode on top with PDMS to gain and loose electrons [7]

of it separated by the spring on the edges. At rest the springs Metals – Metals like aluminium, copper, zinc can be used

are in uncompressed state which keeps the two electrodes as TENG materials when used with proper secondary

separated and when the mechanical force greater than stiffness material.

(K) of spring is applied the contact of the electrodes causes

the exchange of electrons. For this study the material selected for triboelectric

layers is Teflon (PTFE) and commercial Aluminum (Al)

II. AIM AND OBJECTIVE obtained by different processes or even from food packaging

[8], with a layer of copper wires in between the electrode

The following study was conducted in order fabricate layers.

and implement an integrated energy harvesting system using

TENG and to find the output of energy developed by the IV. METHODOLOGY AND MANUFACTURING

small wasted mechanical forces which are available in

environment with an aim to harness these waste energies. A systematic approach will be followed to design the tile

The aim is to develop a small scale, low cost device which like done by U. Bukhari et.al. [9] and integrate it with solar

can be installed on the foot walks or railway stations or high panels for higher energy generation. The compressive

traffic areas which will harness the energy from the human knowledge gathered from the literature review helped in

walking over the tile, the integration of solar panel is selection of material and method of production.

secondary aim to improve the output of the tile when not in

use [5].

Main objective remains the same i.e. to lower the cost

of the device hence it can be used in daily life. Secondary

objective is to optimize the energy conversion efficiency by

changing the parameters like size, thickness, surface texture,

etc. The output received and the challenges faces is discussed

in the paper ahead in the section V of the paper.

Fig 3. 15x15 Tile Prototype

The manufacturing process of TENG tiles integrated

with solar panels will involve several steps, they are as

follows-

Layer fabrication – A substrate is coated with the

triboelectric layer, aluminum and Teflon is used as a

triboelectric layer. Aluminum is manufactured by either

Fig 2. Layer formation sputtering or evaporation or by chemical vapor deposition.

Teflon is coated by spray coating or by spin coating (refer

III. MATRIAL SELECTION [6] fig. 2).

Integration of copper wires – Between aluminium and

Generally, materials with high capability to transfer and Teflon copper wires are integrated to establish electrical

exchange electrons are used for triboelectric layers. The conductivity and connections. The electricity will be

material available for fabrication of triboelectric collected by these wires and they act as a conductive

nanogenerator is as follows - pathway. Uniform distribution of copper wires is

necessary for proper output of the device.

Spring placement – There are two such layers of

triboelectric made one with aluminium on top and other

with Teflon on top, both are coated on a balsa wood which

acts as a substrate. The two layers are separated by springs

IJISRT23JUL248 www.ijisrt.com 362

Volume 8, Issue 7, July – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

on four corners to ensure that the two layers don’t come in mind working and installing the TENG tile. The strength of

contact unless mechanical force is applied. the tile is also compromised seeing the low strength of the

Quality Control – Quality control measures will be solar panel which will lie on top of the triboelectric layer.

implemented through out the manufacturing process to

ensure consistency and reliability. Testing must be To conclude it can be said that the use of TENG tile in

performed while manufacturing to know the strength of high foot fall places will help in generation of energy but at a

the tile. certain cost. The energy developed by the tile may be less

Connections – The copper wires are connected to jumper compared to the other sources but it can help harness the

wires and the wires from solar panels are also connected to waste energy.

a common point of wires, which is divided as positive and

negative. A multimeter can be used to measure the current There must be further studies conducted on TENG tile

or an LED can be installed to check the connectivity of the in order to optimize the design and increase the efficiency.

wires. The further studies require the formation of high strength tile

with the solar panel, increasing the efficiency by either

A 15 x 15 cm tile is manufactured by the above process increasing the surface area or by changing the material and

(refer fig. 3). The materials are selected as per availability observe the findings.

hence it must not be difficult to get the materials.

REFRENCES

V. FINDINGS, CONCLUSION AND FUTURE

SCOPE [1]. Wang, Z.L.; Jiang, T.; Xu, L. Toward the blue energy

dream by triboelectric nanogenerator networks. Nano

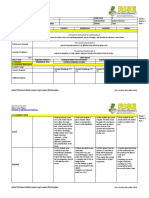

TABLE 1 OBSERVATIONS Energy 2017

[2]. Syed Nasimul Alam, Arka Ghosh, Pankaj Shrivastava,

Sr. Uddeshya Shukla, Kamal Garg, Abhay Chowdary

OBSERVATIONS

No. Edara, Nityananada Sahoo, An introduction to

ELECTRIC ELECTRIC triboelectric nanogenerators, Nano-Structures & Nano-

AL AL Objects, Volume 34,2023

FORCE VALUE OUTPUT OUTPUT [3]. Triboelectric Nanogenerator: Structure, Mechanism,

(N) W/O WITH and Applications Weon-Guk Kim, Do-Wan Kim, Il-

SOLAR SOLAR Woong Tcho, Jin Ki Kim, Moon-Seok Kim, and Yang-

PANEL PANEL Kyu Choi ACS Nano 2021 15 (1), 258-287

[4]. Hong-Joon Yoon, Hanjun Ryu, Sang-Woo Kim,

1. 45 54mW 98mW Sustainable powering triboelectric nanogenerators:

2. 55 68mW 111mW Approaches and the path towards efficient use, Nano

Energy, Volume 51, 2018

3. 65 72mW 123mW [5]. Shaikh, Mohd Rizwan & Shaikh, Sirajuddin &

Waghmare, Santosh & Labade, Suvarna & Tekale, Anil.

4. 75 79mW 129mW (2017). A Review Paper on Electricity Generation from

Solar Energy. International Journal for Research in

5. 85 85mW 134mW

Applied Science and Engineering Technology.

*THE FOLLOWING WAS MEASURED USING A CALIBRATED [6]. Zhang, Renyun & Olin, Håkan. (2020). Material

MULTIMETER *THE SURFACE AREA USED FOR THE TILE IS choices for triboelectric nanogenerators: A critical

15X15 CM * THE OBSERVATIONS WERE FOR A SINGLE review. EcoMat. 2. 10.1002/eom2.12062

CONTACT SEPERATION CYCLE [7]. Kequan Xia, Zhiyuan Zhu, Hongze Zhang, Chaolin Du,

Rongji Wang, Zhiwei Xu,Cost-effective triboelectric

As per the observations it can be concluded that nanogenerator based on teflon tape and conductive

integrating the solar panel with the device aids in increasing copper foil tape, Microelectronic Engineering, Volume

the output of the overall system. But a drawback of it is that 199, 2018

the integration of the solar panel makes the circuit more [8]. P. Ravi Sankar, P. Supraja, Siju Mishra, K. Prakash, R.

complex. The increase in output when increase in force is due Rakesh Kumar, D. Haranath, A novel triboelectric

to the fact that the layers are in contact with each other for a nanogenerator based on only food packaging aluminium

longer period of time compared to less force and also that foils, Materials Letters, Volume 310, 2022M.

higher force causes more surface area to come in contact [9]. U. Bukhari, K. Riaz, T. Tauqeer and M. Sajid, "Simple

within the device within the layers. Hence, it can be inferred and low cost triboelectric nanogenerator (TENG) for

that to increase the efficiency and output more surface area resource limited environment," 2019 International

contact is required hence more the area more the electricity Conference on Robotics and Automation in Industry

production. There is minor effect on the overall cost but the (ICRAI), Rawalpindi, Pakistan,2019

increasing of complexity of circuit causes it to have skilled

IJISRT23JUL248 www.ijisrt.com 363

You might also like

- Shin Et Al-2016-International Journal of Energy ResearchDocument10 pagesShin Et Al-2016-International Journal of Energy ResearchBrnardo RanNo ratings yet

- Application of Piezoelectric Transducer in Energy Harvesting in PavementDocument8 pagesApplication of Piezoelectric Transducer in Energy Harvesting in PavementvisionNo ratings yet

- Triboelectric Nanogenerator Built Inside Shoe Insole For Harvesting Walking EnergyDocument7 pagesTriboelectric Nanogenerator Built Inside Shoe Insole For Harvesting Walking EnergyQuốc TínNo ratings yet

- Review On Thermionic Energy Converters: IEEE Transactions On Electron Devices April 2016Document12 pagesReview On Thermionic Energy Converters: IEEE Transactions On Electron Devices April 2016Ali Waleed JaafarNo ratings yet

- 2018 - Rathore - A Critical Review On Triboelectric NanogeneratorDocument17 pages2018 - Rathore - A Critical Review On Triboelectric Nanogeneratornkor6574No ratings yet

- Thermoelectric Generator (TEG) Technologies and ApplicationsDocument18 pagesThermoelectric Generator (TEG) Technologies and ApplicationsarunachalachandavarNo ratings yet

- Power Genration Using by Peltier ModuleDocument5 pagesPower Genration Using by Peltier ModuleIJRASETPublicationsNo ratings yet

- STRDocument22 pagesSTRJustin Brian MariñasNo ratings yet

- Development, Applications, and Future Directions of Triboelectric NanogeneratorsDocument20 pagesDevelopment, Applications, and Future Directions of Triboelectric NanogeneratorsQuốc TínNo ratings yet

- Impact of Defects On Quality Contact Systems For Photoelectric ConvertersDocument5 pagesImpact of Defects On Quality Contact Systems For Photoelectric ConvertersСергей ХрипкоNo ratings yet

- First Yr Phy 21pyb102j Mp-1 (Finalised) - Thermionic Emission.Document9 pagesFirst Yr Phy 21pyb102j Mp-1 (Finalised) - Thermionic Emission.mangalimadhavaNo ratings yet

- FYP 2 Zakhuan Chp1-5Document42 pagesFYP 2 Zakhuan Chp1-5Zack UwanNo ratings yet

- Power Generation Using Piezoelectric MaterialDocument5 pagesPower Generation Using Piezoelectric MaterialPavan chary SannidanamNo ratings yet

- VIDYUT Generation Via Walking AnalysisDocument3 pagesVIDYUT Generation Via Walking AnalysisMIRACLE JAMESNo ratings yet

- 1 s2.0 S1385894723037208 mainsohelCEJDocument13 pages1 s2.0 S1385894723037208 mainsohelCEJParvin AkterNo ratings yet

- Karthikeyan 2020Document10 pagesKarthikeyan 2020DeepikaNo ratings yet

- Composites Part B: Gui Yang, Mingjie Wang, Jingwen Dong, Fengmei Su, Youxin Ji, Chuntai Liu, Changyu ShenDocument10 pagesComposites Part B: Gui Yang, Mingjie Wang, Jingwen Dong, Fengmei Su, Youxin Ji, Chuntai Liu, Changyu Shen779070870No ratings yet

- IJRPR3848Document7 pagesIJRPR3848litipe9793No ratings yet

- Large-Scale Fabrication of Robust Textile Triboelectric NanogeneratorsDocument9 pagesLarge-Scale Fabrication of Robust Textile Triboelectric NanogeneratorsRana Sabouni TabariNo ratings yet

- J Nanoen 2016 12 035Document9 pagesJ Nanoen 2016 12 035SanNo ratings yet

- Photovoltaic-Thermal (PV/T) Technology: A Comprehensive Review On Applications and Its AdvancementDocument22 pagesPhotovoltaic-Thermal (PV/T) Technology: A Comprehensive Review On Applications and Its AdvancementYADAV VikasNo ratings yet

- A Leaf-Shaped Triboelectric Nanogenerator For Multiple Ambient Mechanical Energy HarvestingDocument7 pagesA Leaf-Shaped Triboelectric Nanogenerator For Multiple Ambient Mechanical Energy Harvestingirappa karaganviNo ratings yet

- IRJMETS31200003556Document8 pagesIRJMETS31200003556but chocNo ratings yet

- Agra SanjeyDocument11 pagesAgra SanjeyafshooabadaniNo ratings yet

- Droplet Based Electricity GenerationDocument4 pagesDroplet Based Electricity GenerationVIVA-TECH IJRINo ratings yet

- Application of Piezoelectric Transducer in Energy Harvesting in PavementDocument20 pagesApplication of Piezoelectric Transducer in Energy Harvesting in Pavementutkarsh kumarNo ratings yet

- 13 IjtimesDocument9 pages13 IjtimesMM GoudNo ratings yet

- 1 s2.0 S2211285518303380 MainDocument7 pages1 s2.0 S2211285518303380 Mainndsannn.1No ratings yet

- Mitigation of Electrical Stresses On Outdoor Polymeric Insulator Using Nano-Zinc Oxide Coating Simulation and Experimental ValidationDocument9 pagesMitigation of Electrical Stresses On Outdoor Polymeric Insulator Using Nano-Zinc Oxide Coating Simulation and Experimental ValidationRajat MandalNo ratings yet

- Triboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsDocument25 pagesTriboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsAnonymous AEicha08AF100% (1)

- Tri Bo ElectricDocument32 pagesTri Bo ElectricAjinkya DarphadeNo ratings yet

- Witricity Transmission by Satellites Using Carbon Nanotubic Solar CellsDocument6 pagesWitricity Transmission by Satellites Using Carbon Nanotubic Solar CellsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Teng PDFDocument19 pagesTeng PDFMd. Amirul IslamNo ratings yet

- Seminar PolytronicDocument23 pagesSeminar PolytronicAbiola AkinshemoyinNo ratings yet

- Fabrication Performance and Applications of Integrated Nanodielectric Properties of Materials A ReviewDocument36 pagesFabrication Performance and Applications of Integrated Nanodielectric Properties of Materials A ReviewMahmoud KhamesNo ratings yet

- Motorcycle Waste Heat Energy Harvesting PDFDocument9 pagesMotorcycle Waste Heat Energy Harvesting PDFMuhammad Umar IqbalNo ratings yet

- MypaperDocument6 pagesMypaperShrabaniPaulNo ratings yet

- Design and Simulation of Electrothermally Activated Bidirectional Microtweezer Using PMMA For Biomedical ApplicationsDocument4 pagesDesign and Simulation of Electrothermally Activated Bidirectional Microtweezer Using PMMA For Biomedical ApplicationstheijesNo ratings yet

- Nano GeneratorDocument4 pagesNano GeneratorSreehari RgNo ratings yet

- A Study of Magnetic Piston Repulsion Engine IJERTV10IS100003Document4 pagesA Study of Magnetic Piston Repulsion Engine IJERTV10IS100003Ananthu SomanNo ratings yet

- Batería HumanaDocument9 pagesBatería HumanaFrancisco Ciaffaroni MNo ratings yet

- Mini Project ReportDocument20 pagesMini Project Reportroks143No ratings yet

- Cao Xia - 2022 - Article - WearableAndHumidity-resistantBDocument7 pagesCao Xia - 2022 - Article - WearableAndHumidity-resistantBLee Jay aNo ratings yet

- Nanocoatings: Randa Abdel-KarimDocument37 pagesNanocoatings: Randa Abdel-KarimEnrique FrancoNo ratings yet

- Nano EnergyDocument12 pagesNano Energysanaul haqueNo ratings yet

- 1 s2.0 S0196890422000681 MainDocument14 pages1 s2.0 S0196890422000681 MainRohith k rNo ratings yet

- Kinetic FootfallDocument16 pagesKinetic Footfallpreetham kumar100% (4)

- 3d Printed Noise Canceling TengDocument8 pages3d Printed Noise Canceling TengIslam HelazaNo ratings yet

- Application of Smart Materials in Civil EngineerinDocument7 pagesApplication of Smart Materials in Civil EngineerinGowtham YvNo ratings yet

- Effect of Permittivity On Breakdown Characteristic of Transformer Oil Based NanofluidDocument5 pagesEffect of Permittivity On Breakdown Characteristic of Transformer Oil Based NanofluidEditor IJTSRDNo ratings yet

- TIE HarvestingDocument7 pagesTIE HarvestingRamKumarNo ratings yet

- Intl J of Energy Research - 2020 - Hasan - Inorganic Thermoelectric Materials A ReviewDocument53 pagesIntl J of Energy Research - 2020 - Hasan - Inorganic Thermoelectric Materials A Reviewsc2208No ratings yet

- Triboelectric Nanogenerators As Flexible Power Sources: A Technical Seminar Report OnDocument29 pagesTriboelectric Nanogenerators As Flexible Power Sources: A Technical Seminar Report OnRajpranabhNo ratings yet

- Final Revision 3Document151 pagesFinal Revision 3KairosNo ratings yet

- Seminar Model Report - ChangesDocument13 pagesSeminar Model Report - ChangesPavanNo ratings yet

- Atomic Layer Deposition For Thin Film Solid State Battery and CapacitorDocument23 pagesAtomic Layer Deposition For Thin Film Solid State Battery and Capacitorpriyono slametNo ratings yet

- 基于静电纺丝纳米纤维的可穿戴电子和自供电传感材料Document23 pages基于静电纺丝纳米纤维的可穿戴电子和自供电传感材料Gymnast PeakNo ratings yet

- Organic Resistive Switching Device Based On Cellulose Gelatine Microcomposite FibersDocument9 pagesOrganic Resistive Switching Device Based On Cellulose Gelatine Microcomposite FibersShuvam PawarNo ratings yet

- Stretchable ElectronicsFrom EverandStretchable ElectronicsTakao SomeyaNo ratings yet

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoDocument6 pagesStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Blockchain Based Decentralized ApplicationDocument7 pagesBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningDocument8 pagesUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersDocument33 pagesCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Industry That Capitalizes Off of Women's Insecurities?Document8 pagesAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyNo ratings yet

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaDocument6 pagesFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Health Care SystemDocument8 pagesSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Insights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesDocument8 pagesInsights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueDocument2 pagesParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Visual Water: An Integration of App and Web To Understand Chemical ElementsDocument5 pagesVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Cities: Boosting Economic Growth Through Innovation and EfficiencyDocument19 pagesSmart Cities: Boosting Economic Growth Through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Compact and Wearable Ventilator System For Enhanced Patient CareDocument4 pagesCompact and Wearable Ventilator System For Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldDocument6 pagesImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Predict The Heart Attack Possibilities Using Machine LearningDocument2 pagesPredict The Heart Attack Possibilities Using Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Air Quality Index Prediction Using Bi-LSTMDocument8 pagesAir Quality Index Prediction Using Bi-LSTMInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship Between Teacher Reflective Practice and Students Engagement in The Public Elementary SchoolDocument31 pagesThe Relationship Between Teacher Reflective Practice and Students Engagement in The Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parkinson's Detection Using Voice Features and Spiral DrawingsDocument5 pagesParkinson's Detection Using Voice Features and Spiral DrawingsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatDocument16 pagesInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Implications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewDocument6 pagesImplications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Keywords:-Ibadhy Chooranam, Cataract, Kann Kasam,: Siddha Medicine, Kann NoigalDocument7 pagesKeywords:-Ibadhy Chooranam, Cataract, Kann Kasam,: Siddha Medicine, Kann NoigalInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Analysis On Mental Health Issues Among IndividualsDocument6 pagesAn Analysis On Mental Health Issues Among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Harnessing Open Innovation For Translating Global Languages Into Indian LanuagesDocument7 pagesHarnessing Open Innovation For Translating Global Languages Into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix Dactylifera) Leaf Fiber As A Main Component in Making An Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix Dactylifera) Leaf Fiber As A Main Component in Making An Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Object Recognition Eyeglasses For The Visually Impaired Using Image AIDocument6 pagesThe Making of Object Recognition Eyeglasses For The Visually Impaired Using Image AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning For Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning For Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions On Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions On Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing As An Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains - CameroonDocument14 pagesTerracing As An Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains - CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nanoheterostructures For Efficient Hydrogen Evolution Reaction in Alkaline Water ElectrolyzersDocument13 pagesNanoheterostructures For Efficient Hydrogen Evolution Reaction in Alkaline Water ElectrolyzersSirigiri ThrineshNo ratings yet

- Nano DeBeeDocument2 pagesNano DeBeeCarmen RaveNo ratings yet

- Sculpting With LightDocument15 pagesSculpting With LightMizuho IeiriNo ratings yet

- Chapter 8Document31 pagesChapter 8helloblarg100% (4)

- Expansion Joints For Power Stations Kompaflex BrochureDocument8 pagesExpansion Joints For Power Stations Kompaflex Brochuremdt3eNo ratings yet

- Aluminium Boat BuildingDocument6 pagesAluminium Boat Buildingjohnknight000No ratings yet

- Grade 8, Quarter 3Document39 pagesGrade 8, Quarter 3Leisor Euqirdnam Oyacnub94% (16)

- Ytong Product Brochure CXDocument8 pagesYtong Product Brochure CXtrickyggNo ratings yet

- Pub 83 Al Bronze Alloys For Industry PDFDocument24 pagesPub 83 Al Bronze Alloys For Industry PDFpbanerjeeNo ratings yet

- Welding Processes Fcaw, Gmaw, Gtaw, Smaw, SawDocument2 pagesWelding Processes Fcaw, Gmaw, Gtaw, Smaw, SawiaftNo ratings yet

- Gaurav Jayaswal Day2 Green Hydrogen in India April2023Document39 pagesGaurav Jayaswal Day2 Green Hydrogen in India April2023Praneet PayodhiNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- (Re) Coating of Pylons With ZINGAENDocument5 pages(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateNo ratings yet

- Chemical Reactions Test Yourself 3Document2 pagesChemical Reactions Test Yourself 3Nizar MTechNo ratings yet

- Delmars Standard Textbook of Electricity 6th Edition Herman Test BankDocument6 pagesDelmars Standard Textbook of Electricity 6th Edition Herman Test Bankphelandieuz7n100% (27)

- Crystallographic Imperfections PDFDocument17 pagesCrystallographic Imperfections PDFAmitNo ratings yet

- Chlor AlkaliDocument4 pagesChlor AlkaliYusof SundangNo ratings yet

- Confining Pressure 10 Mpa Von Mises StressDocument2 pagesConfining Pressure 10 Mpa Von Mises StressMoj TabaNo ratings yet

- Effectiveness of Sodium Polyacrylate (Superabsorbent Polymer) As A Growing Medium of Hydroponically Grown Ocimum Basilicum (Basil)Document18 pagesEffectiveness of Sodium Polyacrylate (Superabsorbent Polymer) As A Growing Medium of Hydroponically Grown Ocimum Basilicum (Basil)Research ParkNo ratings yet

- Concepts of Electric Arc Furnace Fume ControlDocument5 pagesConcepts of Electric Arc Furnace Fume ControlAshutosh SinghNo ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- Mil I 46058CDocument15 pagesMil I 46058Cyamuna yamuNo ratings yet

- InstrumentacionDocument11 pagesInstrumentacionJOSE MARTIN MORA RIVEROSNo ratings yet

- Dental CeramicsDocument434 pagesDental Ceramicskirtiabhi100% (2)

- SOLAR PV TechnologiesDocument33 pagesSOLAR PV TechnologiesMuraryspottyNo ratings yet

- THE Formation of Late Magmatic Oxide Ores.: Alan M. BatemanDocument23 pagesTHE Formation of Late Magmatic Oxide Ores.: Alan M. BatemanRorisang MalebyeNo ratings yet

- Norma Astm F794Document7 pagesNorma Astm F794WalterRamosNo ratings yet

- D4206Document4 pagesD4206saifullah629No ratings yet

- Determination Arsenic by AASDocument13 pagesDetermination Arsenic by AASMartuaHaojahanSaragihSidabutarNo ratings yet

- Palm Oil Mill PipingDocument4 pagesPalm Oil Mill PipingmshkNo ratings yet