Professional Documents

Culture Documents

Manual Telco Sensors Sg15

Uploaded by

adrianhooo89Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Telco Sensors Sg15

Uploaded by

adrianhooo89Copyright:

Available Formats

SG 15 – USER MANUAL …..

NB… series

Space Guard Series

Photoelectric light curtains

EN tel

Important Information Installation & Adjustments

General General Instruction and Precaution

THIS LIGHT CURTAIN SG15 SHOULD ONLY BE INSTALLED BY AUTHORIZED AND FULLY Even though the light curtain has a high degree of immunity to ambient light sources, it is

TRAINED PERSONNEL! recommended to avoid direct exposure to sunlight, and interference from flashlights or other

infrared light sources, such as other photo sensors.

THE LIGHT CURTAIN IS ONLY A SAFETY PROTECTION DEVICE IF ALL INSTRUCTIONS

IN THIS MANUAL, ARE CAREFULLY FOLLOWED AND FULLY COMPLIED WITH. IN If the front cover of the light curtain becomes contaminated, they have to be cleaned with a

ADDITION, THE INSTALLER IS REQUIRED TO COMPLY WITH ALL LOCAL LAWS AND slightly damp cloth. Do not use organic solvents or detergents. If the light curtain is very

STANDARDS. contaminated, the output may go into safe state and de-energize even after the cleaning, due

to safety reasons. The light curtain will automatically make the necessary internal adjustments,

ANY ALTERATIONS TO THE DEVICE BY THE BUYER, INSTALLER OR USER MAY and within less than a few minutes, the light curtain will be fully adjusted and resume normal

RESULT IN UNSAFE OPERATING CONDITIONS. operation. Immediate adjustment can be forced by switching the light curtain off and then on

again.

Compliance to Directives and Standards Ensure that the light curtain is mounted, so that it is mechanically stable during operation.

This device complies with the European directive 2006/42/EC for machinery and with the The light curtain must not be placed on moving doors.

European directive 2004/108/EC for electromagnetic compatibility, when used in accordance

with the instructions in this manual. Severe rain and snow may be detected due to the high sensitivity of the light curtain.

The compliance to the directive of machinery is declared according to EN 12978, with

normative reference to: Indicators

EN 13849-1, category 2, PL d SGT SGR

IEC 61496-2, type 2 ESPE

EC type examination:

TUV NORD CERT GmbH, Langemarckstr. 20, 45141 Essen (NB 0044) Red LED: Status indicator

EC-type certificate No. 44 205 13 413372-001

Yellow LED: Output indicator

Product Data Green LED: Power on indicator

Technical Data

SGT (Transmitter) SGR (Receiver)

Supply voltage 12-30 Vdc

Installation and Adjustment

Max. Voltage ripple 15% (within supply range)

Reverse polarity protected Yes

No initial set up or adjustments are required, due to the automatic signal-tracking (AST)

Max. current consumption 70 mA (RMS) 30 mA

feature, which automatically adjust each individual channel on the system.

Max. output load - 100 mA

Max. output ON resistance - 20Ω ~ 2V@100mA

Use the brackets supplied with the light curtain (at least 2 pcs, with max distance of

Max. leakage current - 80uA

1 135 cm) to mount the transmitter (SGT) and receiver (SGR) facing each other and

Short circuit protected - Yes correctly aligned.

Inductive load protection - Yes

Output type - Opto coupled solid state relay Correct alignment is achieved when the front cover of the light curtains are parallel

Sensing range 1 m - 12 m 2 and when a virtual line connecting top of the transmitter and receiver are

Response time (max.) 50 ms perpendicular to both transmitter and receiver front cover. (Within 2 deg.)

Wire the sensor according to the wiring diagram.

3

Environmental Data Make sure the load does not exceed 100 mA.

Light immunity @ 5º incidence > 100.000 lux

Temperature, operation -20 to + 65 ºC 4 Check for correct wiring.

Temperature, storage -40 to + 80 ºC

5 Turn power on.

Sealing class IP67

Marking 6 The status indicator (red LED) on the SGR will flash quickly when the AST is active.

Output Mode 7 When the power on indicators (green LEDs) is on, the system is operating.

Models Output Mode

SGR 15-xxx-0xx-x1-E-x9-xx NC 8 Notice that the rails must not be moved after the power to the SGR is turned on.

Connection

SGT/R Test Input

Wiring Diagrams

The function of the light curtain has to be tested before any cycle (f.i. door closing acc.

EN 12978 2009, 4.4.3), by activating the test input of the transmitter and the receiver. The

SGR and the SGT test input wires must be connected together. The test is enabled and

disabled via the black (SGT) and white (SGR) control wire. (See “Wiring Diagrams” and table

below).

Activation of the test input will initiate an extensive internal safety test in both the transmitter

and the receiver. A faulty receiver or a faulty transmitter will turn on red led and go into safe

mode; the transmitter will stop transmitting and the receiver will de-energise the output until

test is repeated again with success.

Transmitter SGT 15

An external controller ensures that the receiver de-energizes the output, when the test inputs

are activated, and that the receiver energizes the output, when the test inputs are de-activated

again.

The test input on SGT/R has to be activated a certain minimum time Tr in order to ensure that

the test request is registered and a test sequence is initiated.

On activation of the SGT/R test input, the output of the receiver will switch within a certain

maximum time TON .

When the test input of SGT/R is deactivated the output will be switched back within a certain

maximum time TOFF.

Receiver SGR 15 with solid state Receiver SGR 15 with solid state relay

relay used as NPN output used as PNP output By only activating the test input on the SGT, a switch in output of the SGR should be observed.

If only the SGR test input is activated, no change in its output should be observed.

There must be at least 500ms from the start of one test pulse to the start of the next test pulse.

Note: Refer to “SGT/R Test Input Response Time “.

Receiver SGR 15 with solid state relay output.

Website: www.telcosensors.com Preliminary

E-Mail: info@telcosensors.com October 2013 edition

Made in Denmark Telco A/S reserves the right to make changes without prior notice

SG 15 – USER MANUAL ….. NB… series

Space Guard Series

Photoelectric light curtains

EN tel

How the test inputs are to be operated depends on digit 0X on transmitter (SGT) and X9 on Troubleshooting

receiver (SGR) in the model code;

SGT 15-xxx-0xx-x1-E-0X-xx Troubleshooting

SGR 15-xxx-0xx-x1-E-NBX9-xx Probable Reason Corrective Action

Make sure no object is present in the detection area when test is done.

Model 1. Symptom: Red LED on SGT/R is constant on. All other LEDs are off.

Test input Test input

Test input not

Transmitter Receiver connected to connected to

connected Check supply and cable to the SGT/R.

SGT SGR 0V - GND + supply Error found during test process

Or replace the rail(s).

00 09 Testing activated No testing No testing

03 39 No testing No testing Testing activated 2. Symptom: Red and green LEDs on SGT is constant on.

04 49 Testing activated Testing activated No testing Error found during test process Replace the SGT rail.

SGT/R Test Input Response Time

3. Symptom: Red and green LEDs on SGR is constant on.

Ton (max./min.) Toff (max./min.) Tr (min.)

Error found during test process Replace the SGR rail.

120 ms / 35 ms 120 ms / 5 ms 200 ms

4. Symptom: Yellow LED on SGR is flashing

Cross talk from another light curtain, or

Change position of the SGT and SGR rails.

other powerful light sources.

5. Symptom: Yellow LED on SGR is constant off. Red LED is off.

Rails are out of sensing range Check the sensing range and power to the SGT.

6. Symptom: After start up, red LED on SGR continues to flash quickly. Green LED is on.

Rails are out of sensing range or Check the sensing range and for objects

SGT test input response time graph SGT is not turned ON or an object is between the SGT and the SGR.

obstructing one or more beams. Check SGT is powered or replace rails.

7. Symptom: After start up, green LED on SGT/R is on. Yellow LED on SGR is off.

Test input is constant activated under and

Deactivate the test input on SGT/R.

after start up.

Output Logic

Output Logic Disposal

Output indicator

Detection Output mode Output status Disposal

(yellow led)

The light curtain should only be replaced if a similar protection device is installed. Disposal

Present should be done using the most up-to-date recycling technology according to local rules and

laws.

Light operated Manufacturer

Open Off

(N.C.)

Manufacturer

Telco A/S, Højerupvej 25a, 4660 Store Heddinge, Denmark

Lars Krarup, Managing Director

Absent

Light operated

(N.C.) Closed On

Housing Length and Number of Channels

Housing Length and Number of Channels

Housing length Beam Placement Active Height Channels

C1 1800 mm 40

1928 mm D1 1800 mm 28

E1 1800 mm 16

C1 2160 mm 48

2288 mm D1 2160 mm 30

E1 2160 mm 18

C1 2520 mm 56

2648 mm D1 2520 mm 32

E1 2520 mm 20

Website: www.telcosensors.com Preliminary

E-Mail: info@telcosensors.com October 2013 edition

Made in Denmark Telco A/S reserves the right to make changes without prior notice

You might also like

- Macro MRS PQM130Document12 pagesMacro MRS PQM130luis lopezNo ratings yet

- Rs Smart Solar 486000Document54 pagesRs Smart Solar 486000NhacaNo ratings yet

- Data Sheet Cortina de LuzDocument2 pagesData Sheet Cortina de LuzhudsonbrasfeltNo ratings yet

- Installation Instructions Photoswitchr Bulletin 42ca Cylindrical Photoelectric SensorsDocument4 pagesInstallation Instructions Photoswitchr Bulletin 42ca Cylindrical Photoelectric SensorsAlexander Franklin Alvarez HuillcaNo ratings yet

- Swiss Garde 360 Premium AP User ManualDocument8 pagesSwiss Garde 360 Premium AP User ManualTonyandAnthonyNo ratings yet

- EL Series Service Manual (Including EL302Tv)Document49 pagesEL Series Service Manual (Including EL302Tv)dav_ob50% (2)

- WRL Power Series 10-400K User ManualDocument81 pagesWRL Power Series 10-400K User ManualShahan Mehboob100% (1)

- BEAM1224 ManualDocument13 pagesBEAM1224 Manualjohn freddy GonzalezNo ratings yet

- Prge em I-Prge-12Document12 pagesPrge em I-Prge-12Nam PhanNo ratings yet

- Fuente Fcps 24s6eDocument12 pagesFuente Fcps 24s6eGuido RuizNo ratings yet

- HDC 1400R PDFDocument66 pagesHDC 1400R PDFAlmeida FábioNo ratings yet

- K85001-0560 - Reflective Beam DetectorDocument4 pagesK85001-0560 - Reflective Beam DetectorDauXuan HuynhNo ratings yet

- Vibration TransmitterDocument12 pagesVibration Transmitterahmed elkholanyNo ratings yet

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorDocument15 pagesBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectoryesid rodriguezNo ratings yet

- 300 Series: 330/320 Surge Protective DeviceDocument8 pages300 Series: 330/320 Surge Protective DeviceComspec MarketingNo ratings yet

- Sunny Boy 2500 InverterDocument2 pagesSunny Boy 2500 Inverterbaes47No ratings yet

- Datasheet KPM169xDocument6 pagesDatasheet KPM169xalupricopNo ratings yet

- Reflected Beam Smoke Detector Installation and Maintenance InstructionsDocument24 pagesReflected Beam Smoke Detector Installation and Maintenance Instructionsjames alfarasNo ratings yet

- MAT192 Jun12 Vega Antares OrionDocument28 pagesMAT192 Jun12 Vega Antares OrionOmar ValeraNo ratings yet

- 990 Vibration Transmitter Datasheet-141612m PDFDocument14 pages990 Vibration Transmitter Datasheet-141612m PDFloopkkNo ratings yet

- Q17416-Is M20 User Manual-ALL - r7Document146 pagesQ17416-Is M20 User Manual-ALL - r7Vincent GibsonNo ratings yet

- 9114 Chassis MSA Manual de Servicio SamsungDocument28 pages9114 Chassis MSA Manual de Servicio Samsungjairote1974No ratings yet

- IR140YDocument4 pagesIR140YMiłosz NowakNo ratings yet

- pp2402 Marine Series 65 Base Mounted Uv Flame Detector Ig Issue 2-LockedDocument4 pagespp2402 Marine Series 65 Base Mounted Uv Flame Detector Ig Issue 2-LockedhalrbrahmeNo ratings yet

- AX-70T 130T AnE SpecDocument2 pagesAX-70T 130T AnE SpecrodrigoaranhaNo ratings yet

- fsb-200 Install Sheeti56-2424-04rDocument18 pagesfsb-200 Install Sheeti56-2424-04rcarlos yepezNo ratings yet

- Optex Incorporated Description: Output and EnclosureDocument3 pagesOptex Incorporated Description: Output and EnclosurerodrigoaranhaNo ratings yet

- KPM169x: Bipolar Insulation Guard For Live Non-Grounded DC NetworksDocument6 pagesKPM169x: Bipolar Insulation Guard For Live Non-Grounded DC NetworksRN NNo ratings yet

- GST M200 - DS10103235 5Document3 pagesGST M200 - DS10103235 5Simanjuntak JulpianNo ratings yet

- TN-3000-124B - Datasheet Inversor Antiapagon PDFDocument21 pagesTN-3000-124B - Datasheet Inversor Antiapagon PDFJadinson GuerreroNo ratings yet

- IRD 1020 Infra-Red Flicker Detector: Flame Detection Device For Oil and Gas FlamesDocument4 pagesIRD 1020 Infra-Red Flicker Detector: Flame Detection Device For Oil and Gas FlamesJorge Gustavo GoyecheaNo ratings yet

- Paradox DG-85Document2 pagesParadox DG-85Gabriel BanuNo ratings yet

- User Manual: Upower SeriesDocument28 pagesUser Manual: Upower SeriesRogerio OliveiraNo ratings yet

- Safety Information: Instruction ManualDocument4 pagesSafety Information: Instruction ManualKen JunNo ratings yet

- FSB-200A, FSB-200SA Single-Ended Reflected Type Projected Beam Smoke DetectorDocument14 pagesFSB-200A, FSB-200SA Single-Ended Reflected Type Projected Beam Smoke Detectoradolf07No ratings yet

- Data Sheet Semg436 enDocument2 pagesData Sheet Semg436 ennio756No ratings yet

- AZM300 ManualDocument12 pagesAZM300 ManualBalatenteraislamHelperNo ratings yet

- Video Printer Sony Up597md - MuDocument31 pagesVideo Printer Sony Up597md - MuAnonymous dGFqrw5vONo ratings yet

- Description Installation: Automatic Reset Manual ResetDocument2 pagesDescription Installation: Automatic Reset Manual ResetmostroyaNo ratings yet

- FAR2137S FAR2837S FAR2137S-BB Installation Manual B 2.14.2004Document130 pagesFAR2137S FAR2837S FAR2137S-BB Installation Manual B 2.14.2004Christian ReyesNo ratings yet

- 4422703Document43 pages4422703Zvonko ŠuljakNo ratings yet

- PTX SenzorDocument1 pagePTX SenzorMarius NegreaNo ratings yet

- A Isometer IR475LYDocument3 pagesA Isometer IR475LYUrsula JohnsonNo ratings yet

- Sem203P User Guide: Push Button Pt100 Two Wire (4 To 20) Ma OutputDocument2 pagesSem203P User Guide: Push Button Pt100 Two Wire (4 To 20) Ma OutputCesar Alejandro Lopez PortelesNo ratings yet

- PWM OC10A Rev0808Document5 pagesPWM OC10A Rev0808Patrizia Cudina100% (1)

- FR7062 Installation Manual H3 1-19-06Document32 pagesFR7062 Installation Manual H3 1-19-06Galuh DH Chandra WdyNo ratings yet

- PPD-C-230V: Ceiling Presence DetectorDocument2 pagesPPD-C-230V: Ceiling Presence DetectorIbrahim SNo ratings yet

- ApicsacsplitcoreDocument2 pagesApicsacsplitcoreluat1983No ratings yet

- Manual-Vis Spect - Jenus V1100Document15 pagesManual-Vis Spect - Jenus V1100bashirNo ratings yet

- Notifier Explosion Proof Smoke Detector 30 3003Document2 pagesNotifier Explosion Proof Smoke Detector 30 3003Tee RixNo ratings yet

- Um sxn1230 Rev BDocument3 pagesUm sxn1230 Rev BvbraoNo ratings yet

- E3TA One Touch Setting Photoelectric Sensor With Teachin FunctionDocument2 pagesE3TA One Touch Setting Photoelectric Sensor With Teachin Functionzheng zhengNo ratings yet

- Installation Manualfelcom18 Ime-J1Document62 pagesInstallation Manualfelcom18 Ime-J1TEMILOLUWA ABOLARINNo ratings yet

- RS Calibration Isotech-3610DDocument23 pagesRS Calibration Isotech-3610DMe MeNo ratings yet

- Dsd-060 Earthquake Shutdown Unit: DescriptionDocument2 pagesDsd-060 Earthquake Shutdown Unit: DescriptionPower WhereverNo ratings yet

- E+ E-0V 110 Volt Pot 1K: Installation and MaintenanceDocument12 pagesE+ E-0V 110 Volt Pot 1K: Installation and MaintenanceRonald Gomez tapiaNo ratings yet

- LG 42PQ3000Document55 pagesLG 42PQ3000Jerry WebbNo ratings yet

- Send and Fax GuideDocument322 pagesSend and Fax GuideBhupendra SengarNo ratings yet

- The Design Collaboration ProcessDocument5 pagesThe Design Collaboration ProcesssheikmeeranNo ratings yet

- Tu170 Mta Sample Fall2011Document6 pagesTu170 Mta Sample Fall2011Emma JonesNo ratings yet

- KK2.1.X Instruction Manual V1.19S1 ProDocument38 pagesKK2.1.X Instruction Manual V1.19S1 ProAnonymous Gcqk4Pry3rNo ratings yet

- Service Letter: Hartzell Propeller IncDocument3 pagesService Letter: Hartzell Propeller IncAbdeslamBahidNo ratings yet

- GSM KPI'sDocument38 pagesGSM KPI'sMorteza MoradiNo ratings yet

- Example: Punching Machine Page:1/4Document5 pagesExample: Punching Machine Page:1/4jupudiguptaNo ratings yet

- How To Hack WPA-WPA2 WiFi Using Kali LinuxDocument6 pagesHow To Hack WPA-WPA2 WiFi Using Kali LinuxJoel PérezNo ratings yet

- Openway Centron Meter Spec Sheet PDFDocument4 pagesOpenway Centron Meter Spec Sheet PDFmikeNo ratings yet

- WTL Assignment No. 5Document7 pagesWTL Assignment No. 5Shubham KanchangireNo ratings yet

- Capacitor Testing Using Doble M4000Document10 pagesCapacitor Testing Using Doble M4000KatsukiDaitoNo ratings yet

- Scott GroverDocument3 pagesScott GroverJoe StephensNo ratings yet

- Web TestingFunctionality TestingDocument7 pagesWeb TestingFunctionality TestingkiruthikaveluNo ratings yet

- 31 SDMS 12Document31 pages31 SDMS 12Jalizco RuedaNo ratings yet

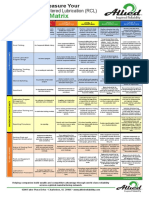

- Allied Maturity Matrix 14 Reliability Centered Lubrication PDFDocument2 pagesAllied Maturity Matrix 14 Reliability Centered Lubrication PDFHossein100% (1)

- How To Check Exide Battery Manufacturing Date - How To Read Exide Battery Date Codes - Exide Battery Manufacturing Date From Serial NumberDocument3 pagesHow To Check Exide Battery Manufacturing Date - How To Read Exide Battery Date Codes - Exide Battery Manufacturing Date From Serial NumberManikandan SudalaiyandiNo ratings yet

- Applications of Thermoelectric Energy: A ReviewDocument5 pagesApplications of Thermoelectric Energy: A ReviewIJRASETPublicationsNo ratings yet

- EWM PICO 162 Pico 62 MVDocument1 pageEWM PICO 162 Pico 62 MVdinescNo ratings yet

- ISO 9001 Mapping Guide PDFDocument8 pagesISO 9001 Mapping Guide PDFSinan İcikNo ratings yet

- Contour CraftingDocument43 pagesContour CraftingTEMY PETERNo ratings yet

- MAS72x EN 04 Install StartupDocument28 pagesMAS72x EN 04 Install StartupRodrigoNo ratings yet

- Medieval/Middle Ages: Science Technology and SocietyDocument10 pagesMedieval/Middle Ages: Science Technology and SocietyMelchorCandelaria100% (1)

- Marantz SR8001 AV Surround Receiver Amplifier User ManualDocument79 pagesMarantz SR8001 AV Surround Receiver Amplifier User Manualtrevor5409No ratings yet

- K EnriquezDocument1 pageK Enriquezbreakitdown yoyoNo ratings yet

- Saksham Singhal ResumeDocument1 pageSaksham Singhal ResumeAnonymous ITkgPWNo ratings yet

- Sun x86 Server Support Consultant Certification Help Desk AssessmenDocument136 pagesSun x86 Server Support Consultant Certification Help Desk AssessmenArmand Basoh100% (1)

- Very GoodDocument5 pagesVery GoodManjulya YeddiNo ratings yet

- GSM Frequency Bands - Wikipedia, The Free EncyclopediaDocument5 pagesGSM Frequency Bands - Wikipedia, The Free EncyclopediaSovannarith HoyNo ratings yet

- Automotive Quality High-Power: Stanley Electric's Latest High-Power IR LEDDocument1 pageAutomotive Quality High-Power: Stanley Electric's Latest High-Power IR LEDbobbbNo ratings yet

- 12 Ip Sample Model Paper Oct2021Document8 pages12 Ip Sample Model Paper Oct2021niyamathNo ratings yet