Professional Documents

Culture Documents

Change of The Mechanical Properties of The Gases Obtained From The Mixture of Fibers With Different Compositions

Uploaded by

Academic JournalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Change of The Mechanical Properties of The Gases Obtained From The Mixture of Fibers With Different Compositions

Uploaded by

Academic JournalCopyright:

Available Formats

95 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

Change of the Mechanical Properties of the Gases Obtained from the Mixture

of Fibers with Different Compositions

Toyirova Tursunoy Abdugapirovna, Mengnarov Shuxrat Soatovich, Ochilov Tulkin Ashurovich

Tashkent Institute of Textile and Light Industry (Uzbekistan)

Eshmamatov Bahadir Kholmurza o’gli

Kimyo international university in Tashkent

ABSTRACT

in this article, 5000 tex pelts were made on the JFA-226 carding machine at the production

enterprise, 3 types of pelts were made on the HSR-1000 type pelting machine in the laboratory of

TTESI under the "Spinning Technology" department, JAT of the Japanese company "Toyota" in the

laboratory under the "Textile Fabric Technology" department On the 810 loom, yarn made of 100%

cotton fibers was thrown into the warp thread, and yarn mixed with secondary fibers was thrown into

the loom yar.

KEYWORDS: pilta, base surface of gasses, bulk density, bulk density, bulk tensile strength, bulk

density, abrasion resistance, bulk tensile strength, bulk tensile strength.

I. INTRODUCTION

With the development of scientific and technical progress in the world, the volume of production of

various materials increases, and the amount of secondary material resources also increases. At the

same time, as a result of the creation of waste-free technology in the textile industry, the consumer

demand for raw materials will increase. As a result of effective use of such raw materials in

production, the cost of the finished product will decrease.

When knitting production scraps are taken as yarn count, sock knitting scraps are up to 7%,

underwear production scraps are 12-20%, outerwear production scraps are 15-20%.

Globally, fibers obtained from waste and secondary material resources from the sewing process

make up 25% of all textile raw materials. This is a huge stock that can be used for production.

However, only 10% of these scraps are used. Basically, they are processed into materials that cannot

be used for various purposes, or they are made into simpler, lower-cost ropes, furniture and technical

fabrics, for wiping and other purpose.

Increasing the competitiveness of textile products, optimizing the assortment and structural

characteristics, as well as reducing the consumption of materials and the cost of raw materials,

cannot be imagined. The rational and efficient use of textile and garment scraps and secondary

material resources (IMR) received from the population and enterprises has a direct impact on the

development and recovery of the local textile industry. Universal technologies and equipment

developed on the basis of newly created or modernized existing aggregates and mechanisms used in

textile production are of particular importance.

The increase in the standard of living of the population is achieved by the exponential growth of the

gross domestic product at the expense of non-renewable natural resources. Only 2% of them are used

as finished products, and the remaining 98% pollutes the environment in the form of secondary

material resources. Therefore, urgent and drastic measures are needed to repeatedly reduce the

consumption of non-renewable resources and environmental pollution.

Middle European Scientific Bulletin, Volume 40 | Sep-2023

96 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

The most important direction in this regard is the reuse of secondary material resources in

production, which means obtaining a finished product that significantly reduces the use of natural

resources and, as a result, environmental pollution. Because the amount of work and energy spent on

processing secondary material resources is 2-3 times less than on primary production.

Modern technological equipment of light industry minimizes the release of harmful substances into

the atmosphere during use, and some of them completely dispose of and recover production waste.

However, these environmentally friendly technologies are very expensive (sometimes the price of

cleaning devices is up to 25% of the product price), because. these networks have many additional

devices, which require more human, material and energy costs and cannot fundamentally solve

environmental problems.

The rational use of raw materials and material resources in the sewing and knitting industry is one of

the main problems, and in solving them, not only enterprises, but also higher education sciences,

scientists and specialists should actively participate in the creation of waste-free and low-waste

technologies.

A large amount of waste is generated in the production of fabrics and products in the sewing and

knitting industry. It depends on the assortment, the equipment used in weaving the canvas, the type

of location and the organization of work on the normalization of fabric consumption. As a result of

equipment malfunctions, insufficient care and skilled maintenance of machines, defects such as

distortion of the pattern, the formation of piles of loops or enlarged loops, crooked rows of loops,

defects such as wrong-colored weaving loop rows in jacquard fabrics, shift of rapport, formation of

unaligned folds in combination woven fabrics appears.

The structure of textile fabrics is determined by the interweaving and connection of warp and weft

threads. The appearance, properties and uses of textile fabrics depend on their structure.

Density is one of the indicators of the structure of gasses, and the other is their shearing. The density

of gauze is determined by the number of threads per unit of length, usually 100 mm. If the density of

the gas is different on the body and on the back, the density of such gas is called uneven gas. If they

are equal to each other, the density is a uniform gas. Generally, gases have a higher bulk density than

their bulk density. However, in some cases it is the opposite.

The density of gases varies widely. The thinner the threads of the same density gauze, the more

sparse the gauze, that is, the less it is filled with threads.

The density of gases varies depending on the purpose of their use. For example, as the density of gas

increases, its tensile strength, air permeability and friction resistance increase. In addition, the fiber

content of the gas has a different effect on its properties.

The mechanical properties of gauzes include tensile strength, elongation at break, abrasion

resistance, and creasing resistance in the body and warp direction. The mechanical properties of

gasses depend on the amount of secondary fibers in the composition. For example, if the amount of

secondary fibers in the pulp increases, the resulting pulp becomes coarser and its hairiness increases.

In addition, one of the main indicators of gas is its resistance to friction. The abrasion resistance of

gauzes depends on the fiber composition, density, thinness or thickness of threads, thickness and

other parameters. For example, the more gauze is rubbed, the structure of the gauze is broken, the

threads in it are broken, and the breaking strength decreases.

Erosion of gases occurs mainly as a result of the effect of friction. The abrasion resistance of gauzes

depends on their fiber content and surface structure. First of all, the ends of the fibers protruding

from the surface of the gauzes are affected by friction.

Fibers protruding into the bent places of the threads in the gauze begin to crumble. Some areas of the

Middle European Scientific Bulletin, Volume 40 | Sep-2023

97 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

fiber surface are damaged and the fibers are broken. Yarns are also broken due to individual fibers or

fiber parts coming out of the yarn composition.

The bent areas of the threads protruding from the surface of the gauzes are the first to be eroded by

friction. These areas are considered as the base surface of the gaskets, that is, the larger the base

surface of the gaskets, the better its resistance to erosion. By strengthening the base surface of the

gaskets, it is possible to increase its resistance to erosion. For this purpose, windings with a long

coating (satin, satin), friction-resistant fibers (kapron, lavsan) or finishing processes (apreting) are

used.

Frictional deterioration of gaskets containing short fibers and especially synthetic fibers usually

begins with pilling. Soft balls-pillars are formed from tangled fibers in the most frequently rubbed

areas of the product. First, the ends of the fibers come to the surface of the gauze. Then, they get

tangled up. When entangled, some fibers break out of the gauze structure. Later, the fibers in the

cocoons break off from the surface of the gauze. As a result, the thickness of the gas is reduced and it

is easily absorbed.

One of the main indicators of gauze is that they do not wrinkle.

Under the influence of various technological processes in the textile industry, fabrics are wrinkled as

a result of bending and compressive deformations, that is, they form folds and wrinkles. Wrinkles

and creases can be removed only with wet ironing.

The non-creasing of gauzes depends on their fiber content, the thickness of the threads used in their

structure, the type of cutting and finishing, and their density.

The non-creasing index of gauze is one of their negative properties. It spoils the appearance of the

item. Easy-to-crinkle gauze wears out quickly, because it rubs a lot in places where it is bent and

creased.

Non-creasing of fabrics means that they resist creasing and return to their original shape after

creasing.

II. METHODOLOGY

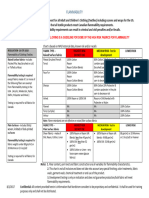

Research work was carried out to determine the technological indicators and mechanical properties

of gasses. For him, 66.4% cotton fiber, 28.8% secondary fiber and 4.8% cotton fiber in 3 variants

based on the scheme obtained from a mixture of 10% nitron, 60% cotton and 30% secondary fibers

under production conditions and presented in the laboratory conditions on a carding machine. a

mixture of nitron fibers was produced in a wick and a pneumomechanical spinning machine, and its

mechanical properties were determined. The results of the study are presented in Table 1 below.

Table 1. Changes in technological indicators and mechanical properties of gasses obtained from a

mixture of different composition and processed fibers

т/р Indicators Made from a A mixture of 66.4% cotton fiber,

blend of 10% 28.8% secondary fiber and 4.8%

nitron, 60% nitrone fiber was obtained according

cotton and 30% to the scheme of placing wicks in the

secondary fibers braiding machine

received 1 2 3

1. Density, pcs

based on 200 200 210 220

by duck 190 180 180 170

Surface density of gas, 193,0 192,8 192,7 192,5

2.

g/m2

Middle European Scientific Bulletin, Volume 40 | Sep-2023

98 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

The tensile strength of gassing,

N

3.

based on 414,0 415,0 380,0 323,0

by duck 503,0 560,0 454,0 387,0

Elongation of gas at break, %

4. based on 19,0 24,0 13,0 17,0

by duck 23,0 25,0 20,0 20,0

5. Abrasion resistance, cycle 20500 23400 19200 17000

III. RESULTS AND DISCUSSION

If we compare the results of the research with the parameters of the gauze obtained from a mixture of

10% nitron, 60% cotton and 30% secondary fibers under production conditions, the density of the

gauze obtained according to the 1st option did not change, the density of the gauze decreased by

5.3%, the tensile strength of the gauze was reduced by 5.3% by 0.3%, tensile strength by 10.2%,

elongation at break by 20.9%, elongation at break by 8.0%, abrasion resistance by 12.4%, according

to option 2 The density of the resulting gas increased by 4.8%, the density of the gas did not change,

the tensile strength of the gas decreased by 8.2%, the tensile strength of the gas decreased by 9.7%,

the elongation at break of the gas decreased by 31.6%. , the elongation at break by 13.1%, friction

resistance decreased by 6.4%, the density of the gas obtained according to option 3 increased by

9.1%, the density by 10.5%, the tensile strength of the gas by 10.5% By 22.0%, tensile strength by

23.1%, elongation at break by 10.5%, elongation at break by 13.1%, abrasion resistance by 17.1%.

IV.CONCLUSION

It has been proven that the parallelization of fibers in the outermost part of the piles in the process of

adding piles in the braiding machine is better compared to other adding processes, and that it has a

positive effect on all the quality indicators of the gas produced from it.

The results of the conducted research showed that the tensile strength of the gauze obtained

according to the 1st option is from 0.3% to 10.2%, abrasion resistance is up to 12.4%, in production

conditions of 10% nitrone, 60% cotton and 30% it was found that it increased compared to the

indicators of the gas obtained from the mixture of secondary fibers.

REFERENCES

1. Frolova I.V. I.V. Frolova, V.V. Makarov // Izv. Vuzov. Technol. textile. prom. 1998. - No. 1. - S.

56-58.

2. Frolov V.D. Технологические условия разволокнения лоскута в зоне питаюшчего

устройства Текст./ V.D. Frolov, M.D. Larionova // Izv. Vuzov. Technol. text, prom-sti. 1999. -

No. 6. - S. 52-54.

3. Ivanova N.N., Misko N.N. K voprosu pererabotki otkhodov tekstilnykh materialov sveynogo

proizvodstva// Pererabotka otkhodov tekstilnoy i light industry: theory and practice, Materialy

dokladov Mejdunarodnoy nauchno-prakticheskoy konferentsii, 2016, Vitebsk, 47 p.

4. Selezneva I. I. Resursosberezhenie v shveynom proizvodstve / I. I. Selezneva, R. N.

Filimonenkova, E. L. Kulazhenko // Materialy dokladov 43 nauchno-teknicheskoy conference of

teachers and students of the university / UO "VGTU". -Vitebsk, 2010. -S. 230-231.

5. Kadnikova O.Yu., Shaldykova B.A. Upravlenie protsessom pererabotki otkhodov kak faktor

ekologo-ekonomicheskogo razvitiya predpriyatiy sveino-trikotajnoy promyshlennosti

//Mejdunarodnyi dvuyazychnyi nauchnyi journal "Nauka i Mir" No. 3 (31).-Volgograd, 2016. -

S. 54 - 56.

Middle European Scientific Bulletin, Volume 40 | Sep-2023

99 MIDDLE EUROPEAN SCIENTIFIC BULLETIN ISSN 2694-9970

https://cejsr.academicjournal.io

6. Gerasimuk I.N., Zimina E.L., Kogan A.G. Ratsionalnogo ispolzovaniya otkhodov na shveynoy

predpriyatiyax. Pererabotka otkhodov textile and light industry: theory and practice. Materialy

dokladov Mejdunarodnoy nauchno-prakticheskoy conference. 2016, Vitebsk, 40 S.

7. Bashkov, A.P. Razrabotka resursosberegayushchih tekhnologii dlya proizvodstva netkanyx

materialov teknicheskogo naznacheniya: monografiya / A.P. Bashkov, V.D. Frolov.-Ivanovo:

IGTA.-2007.-288 p.

8. Kulmetov Mirpolat, Atanafasov Mukhiddin Rakhmonovich, Laysheva Elmira Talgatovna,

Yuldasheva Mavluda Turamuratovna, Akhmedova Mokhinur Fayzullo qizi, “Effect of Rate

Quantity on IP Quality” International Journal of Innovative Research in Science, Engineering and

Technology (IJIRSET), e-ISSN: 2319-8753, p-ISSN: 2347-6710, Volume 10, Issue 11,

November 2021.

9. Atanafasov Mukhiddin Rakhmonovich, Ochilov Tulkin Ashurovich, Valieva Zulfiya

Fakhritdinovna, Vliyanie kolichestvennogo soderjaniya otkhodov na kachestvennye

kharacteristiki pryaji. Scientific magazine Izdaetsya ejemesyachno s December 2013 goda

Yavlyaetsya pechatnoy versiey setevogo jurnala Universum: teknicheskie nauki, Vypusk: 2(95)

February 2022 Chast 4.

10. Muxtarov Jo’rabek Reyimberganovich, Djumaniyozov Muxammadjon Baxromovich, Atanafasov

Mukhiddin Rakhmonovich, Akhmedova Mokhinur Fayzullo qizi, “Virginity of Rops from

Returnschange of Indicators”, International Journal of Innovative Research in Science,

Engineering and Technology (IJIRSET), p-ISSN: 2347-6710, Volume 10, Issue 11, November

2021.

11. Atanafasov Mukhiddin Rakhmonovich, Ochilov Tulkin Ashurovich, Usmonova Shaxnoza

Anvarovna, Yuldashyev Jaxongir Norquvvato’g’li, Hakimov Shahzod Husniddin o’g’li,

Influence of Cotton Fiber of Different Composition and Secondary Material Resources on

Single-Cycle Elongation Deformation of Yarns, International Journal of Innovative Research in

Science, Engineering and Technology (IJIRSET) p-ISSN: 2347-6710, Volume 11, Issue 2,

February 2022.

Middle European Scientific Bulletin, Volume 40 | Sep-2023

You might also like

- Fabric DictionaryDocument68 pagesFabric DictionaryGayatrimoneNo ratings yet

- Effect of Twist On Yarn PropertiesDocument5 pagesEffect of Twist On Yarn PropertiesAbdulqadeerNo ratings yet

- RKM DetailsDocument7 pagesRKM DetailsDurairaj.N90% (10)

- Nonwoven FabricsDocument54 pagesNonwoven FabricsMd. Saidul IslamNo ratings yet

- Textile DesignT&P XI 829Document120 pagesTextile DesignT&P XI 829Meghna KhatriNo ratings yet

- Basic WeaveDocument34 pagesBasic Weavejennygraceshalini100% (4)

- Study On Denim and Gabardine Twill Fabric Cover FactorDocument47 pagesStudy On Denim and Gabardine Twill Fabric Cover FactorAtik U Bhuiyan71% (7)

- Common Types of Woven FabricDocument73 pagesCommon Types of Woven Fabricsayem1563100% (2)

- ROTOR - R40 - R60 - Spinner Guide 2013-02-28 Spinning 2493-V1Document118 pagesROTOR - R40 - R60 - Spinner Guide 2013-02-28 Spinning 2493-V1julian reyNo ratings yet

- D1683 PDFDocument9 pagesD1683 PDFDwi Nur AstriaNo ratings yet

- Knitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Document5 pagesKnitted Fabric: Sardar Vallabhbhai Patel Institute of Textile Management, Coimbatore - 641004Pradeep AhireNo ratings yet

- The Effect of The Mixture of Different Composition and Recycled Fibers On The Single-Cycle Tensile Deformation of GasesDocument5 pagesThe Effect of The Mixture of Different Composition and Recycled Fibers On The Single-Cycle Tensile Deformation of GasesAcademic JournalNo ratings yet

- The Effect of Mixtures of Different Compositions and Recycled Fibers On The Physical Properties of GasesDocument5 pagesThe Effect of Mixtures of Different Compositions and Recycled Fibers On The Physical Properties of GasesAcademic JournalNo ratings yet

- Assessment of The Quality Indicators of Threads Obtained by An Improved Method From Mixtures of Fiber and Secondary Material Resources With Different CompositionsDocument12 pagesAssessment of The Quality Indicators of Threads Obtained by An Improved Method From Mixtures of Fiber and Secondary Material Resources With Different CompositionsAcademic JournalNo ratings yet

- Design Methods Report OutlineDocument7 pagesDesign Methods Report OutlineHATICE BEYZA YILMAZNo ratings yet

- Non WovenDocument73 pagesNon Wovenসময়ের বাহকNo ratings yet

- Stacking SequenceDocument12 pagesStacking SequenceAndrés MercadoNo ratings yet

- Comparison of Recycle Yarn To VirginDocument9 pagesComparison of Recycle Yarn To VirginParvesh Khurana100% (1)

- 578-Article Text-1285-2-10-20200803Document13 pages578-Article Text-1285-2-10-20200803ashishNo ratings yet

- Bgmea University of Fashion and Technology: Final SubmissionDocument34 pagesBgmea University of Fashion and Technology: Final Submissionmortuza hasanNo ratings yet

- 4897 14196 1 PB PDFDocument13 pages4897 14196 1 PB PDFTutunNo ratings yet

- Development and Characterisation of Multi-Layered Jute Fabric-Reinforced HDPE CompositesDocument15 pagesDevelopment and Characterisation of Multi-Layered Jute Fabric-Reinforced HDPE Compositesabilio_j_vieiraNo ratings yet

- The Influence of The Mixture of Fiber Composition and Secondary Material Resources On The Technological and Mechanical Properties of Fabric Intended For Special ClothingDocument6 pagesThe Influence of The Mixture of Fiber Composition and Secondary Material Resources On The Technological and Mechanical Properties of Fabric Intended For Special ClothingAcademic JournalNo ratings yet

- Jteft 04 00139Document8 pagesJteft 04 00139Momtaz Islam SobujNo ratings yet

- Low Melt PET Blend With Nonrmal Fiber NonwovenDocument11 pagesLow Melt PET Blend With Nonrmal Fiber Nonwovenjothi vel muruganNo ratings yet

- Speach For Technical TextileDocument6 pagesSpeach For Technical TextileAlvy Pervez ZidanNo ratings yet

- Composite Materials Manufacturing Using Textile Inserts With Natural Origins FibresDocument8 pagesComposite Materials Manufacturing Using Textile Inserts With Natural Origins FibresSadikur RahmanNo ratings yet

- Ijftr 37 (3) 231-237 PDFDocument7 pagesIjftr 37 (3) 231-237 PDFPriya LathaNo ratings yet

- Analysis of The Performance Properties of Knitted Fabrics Containing ElastaneDocument18 pagesAnalysis of The Performance Properties of Knitted Fabrics Containing ElastaneSudipto BeheraNo ratings yet

- Investigation of Sound Absorption Properties of Nonwoven Webs Produced From Chicken Feather FibersDocument21 pagesInvestigation of Sound Absorption Properties of Nonwoven Webs Produced From Chicken Feather FibersNilimesh MridhaNo ratings yet

- Recycling of Denim Fabric Wastes Into High-Performance Composites Using The Needle-Punching Nonwoven Fabrication RouteDocument15 pagesRecycling of Denim Fabric Wastes Into High-Performance Composites Using The Needle-Punching Nonwoven Fabrication Routeparus bukhariNo ratings yet

- Effects of Fabric Construction and Shear Thickening Fluid On Yarn Pull-Out From High-Performance FabricsDocument11 pagesEffects of Fabric Construction and Shear Thickening Fluid On Yarn Pull-Out From High-Performance FabricshawNo ratings yet

- Solid / Gas Separation With Fabric FiltersDocument2 pagesSolid / Gas Separation With Fabric FiltersAhmadLuqmanNo ratings yet

- Recycling of Non Woven Waste: Usha Sayed, Sneha ParteDocument5 pagesRecycling of Non Woven Waste: Usha Sayed, Sneha Parteebi18750No ratings yet

- Production and Characterization of CottoDocument31 pagesProduction and Characterization of CottoElona Mea FundarNo ratings yet

- A Novel Air-Jet Texturing+Twisting (AJT) Technology: Ertan ÖZNERGİZ, Salih GÜLŞEN, Mehmet BAYKARA, Alparslan KUTLUDocument6 pagesA Novel Air-Jet Texturing+Twisting (AJT) Technology: Ertan ÖZNERGİZ, Salih GÜLŞEN, Mehmet BAYKARA, Alparslan KUTLUGanesh PothuNo ratings yet

- 10 5923 J Textile 20120105 02Document8 pages10 5923 J Textile 20120105 02Éder Cerqueira StefanonNo ratings yet

- Ijftr 34 (2) 137-143Document7 pagesIjftr 34 (2) 137-143Mohammad HussainNo ratings yet

- Effect of Fiber Length and Blending Method On The Tensile Properties of Ring Spun Chitosan-Cotton Blend YarnsDocument14 pagesEffect of Fiber Length and Blending Method On The Tensile Properties of Ring Spun Chitosan-Cotton Blend YarnshawNo ratings yet

- Sewing Technology: M. S. AhmadiDocument29 pagesSewing Technology: M. S. AhmadidieselakiasNo ratings yet

- Processes and Technology of Yarn PreparationDocument3 pagesProcesses and Technology of Yarn PreparationOpen Access JournalNo ratings yet

- Uster Analysis of Cotton/polyester Blended Spun Yarns With Different CountsDocument14 pagesUster Analysis of Cotton/polyester Blended Spun Yarns With Different CountsQuocHuynhNo ratings yet

- A Pproach TRIBOLOGY BroellDocument5 pagesA Pproach TRIBOLOGY BroellDavid Lopez OaxacaNo ratings yet

- Sustainable Non Woven Fabric Composites For Automotive Textiles Using Reclaimed FIBRESDocument3 pagesSustainable Non Woven Fabric Composites For Automotive Textiles Using Reclaimed FIBRESIJERDNo ratings yet

- Properties and Potential Application of The Mulberry Silk Noil Blended Rotor Yarns For Home Textile ApplicationsDocument13 pagesProperties and Potential Application of The Mulberry Silk Noil Blended Rotor Yarns For Home Textile ApplicationsIJRASETPublicationsNo ratings yet

- 1 s2.0 S2666790821003013 MainDocument8 pages1 s2.0 S2666790821003013 MainImran shaownNo ratings yet

- Fibre Dynamics in The Revolving-Flats Card A Critical ReviewDocument23 pagesFibre Dynamics in The Revolving-Flats Card A Critical ReviewParesh HadkarNo ratings yet

- Electro Magnetic ShieldingDocument20 pagesElectro Magnetic ShieldingHafez HawasNo ratings yet

- Effect of Twist On Yarn PropertiesDocument6 pagesEffect of Twist On Yarn Propertiesali4300136No ratings yet

- Simulation of The Effects of Structural Parameters of Glass Fiber Fabric On The Thermal Insulation PropertyDocument11 pagesSimulation of The Effects of Structural Parameters of Glass Fiber Fabric On The Thermal Insulation PropertyhawNo ratings yet

- YEM 2 (LAB) Group-2Document32 pagesYEM 2 (LAB) Group-2mortuza hasanNo ratings yet

- Recycled Fibers An OverviewDocument6 pagesRecycled Fibers An OverviewAngie DevoreNo ratings yet

- 2012 JCM FrottementDocument13 pages2012 JCM Frottementranim najibNo ratings yet

- Investigation of The Quality Properties of Open-End Spun Recycled Yarns Made From Blends of Recycled Fabric Scrap Wastes and Virgin Polyester FibreDocument12 pagesInvestigation of The Quality Properties of Open-End Spun Recycled Yarns Made From Blends of Recycled Fabric Scrap Wastes and Virgin Polyester FibreJJ SerraltaNo ratings yet

- Effects of Different Count and Stitch Length On Spirality, Shrinkage and GSM of Knit FabricsDocument7 pagesEffects of Different Count and Stitch Length On Spirality, Shrinkage and GSM of Knit FabricsPUGAZHENDHI SNo ratings yet

- Effect of Yarn CountDocument12 pagesEffect of Yarn CountSyed Salahuddin MunnaNo ratings yet

- Methodology For The Selection of Chemical Textile Products: Oscar F. Toro, Alexia Pardo Figueroa & Brigitte M. LaricoDocument8 pagesMethodology For The Selection of Chemical Textile Products: Oscar F. Toro, Alexia Pardo Figueroa & Brigitte M. LaricoTJPRC PublicationsNo ratings yet

- 2 PBDocument17 pages2 PBmegersa jemalNo ratings yet

- Title:: Dust Removal in Spinning Section Department Third Year Textile Engineering Peer Group - 8Document13 pagesTitle:: Dust Removal in Spinning Section Department Third Year Textile Engineering Peer Group - 8gizachew adaneNo ratings yet

- Analysis The Influenced of Plain and Twill StructuDocument7 pagesAnalysis The Influenced of Plain and Twill StructuMuhammad MustahsinNo ratings yet

- Raw Materials of Technical TextilesDocument31 pagesRaw Materials of Technical TextilesTanmoy ChoudhuryNo ratings yet

- Çukurova University Institute of Natural and Applied SciencesDocument68 pagesÇukurova University Institute of Natural and Applied SciencesAhmed HabibNo ratings yet

- Textiles MidtermDocument38 pagesTextiles MidtermcamiayoungNo ratings yet

- Curtains Fringe and Passementerie Strips of Lace Design Elements in Current Height Fashion in Mahalet MarhoumDocument18 pagesCurtains Fringe and Passementerie Strips of Lace Design Elements in Current Height Fashion in Mahalet Marhoumayanogemechu58No ratings yet

- Allaoui 2012Document13 pagesAllaoui 2012ranim najibNo ratings yet

- Sustainable Innovations in Recycled TextilesFrom EverandSustainable Innovations in Recycled TextilesNo ratings yet

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- Bacterial Cellulose: Sustainable Material for TextilesFrom EverandBacterial Cellulose: Sustainable Material for TextilesNo ratings yet

- The Usаge of Vаrious Interаctive Methods in TeаchingDocument6 pagesThe Usаge of Vаrious Interаctive Methods in TeаchingAcademic JournalNo ratings yet

- Gender in The Education SystemDocument6 pagesGender in The Education SystemAcademic JournalNo ratings yet

- Preliminary Information About Dragonflies Fauna Distributed in Kashkadarya RegionDocument6 pagesPreliminary Information About Dragonflies Fauna Distributed in Kashkadarya RegionAcademic JournalNo ratings yet

- Results of Quality of Life Indicators in Patients With OsteoarthritisDocument4 pagesResults of Quality of Life Indicators in Patients With OsteoarthritisAcademic JournalNo ratings yet

- Faoliyat Xavfsizligini Ta'minlash Vositalari XususidaDocument3 pagesFaoliyat Xavfsizligini Ta'minlash Vositalari XususidaAcademic JournalNo ratings yet

- Pedagogical Skills of The Tennis Coach in Effective Organization of Tennis Sports and Health Promotion Activities To Strengthen Women's Social Activity and Health, Which Is Its BasisDocument4 pagesPedagogical Skills of The Tennis Coach in Effective Organization of Tennis Sports and Health Promotion Activities To Strengthen Women's Social Activity and Health, Which Is Its BasisAcademic JournalNo ratings yet

- Psychology Empirical Analysis of The Relationship Between Learning Motives and Attention Qualities Formed in StudentsDocument5 pagesPsychology Empirical Analysis of The Relationship Between Learning Motives and Attention Qualities Formed in StudentsAcademic JournalNo ratings yet

- Internal Affairs Bodies As Subjects of Tort Relations: Theoretical and Legal AnalysisDocument6 pagesInternal Affairs Bodies As Subjects of Tort Relations: Theoretical and Legal AnalysisAcademic JournalNo ratings yet

- Crisis and Disintegration of The Nogai HordeDocument3 pagesCrisis and Disintegration of The Nogai HordeAcademic JournalNo ratings yet

- Welfare Schemes For Tribes in West Bengal (2011-2020)Document6 pagesWelfare Schemes For Tribes in West Bengal (2011-2020)Academic JournalNo ratings yet

- Features of Teaching Probabilistic - Statistical ConseptsDocument5 pagesFeatures of Teaching Probabilistic - Statistical ConseptsAcademic JournalNo ratings yet

- Pleonasm As A Phenomenon of Speech RedundancyDocument4 pagesPleonasm As A Phenomenon of Speech RedundancyAcademic JournalNo ratings yet

- Strengthening Access To Justice: Empowering Citizens and Businesses For Fairness and Effective Dispute ResolutionDocument10 pagesStrengthening Access To Justice: Empowering Citizens and Businesses For Fairness and Effective Dispute ResolutionAcademic JournalNo ratings yet

- Concept of Ibn Al-Arabi "Wahdat Ul-Wujud"Document5 pagesConcept of Ibn Al-Arabi "Wahdat Ul-Wujud"Academic JournalNo ratings yet

- The Role of The Principles of International Environmental Law in The Implementation of Environmental Impact AssessmentDocument4 pagesThe Role of The Principles of International Environmental Law in The Implementation of Environmental Impact AssessmentAcademic JournalNo ratings yet

- Social and Economic Importance of The Formation of Insurance RelationsDocument5 pagesSocial and Economic Importance of The Formation of Insurance RelationsAcademic JournalNo ratings yet

- Impact of Subsidy Removal On Supervision of Schools in NigeriaDocument6 pagesImpact of Subsidy Removal On Supervision of Schools in NigeriaAcademic JournalNo ratings yet

- Unsatisfactory Results After Tympanoplasty Surgery in Patients With Chronic Purulent Otitis MediaDocument4 pagesUnsatisfactory Results After Tympanoplasty Surgery in Patients With Chronic Purulent Otitis MediaAcademic JournalNo ratings yet

- To The Study of Studged Painted Ceramics of The Late Bronze and Early Iron Age in Central AsiaDocument5 pagesTo The Study of Studged Painted Ceramics of The Late Bronze and Early Iron Age in Central AsiaAcademic JournalNo ratings yet

- Expression of Some Phraseological Units of Zoonyms in The Uzbek and German LanguagesDocument6 pagesExpression of Some Phraseological Units of Zoonyms in The Uzbek and German LanguagesAcademic JournalNo ratings yet

- Linguistic and Specific MetaphorsDocument3 pagesLinguistic and Specific MetaphorsAcademic JournalNo ratings yet

- A Contextual Analysis of Stylistic Convergences in J. Dryden's Drama "Aureng-Zebe"Document5 pagesA Contextual Analysis of Stylistic Convergences in J. Dryden's Drama "Aureng-Zebe"Academic JournalNo ratings yet

- Modern Issues of Simultaneous Translation: Theory and PracticeDocument3 pagesModern Issues of Simultaneous Translation: Theory and PracticeAcademic JournalNo ratings yet

- Acquiring German Language Via Making A DialogueDocument3 pagesAcquiring German Language Via Making A DialogueAcademic JournalNo ratings yet

- Similarity and Originality of Works About The Travels of English Enlightener Writers and Uzbek Jadid WritersDocument7 pagesSimilarity and Originality of Works About The Travels of English Enlightener Writers and Uzbek Jadid WritersAcademic JournalNo ratings yet

- Translation Strategies For Pun in William Shakespeare's "King Lear"Document5 pagesTranslation Strategies For Pun in William Shakespeare's "King Lear"Academic JournalNo ratings yet

- MORPHOFUNCTIONAL CHANGES IN THE CORNEA AFTER LONG-TERM WEARING OF CONTACT LENSES, CONTRIBUTING TO THE DEVELOPMENT OF ARTIFICIAL (SECONDARY) DRY EYE SYNDROME (Literature Review)Document6 pagesMORPHOFUNCTIONAL CHANGES IN THE CORNEA AFTER LONG-TERM WEARING OF CONTACT LENSES, CONTRIBUTING TO THE DEVELOPMENT OF ARTIFICIAL (SECONDARY) DRY EYE SYNDROME (Literature Review)Academic JournalNo ratings yet

- Development of Sports Infrastructure in Physical Education and SportsDocument7 pagesDevelopment of Sports Infrastructure in Physical Education and SportsAcademic JournalNo ratings yet

- We Select A Variety For Our Republic From Non-Traditional Types of Cabbage To Obtain A High Yield When Planting Kohlrabi Cabbage in ReplantingDocument4 pagesWe Select A Variety For Our Republic From Non-Traditional Types of Cabbage To Obtain A High Yield When Planting Kohlrabi Cabbage in ReplantingAcademic JournalNo ratings yet

- Principles of Teaching Foreign LanguagesDocument4 pagesPrinciples of Teaching Foreign LanguagesAcademic JournalNo ratings yet

- Fabric NotesDocument5 pagesFabric NotesArpan SrivastavaNo ratings yet

- Water Absorbency Test MethodDocument3 pagesWater Absorbency Test MethodVENKATNo ratings yet

- Fundamentals of Yarn Technology: Learning ObjectivesDocument14 pagesFundamentals of Yarn Technology: Learning ObjectivesSalimNo ratings yet

- Electromagnetic Field Shielding FabricsDocument20 pagesElectromagnetic Field Shielding FabricsJorj PaduraruNo ratings yet

- Comparative Analysis of Fabrics Made From Eli-TwisDocument5 pagesComparative Analysis of Fabrics Made From Eli-TwisMễro ĢANo ratings yet

- Design NptelDocument15 pagesDesign Nptelayu nur khafifahNo ratings yet

- Evaluationofwaterabsorptionandtransportpropertiesofweftknittedpolyesterfabricsbyspontaneousuptakewatertransporttesterandconventionaltestmethods PDFDocument10 pagesEvaluationofwaterabsorptionandtransportpropertiesofweftknittedpolyesterfabricsbyspontaneousuptakewatertransporttesterandconventionaltestmethods PDFAphaiwit KhamlekhitNo ratings yet

- Notebook PDFDocument55 pagesNotebook PDFRitu SinghNo ratings yet

- Yarn Testing in ShortDocument4 pagesYarn Testing in ShortRezaul Karim TutulNo ratings yet

- TCP Testing Protocol-V7.9-20231016Document62 pagesTCP Testing Protocol-V7.9-20231016Quang NguyenDucNo ratings yet

- Coated Nylon Farics PDFDocument26 pagesCoated Nylon Farics PDFRa HulNo ratings yet

- An Assginment On BSTI BangladeshDocument23 pagesAn Assginment On BSTI BangladeshAarya Aust92% (13)

- Important Costing Tips For Garments - Textile LearnerDocument5 pagesImportant Costing Tips For Garments - Textile LearnerKhandaker Sakib Farhad100% (1)

- Bed Linen: Profile No.: 05 NIC Code: 13924Document8 pagesBed Linen: Profile No.: 05 NIC Code: 13924amrish raiNo ratings yet

- Flammability Chart For HIGH RISK FABRICS - August 2017Document1 pageFlammability Chart For HIGH RISK FABRICS - August 2017Rao Fahim NazarNo ratings yet

- Effect of Yarn CountDocument12 pagesEffect of Yarn CountSyed Salahuddin MunnaNo ratings yet

- Card Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246 PDFDocument3 pagesCard Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246 PDFRajatNo ratings yet

- BRFL Textiles PVT LTD: Sample DescriptionDocument1 pageBRFL Textiles PVT LTD: Sample DescriptionNarendraSinghNo ratings yet

- ASTM F 1506-10aDocument5 pagesASTM F 1506-10aaft.tiagokosNo ratings yet

- Tariq Mansoor: Info ProfileDocument6 pagesTariq Mansoor: Info ProfileTariq MansoorNo ratings yet

- Scrim FabaricsDocument10 pagesScrim FabaricsGauri PuranikNo ratings yet

- Lecture 10Document10 pagesLecture 10Arham BajwaNo ratings yet