Professional Documents

Culture Documents

Aluminum Alloys

Aluminum Alloys

Uploaded by

Ashish bhattOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Alloys

Aluminum Alloys

Uploaded by

Ashish bhattCopyright:

Available Formats

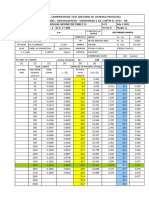

EC Aluminum Wire Data

Aluminum 1350, also referred to as EC (electrical conductor) aluminum, is the primary alloy utilized in aluminum magnet wire. Its

combination of light weight, high thermal conductivity, and high mass electrical conductivity (more than twice that of copper, per

pound), make it an ideal alternative to copper for certain winding applications. Most film insulations are available on round aluminum wire.

For insulation data, see pages 2 and 3. For square aluminum wire data, see page 7.

DIAMETER RESISTANCE

SIZE FEET POUNDS CIRCULAR SIZE

(INCHES) (OHMS PER 1000 FT. AT 20°C) PER PER MILS

(AWG) (AWG)

POUND 1000 FT. NOMINAL

MIN. NOM. MAX. MIN. NOM. MAX.

10 .1009 .1019 .1029 1.58 1.611 1.643 104 9.56 10380 10

11 .0898 .0907 .0916 1.99 2.03 2.07 132 7.57 8230 11

12 .0800 .0808 .0816 2.51 2.56 2.61 166 6.01 6530 12

13 .0713 .0720 .0727 3.17 3.23 3.29 210 4.77 5190 13

14 .0635 .0641 .0647 4.00 4.07 4.15 264 3.78 4110 14

15 .0565 .0571 .0577 5.02 5.13 5.24 333 3.00 3260 15

16 .0503 .0508 .0513 6.36 6.48 6.61 421 2.38 2580 16

17 .0448 .0453 .0458 7.97 8.15 8.33 529 1.89 2050 17

18 .0399 .0403 .0407 10.1 10.3 10.5 669 1.49 1620 18

19 .0355 .0359 .0363 12.7 13.0 13.3 843 1.19 1290 19

20 .0317 .0320 .0323 16.0 16.3 16.6 1060 .942 1020 20

21 .0282 .0285 .0288 20.2 20.6 21.0 1340 .748 812 21

22 .0250 .0253 .0256 25.5 26.1 26.8 1700 .589 640 22

23 .0224 .0226 .0228 32.2 32.8 33.3 2130 .470 510 23

24 .0199 .0201 .0203 40.6 41.4 42.2 2690 .372 404 24

25 .0177 .0179 .0181 51.1 52.2 53.4 3390 .295 320 25

26 .0157 .0159 .0161 64.5 66.2 67.9 4300 .233 253 26

27 .0141 .0142 .0143 81.8 83.0 84.1 5390 .186 202 27

28 .0125 .0126 .0127 103.7 105.3 107.0 6845 .1461 158.8 28

29 .0112 .0113 .0114 128.7 131.0 133.4 8503 .1176 127.7 29

30 .0099 .0100 .0101 164.0 167.3 170.7 10870 .0920 100.0 30

31 .0088 .0089 .0090 206.5 211.2 216.0 13717 .0729 79.21 31

32 .0079 .0080 .0081 255.0 261.4 268.0 16978 .0589 64.00 32

33 .0070 .0071 .0072 322.7 331.8 341.4 21552 .0464 50.41 33

34 .0062 .0063 .0064 408.4 421.5 435.2 27397 .0365 39.69 34

35 .0055 .0056 .0057 514.9 533.4 553.0 34602 .0289 31.36 35

36 .0049 .0050 .0051 643.1 669.1 696.7 43478 .0230 25.00 36

Properties of Aluminum Alloys

Aluminum’s unique combination of properties make it a highly versatile material when alloyed with various metals. Besides light weight,

characteristics of aluminum alloys include excellent workability and inherent corrosion resistance due to the inert oxide coat that forms

directly after exposure to air. Many alloys in the 1000 through 5000 series are non-heat-treatable, their strength depending on the amount

of cold working done. In the case of 5056 alloy, the addition of magnesium as the principal alloying agent increases its initial tensile

strength. Alloy 6061 is a heat-treatable alloy supplied in annealed or strain hardened tempers. The end user may achieve maximum

tensile strength through a multi-step thermal treatment.

ULTIMATE ELECTRICAL COEFFICIENT APPROX.

ELECTRICAL

CHEMICAL COMPOSITION TENSILE CONDUCTIVITY DENSITY SPECIFIC OF THERMAL MELTING

ALLOY RESISTIVITY

(%) STRENGTH IACS (LB/CU IN) GRAVITY EXPANSION X 10-6 POINT

(OHMS-CIRC. MIL/FT)

(PSI) (68°F) (68 - 212°F) (°F)

1350(EC) 99.5 Al min. 13,000 61.8 17 .098 2.7 23.8 1200

1100 .12 Cu, 99 Al min. 13,000 59 18 .098 2.71 23.6 1195

1199 99.996 Al min. 6,800 64.9 15 .0975 2.7 23.6 1220

5056 .12 Mn, 5 Mg, .12 Cr, Al bal. 42,000 29 36 .095 2.64 24.1 1060

6061 .6 Si, .28 Cu, 1 Mg, .2 Cr, Al bal. 17,000 47 22 .098 2.7 23.6 1080

Mechanical and electrical values based on annealed temper.

MWS Wire Industries, 31200 Cedar Valley Drive, Westlake Village, CA 91362 • Phone: 818-991-8553 • Fax: 818-706-0911 • www.mwswire.com 27

Print Revision May 2016

You might also like

- LA City Welder Certification Closed Book Test. 1Document7 pagesLA City Welder Certification Closed Book Test. 1Pipeweldor 1000No ratings yet

- Welding and Heat Treatment of AISI 4130Document66 pagesWelding and Heat Treatment of AISI 4130Дмитрий РыбаковNo ratings yet

- GI Sheet Kg-m2Document1 pageGI Sheet Kg-m2farshan296015100% (1)

- 300zx 1991 FSM SearchableDocument1,248 pages300zx 1991 FSM SearchableMilka Tesla100% (2)

- Clad MetalsDocument1 pageClad MetalsJhunabelle AresgadoNo ratings yet

- Metal SpecificationsDocument1 pageMetal SpecificationsJain EngineeringNo ratings yet

- American Wire Gauge Conductor Size TableDocument6 pagesAmerican Wire Gauge Conductor Size TableGaming PCNo ratings yet

- Sheet Metal Thickness Schedule As Per Smacna: Thinckness in Inches Weight Thickness in MillimetersDocument1 pageSheet Metal Thickness Schedule As Per Smacna: Thinckness in Inches Weight Thickness in MillimetersMuhammedShafiNo ratings yet

- Gauge Vs Current PDFDocument2 pagesGauge Vs Current PDFRnDES1 CML100% (1)

- Tension Wire ChartDocument1 pageTension Wire Chartlaspsieca100% (1)

- Copper WireDocument2 pagesCopper Wiresteve_yNo ratings yet

- Physics RP4 Tensile StrainDocument1 pagePhysics RP4 Tensile StrainNicky.P - PianoNo ratings yet

- Specifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Document3 pagesSpecifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Manish StauffenbergNo ratings yet

- American Conductor StrandingDocument1 pageAmerican Conductor Strandingkariboo karibooxNo ratings yet

- Sheet Metal Gauge ChartDocument4 pagesSheet Metal Gauge Chartahmed100% (1)

- LM6 + 5% Graphite - Tension 3DDocument4 pagesLM6 + 5% Graphite - Tension 3DHareesh R IyerNo ratings yet

- Discount Steel: Gage Number ConversionDocument1 pageDiscount Steel: Gage Number ConversionOliver HermosaNo ratings yet

- AWG - American Wire Gauge vs. Circular MilsDocument8 pagesAWG - American Wire Gauge vs. Circular MilsHew LetNo ratings yet

- SW G DetailsDocument2 pagesSW G Detailsashish_patel111No ratings yet

- AAAC 6201 Type A3 IEC61089Document1 pageAAAC 6201 Type A3 IEC61089Proteksitrans1 p3bsNo ratings yet

- Triaxial STA 2+575Document8 pagesTriaxial STA 2+575rismanNo ratings yet

- Bored PileDocument13 pagesBored PileFrederick TanNo ratings yet

- Triaxial STA 2+875Document11 pagesTriaxial STA 2+875rismanNo ratings yet

- AWG Specifications TableDocument6 pagesAWG Specifications TablediegojhonathanNo ratings yet

- Circular Tubes: (From Kaliti Steel-Mill)Document1 pageCircular Tubes: (From Kaliti Steel-Mill)Eng Abdikarim WalhadNo ratings yet

- SWG To MM - Standard Gauge To MM ConversionDocument3 pagesSWG To MM - Standard Gauge To MM ConversionMRSUPERCOOLNo ratings yet

- Triaxial STA 2+300Document8 pagesTriaxial STA 2+300rismanNo ratings yet

- 002-INTERPIPE SteelDocument32 pages002-INTERPIPE Steeljorge merinoNo ratings yet

- Electrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMDocument1 pageElectrical Wire Sizes AWG Diameter Cross-Sectional Area Mils Inches MM Cmils MMccorp0089No ratings yet

- SWG & Awg TableDocument2 pagesSWG & Awg TableSEHMI14100% (6)

- Products: Blue Strand Class 6x36 Steel CoreDocument1 pageProducts: Blue Strand Class 6x36 Steel Coreindra smiNo ratings yet

- P3 50x50 D125 40 M GrafDocument2 pagesP3 50x50 D125 40 M GrafGilmar BastidasNo ratings yet

- Mathcad - 0-B. Weight and Area of RebarDocument1 pageMathcad - 0-B. Weight and Area of RebarMrAlittle FingerNo ratings yet

- BWG TableDocument1 pageBWG Tablealkeshpatel_731yahooNo ratings yet

- AWG Specifications TableDocument6 pagesAWG Specifications TableMaralo SinagaNo ratings yet

- American Strand ConstructionDocument1 pageAmerican Strand Constructionpratul acharyaNo ratings yet

- 20CV080 MOS Navnath PandharmiseDocument41 pages20CV080 MOS Navnath PandharmiseYashvardhan TodmalNo ratings yet

- American Wire GaugeDocument3 pagesAmerican Wire Gaugeعلي القحطانيNo ratings yet

- Northeast Power Systems, Inc.: 66 Carey Road, Queensbury, NYDocument12 pagesNortheast Power Systems, Inc.: 66 Carey Road, Queensbury, NYkponramNo ratings yet

- Short Time Current Rating of ConductorDocument12 pagesShort Time Current Rating of ConductorAbhinav SinhaNo ratings yet

- MSCL Pipes JKR-DimensionDocument1 pageMSCL Pipes JKR-DimensionChee Soon LeeNo ratings yet

- Codigo de Colores CableadoDocument8 pagesCodigo de Colores CableadoLed Alcalá100% (3)

- American Wire GaugeDocument1 pageAmerican Wire GaugeNoriel CorreaNo ratings yet

- Copper Cable Tech. DetailsDocument8 pagesCopper Cable Tech. DetailsDaya CheluvaNo ratings yet

- Aaac 6201 Type A2 Iec 61089Document1 pageAaac 6201 Type A2 Iec 61089Ayub HasersNo ratings yet

- Acero Carga (kg) b (mm) h = Espesor (mm) h Anchura (mm) Area (mm) σ (kg/mm2) h / hDocument19 pagesAcero Carga (kg) b (mm) h = Espesor (mm) h Anchura (mm) Area (mm) σ (kg/mm2) h / hSANDRA XIMENA PEREZ PERALTANo ratings yet

- Conductors in Raceway in Free AirDocument18 pagesConductors in Raceway in Free AirAngel CalderonNo ratings yet

- DC VoltageDropCalculatorDocument5 pagesDC VoltageDropCalculatorkieden.juriahNo ratings yet

- Kuat Hantar Arus Aac Ec 1350 Jis C 3109Document1 pageKuat Hantar Arus Aac Ec 1350 Jis C 3109Muhamad ZainudinNo ratings yet

- No. Peak Intensity Corr. Intensity Base (H) Base (L) Area Corr. AreaDocument2 pagesNo. Peak Intensity Corr. Intensity Base (H) Base (L) Area Corr. AreaZakenia Khairunnisa FalahNo ratings yet

- iWASH Civil Works and Sanitation and Hygiene Programming: D R Watsan HubDocument40 pagesiWASH Civil Works and Sanitation and Hygiene Programming: D R Watsan Hubsheil.cogayNo ratings yet

- Table 8 Conductor Properties: Chapter 9 - TablesDocument1 pageTable 8 Conductor Properties: Chapter 9 - Tablesknucless1No ratings yet

- mm2 To AWG KcmilDocument2 pagesmm2 To AWG KcmilmaninderpreetNo ratings yet

- Jis g3466-3Document1 pageJis g3466-3Nhuận PhạmNo ratings yet

- American Wire GaugeDocument2 pagesAmerican Wire GaugeprakasharmyNo ratings yet

- 2020 Dwyer Catalog - Rev.12 PDFDocument500 pages2020 Dwyer Catalog - Rev.12 PDFVu Duc ThuongNo ratings yet

- Jack DataDocument11 pagesJack DataKhizer IslamNo ratings yet

- Branch CableDocument8 pagesBranch CablevirgiawanpubgNo ratings yet

- 20CV321-MOS-Kaware AkshayDocument68 pages20CV321-MOS-Kaware AkshayYashvardhan TodmalNo ratings yet

- Endurance Dyform 2018PIDocument1 pageEndurance Dyform 2018PIThanhdong DoNo ratings yet

- AnchorIndustries LR Ch2Document3 pagesAnchorIndustries LR Ch2skylineshareNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Construction Dewatering and Groundwater Control - 2007 - Powers - Appendix A Friction Losses For Water Flow Through PipeDocument6 pagesConstruction Dewatering and Groundwater Control - 2007 - Powers - Appendix A Friction Losses For Water Flow Through PipeBhushan KalgaonkarNo ratings yet

- Adt CNC 4620Document103 pagesAdt CNC 4620Bhushan KalgaonkarNo ratings yet

- Chapter1-Introduction To MLDocument15 pagesChapter1-Introduction To MLBhushan KalgaonkarNo ratings yet

- Furnaces and RefractoriesDocument56 pagesFurnaces and RefractoriesBhushan KalgaonkarNo ratings yet

- Used Taiwan FS 2 CNC Turning Center - Chuck Diameter - 200 MM For Sale at Best Prices - VendaxoDocument2 pagesUsed Taiwan FS 2 CNC Turning Center - Chuck Diameter - 200 MM For Sale at Best Prices - VendaxoBhushan KalgaonkarNo ratings yet

- Status Display by Self Diagnostic Display: Symbol PMC Address M T Signal NameDocument1 pageStatus Display by Self Diagnostic Display: Symbol PMC Address M T Signal NameBhushan KalgaonkarNo ratings yet

- Luna Introduction Catalogue 2020Document38 pagesLuna Introduction Catalogue 2020Bhushan KalgaonkarNo ratings yet

- 3000 L Colchester Parameters-1Document6 pages3000 L Colchester Parameters-1Bhushan Kalgaonkar100% (1)

- OTb DiagonsticDocument2 pagesOTb DiagonsticBhushan KalgaonkarNo ratings yet

- LongShaft Motor CatalogDocument3 pagesLongShaft Motor CatalogBhushan KalgaonkarNo ratings yet

- Farm Duty Motors: TEFC (IP55) Single Phase: DescriptionDocument2 pagesFarm Duty Motors: TEFC (IP55) Single Phase: DescriptionBhushan KalgaonkarNo ratings yet

- Eltex Sales: Manufacturers & Traders of Spare Parts For All Kinds of Monoblocks & PumpsDocument2 pagesEltex Sales: Manufacturers & Traders of Spare Parts For All Kinds of Monoblocks & PumpsBhushan KalgaonkarNo ratings yet

- ICSE Board Class 8 Physics Syllabus PDFDocument15 pagesICSE Board Class 8 Physics Syllabus PDFBhushan KalgaonkarNo ratings yet

- Temp Resis ChartDocument1 pageTemp Resis ChartBhushan KalgaonkarNo ratings yet

- Cam Follower BearingDocument1 pageCam Follower BearingBhushan KalgaonkarNo ratings yet

- Compact Enclosures AE Stainless Steel - AE 1014.600: Date: Jan 22, 2020Document3 pagesCompact Enclosures AE Stainless Steel - AE 1014.600: Date: Jan 22, 2020Luis Alberto Alzate CeballosNo ratings yet

- Water Quality GuidelinesDocument9 pagesWater Quality GuidelinesANTONIO NAVARRONo ratings yet

- Influence of Cooling Rate On The Structure and Formation of Oxide Scale in LowDocument7 pagesInfluence of Cooling Rate On The Structure and Formation of Oxide Scale in LowVarun MangaloreNo ratings yet

- 410 Spec SheetDocument4 pages410 Spec SheetDavid CabreraNo ratings yet

- Juno Lighting Trac-Master Catalog 1988Document48 pagesJuno Lighting Trac-Master Catalog 1988Alan MastersNo ratings yet

- Heat TreatingDocument7 pagesHeat TreatingSachinNo ratings yet

- Composite Materials of Al 7075 TiB2 TiCDocument3 pagesComposite Materials of Al 7075 TiB2 TiCD.T. karthickNo ratings yet

- AWS 7 The Everyday Pocket Handbook For Shielded Metal Arc WeldingDocument33 pagesAWS 7 The Everyday Pocket Handbook For Shielded Metal Arc WeldingScott NorrisNo ratings yet

- Edm English PDFDocument13 pagesEdm English PDFEstherNo ratings yet

- RTD Resistance TableDocument7 pagesRTD Resistance TableJp NairNo ratings yet

- EXTRACTIVEDocument34 pagesEXTRACTIVEraj mehra100% (1)

- HVOF Metalisation - Engineering ApplicationsDocument4 pagesHVOF Metalisation - Engineering ApplicationsAlexandar MarinkovicNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceGerman FavelaNo ratings yet

- Titanium Boron Aluminium Grain Refiners: Alloy Designation Color Code Ti B Si Fe V Others Each Total FormDocument1 pageTitanium Boron Aluminium Grain Refiners: Alloy Designation Color Code Ti B Si Fe V Others Each Total FormsreedharNo ratings yet

- Glass Blend ShoutingDocument7 pagesGlass Blend Shoutingkaveh-bahiraeeNo ratings yet

- Hand BookDocument300 pagesHand BookGregEverett2No ratings yet

- Lecture 06 - Types of Permanent Mold Casting ProcessesDocument26 pagesLecture 06 - Types of Permanent Mold Casting ProcessesThe NoobNo ratings yet

- Workshop Technology Lab Viva Questions and AnswersDocument5 pagesWorkshop Technology Lab Viva Questions and AnswersDe vil100% (3)

- Heat Conservation in Liquid IronDocument2 pagesHeat Conservation in Liquid Ironarnaldorcr8646No ratings yet

- En 755-1 PDFDocument18 pagesEn 755-1 PDFVIJAYAKUMAR T100% (1)

- Tata Steel Is - 26MnB5 HR - Data Sheet enDocument2 pagesTata Steel Is - 26MnB5 HR - Data Sheet enGopi KrishnanNo ratings yet

- Theories of Machine - S.s.rattanDocument16 pagesTheories of Machine - S.s.rattanRohitsingh JadaunNo ratings yet

- Bohler S EMK 6Document1 pageBohler S EMK 6Enaam AtaallahNo ratings yet

- BORTE General Catalogue V4.2 PDFDocument147 pagesBORTE General Catalogue V4.2 PDFKeneth Samson Del CarmenNo ratings yet

- Low Energy Arc Joining Process For Materials Sensitive To HeatDocument5 pagesLow Energy Arc Joining Process For Materials Sensitive To Heatg4okk8809No ratings yet

- MCQ in Machine Design and Shop Practice Part 16 ME Board ExamDocument17 pagesMCQ in Machine Design and Shop Practice Part 16 ME Board Examtagne simo rodrigueNo ratings yet

- Reutilisation of Bayer Red Mud As Moulding Material in Green Sand Casting Process-An Experimental StudyDocument8 pagesReutilisation of Bayer Red Mud As Moulding Material in Green Sand Casting Process-An Experimental Studynamrata chokakkarNo ratings yet

- Metal Partion WallDocument28 pagesMetal Partion WallTanishq RathodNo ratings yet