0% found this document useful (0 votes)

158 views18 pagesOverview of Internal Combustion Engines

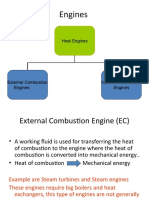

The document discusses internal combustion engines. It describes how internal combustion engines work by combusting fuel inside the engine, unlike external combustion engines which combust fuel outside the engine. It then discusses the classification, parts, nomenclature, and working principles of 4-stroke gasoline (Otto cycle) and diesel (Diesel cycle) internal combustion engines. The 4 strokes are intake, compression, power, and exhaust. It compares gasoline and diesel engines, noting differences in their fuel, ignition method, compression ratio, and fuel introduction process.

Uploaded by

Ajith KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

158 views18 pagesOverview of Internal Combustion Engines

The document discusses internal combustion engines. It describes how internal combustion engines work by combusting fuel inside the engine, unlike external combustion engines which combust fuel outside the engine. It then discusses the classification, parts, nomenclature, and working principles of 4-stroke gasoline (Otto cycle) and diesel (Diesel cycle) internal combustion engines. The 4 strokes are intake, compression, power, and exhaust. It compares gasoline and diesel engines, noting differences in their fuel, ignition method, compression ratio, and fuel introduction process.

Uploaded by

Ajith KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd