Professional Documents

Culture Documents

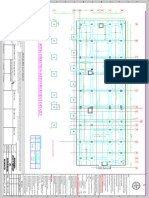

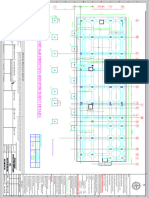

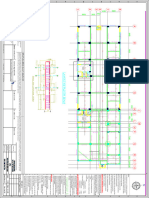

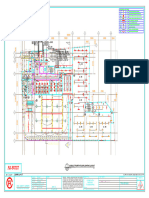

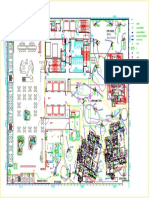

Raft Slab Layout

Uploaded by

DINESH M.NCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raft Slab Layout

Uploaded by

DINESH M.NCopyright:

Available Formats

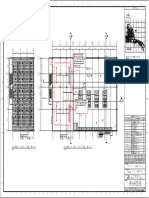

N

J M

A B C D E F G H E L N P Q R S T U

1020 1200

9900 9900 3240 4000 2660 9900 9830 1850 4500 2420 2580 7250 6600 3450

Notes:

86300

32050 1.All dimensions are in millimeters and levels

are in meters unless otherwise specified.

1150

2.Drawing shall not be scaled, only written

8 1050

B1 B1 B1 B1 B1 B1 B1 B1 B1 B1

dimensions to be followed.

3.Any Error or Discrepancies in the

P1 P1 P1 P1 P1 P1 P1 P1 P1 P1 P1

Drawings are to be brought to the notice.

of the Architect/ Engineers.

6900

SBC-320KN/M2 4. This drawings shall not be used other than

B1

B1

B1

B1

B1

B1

B1

B1

B1

B1

B1

the purpose marked/issued specified.

5. The drawings to be read with conjuction

7 P4

B1

P1

B1

P1

B1

P2

B1

P1

B1

P1

B1

P1

B1

P1

B1

P1

B1

P1

B1

P1

with structural drawings.

6. All the drawings prepared by Design

and structural consultants are as per

4250

B4

NBC norms and guidelines.

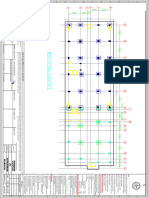

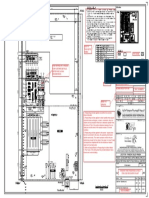

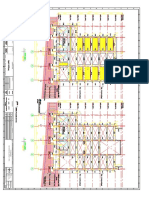

RAFT 650 THICK REMOVAL OF FORMWORK(SHUTTERING) :

6

B2

B2

B2

B2

B1

B1

B1

B1

27500

Shuttering of any part of the structure shall not be

S.W2

2000

1200X1800 BEAM removed until the concrete attains 70% of the specified

5 3000X1800 PEDESTAL

strength of concrete however the following minimum

period (after final pour ) shall be allowed before

removal of shuttering as per clause 11.3.1, is 456:2000

3650

B4

P1 A. Vertical side of shuttering of columns,walls & beams

- 24 hours

4 B2 B2 B2 B2 B2 B3 B3 B3 B1 B. Bottom shuttering of slabs (keeping the props)

- 3 days

P2 P2 P2 P2 P1 P1 C. Bottom shuttering of beams (keeping the props)

- 7 day

D. Props to slabs :

B1

B1

B4

6900

B1

B1

i .spanning upto 4.5 m - 7 days

B4

B4

B4

B4

B4

i i .spanning over 4.5 m - 14 days

E. Props to beams & arches :

P1

i .spanning upto 6 m - 14 days

B1 B1 B4 B4 B1

3 P2 B2

P4

B4 B4 B4

P1

i i.spanning over 6 m

LAP JOINTS FOR REINFORCEMENT BARS :

- 21 days

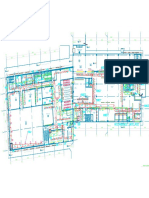

RAFT LINE

3290

1. At any cross section of the member,not more than

50% of the bars shall be lapped.

2 2. Laps shall be staggered with a minimum centre to

centre distance of 1.3 times lap length of the bar for

PCC LINE tension & compression members.

3. Development length (ld) shall be as per (sp:34-1999)

NF2 NF1 NF1 NF1 NF2 table below:

NF1 NF1 NF1

a) Development length for column bars - 40d

b) Development length for beam bars - 50d

4. Laps in columns shall be provided at mid height of

floor and not at slab level .

11105

5. Laps in beams and slabs shall be provided at the

point of contraflexure.

6. Welding of bars shall be done as a stitch weld for 5

3000 times diameter of bar and a gap of 5 times higher

2700

1500 diameter bar and again welding for another 5 times

1350

diameter of bar using arc welding and special

electrodes after obtaining prior written approval from

1350

the structural designer.

1

3000

2700

7. Detailing of rebars shall confirm to sp-34 & is 13920.

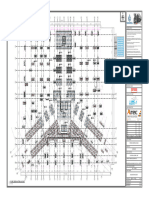

GENERAL NOTES:

NF2 1. Concrete grade shall be M35(design mix) confirming to

NF1 NF1 NF1 NF1 NF1 NF2 M-35 GRADE CONCRETE is 456:2000

2. Minimum cement content = 380 kg/m3.

3. Min.grade of reinforcement marked thus (y) shall be Fe

550D confirming to IS 1786-1985

LAYOUT COLUMNS-BEAM SLAB , RC WALLS & FOOTING 4. Clear cover for reinforcement

01 SCALE: NTS a) Column = 40mm d) Raft slab bottom = 75mm

b) R.C wall = 40mm e) Raft slab top = 50mm

c) Shear wall = 40mm

This drg. read in conjection with arch.drgs.

FOOTING SCHEDULE :

5. Raft & Columns are designed for Ground + Mezzanine +

FOOTING Four floor loads only.

SI. FOOTING REINFORCEMENT NO OF 6. SBC of the soil is taken as 320kN / sqm. @ 2.40m below

NO. NAME FOOTING SIZE X = LONGER DIRECTION FOOTING from N.G.L. as per soil report.

Y = SHORTER DIRECTION

7. Spacer bar - 25mm dia to be provided in between two

Y20 @ 125 C/C

01 NF1 2000 x 2000 BOTTOM - 14 layer of reinforcement at every 750mm c/c

BOTHWAYS

Y16 @ 150 C/C

8. Structural engineer responsibility is limited to design &

D = 750 TOP - BOTHWAYS issual of structural drawing only

9. Onus of construction lies with contractor/owner

10. For concreting water cement ratio should be (0.45) (for

1bag cement= max-25 lit of water only to be added.)

NOTES STRUCTURAL DESIGN QUALITY ASSURANCE

REVISIONS

Notice of no objection from Southern Railways Katpadi is being accorded for design principles based on the The drawing has been prepared based on actual site survey and other terms and conditions of the EPC Agreement. Responsibility of accuracy, correctness , This drawing including its design and detailing has been checked in accordance with the requirements of EPC Agreement and found

recommendations of the Architect/Lead Designer and proposal by the Contractor. However, the completeness, integrity and full compliance with byelaws, standards, statutory, regulations of relevant Codes & Manuals/ Rules and as per EPC Agreement suitable for the execution purpose. The overall responsibility of correctness of design,detailing and compliance with EPC agreement R.NO DATE DESCRIPTION

overall responsibility and design accuracy lies with the contractor (Engineering Projects (india) Pvt Ltd) provisions, rests with the Design Consultants and the Contractor without any financial implications. rests with the Structural Design Consultant and Contractor.

CLIENT: PROJECT: EPC Contractor: DESIGN CONSULTANT Authority Engineer (PMS) AXEN CN/MAS DY. CE CN/MAS CE CN/MAS

Drawing Title :

SOUTHERN RAILWAYS, REDEVELOPMENT OF ENGINEERING PROJECTS M/S VOYANTS SOLUTIONS PVT. LTD.

KATPADI. KATPADI JUNCTION (INDIA) LTD-CHENNAI Drawing Type :

Drawing No.: Scale: 1:100 Date: 12.12.23

Drawing Purpose: Sheet Size: A2 Rev. No: R0

AGM DESIGN DIRECTOR TEAM LEADER LEAD DESIGNER

You might also like

- Raft Slab Top Bars DetailsDocument1 pageRaft Slab Top Bars DetailsDINESH M.NNo ratings yet

- Raft Slab Bottom Long Bars DetailsDocument1 pageRaft Slab Bottom Long Bars DetailsDINESH M.NNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- Plinth Beam LayoutDocument1 pagePlinth Beam LayoutDINESH M.NNo ratings yet

- Foundation Plan Roof Beam Plan: Jomar R. MercialesDocument1 pageFoundation Plan Roof Beam Plan: Jomar R. MercialesJaypee MoradaNo ratings yet

- LIGHTING 4Document1 pageLIGHTING 4jpsablan.gccmNo ratings yet

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Document1 pagePile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiNo ratings yet

- A B C D E F G: Northern IloiloDocument1 pageA B C D E F G: Northern IloiloDan Ney HuboNo ratings yet

- Compressor ShelterDocument3 pagesCompressor ShelterHUSSEIN FNEISHNo ratings yet

- RC Wall LayoutDocument1 pageRC Wall LayoutDINESH M.NNo ratings yet

- Document 1Document1 pageDocument 1MUQEET ahmedNo ratings yet

- 01-04-2024 Layout Sinotrans (Rev 4)Document1 page01-04-2024 Layout Sinotrans (Rev 4)Hans HendryanNo ratings yet

- Apcu & Emergency First FloorDocument1 pageApcu & Emergency First Floorvenkat rajuNo ratings yet

- A A A A F B C D E: Chiller Cooling System DiagramDocument1 pageA A A A F B C D E: Chiller Cooling System DiagramRor GiftsNo ratings yet

- Document overview of structural steel drawingsDocument1 pageDocument overview of structural steel drawingsSuman JanaNo ratings yet

- Retaining Wall Design and DimensionsDocument1 pageRetaining Wall Design and Dimensionsاحمد خليفة خليفةNo ratings yet

- C D B A: BEAM RB1 (600x225)Document1 pageC D B A: BEAM RB1 (600x225)Sampath S. WickramanayakaNo ratings yet

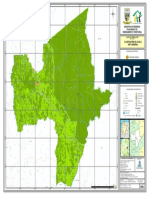

- Base Palma Real Imagen SentinelDocument1 pageBase Palma Real Imagen SentinelEdwin Quispe CahuanticoNo ratings yet

- A2 PDFDocument1 pageA2 PDFCRISCHOUEL ALIMORONGNo ratings yet

- Water Tank Specifications and Parking LayoutDocument1 pageWater Tank Specifications and Parking LayoutMUBASHIRNo ratings yet

- Plan UTILAJEDocument1 pagePlan UTILAJETudor SerbanNo ratings yet

- Victoria Shanghai Academy School Building 9/F Blueprint PlanDocument1 pageVictoria Shanghai Academy School Building 9/F Blueprint PlanZwaaknqNo ratings yet

- Warehouse - Level 01 Columns & Walls Setting Out Plan - Part-1 1Document1 pageWarehouse - Level 01 Columns & Walls Setting Out Plan - Part-1 1projects sureshNo ratings yet

- TIC Pre-Fab Shed 20.12.17-Model - PDF A-1Document1 pageTIC Pre-Fab Shed 20.12.17-Model - PDF A-1Habibur RahmanNo ratings yet

- Mgc-rl2-Sds-cvl-022 Rev.00 - Glass Balustrade Handrail at First Floor - Th43Document4 pagesMgc-rl2-Sds-cvl-022 Rev.00 - Glass Balustrade Handrail at First Floor - Th43jijinsNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- 000 Prel 5s Working DiagramDocument1 page000 Prel 5s Working Diagramakshay kadbeNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- Ar-1.0 - Grand Parkplace Lower Ground Floor Plan W Column - Option 2Document1 pageAr-1.0 - Grand Parkplace Lower Ground Floor Plan W Column - Option 2Gelsey UyNo ratings yet

- Toilet: Block ADocument1 pageToilet: Block Aidesign advertisingNo ratings yet

- Approved For Construction: D A D ADocument1 pageApproved For Construction: D A D AamirNo ratings yet

- Passive Fire Proofing Layout For Proposed EquipmentsDocument1 pagePassive Fire Proofing Layout For Proposed EquipmentsVenkat RanganNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06001 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06001 (A)hemanthsridharaNo ratings yet

- 03A Clasificación Del Suelo Vista GeneralDocument1 page03A Clasificación Del Suelo Vista GeneralANGIE D. ZAMBRANO C.No ratings yet

- FP SDP 20X30 PalanogbirthinghomeDocument1 pageFP SDP 20X30 Palanogbirthinghomeflor johnNo ratings yet

- 2NDFLOOR CVMC MAIN-mergedDocument4 pages2NDFLOOR CVMC MAIN-mergedRafaela VillanuevaNo ratings yet

- B - Ar-2 PlanDocument1 pageB - Ar-2 PlanAlexxis LipuraNo ratings yet

- Nenmong Tranphucduy FinallyDocument1 pageNenmong Tranphucduy FinallyPhúc DuyNo ratings yet

- KIC 20F 冷氣風咀配置圖-1 (26-1-2022)Document1 pageKIC 20F 冷氣風咀配置圖-1 (26-1-2022)Wilson YanNo ratings yet

- Denah Instalasi Sistem Antrian R1-LT 1Document1 pageDenah Instalasi Sistem Antrian R1-LT 1Jafar SidiqNo ratings yet

- Cyclone Raw MillDocument1 pageCyclone Raw MillADOFSLNo ratings yet

- Backup Assignment Working Drawing 2 1211267Document1 pageBackup Assignment Working Drawing 2 1211267Nabil SyadiqNo ratings yet

- Box Culvert 2X2Document6 pagesBox Culvert 2X2abhishek singhNo ratings yet

- 29-0034920-B002 - b-XR-PERI UP For Level 4 High ShoringDocument1 page29-0034920-B002 - b-XR-PERI UP For Level 4 High ShoringPaplu PaulNo ratings yet

- Double Side Al Khalij-Layout1Document1 pageDouble Side Al Khalij-Layout1Albader .MNo ratings yet

- 1251 A 301 Sections A 3011410933459381Document1 page1251 A 301 Sections A 3011410933459381Fadi AlatrashNo ratings yet

- MATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesDocument1 pageMATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesJonathanSaucedoNo ratings yet

- Majd Maher Anbar: W1 W1 W2 W1 W1 W2Document1 pageMajd Maher Anbar: W1 W1 W2 W1 W1 W2Majd AnbarNo ratings yet

- AIR KOTORDocument1 pageAIR KOTORAsep fauzanNo ratings yet

- POSITE INSTALATION LAYOUT 102 28.09.2022 - CommentDocument1 pagePOSITE INSTALATION LAYOUT 102 28.09.2022 - CommentrenvouzNo ratings yet

- Detail A Option 2 Option 1: 5000 12cm 12cmDocument1 pageDetail A Option 2 Option 1: 5000 12cm 12cmCasmir TayagNo ratings yet

- A1Document1 pageA1Mary FelicianoNo ratings yet

- Chabari ZKDocument1 pageChabari ZKGershon ZebedeeNo ratings yet

- Archtctrl P3 - UpdtdDocument1 pageArchtctrl P3 - Updtdchedita obiasNo ratings yet

- Steel beam structural diagramDocument1 pageSteel beam structural diagrambert cruzNo ratings yet

- Bo Cuc Ban Ve Tham KhaoDocument1 pageBo Cuc Ban Ve Tham Khao21149257No ratings yet

- Speakers UpdatedDocument1 pageSpeakers UpdatedDINESH M.NNo ratings yet

- We Confirm This Footing After Do This WorkDocument1 pageWe Confirm This Footing After Do This WorkDINESH M.NNo ratings yet

- Kalidas Selvaperumal: About Me ContactDocument5 pagesKalidas Selvaperumal: About Me ContactDINESH M.NNo ratings yet

- Kalidas Selvaperumal: About Me ContactDocument5 pagesKalidas Selvaperumal: About Me ContactDINESH M.NNo ratings yet

- Ce 6002 CT QBDocument27 pagesCe 6002 CT QBrajivkannanNo ratings yet

- Interior Design WoodDocument48 pagesInterior Design Wood4uengineerNo ratings yet

- Schedule Delay in Construction Project Using TIADocument97 pagesSchedule Delay in Construction Project Using TIAfarhanyazdaniNo ratings yet

- Astm C94Document14 pagesAstm C94Ali ArsalanNo ratings yet

- 8 BibiliografieDocument4 pages8 BibiliografiesamiNo ratings yet

- C EngrNB Antiquated Stuart Sept08 PDFDocument4 pagesC EngrNB Antiquated Stuart Sept08 PDFJason PowellNo ratings yet

- Bendable Concrete PDFDocument14 pagesBendable Concrete PDFKunal Bathija100% (24)

- Sagar Final PPT FullDocument13 pagesSagar Final PPT FullPramod Kumar HTNo ratings yet

- Masonry Works Materials Quantities and Cost EstimatesDocument12 pagesMasonry Works Materials Quantities and Cost EstimatesAsher MileyNo ratings yet

- Lateral pressures for 15 ft concrete wall to ACI 347R-14Document1 pageLateral pressures for 15 ft concrete wall to ACI 347R-14Raja RajanNo ratings yet

- Course 46420 - Lecture Plan - Autumn 2012Document1 pageCourse 46420 - Lecture Plan - Autumn 2012Rashid KhanNo ratings yet

- IRC 112 Creep Shrinkage Manual Calculation Vs Midas Civil ValuesDocument5 pagesIRC 112 Creep Shrinkage Manual Calculation Vs Midas Civil ValuesDhimas Surya NegaraNo ratings yet

- Influence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsDocument11 pagesInfluence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsJohn GiannakopoulosNo ratings yet

- Boundary Wall (Final)Document1 pageBoundary Wall (Final)Engineering CivilMantra100% (1)

- Low Strength Infill: Specification 410Document11 pagesLow Strength Infill: Specification 410alejandraoy9No ratings yet

- Cebacom 2022 676Document4 pagesCebacom 2022 676Asif KhanNo ratings yet

- Analisis Kuat Lekat Tulangan Bambu Ori Bertakikan Tipe "U"Jarak Takikan 10 CM Terhadap Tulangan Baja Yudha Krakata, Agus Setiya Budi, Slamet PrayitnoDocument8 pagesAnalisis Kuat Lekat Tulangan Bambu Ori Bertakikan Tipe "U"Jarak Takikan 10 CM Terhadap Tulangan Baja Yudha Krakata, Agus Setiya Budi, Slamet PrayitnoOcta IrawanNo ratings yet

- Types of Cement: Advanced Concrete Technology CE484/CE684Document24 pagesTypes of Cement: Advanced Concrete Technology CE484/CE684Gyanesh PatnaikNo ratings yet

- Is.459.1992 - Asbestos Sheet Specs PDFDocument15 pagesIs.459.1992 - Asbestos Sheet Specs PDFcharanNo ratings yet

- Waiting ShedDocument2 pagesWaiting ShedCristina Dangla CruzNo ratings yet

- LEADING SUPPLIER OF LUMBER AND WOOD PRODUCTSDocument12 pagesLEADING SUPPLIER OF LUMBER AND WOOD PRODUCTSerleosNo ratings yet

- B001586 CT ISGEC 103 - Pour - Card - FormatDocument4 pagesB001586 CT ISGEC 103 - Pour - Card - Formatsyed sulemanNo ratings yet

- Construction and Building Materials: Muhd Fadhil Nuruddin, Norzaireen Mohd Azmee, Chang Kok YungDocument6 pagesConstruction and Building Materials: Muhd Fadhil Nuruddin, Norzaireen Mohd Azmee, Chang Kok YungMarden Rengifo RuizNo ratings yet

- Prestressing Classification and MaterialsDocument12 pagesPrestressing Classification and MaterialsognjenristicNo ratings yet

- 265 HcsDocument3 pages265 HcsNaveen NunnaNo ratings yet

- FRP Lamella V3 Manual EngDocument96 pagesFRP Lamella V3 Manual EngNaida AdemovicNo ratings yet

- Construction CalculatorDocument7 pagesConstruction CalculatorholyNo ratings yet

- Superstructure Concrete Quality Control Plan ChecklistDocument5 pagesSuperstructure Concrete Quality Control Plan ChecklistallennicoleNo ratings yet

- As 3972-2010Document29 pagesAs 3972-2010Yuvaraj Dhandapani100% (2)

- On MIX DesignDocument27 pagesOn MIX DesignGaurav naddaNo ratings yet