Professional Documents

Culture Documents

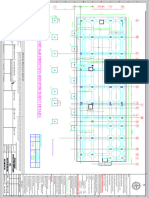

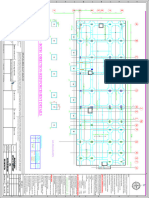

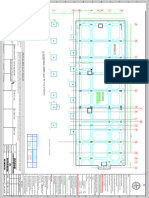

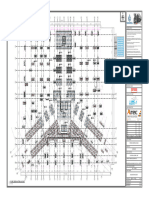

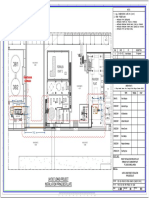

Plinth Beam Layout

Uploaded by

DINESH M.NOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plinth Beam Layout

Uploaded by

DINESH M.NCopyright:

Available Formats

N

J M

A B C D E F G H E L N P Q R S T U

1020 1850 1200

9900 9900 3240 4000 2660 9900 9830 4500 2420 2580 7250 6600 3300 2200 2200 Notes:

1.All dimensions are in millimeters and levels

are in meters unless otherwise specified.

2.Drawing shall not be scaled, only written

dimensions to be followed.

8

PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB7= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900'P PB3= 400 X 900

3.Any Error or Discrepancies in the

400

400

400

500

500

Drawings are to be brought to the notice.

170 380

PB3= 400 X 900

of the Architect/ Engineers.

PB3= 400 X 900

PB3= 400 X 900

B3= 400 X 900

300 400 4500 300 4550 500 4575 300 4695 380 4662 300 4513 500 4512 300 4663 380 7470 500 4000 775 6875 500 6150 500 4970 380

PB7= 400 X 900

PB2= 300 X 750

PB4= 500 X 900

PB4= 500 X 900

PB3= 400 X 900

PB4= 500 X 900

PB7= 400 X 900

PB9= 400 X 900

6900

PB7= 400 X 900

PB8= 400 X 900

4. This drawings shall not be used other than

6700

6700

6500

6500

the purpose marked/issued specified.

500 5. The drawings to be read with conjuction

with structural drawings.

7 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB8= 400 X 900 PB7= 400 X 900 B5= 500 X 900 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB7= 400 X 900

PB3= 400 X 900

6. All the drawings prepared by Design

500

500

400

400

PB7= 400 X 900

and structural consultants are as per

PB1= 230 X 600

PB2= 300 X 750

4250

PB3= 400 X 900

NBC norms and guidelines.

4310

4390

300 400 9350 500 9450 500 9475 500 9545 380500 7350 500 4275 500 6875 500 9570 380 LIFT

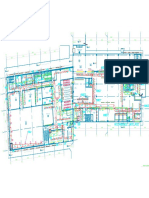

REMOVAL OF FORMWORK(SHUTTERING) :

100

6 Shuttering of any part of the structure shall not be

PB7= 400 X 900

PB3= 400 X 900

PB3= 400 X 900

2000

PB7= 400 X 900

PB3= 400 X 900

230

PB2= 300 X 750 PB2= 300 X 750 PB2= 300 X 750 PB2= 300 X 750 removed until the concrete attains 70% of the specified

230 1900

LIFT

LIFT

380

300

CUTOUT

CUTOUT PB1= 230 X 600

strength of concrete however the following minimum

PB2= 300 X 750

PB4= 500 X 900

PB3= 400 X 900

PB1= 230 X 600

5 period (after final pour ) shall be allowed before

removal of shuttering as per clause 11.3.1, is 456:2000

PB7= 400 X 900

4310

4310

3650

A. Vertical side of shuttering of columns,walls & beams

- 24 hours

300

PB7= 400 X 900 PB7= 400 X 900 PB8= 400 X 900 PB8= 400 X 900 PB8= 400 X 900 PB2= 300 X 750 PB2= 300 X 750 PB3= 400 X 900 PB3= 400 X 900 B. Bottom shuttering of slabs (keeping the props)

4

300

380

380

380

380

- 3 days

C. Bottom shuttering of beams (keeping the props)

2240 230 2000 230 2120

LIFT

PB3= 400 X 900

1950

LIFT CUTOUT - 7 day

230

PB3= 400 X 900

CUTOUT

B6= 300 X 750

PB8= 400 X 900

D. Props to slabs :

PB2= 300 X 750

0

PB5= 230 X 750

PB5= 230 X 750

PB4= 500 X 900

PB3= 400 X 900

PB3= 400 X 900

PB7= 400 X 900

75

100

PB3= 400 X 900

X

i .spanning upto 4.5 m - 7 days

6900

PB3= 400 X 900

300 500 4550 300 4550 500 2760 230 4000 230 2650 230 4513 300 4513 500 4512 300 4733 380 2650 230 4000 230 2810 500 4430

0

38

1950

6900

230

LIFT LIFT i i .spanning over 4.5 m - 14 days

6740

6=

STAIRCASE CUTOUT STAIRCASE

PB

CUTOUT CUTOUT E. Props to beams & arches :

i .spanning upto 6 m - 14 days

230

2240

i i.spanning over 6 m - 21 days

3 LAP JOINTS FOR REINFORCEMENT BARS :

380

380

300

300

PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB3= 400 X 900 PB2= 300 X 750PB2= 300 X 750 PB2= 300 X 750 PB3= 400 X 900 PB3= 400 X 900 1. At any cross section of the member,not more than

50% of the bars shall be lapped.

2. Laps shall be staggered with a minimum centre to

centre distance of 1.3 times lap length of the bar for

tension & compression members.

3. Development length (ld) shall be as per (sp:34-1999)

table below:

a) Development length for column bars - 40d

b) Development length for beam bars - 50d

4. Laps in columns shall be provided at mid height of

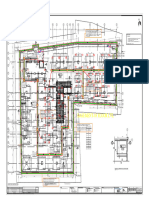

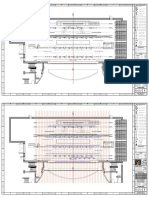

LAYOUT OF PLINTH BEAM floor and not at slab level .

5. Laps in beams and slabs shall be provided at the

point of contraflexure.

6. Welding of bars shall be done as a stitch weld for 5

times diameter of bar and a gap of 5 times higher

diameter bar and again welding for another 5 times

diameter of bar using arc welding and special

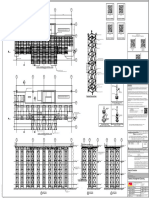

Max of 0.25L1 (or) Ld Max of 0.25L1 (or) Ld Max of 0.25L2 (or) Ld electrodes after obtaining prior written approval from

the structural designer.

50 mm 50 mm 7. Detailing of rebars shall confirm to sp-34 & is 13920.

TOP

REINFORCEMENT GENERAL NOTES:

1. Concrete grade shall be M35(design mix) confirming to

is 456:2000

2. Minimum cement content = 380 kg/m3.

3. Min.grade of reinforcement marked thus (y) shall be Fe

550D confirming to IS 1786-1985

0.1L1 BOTTOM 0.15L1 0.15L2 4. Clear cover for reinforcement

REINFORCEMENT a) Column = 40mm d) Raft slab bottom = 75mm

Max of L1/4 HOOP SPACING > d/2 Max of L1/4 Max of L2 /4 HOOP SPACING > d/2 b) R.C wall = 40mm e) Raft slab top = 50mm

(or) 2d (or) 2d (or) 2d c) Shear wall = 40mm

L1 L2

This drg. read in conjection with arch.drgs.

END SUPPORT INTERMEDIATE 5. Raft & Columns are designed for Ground + Mezzanine +

RESTRAINED SUPPORT Four floor loads only.

6. SBC of the soil is taken as 320kN / sqm. @ 2.40m below

from N.G.L. as per soil report.

7. Spacer bar - 25mm dia to be provided in between two

layer of reinforcement at every 750mm c/c

8. Structural engineer responsibility is limited to design &

issual of structural drawing only

9. Onus of construction lies with contractor/owner

10. For concreting water cement ratio should be (0.45) (for

1bag cement= max-25 lit of water only to be added.)

NOTES STRUCTURAL DESIGN QUALITY ASSURANCE

REVISIONS

Notice of no objection from Southern Railways Katpadi is being accorded for design principles based on the The drawing has been prepared based on actual site survey and other terms and conditions of the EPC Agreement. Responsibility of accuracy, correctness , This drawing including its design and detailing has been checked in accordance with the requirements of EPC Agreement and found

recommendations of the Architect/Lead Designer and proposal by the Contractor. However, the completeness, integrity and full compliance with byelaws, standards, statutory, regulations of relevant Codes & Manuals/ Rules and as per EPC Agreement suitable for the execution purpose. The overall responsibility of correctness of design,detailing and compliance with EPC agreement R.NO DATE DESCRIPTION

overall responsibility and design accuracy lies with the contractor (Engineering Projects (india) Pvt Ltd) provisions, rests with the Design Consultants and the Contractor without any financial implications. rests with the Structural Design Consultant and Contractor.

CLIENT: PROJECT: EPC Contractor: DESIGN CONSULTANT Authority Engineer (PMS) AXEN CN/MAS DY. CE CN/MAS CE CN/MAS

Drawing Title :

SOUTHERN RAILWAYS, REDEVELOPMENT OF ENGINEERING PROJECTS M/S VOYANTS SOLUTIONS PVT. LTD.

KATPADI. KATPADI JUNCTION (INDIA) LTD-CHENNAI Drawing Type :

Drawing No.: Scale: 1:100 Date: 12.12.23

Drawing Purpose: Sheet Size: A2 Rev. No: R0

AGM DESIGN DIRECTOR TEAM LEADER LEAD DESIGNER

You might also like

- Raft Slab Bottom Long Bars DetailsDocument1 pageRaft Slab Bottom Long Bars DetailsDINESH M.NNo ratings yet

- Raft Slab Top Bars DetailsDocument1 pageRaft Slab Top Bars DetailsDINESH M.NNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- HNK - Ground Floor Structural Drawings 13-09-2023 - r3Document10 pagesHNK - Ground Floor Structural Drawings 13-09-2023 - r3Karan KumarNo ratings yet

- Drawing4 ModelDocument1 pageDrawing4 ModelKaran KumarNo ratings yet

- Foundation Plan Roof Beam Plan: Jomar R. MercialesDocument1 pageFoundation Plan Roof Beam Plan: Jomar R. MercialesJaypee MoradaNo ratings yet

- Raft Slab LayoutDocument1 pageRaft Slab LayoutDINESH M.NNo ratings yet

- R4 Footing Lay-OutDocument1 pageR4 Footing Lay-OutKaran KumarNo ratings yet

- Sub Soil With Raft Layout-ModelDocument1 pageSub Soil With Raft Layout-ModelKaran KumarNo ratings yet

- Document 1Document1 pageDocument 1MUQEET ahmedNo ratings yet

- Cyclone Raw MillDocument1 pageCyclone Raw MillADOFSLNo ratings yet

- Duty Corrector: Schematic Diagram (DSP)Document11 pagesDuty Corrector: Schematic Diagram (DSP)Robertas PutinasNo ratings yet

- First Floor Plan PDFDocument1 pageFirst Floor Plan PDFDennisIgoyDacanayNo ratings yet

- Instalación Eléctrica 3Document4 pagesInstalación Eléctrica 3Alda MarínNo ratings yet

- Sony 1-876-467-11 A1556720a Ip5-Board PsuDocument3 pagesSony 1-876-467-11 A1556720a Ip5-Board PsuJohnny MarquesNo ratings yet

- A B C D E F G: Northern IloiloDocument1 pageA B C D E F G: Northern IloiloDan Ney HuboNo ratings yet

- 1st Floor Duct-ModelDocument1 page1st Floor Duct-Modelاحمد خليفة خليفةNo ratings yet

- 29-0034920-B002 - b-XR-PERI UP For Level 4 High ShoringDocument1 page29-0034920-B002 - b-XR-PERI UP For Level 4 High ShoringPaplu PaulNo ratings yet

- Building Plan - B400 - FarrukhnagarDocument1 pageBuilding Plan - B400 - FarrukhnagarsnvdelhiNo ratings yet

- Ips-Mbd23908-El-3151-Power Layout at Proposed Pack A.S.R.SDocument1 pageIps-Mbd23908-El-3151-Power Layout at Proposed Pack A.S.R.SJEET PRATAP PATHAKNo ratings yet

- Backup Assignment Working Drawing 2 1211267Document1 pageBackup Assignment Working Drawing 2 1211267Nabil SyadiqNo ratings yet

- Bo Cuc Ban Ve Tham KhaoDocument1 pageBo Cuc Ban Ve Tham Khao21149257No ratings yet

- 42nd PlotsDocument6 pages42nd PlotsMike WoodNo ratings yet

- Archtctrl P3 - UpdtdDocument1 pageArchtctrl P3 - Updtdchedita obiasNo ratings yet

- Mauli 9 Layout and Area Statement - Oct 06Document2 pagesMauli 9 Layout and Area Statement - Oct 06smarty pokemonNo ratings yet

- Yamaha p-150 SchematicsDocument2 pagesYamaha p-150 SchematicsMichael KageorgeNo ratings yet

- Floor PlanDocument1 pageFloor PlanFareez SedakaNo ratings yet

- Formalin Plant 3: Pt. Dover ChemicalDocument1 pageFormalin Plant 3: Pt. Dover Chemicalviero widyantoNo ratings yet

- M10 Class H Power Amp.Document10 pagesM10 Class H Power Amp.alanbermeo058No ratings yet

- Ab-By Bang RonieDocument1 pageAb-By Bang Ronieronie lastriNo ratings yet

- HNK GF Tendon Profile r3!13!09-2023Document2 pagesHNK GF Tendon Profile r3!13!09-2023Karan KumarNo ratings yet

- Smart Winner New SchematicDocument5 pagesSmart Winner New Schematicscales100% (1)

- General Arrangement Plan - Podium Level 00: NotesDocument1 pageGeneral Arrangement Plan - Podium Level 00: Notesprasahnthrk07No ratings yet

- Power Supply TNP8EPL90 Panasonic GLP23Document3 pagesPower Supply TNP8EPL90 Panasonic GLP23Анатоли АнгеловNo ratings yet

- Victoria Shanghai Academy School Building 9/F Blueprint PlanDocument1 pageVictoria Shanghai Academy School Building 9/F Blueprint PlanZwaaknqNo ratings yet

- Mgc-rl2-Sds-cvl-022 Rev.00 - Glass Balustrade Handrail at First Floor - Th43Document4 pagesMgc-rl2-Sds-cvl-022 Rev.00 - Glass Balustrade Handrail at First Floor - Th43jijinsNo ratings yet

- Bim Aft Ar 059Document1 pageBim Aft Ar 059vern pamNo ratings yet

- External Mep Services Layout-Ex-1001Document4 pagesExternal Mep Services Layout-Ex-1001Srinivas RegulavalasaNo ratings yet

- VGD HV 700Document1 pageVGD HV 700pablo carrizoNo ratings yet

- Key Plan: THE University of Islamic UnityDocument1 pageKey Plan: THE University of Islamic UnityAndi Ulil Amri UPNo ratings yet

- Mapa Usos Del Suelo (Municipal)Document1 pageMapa Usos Del Suelo (Municipal)J SáenzNo ratings yet

- Franklin G. Cale JR.: Roberto Jr. & Jackielou B. NavarroDocument1 pageFranklin G. Cale JR.: Roberto Jr. & Jackielou B. NavarroDanica Mae AmicayNo ratings yet

- 201853C 509 DW 1841 0005 Rev 2Document1 page201853C 509 DW 1841 0005 Rev 2Suman JanaNo ratings yet

- 1Document1 page1muhammadulil abrorNo ratings yet

- Asis UlilDocument7 pagesAsis Ulilmuhammadulil abrorNo ratings yet

- Plan UTILAJEDocument1 pagePlan UTILAJETudor SerbanNo ratings yet

- Majd Maher Anbar: W1 W1 W2 W1 W1 W2Document1 pageMajd Maher Anbar: W1 W1 W2 W1 W1 W2Majd AnbarNo ratings yet

- Isometric View: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetDocument1 pageIsometric View: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetParikh DhavalNo ratings yet

- 1700 43D1 0010 - A PDFDocument1 page1700 43D1 0010 - A PDFTonee Rose Reyes AdvientoNo ratings yet

- (RFC) PE-V1-417-165-N023 R2P0 StaircaseDocument6 pages(RFC) PE-V1-417-165-N023 R2P0 StaircaseParshuram ManjareNo ratings yet

- A B C D A B C D A B C D: Roof Storm Layout Ground Floor Storm Layout Second Floor Storm LayoutDocument1 pageA B C D A B C D A B C D: Roof Storm Layout Ground Floor Storm Layout Second Floor Storm LayoutDenzelNo ratings yet

- Detalle 3: Salares Norte Ep ProjectDocument1 pageDetalle 3: Salares Norte Ep ProjectDaniel QuezadaNo ratings yet

- LD-Board TNP4G549 Panasonic KM21EDocument2 pagesLD-Board TNP4G549 Panasonic KM21Emsg2000No ratings yet

- PCS Network Block Diagram 105230-Ei-00000-31341-002 - R4Document1 pagePCS Network Block Diagram 105230-Ei-00000-31341-002 - R4Francisco AndresNo ratings yet

- Naffco: Verified By: Mohammad Jaber AlmajediDocument1 pageNaffco: Verified By: Mohammad Jaber AlmajediArun UdayabhanuNo ratings yet

- Bombeo 1%: Documentos de ReferenciaDocument4 pagesBombeo 1%: Documentos de Referenciajose luisNo ratings yet

- Estructuras Modulo I-CimentacionDocument1 pageEstructuras Modulo I-CimentacionFrank Azambuja riveraNo ratings yet

- Leyenda: Recorrido Línea de ConducciónDocument1 pageLeyenda: Recorrido Línea de ConducciónEdwinACHNo ratings yet

- Dry Street Lighting Network Layout Ci SL LP 104Document1 pageDry Street Lighting Network Layout Ci SL LP 104Ahmed BoraeyNo ratings yet

- Speakers UpdatedDocument1 pageSpeakers UpdatedDINESH M.NNo ratings yet

- We Confirm This Footing After Do This WorkDocument1 pageWe Confirm This Footing After Do This WorkDINESH M.NNo ratings yet

- Kalidas Selvaperumal: About Me ContactDocument5 pagesKalidas Selvaperumal: About Me ContactDINESH M.NNo ratings yet

- Kalidas Selvaperumal: About Me ContactDocument5 pagesKalidas Selvaperumal: About Me ContactDINESH M.NNo ratings yet

- 10 HSE MATSIWE Eng drAWINGS - Model (2) - 1Document1 page10 HSE MATSIWE Eng drAWINGS - Model (2) - 1Leenon MatsiweNo ratings yet

- Cambr Palos MapDocument1 pageCambr Palos MapLyonsMastersNo ratings yet

- Orc - Layout DrawingDocument1 pageOrc - Layout DrawingON ROADING CONTRACTING LLCNo ratings yet

- Trends+Challenges+Civil EnggDocument6 pagesTrends+Challenges+Civil EnggAbhijeeth NagarajNo ratings yet

- Bridge Strengthening Using Advanced Composite SystemDocument103 pagesBridge Strengthening Using Advanced Composite SystemSravaniChintalapani100% (1)

- SW1Document2 pagesSW1Alexander P. BelkaNo ratings yet

- Region 1 - Concreting Works Materials Prices - PHILCON PRICESDocument9 pagesRegion 1 - Concreting Works Materials Prices - PHILCON PRICESMark Gregory RimandoNo ratings yet

- Preparatory Checklist For Structural ConcreteDocument8 pagesPreparatory Checklist For Structural ConcreteBunyamin SelimogluNo ratings yet

- Get TRDocDocument347 pagesGet TRDockrishnamoorthy_krish100% (1)

- 1 PTBarsBrochure-Oct2015Document6 pages1 PTBarsBrochure-Oct2015Dong-Yong KimNo ratings yet

- Concrete Structures For Retaining Aqueous Liquids - Code of PracticeDocument16 pagesConcrete Structures For Retaining Aqueous Liquids - Code of PracticeManvendra NigamNo ratings yet

- Shell Omala F Wind Oil 320Document2 pagesShell Omala F Wind Oil 320Muhammad SaputraNo ratings yet

- Selection of Bridge TypeDocument31 pagesSelection of Bridge TypeIrene Grace BatalaoNo ratings yet

- Design Calculation-Skylight StructureDocument5 pagesDesign Calculation-Skylight Structuremsiddiq150% (4)

- Geotechnical Laboratory Manual-IIDocument124 pagesGeotechnical Laboratory Manual-IIMir100% (6)

- Pavement DesignDocument43 pagesPavement DesignUmair NawazNo ratings yet

- Checklist For Fabrication & Installation of Tensile Fabric ShadesDocument1 pageChecklist For Fabrication & Installation of Tensile Fabric ShadesSun ShadeNo ratings yet

- Experimental Study On The Banana Fiber RCDocument4 pagesExperimental Study On The Banana Fiber RCAfsin Ecer.No ratings yet

- CE Reference EbooksDocument4 pagesCE Reference EbooksTech12No ratings yet

- How To Fix Leaks On Clay Tile Roofs PDFDocument4 pagesHow To Fix Leaks On Clay Tile Roofs PDFNishith ReddyNo ratings yet

- Brief For Geotechnical Investigations Maitama AbujaDocument6 pagesBrief For Geotechnical Investigations Maitama AbujaAdakole ObekaNo ratings yet

- Reynolds - 2013 - Thesis UQ - Eng Correlations For The Characterisation of Reactive Soil Behaviour For Use in Road DesignDocument100 pagesReynolds - 2013 - Thesis UQ - Eng Correlations For The Characterisation of Reactive Soil Behaviour For Use in Road DesignAnton ManojNo ratings yet

- Cyprus National Annex en 1992-4Document9 pagesCyprus National Annex en 1992-4Anonymous PibYPghNo ratings yet

- NYSDOT Bridge ManualDocument564 pagesNYSDOT Bridge Manualalum_91100% (1)

- CE 701 - Fall 2020 - Lecture 3 (Part 2)Document15 pagesCE 701 - Fall 2020 - Lecture 3 (Part 2)Shahriar Nazim shuvroNo ratings yet

- EQ04Document121 pagesEQ04chandan naiduNo ratings yet

- Bearing Capacity of Eccentrically Loaded FootingsDocument18 pagesBearing Capacity of Eccentrically Loaded FootingsAlaaGaballaNo ratings yet

- ReportDocument13 pagesReportAris putra2012No ratings yet

- Activity 1 - StressDocument3 pagesActivity 1 - StressKenneth ManuelNo ratings yet