0% found this document useful (0 votes)

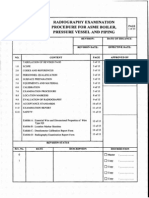

55 views8 pagesNDT Instruction and Inspection Report Guide

The document describes the format of the PCIP examination for NDT personnel certification. The exam assesses a candidate's ability to comprehend a procedure and prepare an instruction by providing a technique sheet and inspection report for the candidate to extract relevant information from the procedure. The candidate must demonstrate the technique judgments needed and complete the appropriate areas of the provided forms. In addition, the candidate will answer approximately 30 multiple choice questions testing their comprehension of the given procedure and ability to prepare instructions.

Uploaded by

amin.adineh97Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

55 views8 pagesNDT Instruction and Inspection Report Guide

The document describes the format of the PCIP examination for NDT personnel certification. The exam assesses a candidate's ability to comprehend a procedure and prepare an instruction by providing a technique sheet and inspection report for the candidate to extract relevant information from the procedure. The candidate must demonstrate the technique judgments needed and complete the appropriate areas of the provided forms. In addition, the candidate will answer approximately 30 multiple choice questions testing their comprehension of the given procedure and ability to prepare instructions.

Uploaded by

amin.adineh97Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd