Professional Documents

Culture Documents

Apron Feeders en

Apron Feeders en

Uploaded by

Marian ZatkoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apron Feeders en

Apron Feeders en

Uploaded by

Marian ZatkoCopyright:

Available Formats

Apron feeders CPLP, CPLD, CPLDT

Apron feeders are used for continuous feeding Feeders CPLD and CPLDT are used especially

FEEDING

or volume dosing of lump or grain materials the for feeding coarse-grain and lump fractions in

temperature of which is up to 200 °C. Feeders process lines of material treatment plants and

CPLP are designed for material of a smaller primary crushing plants.

grain size – already crushed.

The exceptional operating properties of apron feeders are:

High operating reliability Easy exchange of spare parts

Low cost for operating and maintenance Simple attendance and maintenance

High capacity

Basic characteristics of apron feeders

Feeders CPLP can be installed horizontally The suspended collecting conveyor belt

for material discharged from a closed bin can discharge the undersize portion of fine

or they can be installed with an inclination fractions.

of up to 18 ° in case the material is fed from Adjustment of the capacity is controlled

an opened hopper. by a frequency converter, variable speed

Feeders CPLD and CPLDT are generally gearbox or asynchronous motor with pole

installed under an opened hopper with the switching.

inclination up to 20 °.

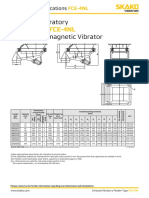

Assembly of the apron feeder CPLDT 1600x12000

Principle parameters

Feeder Max. layer

Type Feeder width of material Capacity Power input

length conveyed

mm mm mm t/h kW

CPLP 500 500 100 10 - 60

CPLP 650 650 150 20 - 120

CPLP 800 800 2400 - 8000 200 30 - 200 1.5 - 15 Apron feeder CPLDT 1600x10000

CPLP 1000 1000 250 50 - 320

CPLP 1200 1200 300 75 - 480

Max. layer

Feeder

Type Feeder width of material Capacity Power input

length conveyed

mm mm mm t/h kW

CPLD 800 800 400 30 - 150

CPLD 1000 1000 600 55 - 265

CPLD 1200 1200 800 90 - 410

2500 - 12000 5.5 - 42

CPLD 1600 1600 800 160 - 740

CPLDT 1600 1600 1200 160 - 740

CPLDT 2000 2000 1500 225 - 1050

Apron feeder CPLD 1000x4000

The capacity of the feeder is determined for a material bulk density of 1.6 t/m .3

You might also like

- 2009 2011 DS Manual - Club Car (001-061)Document61 pages2009 2011 DS Manual - Club Car (001-061)misaNo ratings yet

- 6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDDocument58 pages6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDSANTOSH TIWARINo ratings yet

- Seaharvest 650 HP Workover Rig Technical Specs1Document20 pagesSeaharvest 650 HP Workover Rig Technical Specs1Ali mohammad100% (1)

- Rig Spec1500hp DBLDocument48 pagesRig Spec1500hp DBLCandra Wae Lah100% (1)

- Ideco h25 Technical SpecsDocument20 pagesIdeco h25 Technical SpecsSergio Fabian VasicekNo ratings yet

- MS - Rock Blasting SLCB3Document10 pagesMS - Rock Blasting SLCB3Dinesh PriyankaraNo ratings yet

- Speed Control of DC Motor Under Varying Load Using PID ControllerDocument11 pagesSpeed Control of DC Motor Under Varying Load Using PID ControllerAI Coordinator - CSC Journals100% (1)

- 650HP Rig SpecsDocument35 pages650HP Rig Specsyelmustafaali100% (1)

- Deep ExcavationDocument59 pagesDeep ExcavationIsbelNo ratings yet

- Sandvic DD420 60C SpecDocument4 pagesSandvic DD420 60C SpecAlterSon Grafi KalayNo ratings yet

- MV Pacific D - ClassDocument9 pagesMV Pacific D - ClassCaptIsqanNo ratings yet

- Weichai - 8170 Series - Technical Data Sheet PDFDocument3 pagesWeichai - 8170 Series - Technical Data Sheet PDFJohn Rey Payunan0% (1)

- New PDFDocument24 pagesNew PDFGolbert GolbiNo ratings yet

- Lean Manufacturing Module 2Document20 pagesLean Manufacturing Module 2pravit08No ratings yet

- 01-01-PODFA-Equipment OverviewDocument31 pages01-01-PODFA-Equipment OverviewДен СтаднікNo ratings yet

- 351 Pit ViperDocument6 pages351 Pit Vipereddyfredy100% (1)

- Coal Handling Plant: at Heads of CHP MeetDocument46 pagesCoal Handling Plant: at Heads of CHP MeetMANISH SHARMANo ratings yet

- E Fabricated DIN 15231 DIN 15232 DIN 15233 DIN 15234 and DIN 15235Document5 pagesE Fabricated DIN 15231 DIN 15232 DIN 15233 DIN 15234 and DIN 15235Marian ZatkoNo ratings yet

- Apron Feeder PDFDocument3 pagesApron Feeder PDFabdulloh_99100% (1)

- CX201 SalesSpecSheet RevGDocument2 pagesCX201 SalesSpecSheet RevGRobertNo ratings yet

- Feeder Type FCE-4NL GBDocument2 pagesFeeder Type FCE-4NL GBsameh ibrahemNo ratings yet

- Refractory Equipment GAODETECDocument9 pagesRefractory Equipment GAODETECorangel anayaNo ratings yet

- Idah AirSaperatorDocument8 pagesIdah AirSaperatortranngt2020No ratings yet

- SBM 1250 Double Twist Bunching LineDocument12 pagesSBM 1250 Double Twist Bunching LineEMRE KAAN USTANo ratings yet

- Sugar Factory 2 - Equipment PassportDocument64 pagesSugar Factory 2 - Equipment PassportOTOMASYON PLCNo ratings yet

- Comparision of Shutlleless and Shuttle LoomsDocument13 pagesComparision of Shutlleless and Shuttle Loomslohitbakore50% (4)

- BUDGETINGDocument22 pagesBUDGETINGSuresha VSINNo ratings yet

- Jai Shree Poly HaryanaDocument12 pagesJai Shree Poly Haryanadeepak madaanNo ratings yet

- Machines ComparativeDocument4 pagesMachines ComparativePraveen SahniNo ratings yet

- Process Pumps and Industrial Dredges: More Uptime. Higher Productivity. Increased ProfitsDocument3 pagesProcess Pumps and Industrial Dredges: More Uptime. Higher Productivity. Increased ProfitsSekson JunsukplukNo ratings yet

- Baler HPK EN PDFDocument4 pagesBaler HPK EN PDFliu zhao liu zhaoNo ratings yet

- ITC 312N H6 ADocument2 pagesITC 312N H6 Ams79100% (1)

- UntitledDocument112 pagesUntitledkennethNo ratings yet

- Specifications:: 1. Traveling Block (YG-150)Document6 pagesSpecifications:: 1. Traveling Block (YG-150)Dewantoro HarisNo ratings yet

- UH320 ClassicDocument2 pagesUH320 ClassicRicardo E Andrea RachelNo ratings yet

- Creative Forge Pvt. Ltd.Document13 pagesCreative Forge Pvt. Ltd.Naveen PradeepanNo ratings yet

- 1 Concept of Precipitation 23 enDocument23 pages1 Concept of Precipitation 23 enDodik NugrohoNo ratings yet

- Johnston CN101 Specification SheetDocument2 pagesJohnston CN101 Specification SheetAlan NaylorNo ratings yet

- Datasheet - CPA 1000 CSZDocument2 pagesDatasheet - CPA 1000 CSZElsad HuseynovNo ratings yet

- Ancillaries 2020 - Rev2Document16 pagesAncillaries 2020 - Rev2Ajay kumarNo ratings yet

- Kabra Extrusion Technik LTD - Revisd Special Offer For KET 382 (SP) 070819Document10 pagesKabra Extrusion Technik LTD - Revisd Special Offer For KET 382 (SP) 070819Freddy FiallosNo ratings yet

- Frozen French Fries Processing Line For 300KGHDocument9 pagesFrozen French Fries Processing Line For 300KGHAnkit PatelNo ratings yet

- Mac ListDocument13 pagesMac ListHariman SallehNo ratings yet

- Eco-Friendly: Ruian Zhenjing Machinery. PVT - LTDDocument8 pagesEco-Friendly: Ruian Zhenjing Machinery. PVT - LTDBikash NayakNo ratings yet

- Pusher CentrifugeDocument4 pagesPusher Centrifugeberkay100% (1)

- PP Spun New 1Document8 pagesPP Spun New 1diyaindustries12No ratings yet

- Raw Mill P9: Eqpt No. 9MNE020A 9MNE030A 9MNE040A 9MNE050A Type Material DataDocument3 pagesRaw Mill P9: Eqpt No. 9MNE020A 9MNE030A 9MNE040A 9MNE050A Type Material Datamuziibu alfisyahNo ratings yet

- List Barang PT Kawan Lama SolusiDocument1 pageList Barang PT Kawan Lama SolusiTeguh PrasetyoNo ratings yet

- LDC LP No. 05 DTD 20th August 2020Document26 pagesLDC LP No. 05 DTD 20th August 2020nikhilbhorNo ratings yet

- Spunlace-3500mm Production Line - КопияDocument6 pagesSpunlace-3500mm Production Line - КопияДенис КутькоNo ratings yet

- Troughed - Design Guidelines and StandardsDocument6 pagesTroughed - Design Guidelines and StandardshaqjmiNo ratings yet

- Brochure OLF 15-60Document4 pagesBrochure OLF 15-60hangmann169No ratings yet

- FICHA TECNICA Rig 132Document12 pagesFICHA TECNICA Rig 132Joef Flores AzocarNo ratings yet

- Cricket DryDocument4 pagesCricket DryMuhamad Ekbar SeninNo ratings yet

- Di450 t3 Specification Sheet EnglishDocument4 pagesDi450 t3 Specification Sheet EnglishjiaozhongxingNo ratings yet

- Provision of Export Terminal Tug-ChecklistDocument5 pagesProvision of Export Terminal Tug-ChecklistMathias OnosemuodeNo ratings yet

- Y12f PresentationDocument15 pagesY12f Presentationthilina mallawaarachchiNo ratings yet

- 50HZ SMI1815 CHINA Mitsubishi GeneratorDocument4 pages50HZ SMI1815 CHINA Mitsubishi GeneratorsunshinemachineryNo ratings yet

- Pile Driving Rig: Data SheetDocument4 pagesPile Driving Rig: Data SheetSergeyNo ratings yet

- 100KVA Rigsafe Framed GeneratorDocument1 page100KVA Rigsafe Framed GeneratorElsad HuseynovNo ratings yet

- Surface Drills: Commando DC300Ri S5Document4 pagesSurface Drills: Commando DC300Ri S5Agus purwantoNo ratings yet

- Omveer Pharma Machines InformationDocument15 pagesOmveer Pharma Machines InformationHerbal H2ONo ratings yet

- 45 MM Monolayer 2 May 1450 NewDocument8 pages45 MM Monolayer 2 May 1450 Newmaddy7023No ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Apron Feeder Email PDFDocument4 pagesApron Feeder Email PDFMarian ZatkoNo ratings yet

- Lageweg 25 - 2222 AG Katwijk - The Netherlands - T +31 (0) 71 40 237 01 - Contact@vav - NL - WWW - Vav.nlDocument3 pagesLageweg 25 - 2222 AG Katwijk - The Netherlands - T +31 (0) 71 40 237 01 - Contact@vav - NL - WWW - Vav.nlMarian ZatkoNo ratings yet

- SNL 3134 + 22326 K + H 2326 Large SNL Plummer Block Housings For Bearings On An Adapter Sleeve, With Standard Seals - 20210416Document4 pagesSNL 3134 + 22326 K + H 2326 Large SNL Plummer Block Housings For Bearings On An Adapter Sleeve, With Standard Seals - 20210416Marian ZatkoNo ratings yet

- Biznis Akciovy Cennik Zariadeni K Programom Sluzieb T Pausal - 2020 - 07 - 10 PDFDocument2 pagesBiznis Akciovy Cennik Zariadeni K Programom Sluzieb T Pausal - 2020 - 07 - 10 PDFMarian ZatkoNo ratings yet

- db01 Laufen Save 022020 en PDFDocument16 pagesdb01 Laufen Save 022020 en PDFMarian ZatkoNo ratings yet

- NORMACLAMP FBS en PDFDocument6 pagesNORMACLAMP FBS en PDFMarian ZatkoNo ratings yet

- MT Profesional - 2020-07-10 PDFDocument1 pageMT Profesional - 2020-07-10 PDFMarian ZatkoNo ratings yet

- Ceny Neakciových Zariadení: D DK K D DK D K DK K KDocument2 pagesCeny Neakciových Zariadení: D DK K D DK D K DK K KMarian ZatkoNo ratings yet

- Faro Katalog - Osvetleni Zasuvek PDFDocument2 pagesFaro Katalog - Osvetleni Zasuvek PDFMarian ZatkoNo ratings yet

- Akciovy Cennik Zariadeni K Programom Sluzieb T Pausal - 2020 - 07 - 10 PDFDocument2 pagesAkciovy Cennik Zariadeni K Programom Sluzieb T Pausal - 2020 - 07 - 10 PDFMarian ZatkoNo ratings yet

- Strazne Dopravnikove Valce PDFDocument1 pageStrazne Dopravnikove Valce PDFMarian ZatkoNo ratings yet

- Inches To MilDocument1 pageInches To MilMarian ZatkoNo ratings yet

- What Is "Top Overhaul" and "Major Overhaul" of An Engine?Document6 pagesWhat Is "Top Overhaul" and "Major Overhaul" of An Engine?arjun singhNo ratings yet

- Process SynchronizationDocument72 pagesProcess SynchronizationAmit BhattNo ratings yet

- SharePtServTechRef PDFDocument628 pagesSharePtServTechRef PDFRodolfo Pérez GNo ratings yet

- Weishaupt Gas Burner Wg30-1-C-And-Wg40-1-A - Version-Zm-Ln-Low No X Installation and Operating Instructions ManualDocument52 pagesWeishaupt Gas Burner Wg30-1-C-And-Wg40-1-A - Version-Zm-Ln-Low No X Installation and Operating Instructions ManualandrecjfNo ratings yet

- Pafa (Fairbanks Intl) - R (11dec15) PDFDocument26 pagesPafa (Fairbanks Intl) - R (11dec15) PDFnabatmanNo ratings yet

- Special Tools and EquipmentDocument3 pagesSpecial Tools and Equipmentsubia khanNo ratings yet

- C 475 - C 475M - 02 - QZQ3NS9DNDC1TQDocument2 pagesC 475 - C 475M - 02 - QZQ3NS9DNDC1TQMalak HindiNo ratings yet

- Mod2Lab1 Unpacking The WalkthroughDocument4 pagesMod2Lab1 Unpacking The WalkthroughDwiAryantiNo ratings yet

- Fink OilFieldChemicals DefomamersDocument9 pagesFink OilFieldChemicals DefomamersmarriolavNo ratings yet

- C Operators PDFDocument5 pagesC Operators PDFAshutosh KumarNo ratings yet

- Internet As SpaceDocument14 pagesInternet As SpaceNor ZaNo ratings yet

- Design and Testing of Bored Pile Foundation To The 2 Penang Bridge, MalaysiaDocument43 pagesDesign and Testing of Bored Pile Foundation To The 2 Penang Bridge, MalaysiaOsama EL HakimNo ratings yet

- U BoltsDocument14 pagesU BoltsLuz DuarteNo ratings yet

- Welding Qualification: by Hema SantoshDocument45 pagesWelding Qualification: by Hema Santoshravi00098No ratings yet

- Il96 400Document4 pagesIl96 400Joey CaoNo ratings yet

- Data Sheet 3VA2110-5MN32-0AA0: ModelDocument5 pagesData Sheet 3VA2110-5MN32-0AA0: Modelcipri1981No ratings yet

- MCCB SchneiderDocument2 pagesMCCB SchneiderkumontholNo ratings yet

- MONTABERT Brochure - Conexpo - 2023Document13 pagesMONTABERT Brochure - Conexpo - 2023Александр ПравосудовNo ratings yet

- Plate No 31 Modular Wardrobe - Bed Room Floor Plan: Bedroom 5000Mmx4000Mm Bedroom 5000Mmx4000MmDocument5 pagesPlate No 31 Modular Wardrobe - Bed Room Floor Plan: Bedroom 5000Mmx4000Mm Bedroom 5000Mmx4000MmPavithra ValluvanNo ratings yet

- CivilscehemeDocument4 pagesCivilscehemeVikramNo ratings yet

- Plone Cheatsheets 3.0Document3 pagesPlone Cheatsheets 3.0Kim Chee LeongNo ratings yet

- TempDocument18 pagesTempcaoap3847No ratings yet

- Hydrogen Spectral LinesDocument17 pagesHydrogen Spectral LinesarnoldNo ratings yet

- PCB CharacteristicsDocument7 pagesPCB Characteristicssanthoshkvs2005No ratings yet