Professional Documents

Culture Documents

4

Uploaded by

حيدر خالد خلفCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4

Uploaded by

حيدر خالد خلفCopyright:

Available Formats

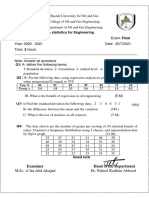

Q4J The heaviest string of pipe to be run in the14000FT offshore Texas well is the

intermediate

casing. It weighs approximately 400000Ibs. buoyed in mud. hoisting system must also

lift the

traveling block that weighs 40000lbs. and provide 100000lbs. of over-pull

capability. The drawworks

can provide 3000hp. Eight lines are strung between the crown block and the

traveling block. Drum

diameter 30in.

A. Calculate the total pull that the hoisting system must be able to apply for this

well(ie. the

maximum expected hoisting load seen on the weight indicator including the over-pull

capability). Use this maximum expected hoisting load for the remaining

calculations.

B. Calculate the tension in one of the lines between the crown block and the

traveling block

assuming a friction-less system

C. Calculate the static tension in the fast line when upward motion is pending (use

the

appropriate average efficiency factor for a real system where there is friction)

D. Calculate the maximum hook horsepower available.

E. Calculate the maximum hoisting speed.(This is a mechanical limitation. The

practical

limitation will usually be the swabbing effect on the hole)

You might also like

- DPT1 - 01 - Rig Sizing and SelectionDocument65 pagesDPT1 - 01 - Rig Sizing and SelectionBrahim Letaief100% (5)

- Machines For O Level Physics PDFDocument27 pagesMachines For O Level Physics PDFRwabahinda100% (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- TUTORIAL 1 Drilling EngineerDocument4 pagesTUTORIAL 1 Drilling EngineerAnonymous AkV8maWxGNNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- PETE 491 Drilling Engineering: Mini Project Drilling Rig AnalysisDocument5 pagesPETE 491 Drilling Engineering: Mini Project Drilling Rig AnalysisAnkit BansalNo ratings yet

- Lecture2 Hoisting SystemDocument26 pagesLecture2 Hoisting SystemART BAJALAN100% (3)

- ConveyorDocument81 pagesConveyorhaymanotNo ratings yet

- Load Calculations On Drilling RigDocument7 pagesLoad Calculations On Drilling RigAnant BajpaiNo ratings yet

- Belt ConveyorDocument11 pagesBelt Conveyormishra_1982No ratings yet

- Wire Rope Sheave Friction TU2Document5 pagesWire Rope Sheave Friction TU2manoj983@gmail.comNo ratings yet

- Problem On Equation of Motion For Damped Free VibrationDocument4 pagesProblem On Equation of Motion For Damped Free VibrationKristine Ann Reclosado100% (1)

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDocument14 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasNo ratings yet

- 2263Document3 pages2263gaziahmad0% (1)

- If Morrison Structural LabDocument10 pagesIf Morrison Structural LabCarlos AcnNo ratings yet

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDocument22 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasNo ratings yet

- PhysicsDocument22 pagesPhysicsRed Crazy0% (1)

- 2 Machine Design 2Document8 pages2 Machine Design 2Jonah Lyn AsendidoNo ratings yet

- Faculty of Engineering Petroleum Engineering Department: Drilling Technology I Third StageDocument21 pagesFaculty of Engineering Petroleum Engineering Department: Drilling Technology I Third StageMUHAMMED FUADNo ratings yet

- Practice Problems Based On Free & Forced Vibrations of SDOF SystemDocument3 pagesPractice Problems Based On Free & Forced Vibrations of SDOF Systemzeeshanahmad111No ratings yet

- 04 Work Energy and PowerDocument6 pages04 Work Energy and PowerJerico LlovidoNo ratings yet

- M.tech Sem-2 DYN Tutorial-1Document2 pagesM.tech Sem-2 DYN Tutorial-1Rutvik ShethNo ratings yet

- ME 353 - Assgn1Document4 pagesME 353 - Assgn1Amar KumarNo ratings yet

- DampedFreeVibrationTutorial Tut02Document3 pagesDampedFreeVibrationTutorial Tut02blackant007No ratings yet

- ME1 Lec2 ShaftDocument38 pagesME1 Lec2 ShaftXia MarkNo ratings yet

- Dynamic Load Sharing For Conveyor Belts With Multiple Drive StatDocument14 pagesDynamic Load Sharing For Conveyor Belts With Multiple Drive StatGuilherme Henrique Leite VianaNo ratings yet

- Handelling ProblemsDocument2 pagesHandelling ProblemsAkash NandiNo ratings yet

- CL708 - Earthquake Engineering - Tutorial 3Document1 pageCL708 - Earthquake Engineering - Tutorial 3Rutvik ShethNo ratings yet

- CT Hydraulic JarsDocument2 pagesCT Hydraulic JarsAde RiantoNo ratings yet

- Simple Machine Practice ProblemsDocument2 pagesSimple Machine Practice Problemsflounder33No ratings yet

- Materials Handling and HoistingDocument6 pagesMaterials Handling and HoistingNARGISNo ratings yet

- 07a1ec09 Engineering MechanicsDocument4 pages07a1ec09 Engineering Mechanicsأشرف عليNo ratings yet

- Forced Vibration123Document4 pagesForced Vibration123Himanshu KhannaNo ratings yet

- Assignment 3 PDFDocument5 pagesAssignment 3 PDFJamil ChaabanNo ratings yet

- Design Rating Rail Bridge Majedski 00006Document25 pagesDesign Rating Rail Bridge Majedski 00006rkgcrriNo ratings yet

- Model QuestionsDocument4 pagesModel Questions6nkumar_vnrNo ratings yet

- Mechanical Vibration Individual Assignment - I FinalDocument3 pagesMechanical Vibration Individual Assignment - I FinalBefikad BekeleNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSNo ratings yet

- Method Statement Axial Test P203Document36 pagesMethod Statement Axial Test P203Febry Tri WahyoeNo ratings yet

- DrillingDocument26 pagesDrillingArgelia Gómez RiveraNo ratings yet

- 081 - ME8594, ME6505 Dynamics of Machines - Important QuestionsDocument20 pages081 - ME8594, ME6505 Dynamics of Machines - Important QuestionsKannathal3008 88No ratings yet

- 05Document84 pages05hammouche_soufianeNo ratings yet

- Set No. 1Document2 pagesSet No. 1rafikhanpathanNo ratings yet

- Ca - 2Document2 pagesCa - 2balaguru78No ratings yet

- 8 Mechanical VibrationsDocument10 pages8 Mechanical VibrationsTsihatesfaNo ratings yet

- : مسلاا - فسوي معنملادبع ءارهز Report:-Hoisting SystemDocument6 pages: مسلاا - فسوي معنملادبع ءارهز Report:-Hoisting Systemزهراء عبد المنعم يوسف 17No ratings yet

- CENG6206 Soil Dynamics ExerciseProblemDocument4 pagesCENG6206 Soil Dynamics ExerciseProblemFekadu Wub100% (1)

- Assignment 2Document2 pagesAssignment 2sasaNo ratings yet

- Design of Belt Conveyor System: Prepared By: Ankit Kumar Dept of Mechanical Engineering Wbut University (West Bengal)Document14 pagesDesign of Belt Conveyor System: Prepared By: Ankit Kumar Dept of Mechanical Engineering Wbut University (West Bengal)Murugesan kNo ratings yet

- Ch03 - Harmonically Excited Vibrations - Part1Document19 pagesCh03 - Harmonically Excited Vibrations - Part1Khaled Reda67% (3)

- Equilibrium Elevation.: FC (W V) / (G R)Document12 pagesEquilibrium Elevation.: FC (W V) / (G R)BEN NARENDRANNo ratings yet

- Machine Dynamics and Vibration-Forced Vibration AssignmentDocument4 pagesMachine Dynamics and Vibration-Forced Vibration AssignmentVijay ReddyNo ratings yet

- Paper English - Sobirin - Perencanaan Kapasitas Dan Biaya Sewa RigDocument15 pagesPaper English - Sobirin - Perencanaan Kapasitas Dan Biaya Sewa RigsobirinNo ratings yet

- Chapter 6-Dynamics-Kinematics-KineticsDocument36 pagesChapter 6-Dynamics-Kinematics-Kineticsعمر صرانNo ratings yet

- ME 354 VIBRATION & CONTROL (2018-19) Problems On Single-Degree-of-Freedom SystemsDocument4 pagesME 354 VIBRATION & CONTROL (2018-19) Problems On Single-Degree-of-Freedom SystemsMukul Chandra0% (1)

- C9 WorkbyIntegration BP 9 22 14Document6 pagesC9 WorkbyIntegration BP 9 22 14Nicholson ZapantaNo ratings yet

- Machine Design Problems - DAY 4Document1 pageMachine Design Problems - DAY 4Kers CelestialNo ratings yet

- Single DOF System Excited Vibrations ProblemsDocument3 pagesSingle DOF System Excited Vibrations ProblemsghulmNo ratings yet

- VstilagoDocument6 pagesVstilagoحيدر خالد خلفNo ratings yet

- VstilagoDocument7 pagesVstilagoحيدر خالد خلفNo ratings yet

- PowerPoint TemplateDocument7 pagesPowerPoint Templateحيدر خالد خلفNo ratings yet

- Sand ProductionDocument8 pagesSand Productionحيدر خالد خلفNo ratings yet

- Final Exam StatisticsDocument1 pageFinal Exam Statisticsحيدر خالد خلفNo ratings yet