Professional Documents

Culture Documents

GORE Torque Table en Raised FRP Ring UPG Dec2017

Uploaded by

Debelme0 ratings0% found this document useful (0 votes)

3 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageGORE Torque Table en Raised FRP Ring UPG Dec2017

Uploaded by

DebelmeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

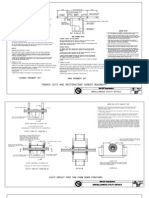

Sealant Technologies

Torque Guidelines EN

Flange Type: Raised Face FRP Flange

Gasket Type: Ring Gasket

Product Name: GORE® Universal Pipe Gasket (Style 800)

To achieve a reliable seal, adequate gasket stress must be

applied during installation. This table provides an estimation

of torque for use during assembly of standard face dimension

FRP pipe flanges.

Ring Gasket Fiber-Reinforced Plastic (FRP)

The user must verify these conditions, as outlined, are Raised Face Flange

appropriate for the specific application.

Due to the wide variation of FRP flange materials, designs,

and manufacturing processes, the user must confirm that

Torque Values Requirements

torque values do not exceed pipe manufacturer’s maximum

torque recommendation. Consult Gore when selecting a • Use of well lubricated bolts, Grade 24CrMo5 or better

lower torque value.

• Use of 1.5 mm (1/16 in) or 3.0 mm (1/8 in) gasket

Caution should be used when using this documentation as thickness

proof of flange design. It is the user’s responsibility to meet

• Installation practices according to ASME PCC-1

all applicable local laws and requirements. This estimation

does not account for the influence of flange rotation, flange

strength, external forces, temperature expansion, pressure Torque Estimation Conditions

peaks and installation error. • Gasket dimensions according to EN1514-1 Form IBC

• Flange dimensions according to EN 1092-1

GORE® Universal Pipe Gasket (Style 800) Type 11 Form B

Bolt Torque: Ring Gasket on Raised Face FRP Flange

• Calculated for 10 bar (145 psi) maximum.

DN PN 10

Please ensure suitability of the pipe class.

(mm) Nm Ft-lbs

20 11 8 • Friction factor µ = 0.12; Nut factor K = 0.15

25 15 10 • Suggested torque values are based on best practices.

32 25 20 In general, 10 MPa average gasket stress is targeted.

40 30 20

• Calculation according to ASME PCC-1 Appendix J

50 40 30

65 50 40

80 30 20

100 35 25

125 45 35

150 60 45

200 85 65

250 65 50

300 75 55

350 100 70

400 140 100

All technical information and advice given here is based on our previous experiences and/or test results. We give

450 120 90 this information to the best of our knowledge, but assume no legal responsibility. Customers are asked to check the

suitability and usability in the specific application, since the performance of the product can only be judged when

500 140 100 all necessary operating data are available. Specifications are subject to change without notice. Gore’s terms and

conditions of sale apply to the purchase and sale of the product.

600 190 140

For detailed selection criteria, technical information, installation guidelines and

the complete listing of local sales offices, please visit gore.com/sealants.

SEAL-212-R1-TEC-US-DEC17

Europe/Middle East/Africa

W. L. Gore & Associates GmbH (Germany)

Tel.: +49 89 4612-2215

Email: sealants_EU@wlgore.com

GORE and designs are registered trademarks of W. L. Gore & Associates

©2015–2017 W. L. Gore & Associates, Inc.

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Astm A420Document6 pagesAstm A420Joffre ValladaresNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- ASME B16.47 Series B FlangeDocument4 pagesASME B16.47 Series B Flange41h189No ratings yet

- Sae J51-2004Document11 pagesSae J51-2004khhoseNo ratings yet

- Protech Seal BrochureDocument10 pagesProtech Seal BrochureRodrigo Jechéla Barrios0% (1)

- SatipDocument5 pagesSatipMuhammad Abdul Kadher100% (3)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- OPENING IDEAS FOR WHITE AND BLACKDocument110 pagesOPENING IDEAS FOR WHITE AND BLACKJohn SteveNo ratings yet

- Sae J20-2015Document18 pagesSae J20-2015NastyNo ratings yet

- Flange Leakage (Working Copy)Document7 pagesFlange Leakage (Working Copy)abrarakbarNo ratings yet

- Soft Copy - Technical Submittal - Booster PumpsDocument240 pagesSoft Copy - Technical Submittal - Booster Pumps721917114 47No ratings yet

- Training in Chess: A Scientific ApproachDocument24 pagesTraining in Chess: A Scientific Approachdoctorlicious100% (6)

- Asme BpeDocument41 pagesAsme BpeSiva Venkateswara Rao Bolla67% (3)

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- 835-ASMESectionIIID1NC 3658Document2 pages835-ASMESectionIIID1NC 3658nurilmuNo ratings yet

- Calculation Bolt Torque From Seating StressDocument3 pagesCalculation Bolt Torque From Seating StressPranpath NarupantawartNo ratings yet

- ASME PaperDocument17 pagesASME PaperChristopher BrownNo ratings yet

- Rational CombiMaster Plus 202E Service ManualDocument56 pagesRational CombiMaster Plus 202E Service Manualwin369100% (1)

- Pressure VesselDocument32 pagesPressure VesselYonjon SubhaNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- GORE Torque Table ASME Raised FRP Ring FullFace UPG Dec2017Document1 pageGORE Torque Table ASME Raised FRP Ring FullFace UPG Dec2017Rodrigo Escárate BernalNo ratings yet

- Torque Table UPG GR ASME Raised Steel Ring Full GasketDocument1 pageTorque Table UPG GR ASME Raised Steel Ring Full GasketgonzalezlopezjNo ratings yet

- Conexiones TycoDocument27 pagesConexiones TycoAdriana Agundiz RomeroNo ratings yet

- Torque Table GR ASME Flat-Steel Full-Gasket r2Document1 pageTorque Table GR ASME Flat-Steel Full-Gasket r2icarusNo ratings yet

- GORE Torque Tables DIN enDocument4 pagesGORE Torque Tables DIN enDawid DobrzańskiNo ratings yet

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Sonny LuuNo ratings yet

- Gate Valve VAGDocument5 pagesGate Valve VAGrosiNo ratings yet

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Jeffrey Calinao ManaloNo ratings yet

- Kopr Kote Oilfield TdsDocument1 pageKopr Kote Oilfield Tdsbob smithNo ratings yet

- Energol SHF-HV RangeDocument2 pagesEnergol SHF-HV RangeArthur Sanda LayukNo ratings yet

- Tapping Screw Performance Specifications: Greenslade & Company, IncDocument22 pagesTapping Screw Performance Specifications: Greenslade & Company, Inco_l_0No ratings yet

- ReCoTec® LSR-Injection Flyer IN3534366 02 enDocument16 pagesReCoTec® LSR-Injection Flyer IN3534366 02 enTESLA IngenieriaNo ratings yet

- Bray Butterfly Valves Catalog JECDocument23 pagesBray Butterfly Valves Catalog JECRawadabdoNo ratings yet

- Kopr-Kote TDS 2Document1 pageKopr-Kote TDS 2jesusNo ratings yet

- Genset: Most Advanced Save Fuel Up To 30%Document8 pagesGenset: Most Advanced Save Fuel Up To 30%Devidas JaiswalNo ratings yet

- FS709 HP Intumescent Sealant Key BenefitsDocument3 pagesFS709 HP Intumescent Sealant Key BenefitsLeo SerasingheNo ratings yet

- GRINNEL Serie G Accesorios RanuradosDocument26 pagesGRINNEL Serie G Accesorios RanuradosFIRE RL SYSTEMSNo ratings yet

- A6V12101380Document6 pagesA6V12101380hanselozgumusNo ratings yet

- High Performance Axial Fans: Model RA - Standard and High TemperatureDocument8 pagesHigh Performance Axial Fans: Model RA - Standard and High Temperaturerijothomasv777No ratings yet

- Bell 1 Hydraulic Oil Awp (Ua6301)Document2 pagesBell 1 Hydraulic Oil Awp (Ua6301)randiNo ratings yet

- ST CT Combined Series US0621Document4 pagesST CT Combined Series US0621QuietRideNo ratings yet

- Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsDocument4 pagesMechanical Seals - Mechanical Seals For Pumps - Pusher Sealscesarobeso83No ratings yet

- XPE440 Technical Datasheet v1.3Document17 pagesXPE440 Technical Datasheet v1.3Kovacs Zsolt-IstvanNo ratings yet

- Sal 18200Document57 pagesSal 18200German Tirado MontoyaNo ratings yet

- Am GF Gi-Gg Gi-Gg AmDocument3 pagesAm GF Gi-Gg Gi-Gg AmYesid Ruiz cañónNo ratings yet

- 125 1193218825specificationDocument7 pages125 1193218825specificationSardar Gurpreet SinghNo ratings yet

- KAT-A 1360 EKN-H Edition3 05.02.2021 ENDocument6 pagesKAT-A 1360 EKN-H Edition3 05.02.2021 ENkad-7No ratings yet

- Eng 16 2022 ChemchlorDocument2 pagesEng 16 2022 Chemchlortms.ofissNo ratings yet

- Turftech Turf Ovr TDocument15 pagesTurftech Turf Ovr TSony CNo ratings yet

- Explosive DecompressionDocument11 pagesExplosive DecompressionAndrey EkkertNo ratings yet

- GG CYLINDRICALDocument4 pagesGG CYLINDRICALYesid Ruiz cañónNo ratings yet

- PETRONAS Tutela Trans TO4 Series - PDS - 200218Document2 pagesPETRONAS Tutela Trans TO4 Series - PDS - 200218johnNo ratings yet

- tl15 (3) - 231207 - 141952Document2 pagestl15 (3) - 231207 - 141952Sam JohnNo ratings yet

- Sustaining Our Environment: Eaton® Introduces GH109 Hose and Connectors To Support EPA Emission ReductionsDocument2 pagesSustaining Our Environment: Eaton® Introduces GH109 Hose and Connectors To Support EPA Emission Reductionszahar222No ratings yet

- O Ring Catalogue 2022Document179 pagesO Ring Catalogue 2022Muhammad Kamran AsgharNo ratings yet

- TFP1815 02 2021Document26 pagesTFP1815 02 2021yeye JNo ratings yet

- Texamatic 7045EDocument3 pagesTexamatic 7045EIgor MitrovićNo ratings yet

- Am CYLINDRICALDocument4 pagesAm CYLINDRICALYesid Ruiz cañónNo ratings yet

- h07rn 8 F Bs en 50525 2 21 Flexible Rubber CableDocument2 pagesh07rn 8 F Bs en 50525 2 21 Flexible Rubber Cableheri fauziNo ratings yet

- Schrader VentiliDocument8 pagesSchrader VentiliSLANO77No ratings yet

- GREPipe Systems Marine Industry June 2010Document45 pagesGREPipe Systems Marine Industry June 2010vinonagu100% (1)

- Series SS RiserDocument4 pagesSeries SS RiserMarkNo ratings yet

- Rotex Pneumatic Cylinder CatalogueDocument4 pagesRotex Pneumatic Cylinder Cataloguekumar ambujNo ratings yet

- Gore DC Tool Replacement Assemblies For George Renault ToolsDocument1 pageGore DC Tool Replacement Assemblies For George Renault ToolsItamarNo ratings yet

- Screw-In Direct Operated Pressure Relief Valve (DBDE04) For Use in ManifoldsDocument8 pagesScrew-In Direct Operated Pressure Relief Valve (DBDE04) For Use in ManifoldsTejas MahadikNo ratings yet

- Moog CartridgeValves DBD04 Catalog enDocument8 pagesMoog CartridgeValves DBD04 Catalog enTejas MahadikNo ratings yet

- PDSDetail PageDocument3 pagesPDSDetail PageEduleofNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- Surface Vehicle Standard: Coolant System HosesDocument18 pagesSurface Vehicle Standard: Coolant System HosesAdriana SukmanaputraNo ratings yet

- A Technical Guide To Taper-Lok Sealing Technology: Assembly FeaturesDocument2 pagesA Technical Guide To Taper-Lok Sealing Technology: Assembly FeaturesDebelmeNo ratings yet

- Nubbin - DJDocument6 pagesNubbin - DJDebelmeNo ratings yet

- Zero Fugitive EmissionsDocument2 pagesZero Fugitive EmissionsDebelmeNo ratings yet

- Editpipe 8Document1 pageEditpipe 8DebelmeNo ratings yet

- Leaking Heat Exchangers?: Is This How You Are Stopping YourDocument2 pagesLeaking Heat Exchangers?: Is This How You Are Stopping YourDebelmeNo ratings yet

- Hanger DesignDocument18 pagesHanger DesignDebelmeNo ratings yet

- TL Throughbore Zerogap9Document1 pageTL Throughbore Zerogap9DebelmeNo ratings yet

- Torque Value GuideDocument2 pagesTorque Value GuideSaurabh KaushikNo ratings yet

- Design of Blast Resistant Buildings in Petrochemical FacilitiesDocument20 pagesDesign of Blast Resistant Buildings in Petrochemical FacilitiesDebelmeNo ratings yet

- Chess TacticsDocument2 pagesChess TacticsDebelmeNo ratings yet

- Pressure Thrust NotesDocument2 pagesPressure Thrust NotesDebelmeNo ratings yet

- Pipe Design Basic MaterialDocument1 pagePipe Design Basic MaterialpandiangvNo ratings yet

- Influence of Support Stiffness in Dynamic Analysis of Piping SystemsDocument77 pagesInfluence of Support Stiffness in Dynamic Analysis of Piping SystemssuyogbhaveNo ratings yet

- Insu Joints Gas Piepelines ComplDocument55 pagesInsu Joints Gas Piepelines ComplDebelmeNo ratings yet

- Tube Turns INC. - Piping EngineeringDocument224 pagesTube Turns INC. - Piping EngineeringDebelme60% (5)

- UPLOADS CA... Rs May-2011-WebinarDocument24 pagesUPLOADS CA... Rs May-2011-WebinarDebelmeNo ratings yet

- (KT&G) Fire Fighting Technical SpecificationDocument77 pages(KT&G) Fire Fighting Technical SpecificationCahyo Hening Pamardi STNo ratings yet

- Pipe Preservation Internal Job 2020Document169 pagesPipe Preservation Internal Job 2020Tri HeriNo ratings yet

- Schedule No.: Bill of Materials With Pipe Cut LengthsDocument3 pagesSchedule No.: Bill of Materials With Pipe Cut LengthsIndra HarapanNo ratings yet

- 396 001230 PumpRight For Field IQ Rev 02.20.201411Document71 pages396 001230 PumpRight For Field IQ Rev 02.20.201411Denis OhmakNo ratings yet

- CG 2015144 04 Between Flange ProportionersDocument2 pagesCG 2015144 04 Between Flange Proportionersmohd zakiNo ratings yet

- Trench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutDocument3 pagesTrench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutIqueline JacqelineNo ratings yet

- Qcs 2010 Part 10.01 GeneralDocument13 pagesQcs 2010 Part 10.01 GeneralRotsapNayrbNo ratings yet

- Iomifb 7Document20 pagesIomifb 7Phong Hoang LeNo ratings yet

- Final Combined HP Catalogue Nov 2021Document11 pagesFinal Combined HP Catalogue Nov 2021SK EnergyNo ratings yet

- Ice Freezer CatalogDocument32 pagesIce Freezer CatalogBog QuinteroNo ratings yet

- CPP Pipeline Proposed Pwps List For Mol Project: 36' Pipe To Anchor Flange Repair WeldingDocument2 pagesCPP Pipeline Proposed Pwps List For Mol Project: 36' Pipe To Anchor Flange Repair WeldingYasar ArshadNo ratings yet

- Technical Delivery Condition - GTU & SRUDocument6 pagesTechnical Delivery Condition - GTU & SRUpratikbhardwajNo ratings yet

- Plumber Apprenticeship GuideDocument2 pagesPlumber Apprenticeship GuideEmad BassemNo ratings yet

- Astm A 1053 A 1053M 2006Document5 pagesAstm A 1053 A 1053M 2006Jorge ToribioNo ratings yet

- Drainage Fittings - Washbasin: G DN FPL PUDocument2 pagesDrainage Fittings - Washbasin: G DN FPL PUtp_fasilNo ratings yet

- Nida Baig PPT PBDocument7 pagesNida Baig PPT PBShifa ShaikhNo ratings yet

- Instalación FMP51 - 043Document25 pagesInstalación FMP51 - 043Javier LopezNo ratings yet

- Red Book GlossaryDocument6 pagesRed Book GlossaryAlejandro ViscarraNo ratings yet

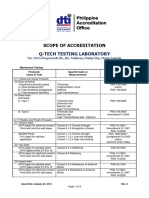

- Philippine Accreditation Office: Q-Tech Testing LaboratoryDocument5 pagesPhilippine Accreditation Office: Q-Tech Testing LaboratoryJames BonitoNo ratings yet

- Focus Training Brochure - Aug 2016Document2 pagesFocus Training Brochure - Aug 2016Abdul Hamid DjaelaniNo ratings yet

- GenusDocument68 pagesGenussmokefieldNo ratings yet

- 75:1 Fire-Ball 425 Pumps: Instructions - Parts ListDocument20 pages75:1 Fire-Ball 425 Pumps: Instructions - Parts ListJulioNo ratings yet

- 2.1 Facilities of Existing Water Supply SchemeDocument3 pages2.1 Facilities of Existing Water Supply SchemeLakmal SooriyabandaraNo ratings yet

- PDF Ou220brbrn030 DRWDocument1 pagePDF Ou220brbrn030 DRWDeepak Bhanushali ifbNo ratings yet